Chimney expansion joint

A technology of expansion joints and chimneys, which is applied in the field of chimney expansion joints, can solve problems such as unsatisfactory use conditions, arc tearing, and downward leakage of acid liquid, so as to avoid natural leakage, prolong service life, and prolong installation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

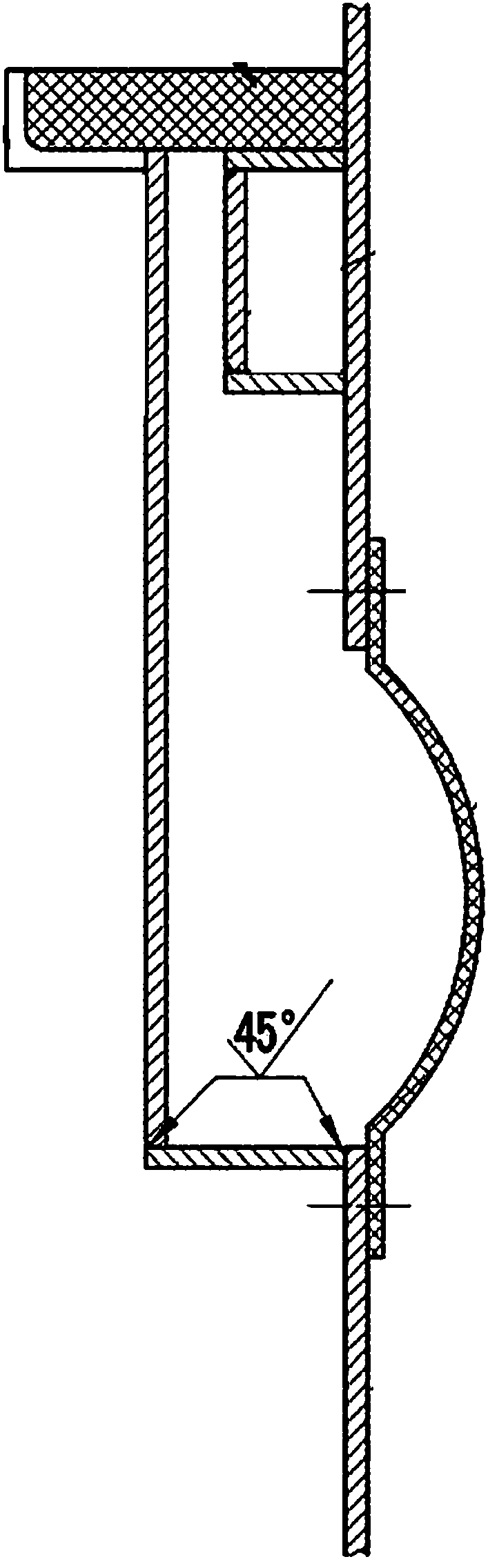

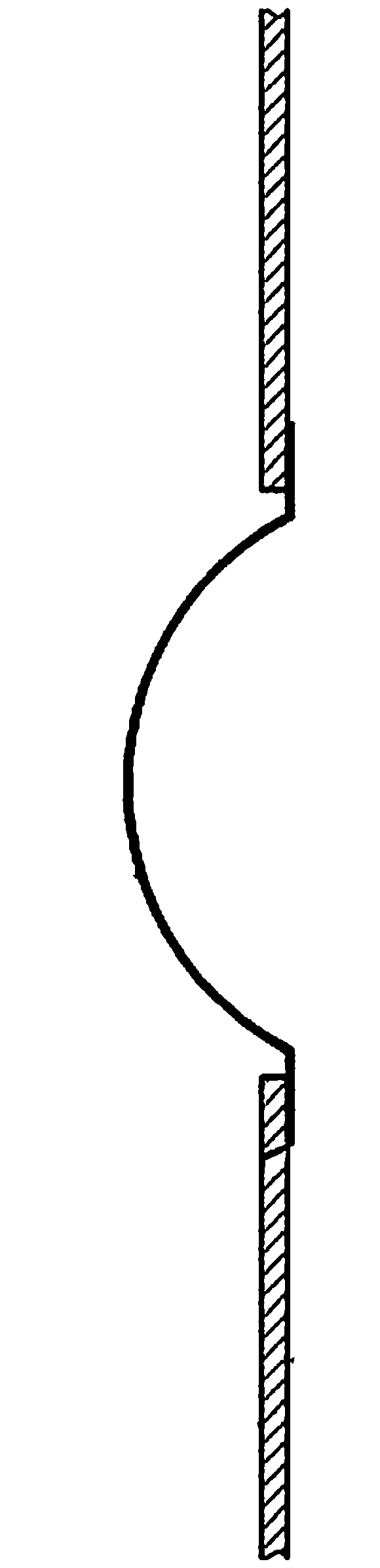

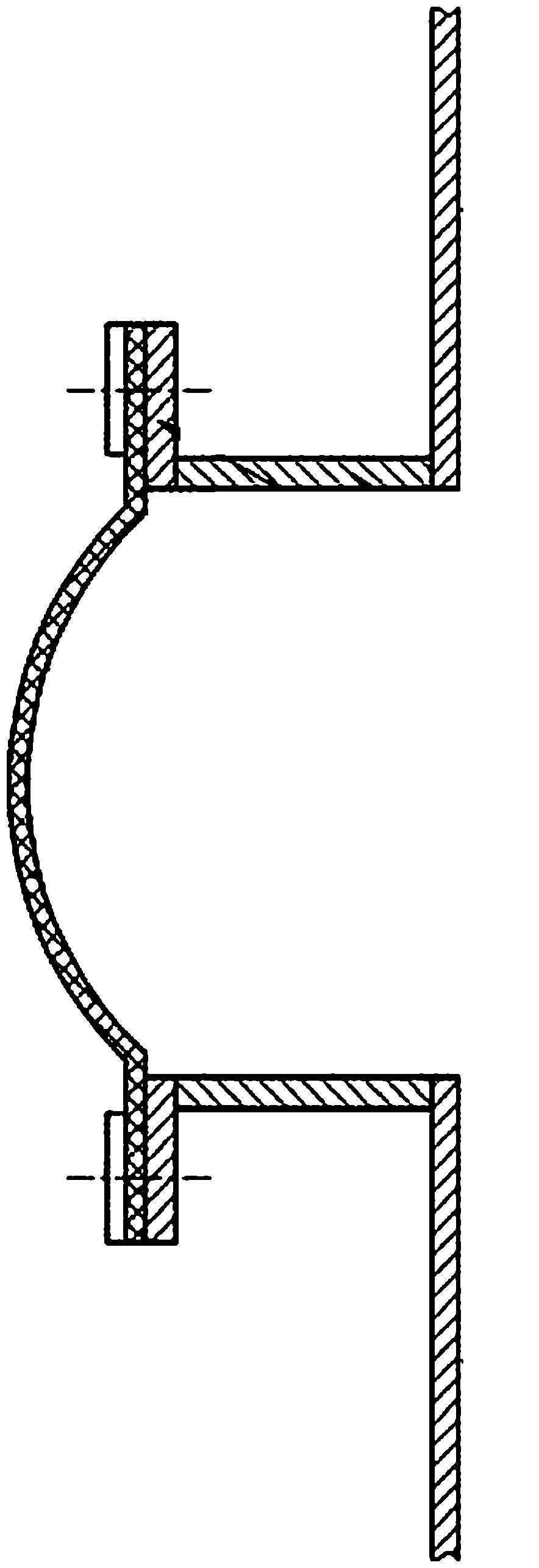

[0021] As shown in the accompanying drawings, a chimney expansion joint includes a steel inner cylinder 1, a flange frame part, and a sealing ring 6. The sealing ring 6 is fixedly connected to the steel inner cylinder 1 through the flange frame part, and the flange frame part Including the upper cone angle flange 3, the lower cone angle flange 7, the upper compression flange 4, the lower compression flange 8 and the bolt assembly 5, the inner rings of the upper and lower cone angle flanges and the steel inner cylinder welding, the mounting surfaces 9 at both ends of the sealing ring 6 are press-fitted and fixed between the upper and lower cone angle flanges through the upper and lower compression flanges, and the mounting surfaces 9 at both ends of the sealing ring 6 are respectively located on the corresponding upper Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com