A metal skeleton tooth-shaped composite pad with special-shaped teeth

A metal skeleton and composite pad technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the high requirements of flange accuracy and equipment working condition stability, cannot use fluid pressure to seal compensation force, tooth The sharp angle of the shape is easy to damage the flange surface and other problems, so as to achieve the effect of enhancing the anti-yielding ability, high resilience and improving the elastic deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

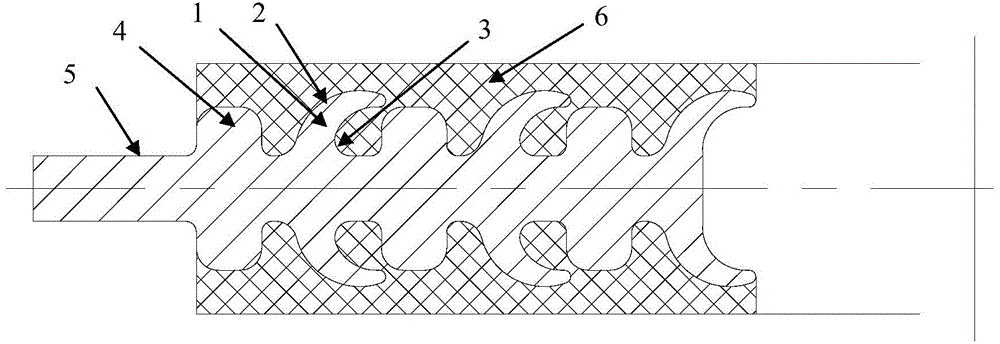

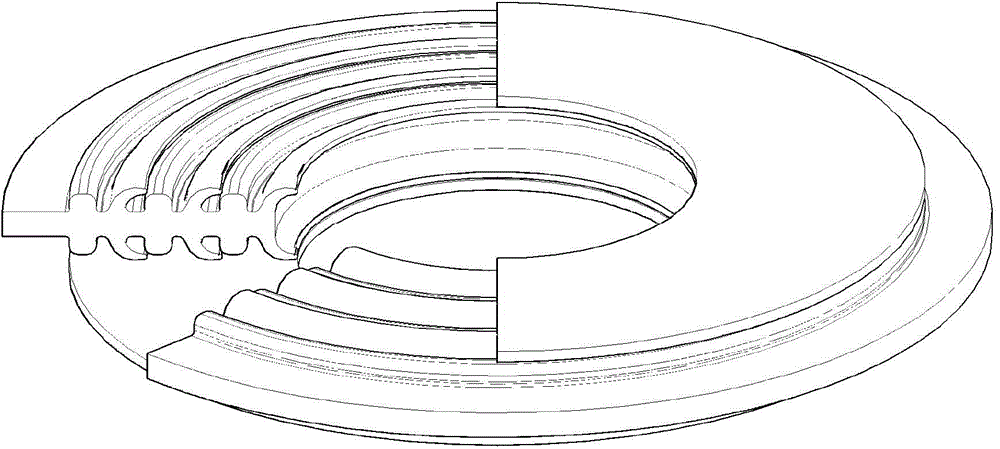

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0035]First of all, in order to solve the shortcomings of straight helical or straight teeth without additional resilience and easy to be brittle, the present invention provides two semicircular surface designs on the inside of the tooth top and root: these two semicircular surfaces provide a The extra two rebound points and extra flexibility avoid the stress concentration of the upper and root two kinks. And compared to the sharp corner or the flat corner top, the semicircular top design of the present invention still does not damage the flange under the condition of torsional deformation under pressure. Secondly, as a supplementary design feature, the crescent-shaped tooth with a wide bottom and a narrow top section design disclosed by the present invention makes the tooth have high elasticity, yield resistance and fatigue resistance, and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com