Support

A body and fixing device technology, applied in the field of anti-rust tool holders, can solve the problems of tool production process impact, lack of cleaning function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

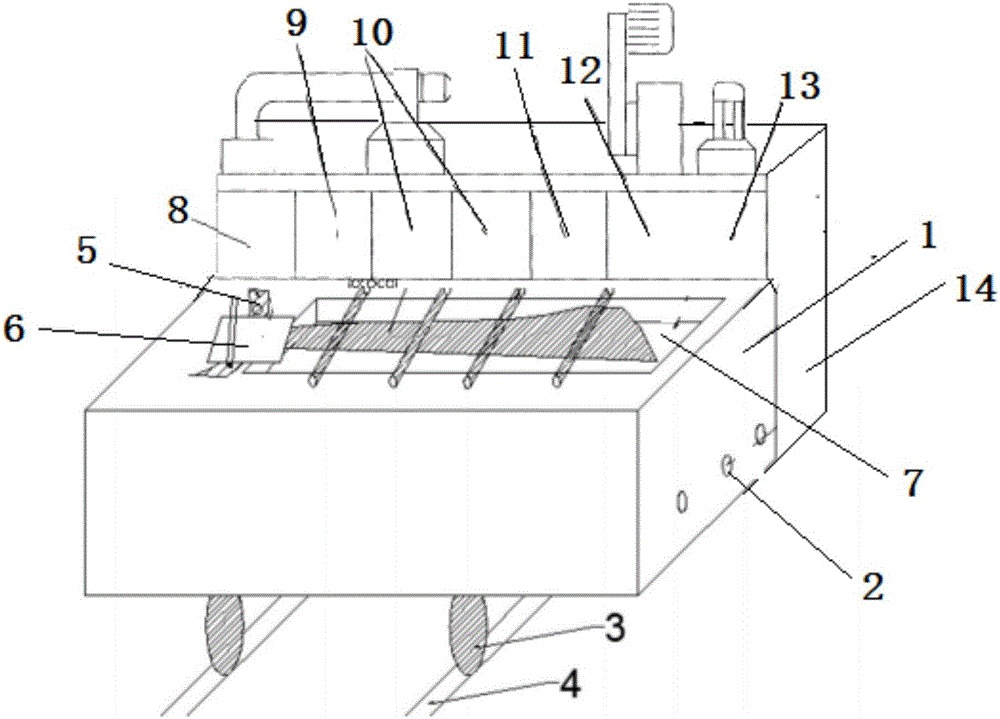

[0015] like figure 1 As shown, a bracket includes a bracket body 1, a fixing hole 2, a roller 3, a track 4, a handle fixing device 5, a blade fixing device 6 and a cavity 7, wherein a plurality of fixing holes 2 are respectively fixed on two sides of the bracket body 1. Side, the roller 3 is arranged below the bracket body 1, and the corresponding ground is provided with a track 4, and a cavity 7 is arranged above the bracket body 1, and a knife handle fixing device 5 is arranged on the left side of the cavity 7, and a knife handle fixing device 5 The right side of the blade is provided with a blade fixing device 6, and the back of the bracket body 1 is provided with a cleaning device, which includes an ultrasonic cleaning device 8, a spray cleaning device 9, a spray rinsing device 10, a blowing liquid dripping device 11, a hot air Drying device 12 and atomizing antirust device 13, ultrasonic cleaning device 8, spray cleaning device 9, spray rinsing device 10, blowing liquid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com