Adjustable injection mold machining workbench

A technology of injection mold and processing table, which is applied in the field of processing table, can solve problems such as single structure and inability to adjust, and achieve the effect of strong practicability and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

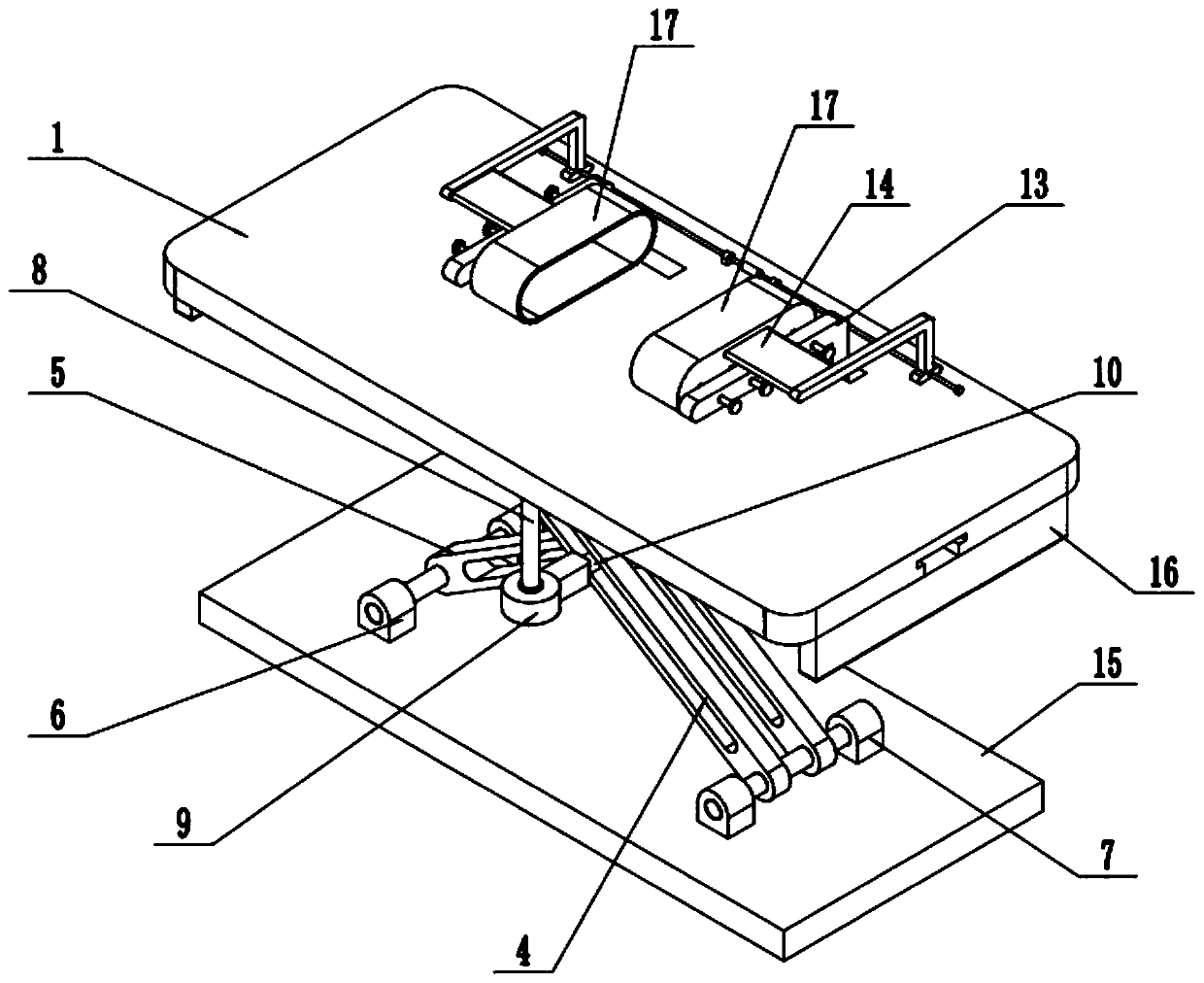

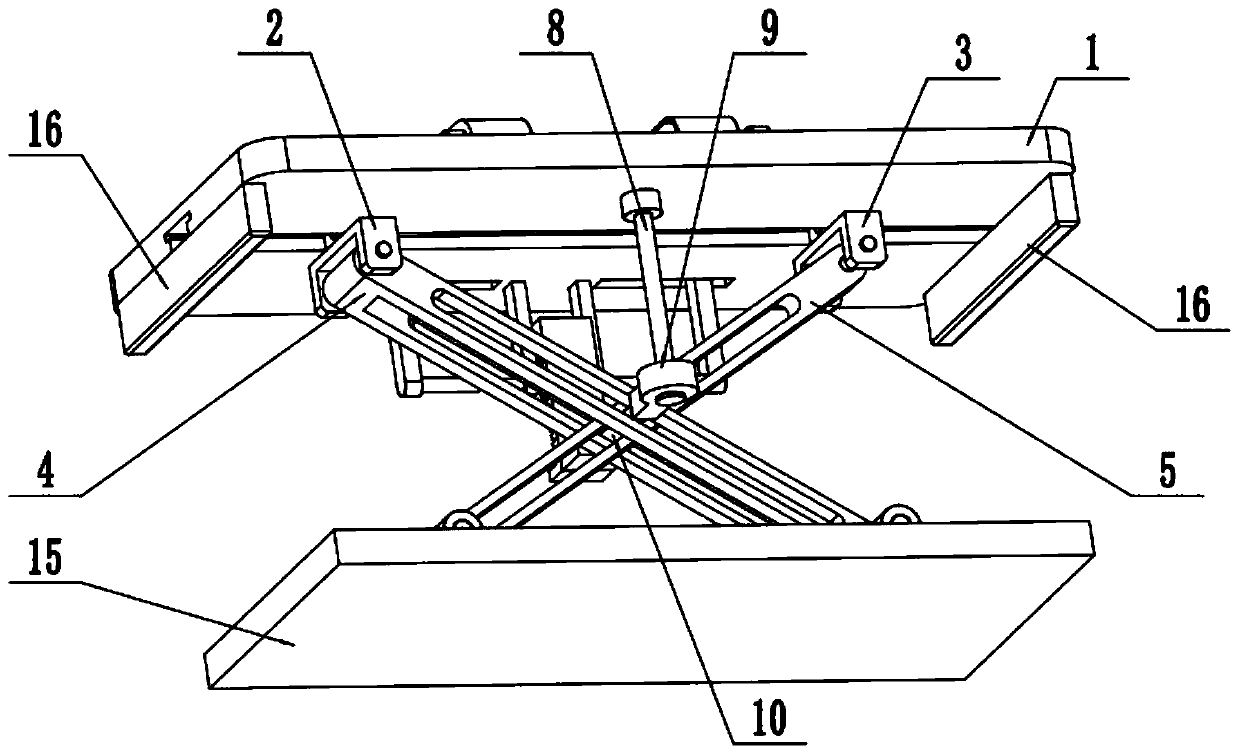

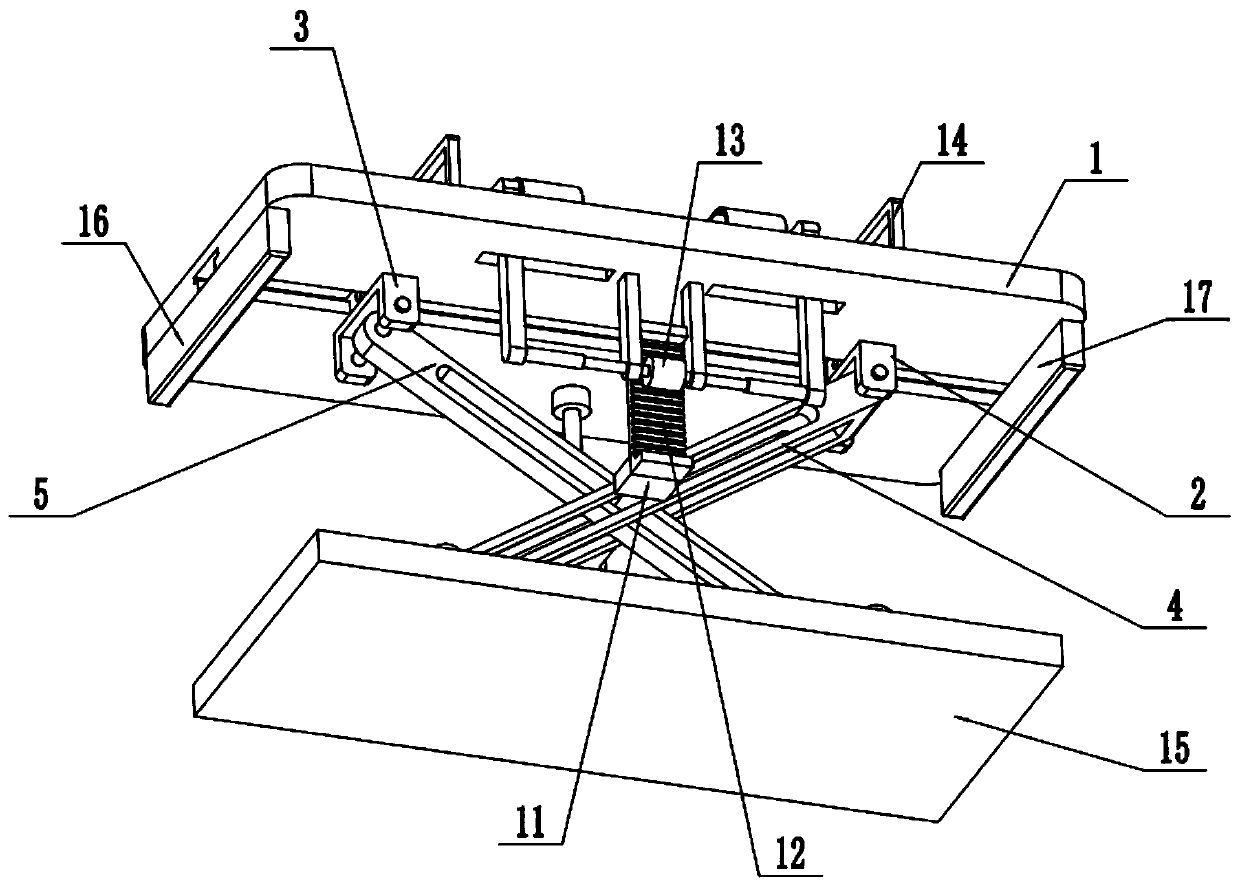

[0028] Such as Figure 1-10 As shown, an adjustable injection mold processing table includes a processing table body 1, a left sliding seat 2, a right sliding seat 3, a left outrigger 4, a right outrigger 5, a left fixing seat 6, a right fixing seat 7, an electric Push rod 8, lifting seat 9, slide bar 10, linkage seat 11, rack 12, mold fixing frame 13, ejector 14 and base plate 15, the middle end of the bottom surface of the processing table body 1 is provided with a T-shaped chute The left sliding seat 2 and the right sliding seat 3 are symmetrically slid and connected to the two ends of the T-shaped chute, and the left sliding seat 2 and the right sliding seat 3 have the same structure; the left fixed seat 6 and the right fixed seat 7 are symmetrical Fixedly connected to the two ends of the top surface of the base plate 15; the two ends of the left support leg 4 are connected to the left sliding seat 2 and the right fixed seat 7 in rotation and fit respectively; the two ends...

specific Embodiment approach 2

[0029] Such as Figure 1-10 As shown, the left and right ends of the bottom surface of the processing table body 1 are respectively fixedly connected with a vertical board, and the two vertical boards are located outside the left sliding seat 2 and the right sliding seat 3 . The setting of the vertical plate is used to prevent the left sliding seat 2 and the right sliding seat 3 from breaking away from the T-shaped chute.

specific Embodiment approach 3

[0030] Such as Figure 1-10 As shown, the top surface of the processing table body 1 is a smooth stainless steel table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com