Environmentally-friendly safety type copper material cleaning protection agent and preparation method thereof

A safe, copper-based technology, used in the field of chemical cleaning agents, can solve the problems of long cleaning time, complicated process steps, affecting the quality and appearance of workpieces, etc. mutual solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

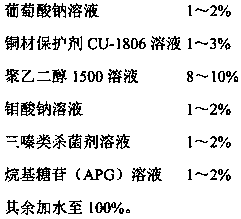

[0022] Each component and its content, weight ratio are respectively:

[0023]

[0024] The preparation method is as follows:

[0025] ⑴. Check and confirm that the reactor equipment is clean and dry, and start the reactor equipment to confirm that the equipment is in normal operation and ready for standby;

[0026] ⑵. Metering Add copper protection agent CU-1806 solution, polyethylene glycol 1500 solution and sodium molybdate solution according to the metering standard, continue stirring for about 30 minutes, and observe that the color of the solution is a light yellow transparent liquid;

[0027] ⑶. Finally, add the triazine fungicide solution and the alkyl glycoside (APG) solution in sequence according to the measurement standard, and stir for about 20 minutes to confirm that the product is completely stirred evenly.

Embodiment 2

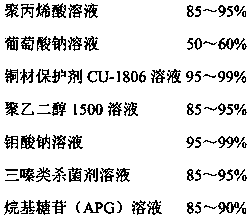

[0029] Each component and its content, weight ratio are respectively:

[0030]

[0031] The preparation method is as follows:

[0032] ⑴. Check and confirm that the reactor equipment is clean and dry, and start the reactor equipment to confirm that the equipment is in normal operation and ready for standby;

[0033] ⑵. Metering Add copper protection agent CU-1806 solution, polyethylene glycol 1500 solution and sodium molybdate solution according to the metering standard, continue stirring for about 30 minutes, and observe that the color of the solution is a light yellow transparent liquid;

[0034] ⑶. Finally, add the triazine fungicide solution and the alkyl glycoside (APG) solution in sequence according to the measurement standard, and stir for about 20 minutes to confirm that the product is completely stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com