Preparation method of damp-proof slow-release antirust paper

A technology of antirust paper and preparation steps, which is applied in the field of preparation of moisture-proof slow-release antirust paper, which can solve the problems of fast volatilization speed of antirust agent, need to improve moisture-proof performance, and large loss of antirust agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

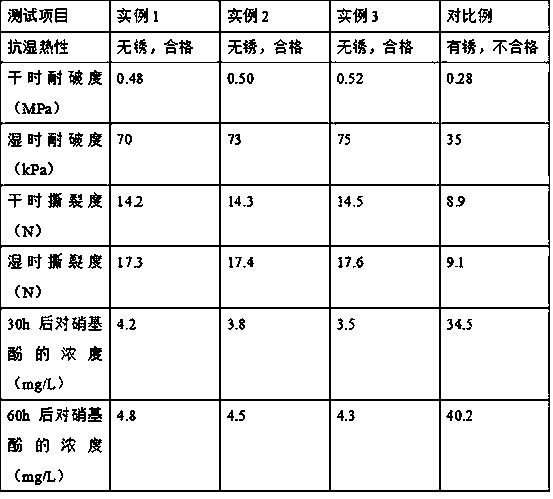

Examples

example 1

[0026] Peel broad beans and grind them into powder, pass through a 200-mesh sieve to obtain broad bean powder, mix broad bean powder and water at a mass ratio of 1:6 to obtain a suspension, adjust the pH to 1.5 with 10% hydrochloric acid, and stir for 35 minutes at room temperature , get the filtrate and filter residue after suction filtration, wash the filter residue with hydrochloric acid with a mass fraction of 5% again, remove the filter residue, combine the filtrate and washing liquid to obtain the leachate; add lime water with a mass fraction of 20% to the leachate and neutralize until the pH value is 6.5, stir for 10 minutes, let stand for 40 minutes, filter and separate to obtain the precipitate, grind the rotten wood through a 400-mesh sieve to obtain the rotten wood powder, take the pomegranate peel, sediment, rotten wood powder, and water in a mass ratio of 4:1:2 : 10 mixed, placed in a fermenter, sealed and fermented at a temperature of 30°C for 4 days to obtain a f...

example 2

[0028] Peel broad beans and grind them into powder, pass through a 200-mesh sieve to obtain broad bean powder, mix broad bean powder and water at a mass ratio of 1:6 to obtain a suspension, adjust the pH to 1.7 with 10% hydrochloric acid, and stir for 37 minutes at room temperature , get the filtrate and filter residue after suction filtration, wash the filter residue with hydrochloric acid with a mass fraction of 5% again, remove the filter residue, combine the filtrate and washing liquid to obtain the leachate; add lime water with a mass fraction of 20% to the leachate and neutralize until the pH value is 6.7, Stir for 12 minutes, let stand for 42 minutes, filter and separate to obtain the precipitate, grind the rotten wood through a 400-mesh sieve to obtain the rotten wood powder, take the pomegranate peel, sediment, rotten wood powder, and water in a mass ratio of 4:1:2 : 10 mixed, placed in a fermenter, sealed and fermented at a temperature of 32°C for 4 days to obtain a f...

example 3

[0030] Peel broad beans and grind them into powder, pass through a 200-mesh sieve to obtain broad bean powder, mix broad bean powder and water at a mass ratio of 1:6 to obtain a suspension, adjust the pH to 2.0 with 10% hydrochloric acid, and stir for 40 minutes at room temperature , get the filtrate and filter residue after suction filtration, wash the filter residue with hydrochloric acid with a mass fraction of 5% again, remove the filter residue, combine the filtrate and washing liquid to obtain the leachate; add lime water with a mass fraction of 20% to the leachate and neutralize until the pH value is 7.0, stirred for 15 minutes, allowed to settle for 45 minutes, filtered and separated to obtain the precipitate, ground the rotten wood through a 400-mesh sieve to obtain the rotten wood powder, and took the pomegranate peel, sediment, rotten wood powder, and water in a mass ratio of 4:1:2 : 10 mixed, placed in a fermenter, sealed and fermented at a temperature of 35°C for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com