Preparation method of grouting material

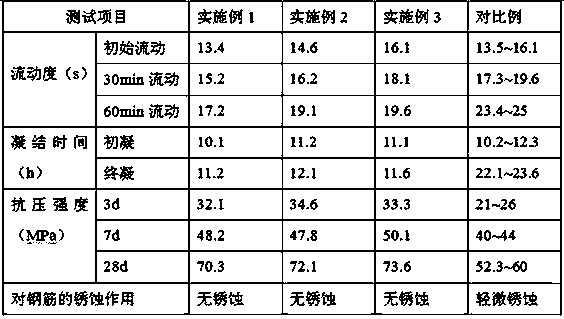

A technology for pressing slurry and raw materials, which is applied in the field of preparation of pressing slurry, which can solve the problems of long setting time of slurry, insufficient strength, poor rust resistance, etc., and achieve the effect of improving final setting time, uniform distribution and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of grouting material, this preparation method comprises the steps:

[0025] (1) According to the mass ratio of 1:5~6, mix the papermaking black liquor and concentrated sulfuric acid with a mass fraction of 70~78%, let it stand for 1~2h, filter, and obtain the filter residue according to the mass ratio of 10~15:1~2 , put the filter residue and sulfonating agent in the reaction kettle, pass in steam, mix at a temperature of 70-80°C for 1-2 hours, take it out, and air-dry naturally to obtain an air-dried product;

[0026] (2) In parts by weight, take 10~15 parts of air-dried matter, 2~3 parts of sodium sulfite, 1~2 parts of formaldehyde, 1~2 parts of hydrogen peroxide, 1~2 parts of acrylic acid, and 0.04~0.06 parts of ammonium persulfate , mix the air-dried material and hydrogen peroxide, oxidize at a temperature of 70~80°C for 1~2h, add ammonium persulfate and acrylic acid for grafting for 1~2h, raise the temperature to 80~90°C, and adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com