Electrostatic powder coating sprayed on tent support

An electrostatic powder and tent technology, applied in the field of powder coatings, can solve the problems of affecting product appearance, high production cost, poor anti-rust effect, etc., and achieve the effect of low production cost, good adhesion, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] raw material epoxy resin polyester resin leveling agent Titanium dioxide calcium carbonate wax powder pigment Accelerator parts by weight 25 30 0.15 10 6 0.4 0.8 0.5

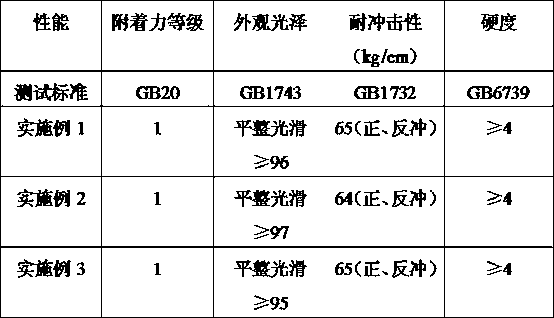

[0029] Table 1

[0030] The production method step of the electrostatic powder coating that present embodiment is used for tent frame spraying is as follows:

[0031] (1) Weigh epoxy resin, polyester resin, leveling agent, titanium dioxide, calcium carbonate, wax powder, pigment and accelerator according to the weight fraction of each component in Table 1, and put the materials into a temperature of 30°C , the relative humidity is 23%, the rotating speed is to mix in the mixer of 1420r / min, the time of mixing is 43min;

[0032] (2) Put the material after step (1) into a temperature of 150°C, a relative humidity of 4%, and a pressure of 4Kg / cm 2 Extruded in the pressing machine to obtain block powder;

[0033] (3) Put the block powder obtained in step (2) into a...

Embodiment 2

[0036] raw material epoxy resin polyester resin leveling agent Titanium dioxide calcium carbonate wax powder pigment Accelerator parts by weight 30 32 1.0 15 8 1 1.6 1.0

[0037] Table 2

[0038] The production method step of the electrostatic powder coating that present embodiment is used for tent frame spraying is as follows:

[0039] (1) Weigh epoxy resin, polyester resin, leveling agent, titanium dioxide, calcium carbonate, wax powder, pigment and accelerator according to the weight fraction of each component in Table 2, and put the materials into a temperature of 40°C , the relative humidity is 25%, the rotating speed is to mix in the mixer of 1550r / min, the time of mixing is 45min;

[0040] (2) Put the material after step (1) into a temperature of 160°C, a relative humidity of 5%, and a pressure of 5Kg / cm 2 Extruded in the pressing machine to obtain block powder;

[0041] (3) Put the block powder obtained in step (2) into a pu...

Embodiment 3

[0044] raw material epoxy resin polyester resin leveling agent Titanium dioxide calcium carbonate wax powder pigment Accelerator parts by weight 40 35 0.25 30 12 3.0 3.2 2.5

[0045] table 3

[0046] The production method step of the electrostatic powder coating that present embodiment is used for tent frame spraying is as follows:

[0047] (1) Weigh epoxy resin, polyester resin, leveling agent, titanium dioxide, calcium carbonate, wax powder, pigment and accelerator according to the weight fraction of each component in Table 3, and put the materials into a temperature of 50°C , the relative humidity is 28%, the rotating speed is to mix in the mixer of 1680r / min, the time of mixing is 48min;

[0048] (2) Put the material after step (1) into a temperature of 170°C, a relative humidity of 6%, and a pressure of 6Kg / cm 2 Extruded in the pressing machine to obtain block powder;

[0049] (3) Put the block powder obtained in step (2) into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com