After-grouting self-guiding hole PHC tubular pole tip anti-rusting cap construction device and construction process

A technology of PHC pipe piles and construction devices, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems affecting the bearing capacity of PHC pipe piles, achieve the purpose of strengthening the foundation, improving the bearing capacity of pile foundations, and improving The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

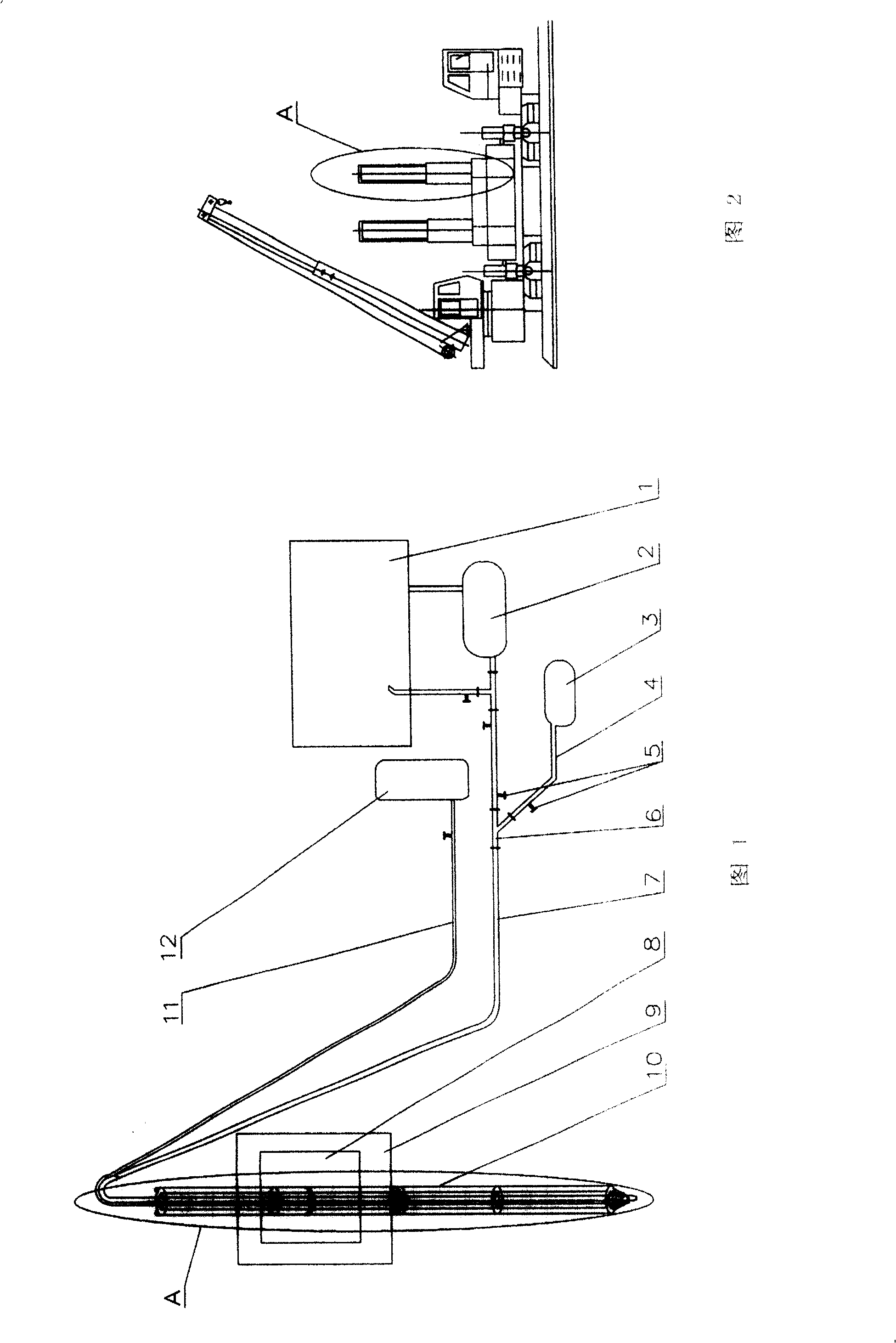

[0013] An example of an embodiment is shown in Figure 1-2: a post-grouting self-guiding hole PHC pipe pile tip anti-rust cap construction device, which is composed of a water tank (1), a multi-stage centrifugal pump (2), a high-pressure water pipe (7), a clip Static hydraulic pressure pile with flushing water and air introduction hole composed of pile device (8), pile feeder (9), PHC cavity pipe pile (10), high-pressure gas transmission pipe (11) and air compressor (12) The machine phase is connected; the high-pressure grouting pump (3) is connected to the high-pressure water delivery pipe (7) through the high-pressure grouting pipe (4) and the three-way pipe (6), and the multi-stage centrifugal pump (2) is connected to the three-way pipe (6) And a one-way valve (5) is housed between the three-way pipe (6) and the high-pressure grouting pump (3).

[0014] A post-grouting self-guiding hole PHC pipe pile tip anti-rust cap construction process, when the PHC cavity pipe pile is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com