Blanking device for production of pressure sensor diaphragms

A pressure sensor and punching technology, used in shearing devices, accessories of shearing machines, machine tools suitable for grinding workpiece edges, etc. , increase the labor intensity of staff and other issues, to achieve the effect of reducing processing costs, avoiding offsets, and facilitating processing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

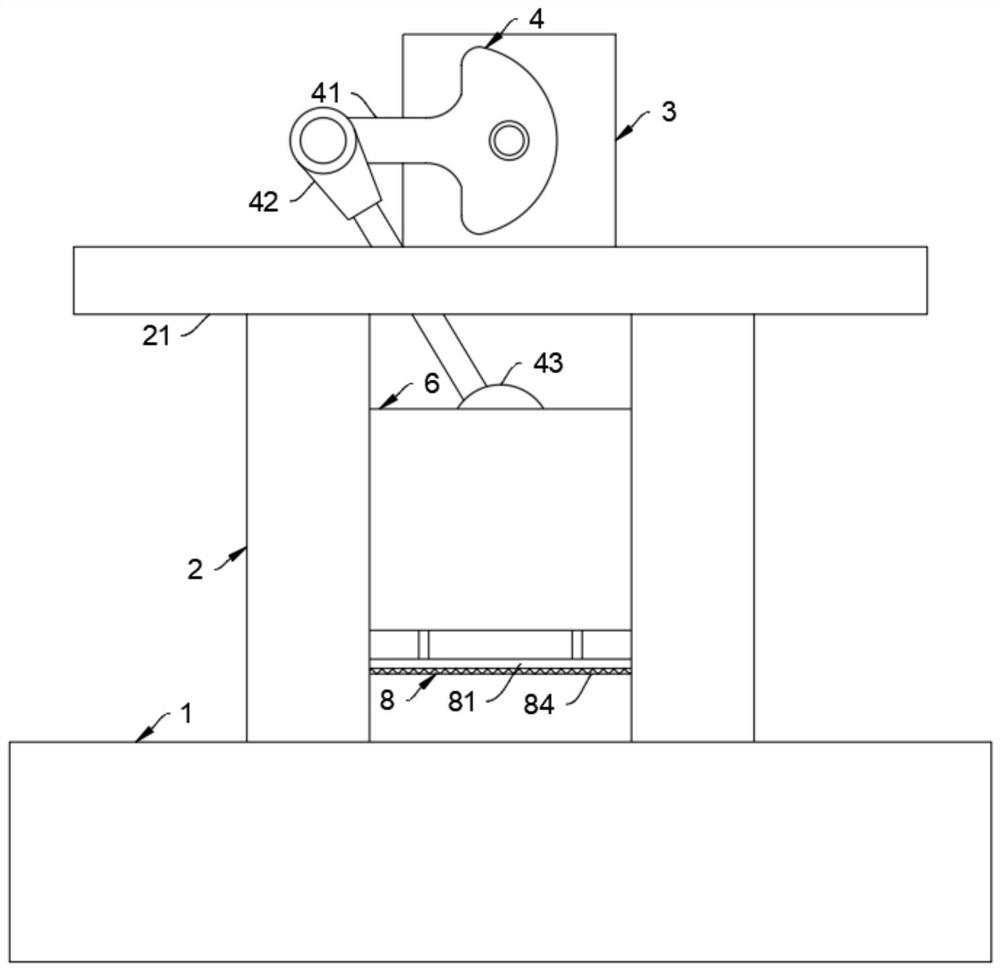

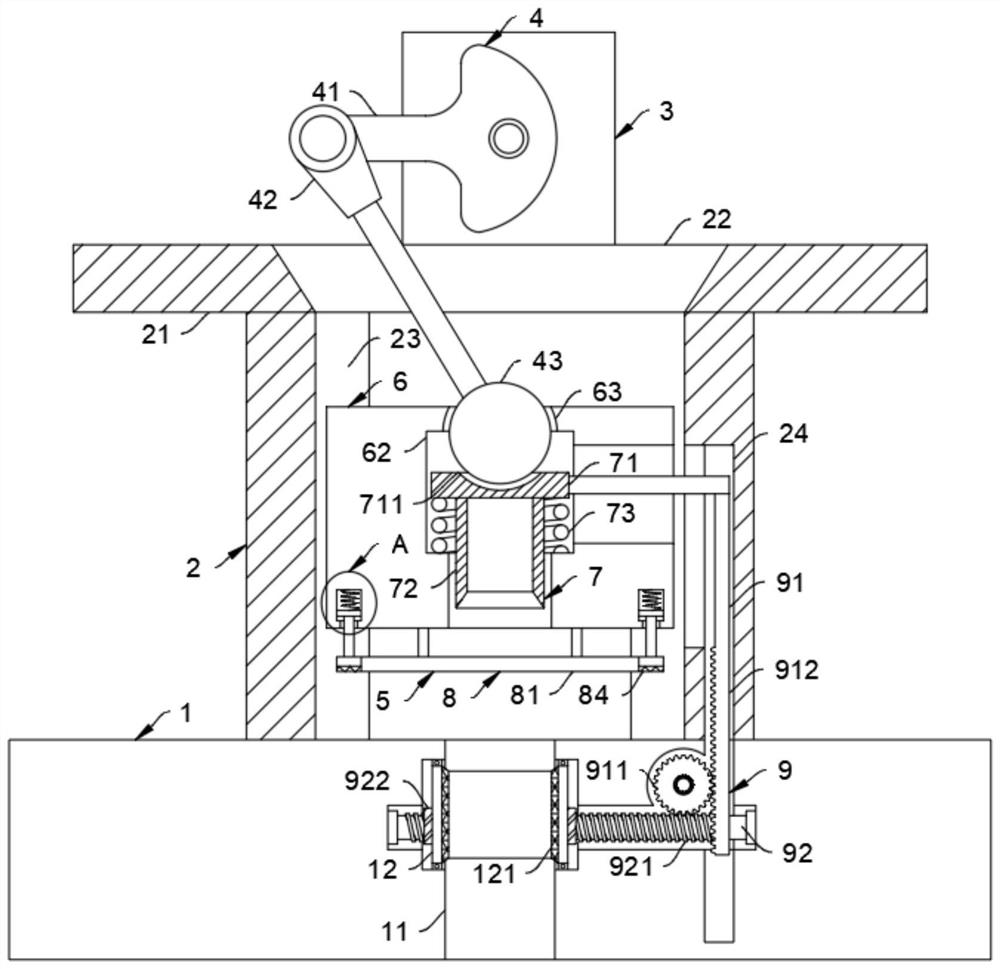

[0028] like Figure 1-5 As shown, a punching device for pressure sensor diaphragm production includes a workbench 1. The workbench 1 is provided with a bracket 2. The bracket 2 is fixedly connected to a motor 3. The output shaft of the motor 3 is movably connected to a punching machine through a rotating part 4 Device 5, it should be noted that the top plate 21 adopts a back-shaped structure, the motor 3 is fixedly connected to one side of the top plate 21, the motor 3 adopts a SJGB-57 geared motor, and the rotating part 4 passes through the opening 22 of the top plate 21 and the punching device 5 active connections.

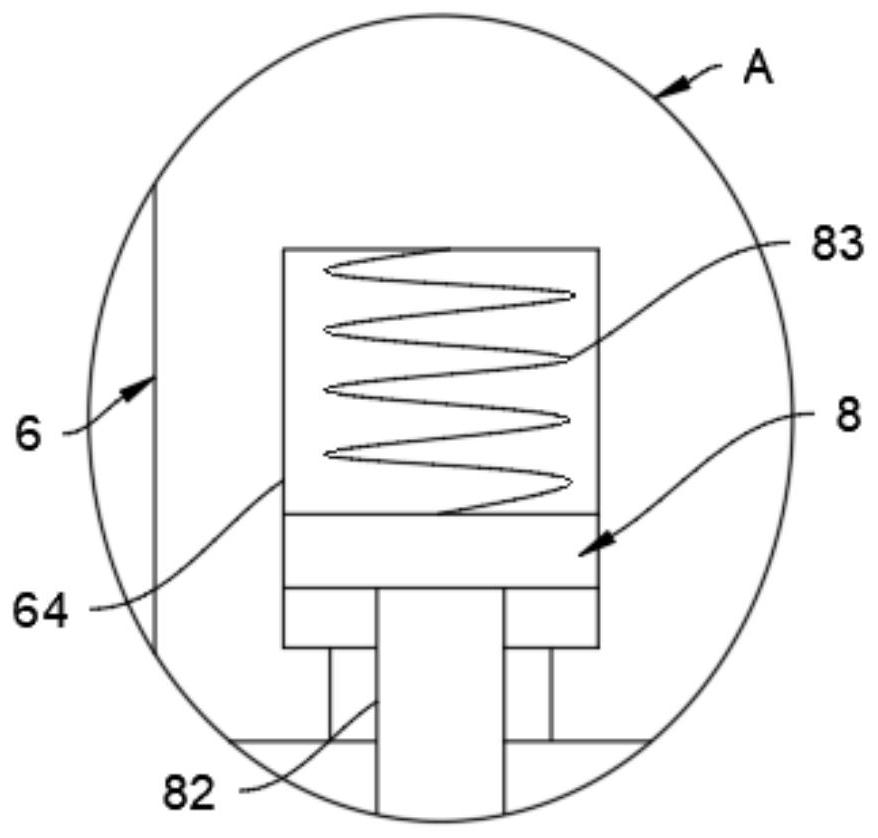

[0029] The punching device 5 includes a lifting platform 6, a blanking part 7 and a pressing part 8. The lifting platform 6 and the bracket 2 are slidably connected. It should be noted that the bracket 2 is provided with a concave groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com