Double-wall type glass fiber reinforced plastic smoke exhaust cylinder

A chimney and fiberglass technology, which is applied to vertical pipes, building components, building types, etc., can solve the problems of low strength utilization rate of fiberglass chimney and high engineering cost, so as to improve stability and overall carrying capacity and save engineering cost , The effect of saving barrel material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

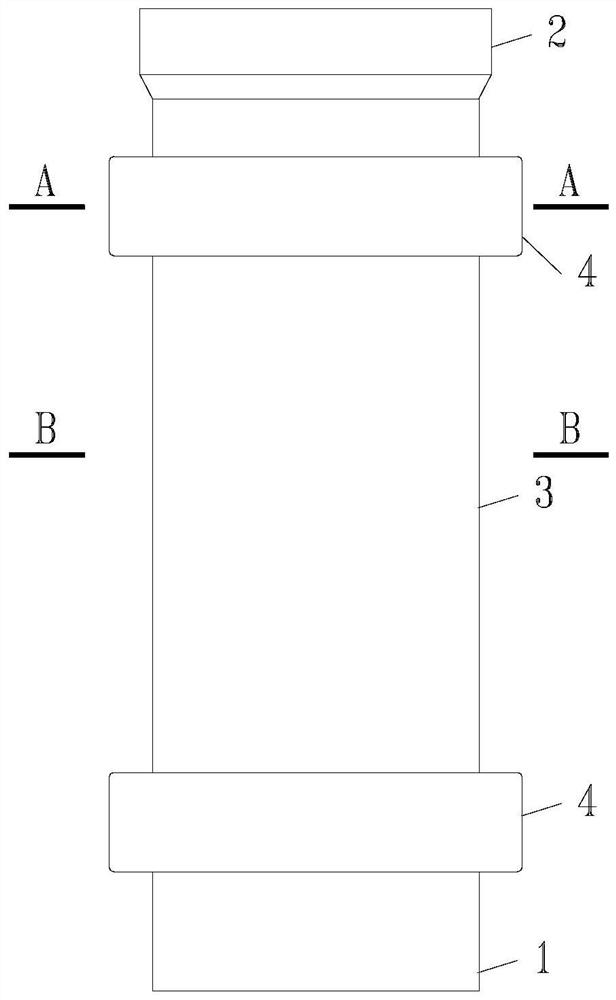

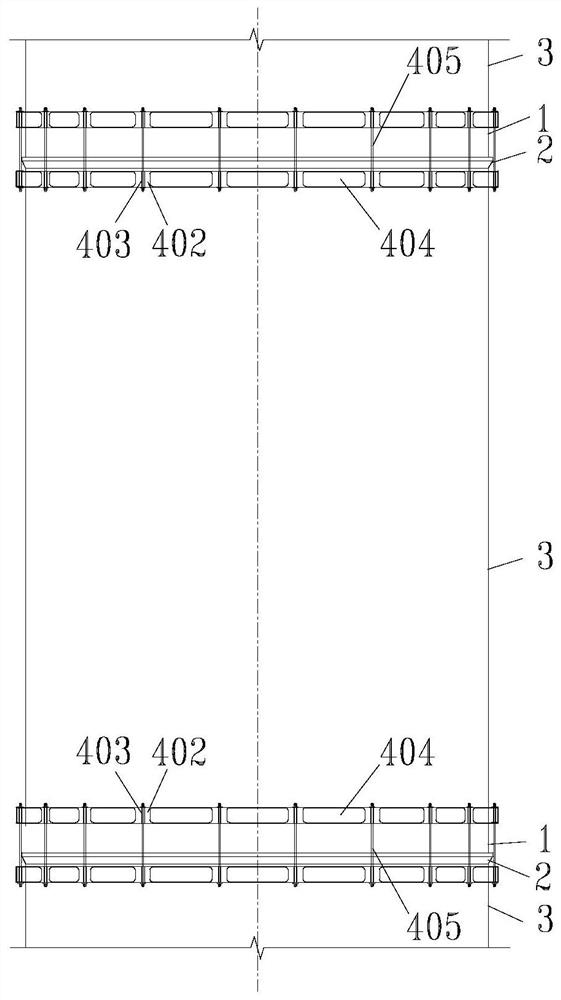

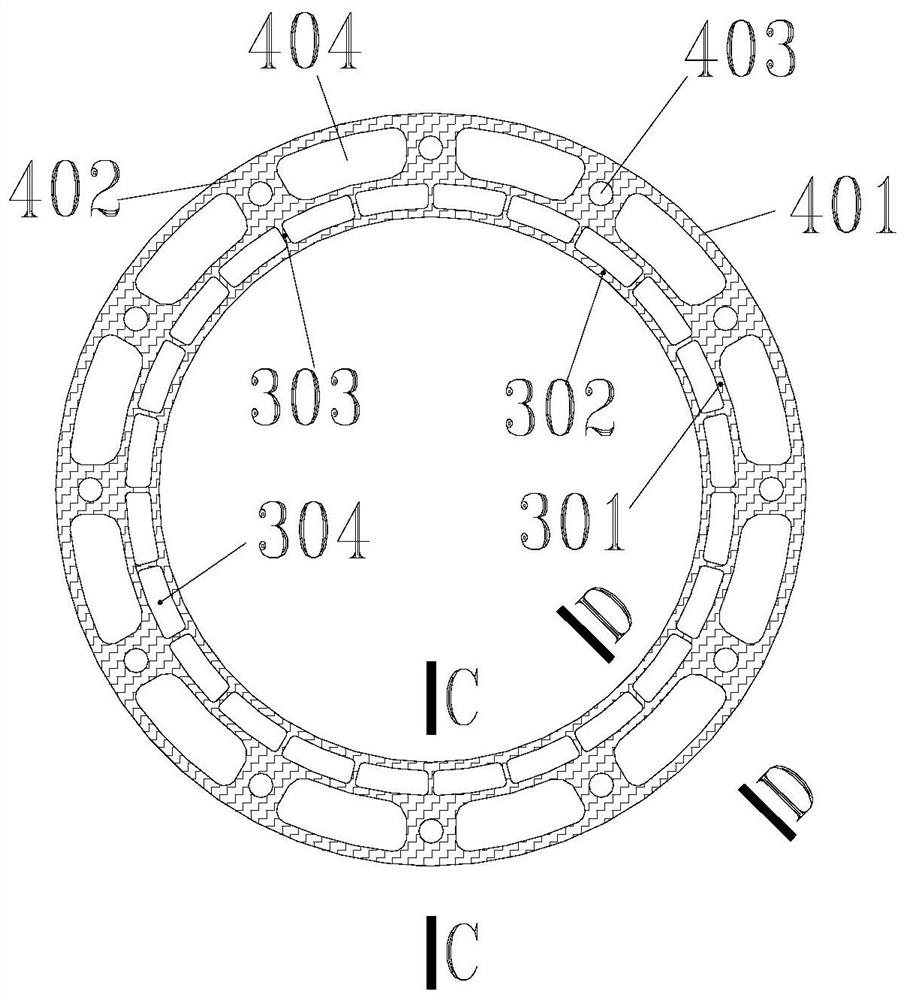

[0028] Such as Figure 1-10 As shown, the present invention provides a double-walled FRP smoke exhaust tube. The smoke exhaust tube is provided with a double wall. The double wall includes an inner wall 302 and an outer wall 301. A connecting web 303 is provided between the inner wall 302 and the outer wall 301; 302 , a cavity 1 304 is provided between the outer wall 301 and the connecting web 303 ; an annular stiffener 4 is provided on the outer peripheral cylinder body 3 of the double-walled outer wall 301 . The two ends of the exhaust pipe are provided with a connection structure, and the connection structure includes a socket connection or a flange bolt connection; or the smoke exhaust pipe is set as an integral structure without joints. A socket 1 and a socket 2 are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com