Multipurpose primer-topcoat water-based coating and preparation method thereof

A water-based paint, multi-purpose technology, applied in the direction of anti-corrosion paint, coating, etc., can solve the problems of poor salt spray resistance, difficult to meet customer needs, etc., to achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

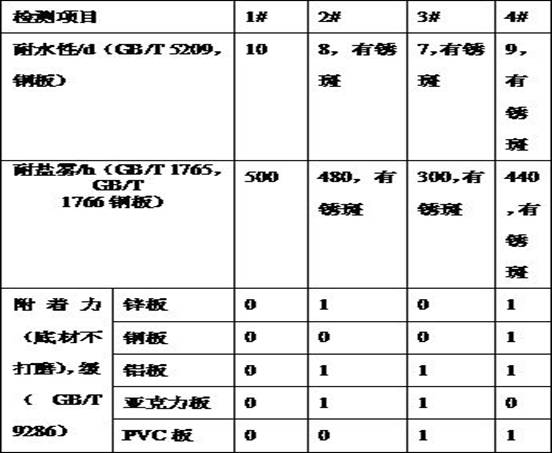

[0030] A kind of water-based coating with multi-purpose base and surface, which is tested by changing the type of anti-rust pigment, numbered 1#, 2#, 3#, 4#, the specific formula is shown in Table 1, and its preparation method is as follows:

[0031] S1: Add the formulated amount of dispersant, zinc molybdate modified pigment, silicon-based calcium ion-exchange anti-rust pigment, calcium phosphate-based anti-corrosion inhibitor, siloxane modified nano-mica powder, ultra-fine talc powder, ultra-fine Fine barium sulfate, titanium dioxide, organic soil, anti-flash embroidery agent, pre-dispersed at 900-1200 rpm, grind to a fineness below 15um with a horizontal sand mill, temperature 40-50°C, flow rate 10-15L / min to get slurry;

[0032] S2: drop into the water-based acrylic emulsion of formula quantity successively, ethylene glycol butyl ether, dipropylene glycol methyl ether, alcohol ester twelve, at 300-600 rpm, stir for 5-10 minutes;

[0033] S3:: add the siloxane-based coupl...

Embodiment 2

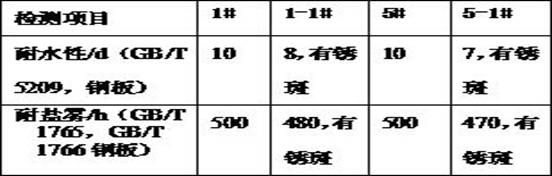

[0042] A kind of water-based coating with multi-purpose base and surface, experimented by changing the ratio of calcium ion exchange anti-rust pigment and calcium phosphate-based anti-corrosion inhibitor, numbered 5#, 6#, 7#, 8#, see Table 3, The paint preparation method is the same as in Example 1, and the performance of the paint film is tested, as shown in Table 4. It is known from the table that changing the amount of anti-rust pigments and inhibitors has a certain impact on the water resistance and salt spray resistance of the paint film , wherein the amount of anti-rust pigment and inhibitor is between 1:0.8-1.2, which can realize the complementary performance of anti-rust pigment and inhibitor. A synergistic effect is produced in the removal and passivation to reduce the penetration of water. The concentration of calcium ions in this ratio is complementary, so that silicate ions and calcium ions can fully generate insoluble silicates, forming a dense passivation protecti...

Embodiment 3

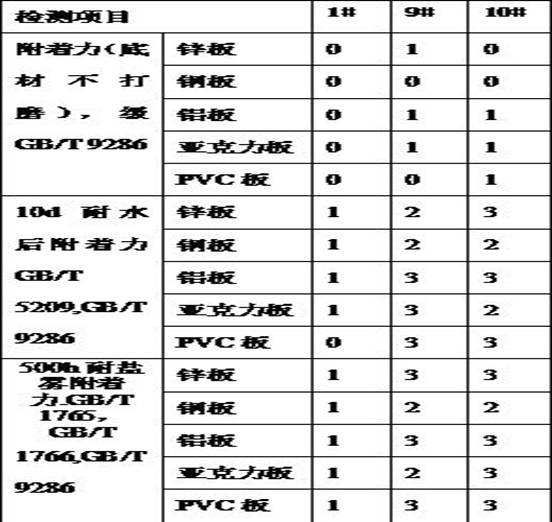

[0048] A kind of water-based coating with multi-purpose base surface, change the kind of adhesion promoter to carry out experiment, numbering is 1#, 9#, 10#, see table 5, the preparation method of colored paint is the same as embodiment 1, and the performance of paint film Test, see Table 6. It is known from the table that changing the adhesion promoter affects the adhesion of the paint film. Adhesion is acceptable, but with water resistance or salt spray resistance, the adhesion of the paint film is seriously reduced, which affects the service life, and the epoxy phosphate polymer adhesion promoter is used, and the epoxy phosphate polymer main chain It contains a large number of groups that can bond with the surface of the substrate, which improves the adhesion of the coating to the substrate and expands the application field of the formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com