Automatic industrial cleaning method

An industrial cleaning and automatic technology, which is applied in the field of cleaning, can solve the problems of difficult cleaning of oil stains on the inner wall of nuts, poor cleaning effect, and difficulty in meeting cleaning quality requirements, so as to improve cleaning effect and achieve better cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

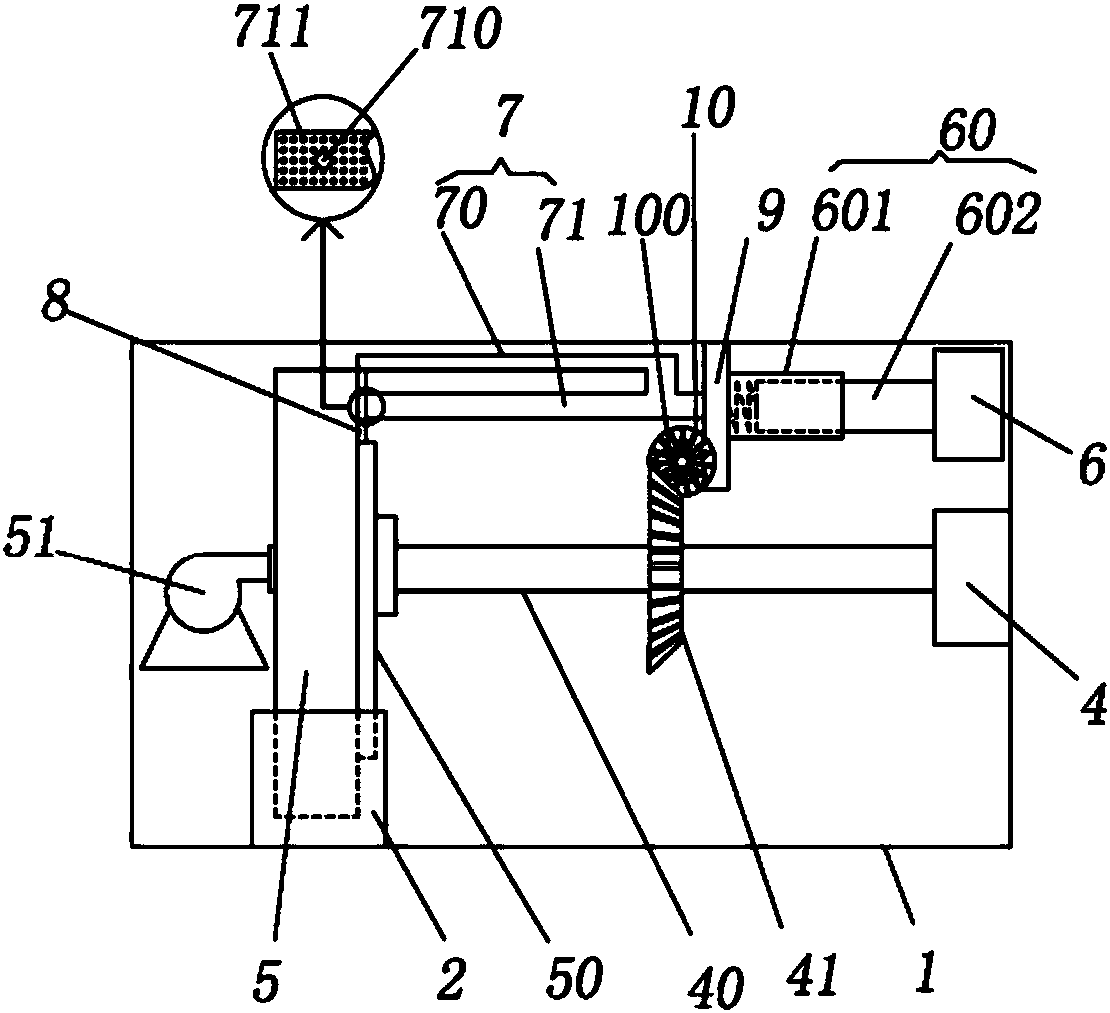

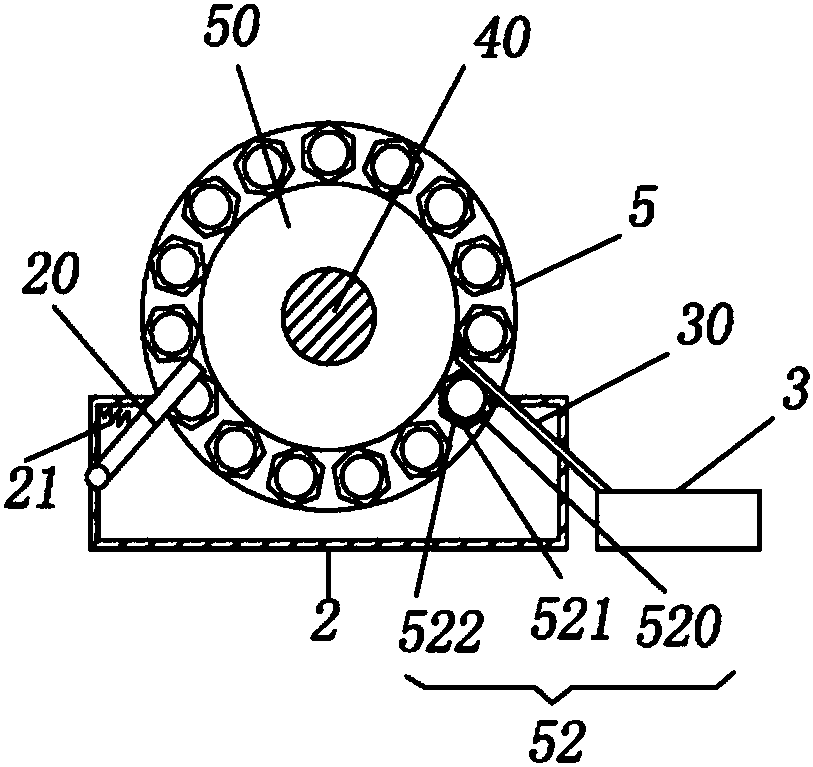

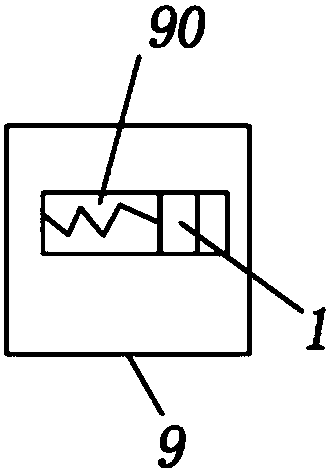

[0027] The embodiment is basically as figure 1 with figure 2 As shown, the automatic industrial cleaning method comprises the following steps:

[0028] Step 1, cleaning solution preparation: weigh 10kg sodium dodecylsulfonate, 5kg sodium hypochlorite, 3kg sodium carbonate, 5kg acetone, 3kg vaseline and 100kg water by mass.

[0029] Step 2, preparation of cleaning solution: heat sodium dodecylsulfonate, acetone and vaseline to 35°C while stirring, and keep for 5 minutes to obtain an organic phase mixture; mix hypochlorite, carbonate and water evenly , to obtain the inorganic phase mixed liquid; then slowly add the organic phase mixed liquid into the inorganic phase mixed liquid, and continuously stir and mix to obtain the cleaning liquid.

[0030] Step 3, prepare a feed box 2, put the nut 8 to be cleaned into the feed box 2, install a turntable 5 for automatically sucking the nut 8 in the feed box 2 above the feed box 2; One side is installed a cleaning mechanism for cleani...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The cleaning liquid in step 1 comprises 15kg sodium dodecylsulfonate, 10kg sodium hypochlorite, 6kg sodium carbonate, 7kg acetone, 5kg vaseline and 100kg water by mass.

[0040] In step 2, sodium dodecylsulfonate, acetone and petrolatum were heated to 45°C while stirring, and kept for 8 minutes to obtain an organic phase mixture.

[0041] The pressure of the vacuum pump 51 in step 3 is 95MPa.

[0042] In step 4, the rotation speed of the turntable 5 is 1 r / min, the rotation speed of the cleaning assembly 7 is 0.5 r / s, and the time for the cleaning assembly 7 to leave the fixing part 52 is 1 s.

[0043] In step 5, the stirring speed is 120r / min.

[0044] The drying temperature in step 6 is 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com