Patents

Literature

31results about How to "High temperature high strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound bricks of phosphogypsum, and producing method

This invention discloses a method for producing phosphogypsum composite bricks, which are produced from: steam-cured phosphogypsum 30-55 parts, gel material 10-30 parts, curing agent 5-15 parts, aggregrate 5-37 parts, and reinforcer 1-5 parts. The method comprises: (1) steam-curing phosphogypsum, mixing and strring with the other raw materials; (2) adding water so that the water content is 12-20%; (3) molding under 10-80 MPa; (4) steam-curing at high temperatures and high pressure for 5-24 h. The composite bricks have such advantages as high flexural strength, high compressive strength and good freeze resistance, thus can be used on main walls. The method efficiently and largely consumes phosphogypsum, thus saving soil resources and preventing environmental pollution by phosphogypsum piling. Besides, the method has high profit, and is environmentally friendly.

Owner:HUAZHONG UNIV OF SCI & TECH

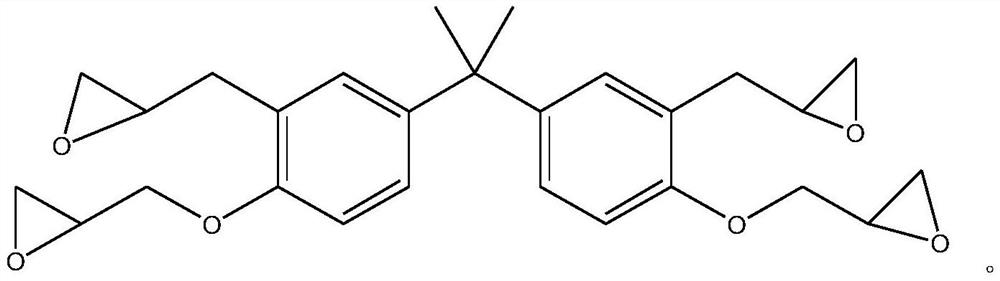

Epoxy resin adhesive and preparation method thereof

ActiveCN105950027AEasy accessIncreased shear strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolyamide

The invention relates to a high-temperature resistant and high-toughness epoxy resin adhesive and a preparation method thereof. With the use of common epoxy resin, a toughening agent, an acrylic oligomer, a modified polyamide curing agent and the like, the epoxy resin adhesive has good toughness, and excellent breaking elongation and elasticity modulus, and can maintain higher shear strength at high temperature. The preparation method is simple, the process can be regulated and controlled easily, the cost is low, and the high-temperature resistant and high-toughness epoxy resin adhesive can be cured at room temperature, is particularly applicable to fragile material adhering, and is the high-performance adhesive with both high strength and high elastoplasticity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

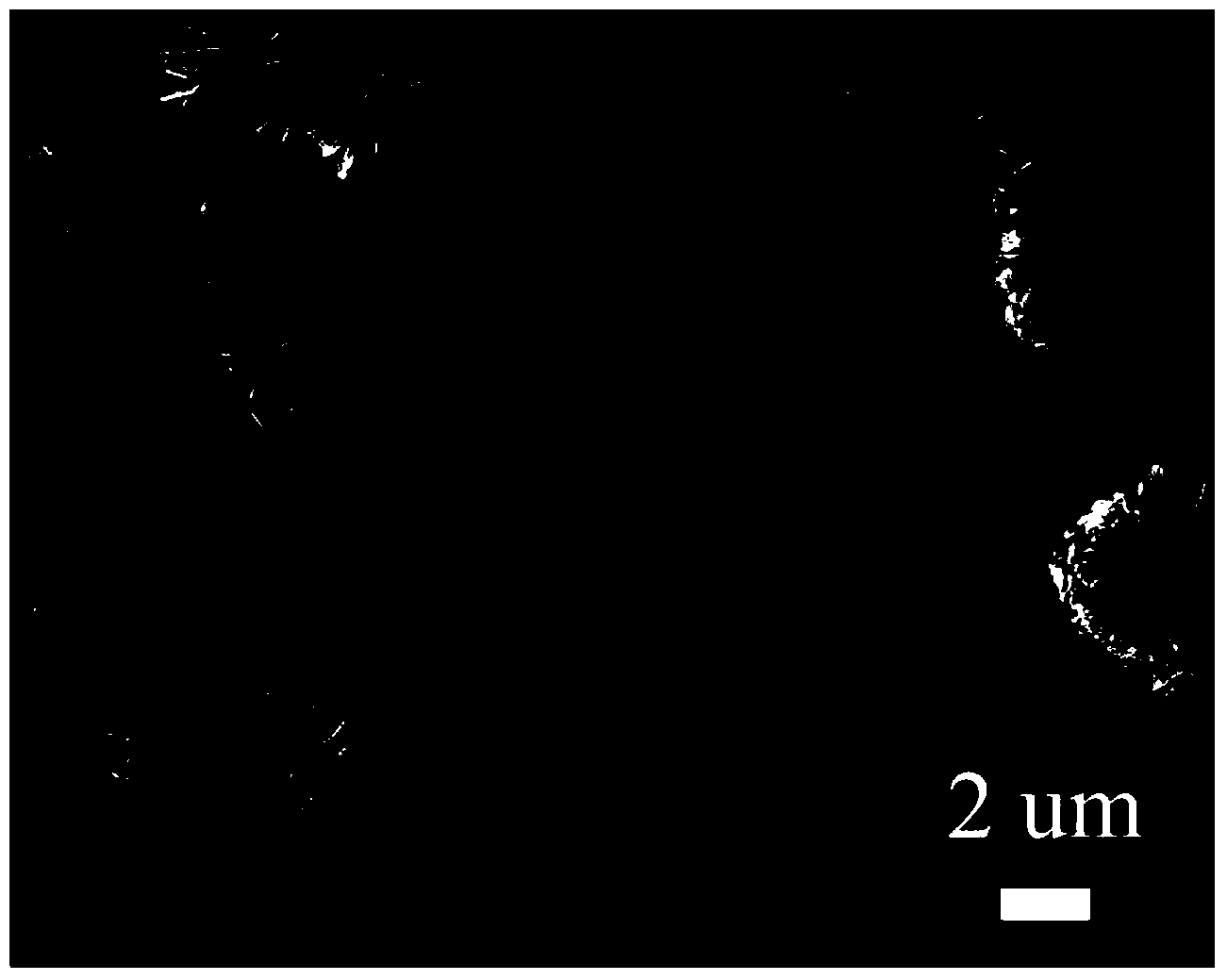

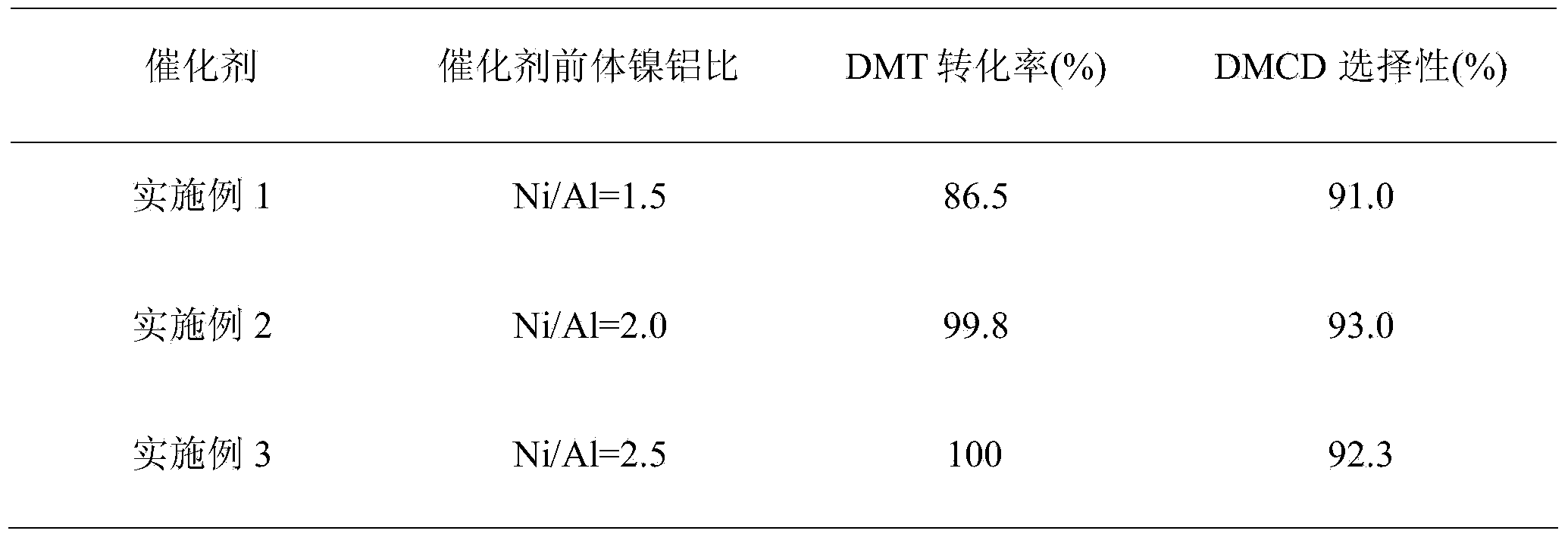

Micro spherical hollow structure nickel-based hydrogenation catalyst as well as preparation method thereof

InactiveCN103962140AIncrease the areaHigh strengthOrganic compound preparationCarboxylic acid esters preparationDimethyl terephthalateOpen framework

The invention discloses a micro spherical hollow structure nickel-based hydrogenation catalyst as well as a preparation method thereof in the technical field of catalyst preparation. The method comprises the following steps: controlling the morphology of an aluminum raw material serving as a mold plate which is consumed gradually along with the reaction, inducing hydrotalcite assembly to obtain a micro spherical hollow hydrotalcite assembly body, and carrying out in-situ reduction to obtain the micro spherical hollow nickel-based catalyst. The catalyst material obtained by preparation has high specific surface area, and the internal empty cavity structure and the abundant open-framework structures have great actual application value. The catalyst has relatively high hydrogenation activity and selectivity when being used for catalyzing dimethyl terephthalate (DMT) benzene ring hydrogenation in the reaction for preparing dimethyl 1, 4-cyclohexanedicarboxylate.

Owner:BEIJING UNIV OF CHEM TECH

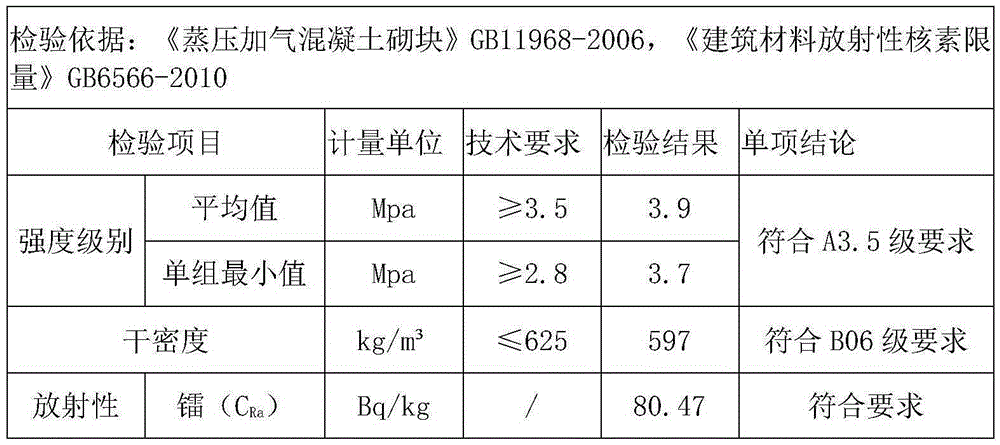

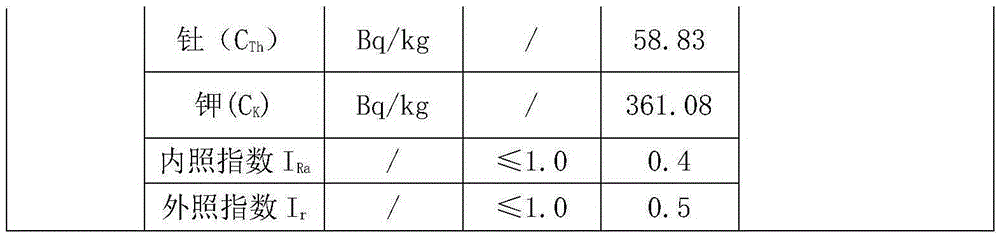

Red mud autoclaved aerated concrete building block and preparation method of red mud autoclaved aerated concrete building block

The invention discloses a red mud autoclaved aerated concrete building block and a preparation method of the red mud autoclaved aerated concrete building block. The building block is prepared from the following ingredients in parts by weight: 5 to 15 parts of red mud, 15 to 60 parts of pulverized fuel ash, 2 to 8 parts of plaster, 10 to 35 parts of quicklime, 5 to 10 parts of concrete, 0.01 to 0.03 parts of aluminum powder and water. The red mud is used for replacing phosphorus slag and undergoes a series of reactions with raw materials such as the pulverized fuel ash, the plaster, the quicklime, the concrete and the aluminum powder to prepare the aerated concrete building block; the product weight is light; the strength is high; the stability is good; the heat conductivity coefficient is low; the performance is excellent; the problem that the red mud cannot be easily and synthetically utilized is solved; the stored red mud can be fast digested; the goal of saving national resources is achieved, a lot of soil is also restored; in addition, the production process is environment-friendly and has no pollution; a new path is opened up for the comprehensive utilization of the red mud.

Owner:贵州源隆新型环保墙体建材有限公司

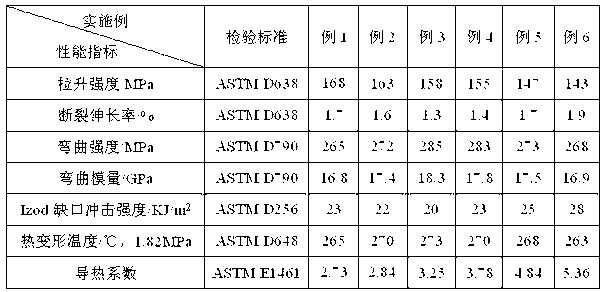

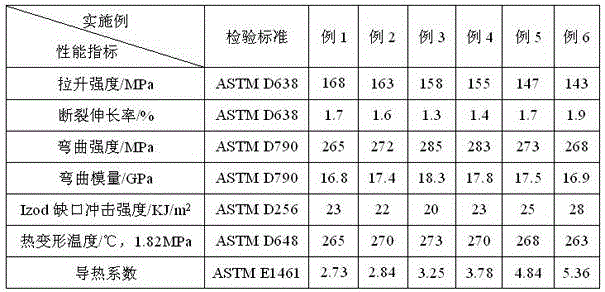

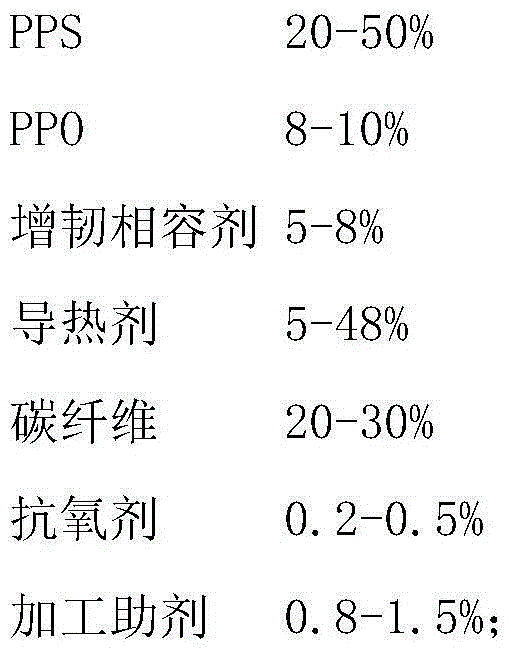

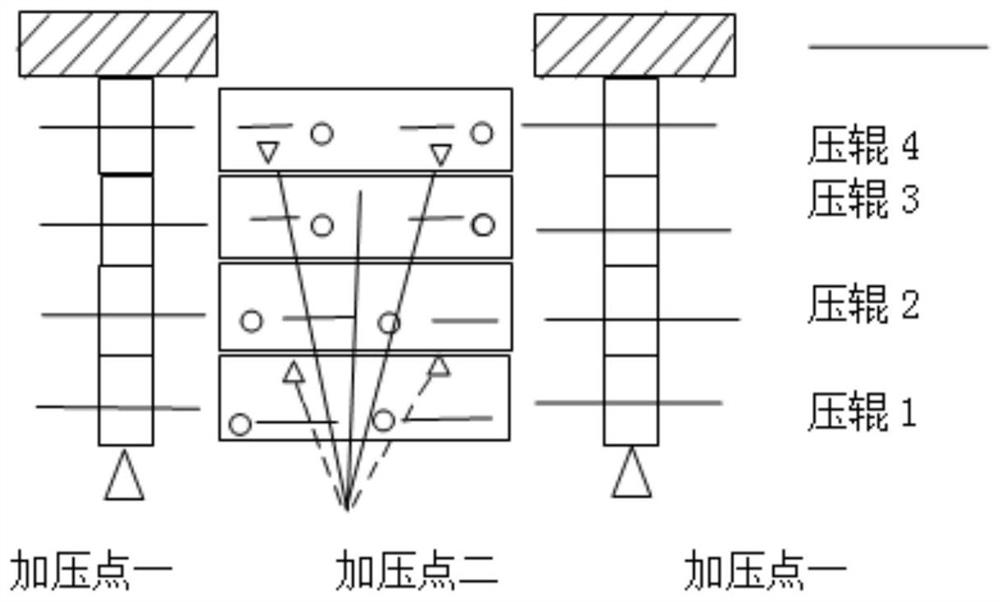

High temperature resistance high heat conduction PPS/PPO alloy and preparation method thereof

The present invention discloses a high temperature resistance high heat conduction PPS / PPO alloy and a preparation method thereof, and belongs to the technical field of polymer materials. The PPS / PPO alloy comprises the following raw materials, by weight, 20-50% of PPS, 8-10% of PPO, 5-8% of a toughening compatibilizing agent, 5-48% of a heat conduction agent, 20-30% of carbon fibers, 0.2-0.5% of an antioxidant, and 0.8-1.5% of a processing aid. The PPS / PPO alloy preparation method comprises: uniformly stirring the heat conduction agent, carrying out stirring mixing on the heat conduction agent and other raw materials (except the carbon fibers), adding the obtained mixture to a zone 1 of a twin-screw extruder (divided into 10 zones), adding the carbon fibers to a zone 10, and carrying out extrusion granulation, drying and injection molding to obtain the product. The high temperature resistance high heat conduction PPS / PPO alloy has characteristics of high heat conduction coefficient, high impact strength, good processing property and the like.

Owner:GUANGDONG WAYLAM ENG PLASTICS

High temperature and high pressure direct synthesis method of cubic boron nitride in titanium nitride plated coating

InactiveCN103272527AHigh hardnessImprove wear resistanceUltra-high pressure processesAlkaline earth metalHexagonal boron nitride

The invention relates to a high temperature and high pressure direct synthesis method of cubic boron nitride in a titanium nitride plated coating, relating to a high temperature and high pressure synthesis method of an ultra-hard material. The method takes hexagonal boron nitride as a raw material, an alkali metal nitride or alkaline-earth metal nitride or boron nitride as a catalyst, and metallic titanium powder or a metallic titanium compound as an additive. The method comprises the following steps of: mixing the hexagonal boron nitride and the alkali metal nitride or the alkaline-earth metal nitride or the boron nitride according to a weight proportion of 1:(0.1-0.3), adding the metallic titanium powder or the metallic titanium compound accounting for 0.5wt%-10wt% of the total mixture, and synthesizing a cubic boron nitride product with the titanium nitride plated coating at a high temperature and a high pressure, wherein the synthesis temperature is 1000 to 1800 DEG C, the synthesis pressure is 4.0-6.0 GPa, and the temperature and the pressure last for 3-15 minutes. The cubic boron nitride provided by the invention has the characteristics of high hardness, good abrasion resistance, good high temperature resistance, good tenacity, thermal conduction and electrical conduction, and is particularly suitable for preparation of polycrystalline cubic boron nitride products and tools.

Owner:柳州市大荣非金属材料有限公司

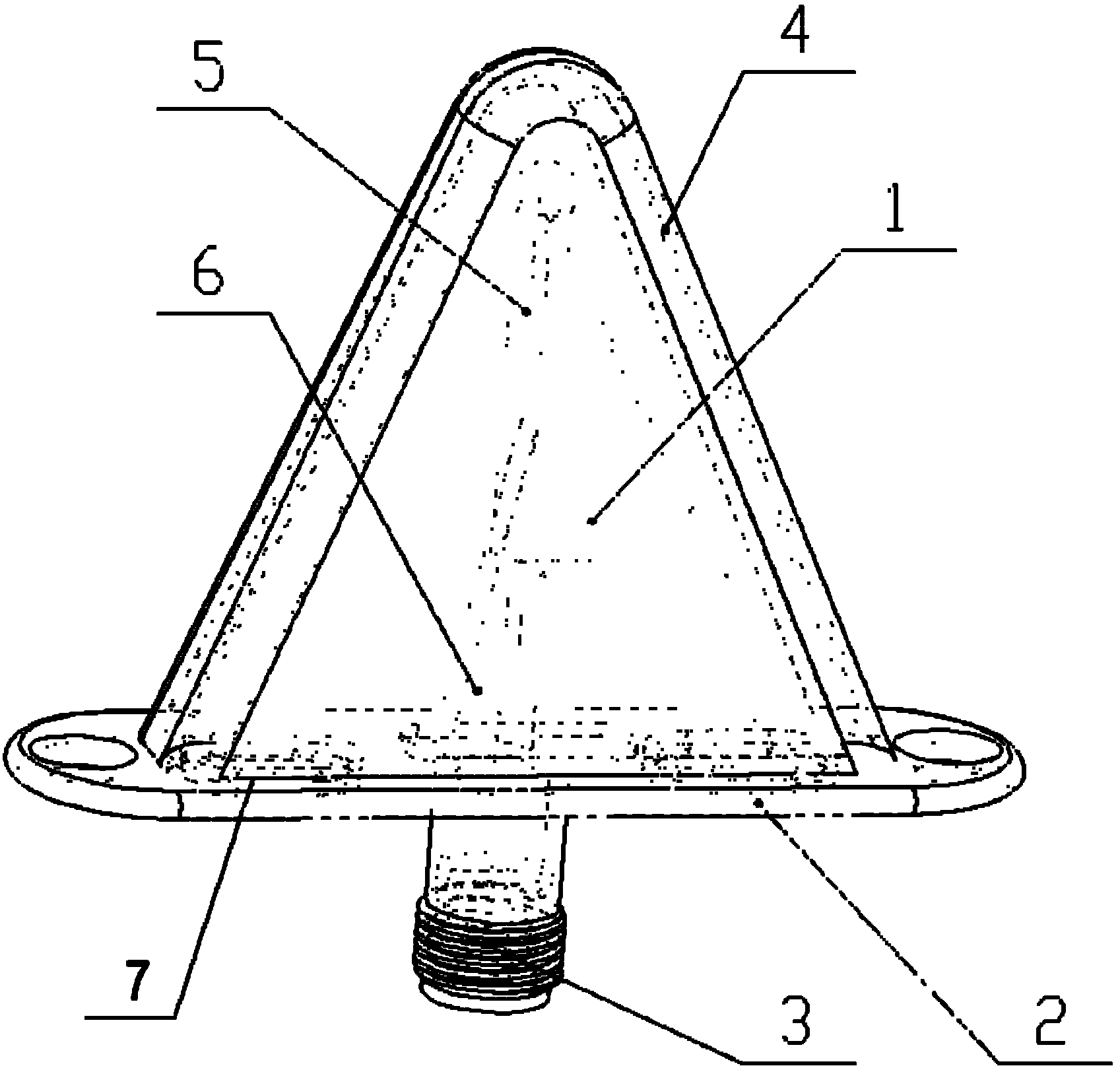

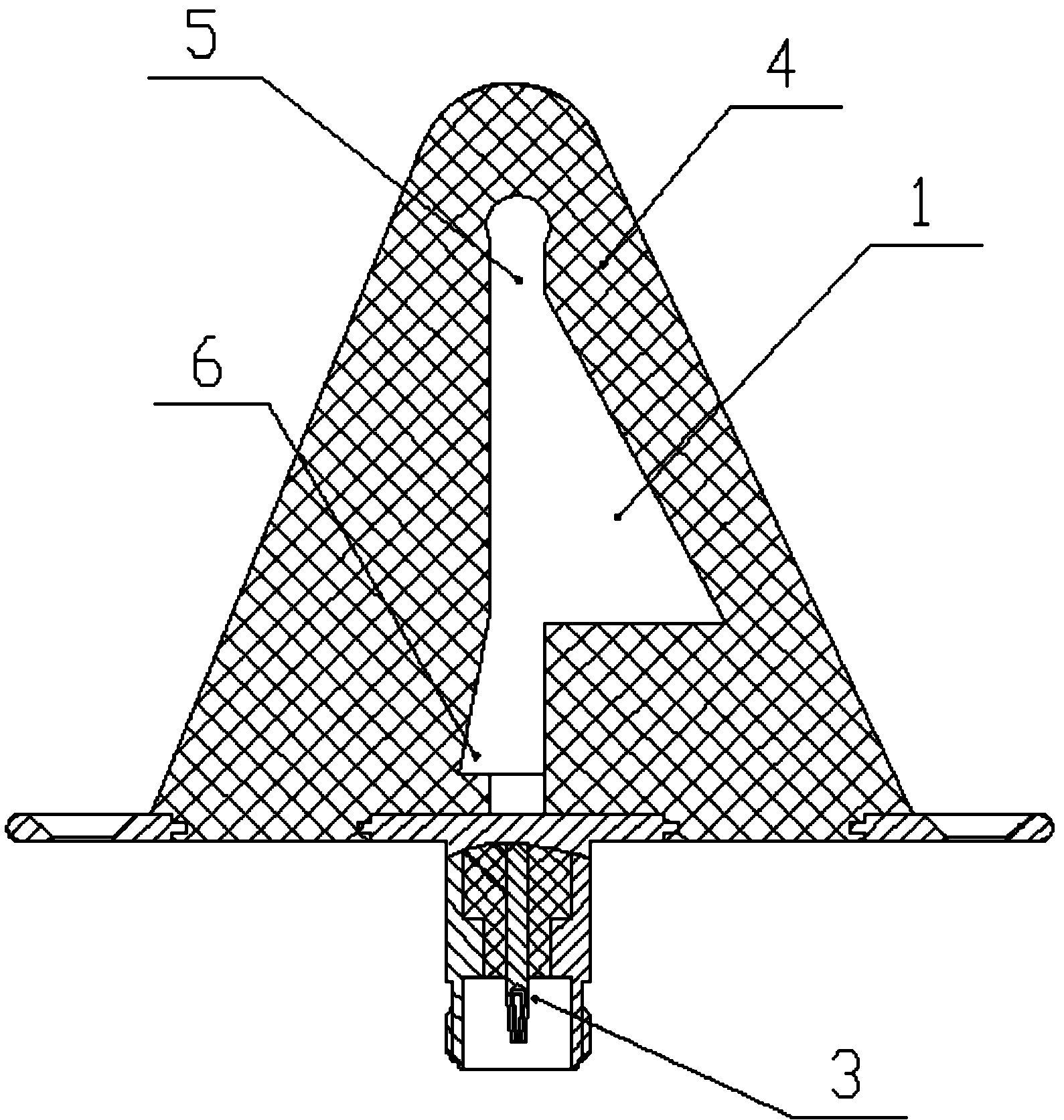

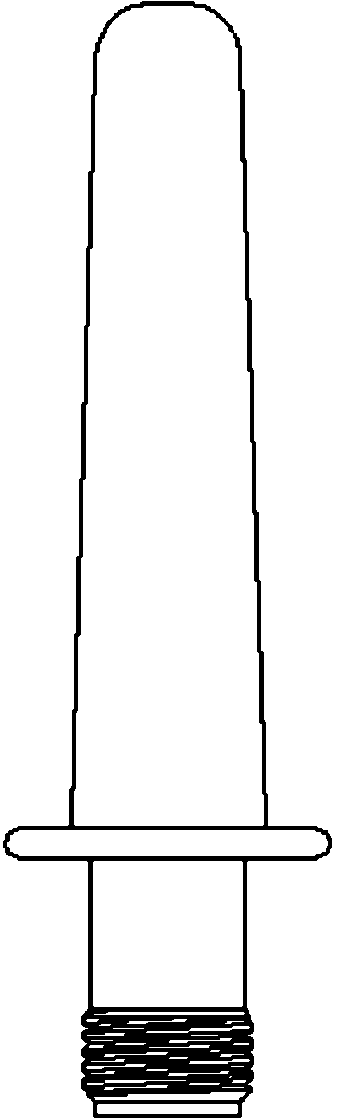

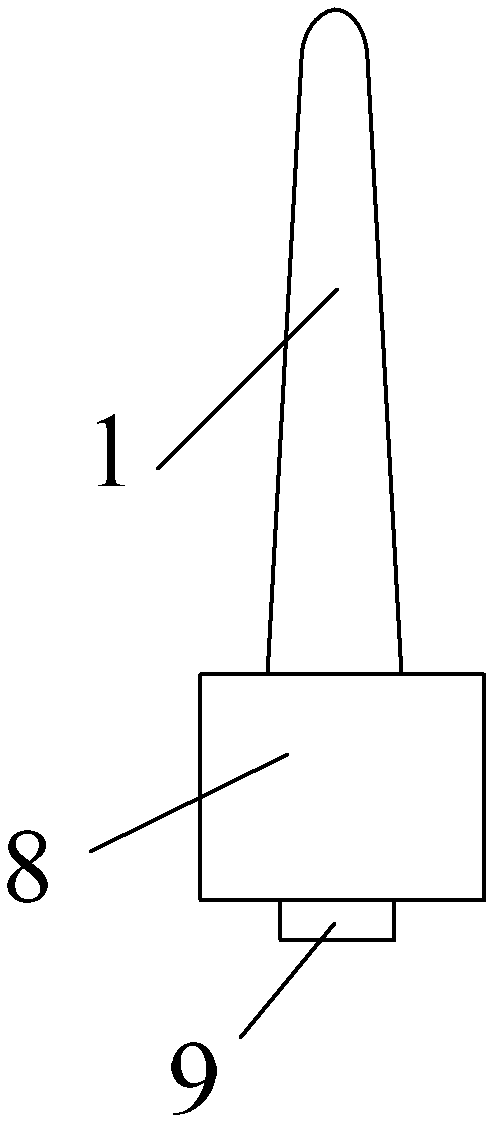

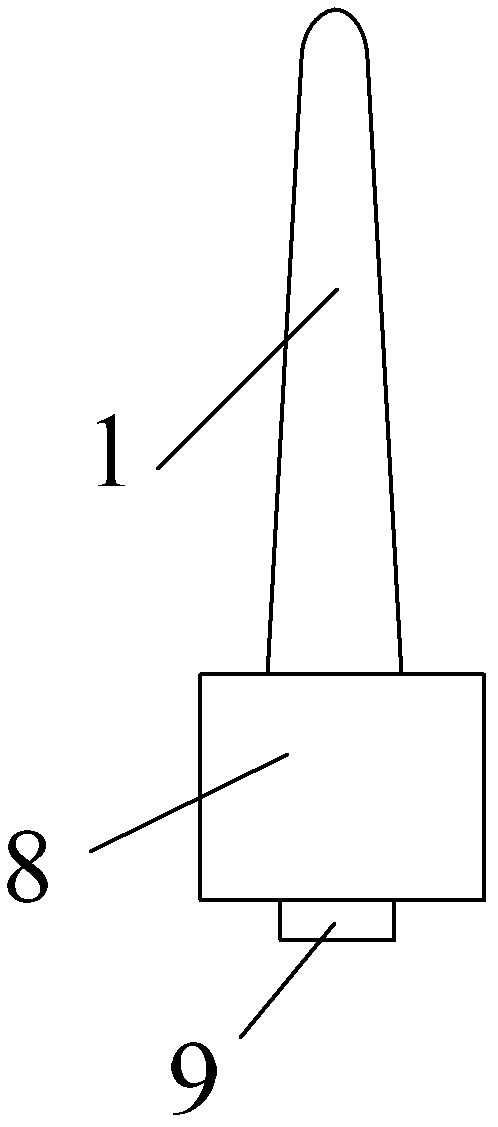

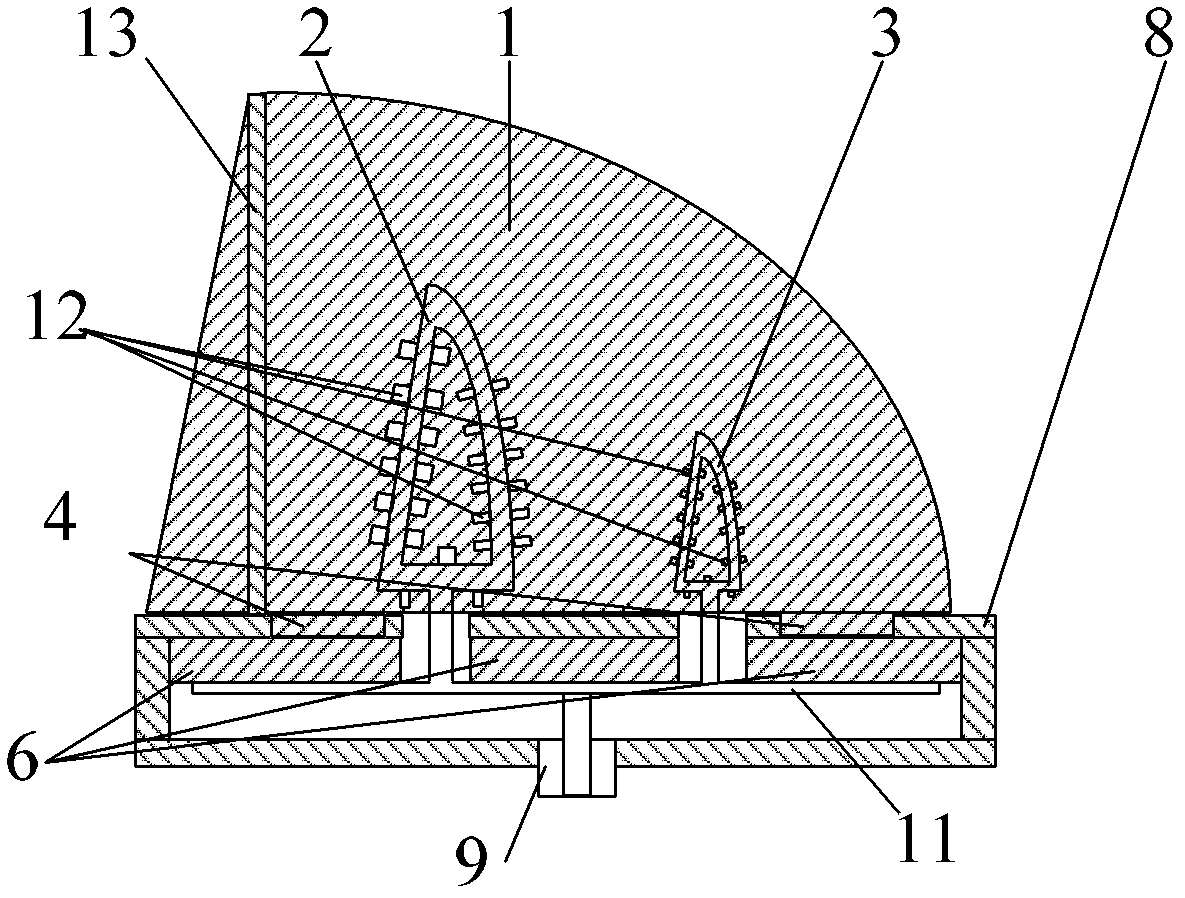

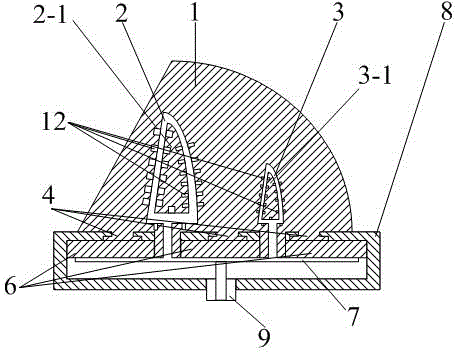

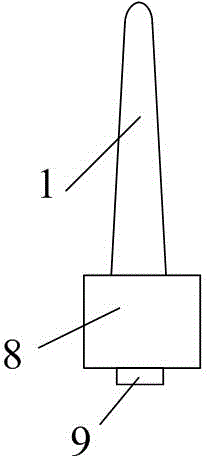

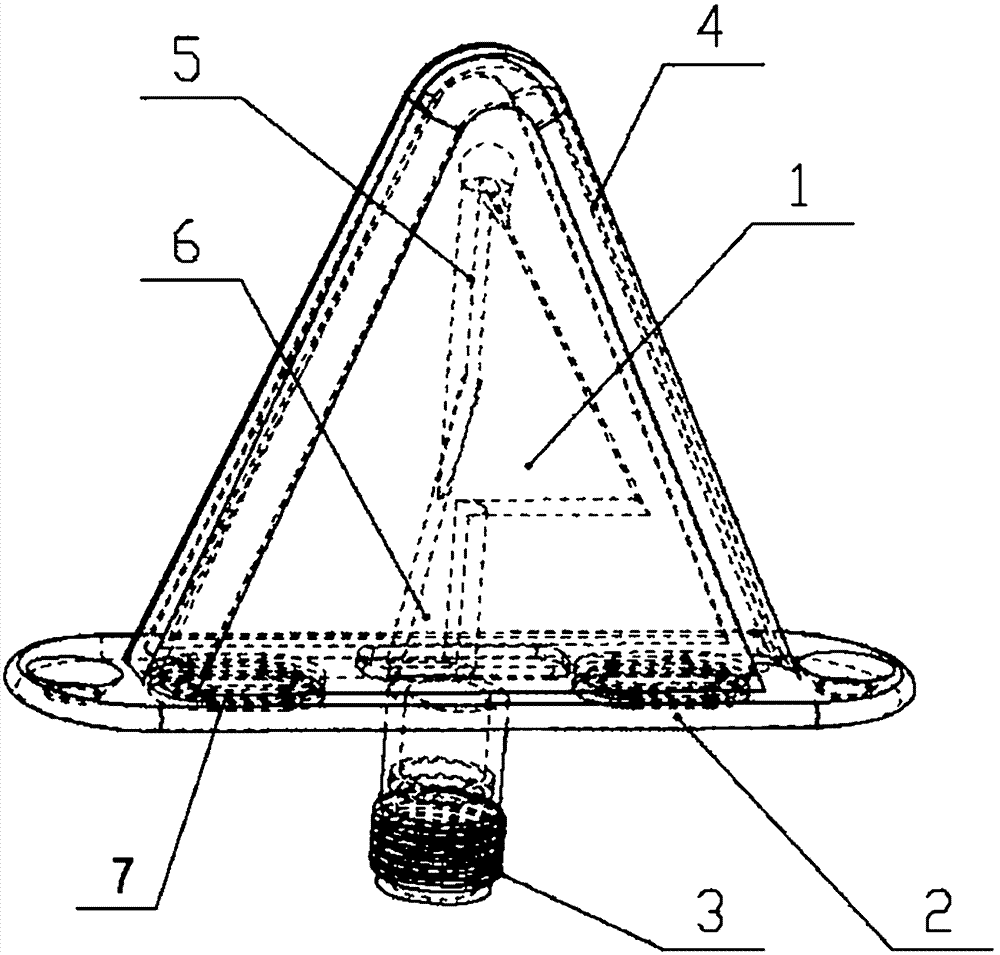

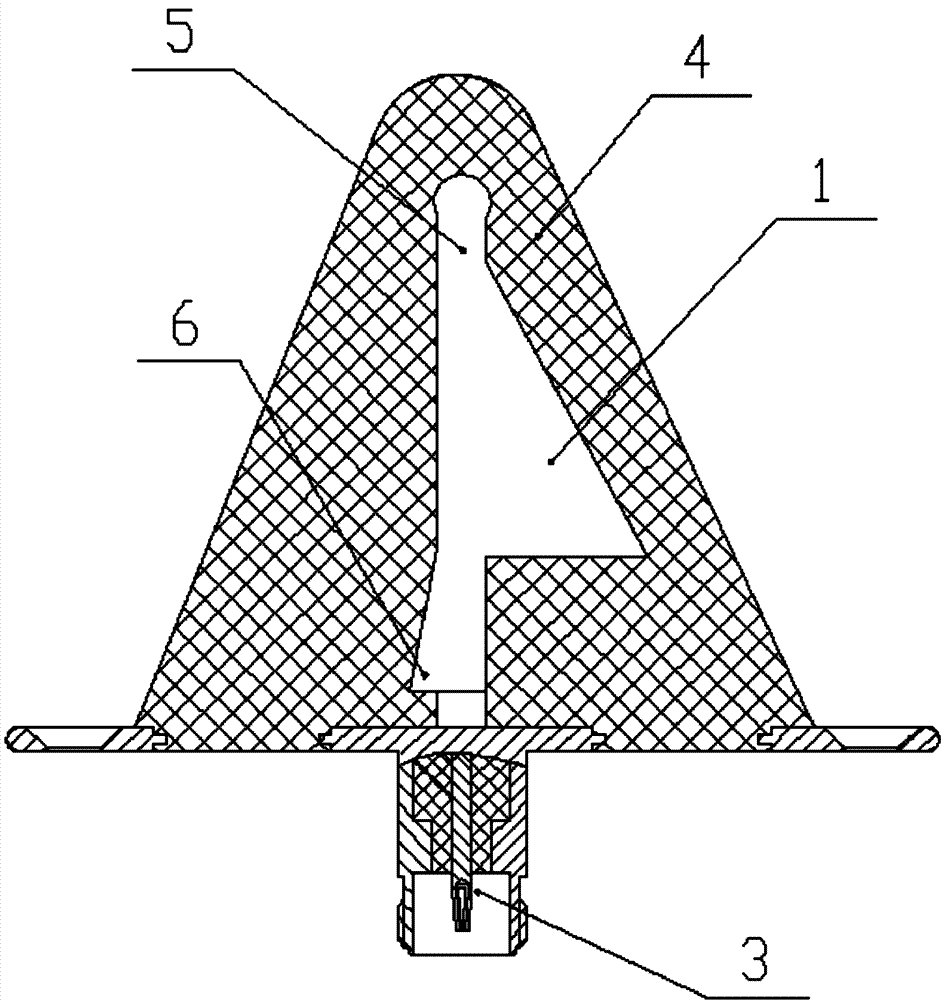

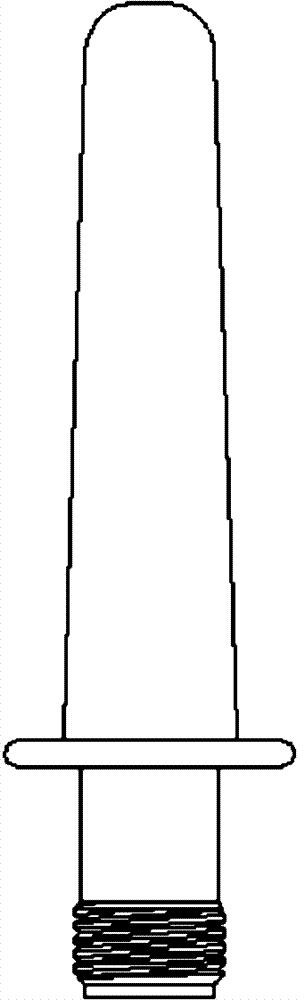

Strong-strength broadband antenna for flying carrier and preparation process thereof

InactiveCN102157781AHigh bandwidthHigh gainAntenna adaptation in movable bodiesRadiating elements structural formsDielectricStructure of the Earth

The invention discloses a strong-strength broadband antenna for a flying carrier, which comprises a metallic reflective ground with a central hole. A solid antenna housing is connected to the metallic reflective ground. A radiation oscillator is embedded in the solid antenna housing, and comprises a columnar monopole metallic oscillator on which at least one side wing is arranged. The columnar monopole metallic oscillator is extended from the interior of the solid antenna housing, and passes through the central hole on the metallic reflective ground until reaching the outside of the solid antenna housing. The part, exposed outside the solid antenna housing, of the columnar monopole metallic oscillator is connected with an N terminal. The preparation process of the strong-strength broadband antenna for the flying carrier comprises the following specific steps of: reserving a mould according to the solid antenna housing and the reflective ground structure of the antenna, arranging the reflective ground and radiation oscillator of the antenna in the mould, simultaneously injecting a fluidic solid antenna housing dielectric material into the mould through a small hole, performing cooling after the whole mould is filled with the material, and finally removing the mould to obtain the integrated antenna.

Owner:CETC YANGZHOU BAOJUN ELECTRONICS

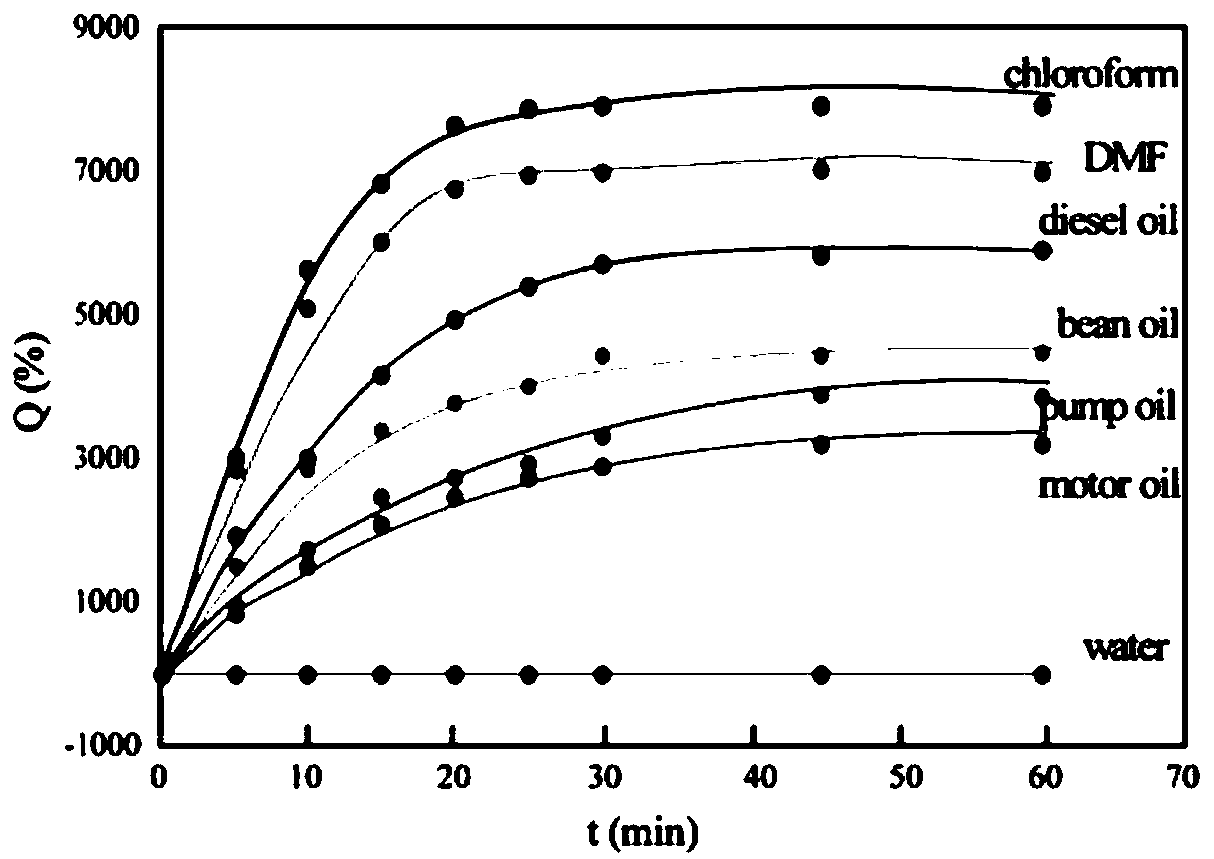

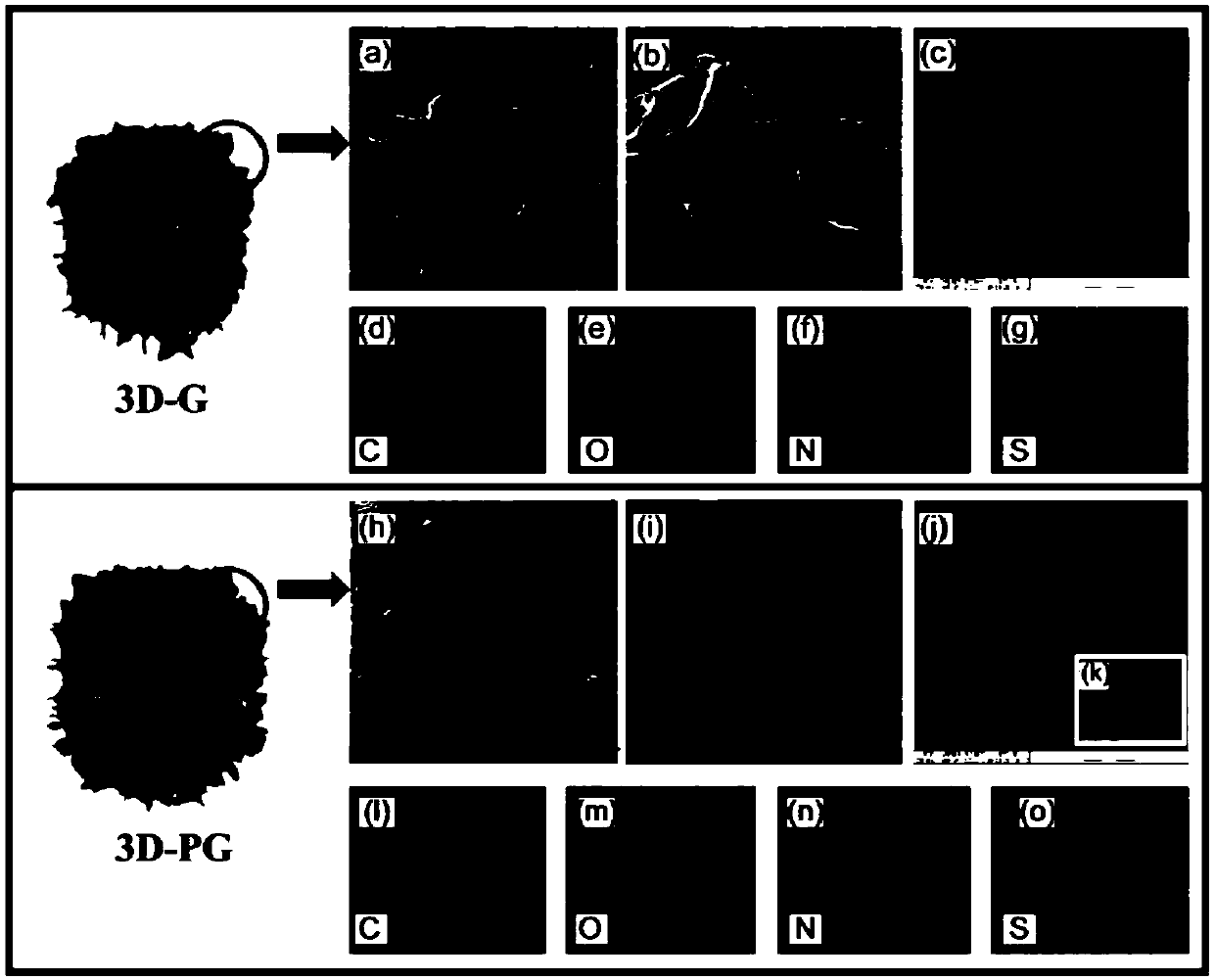

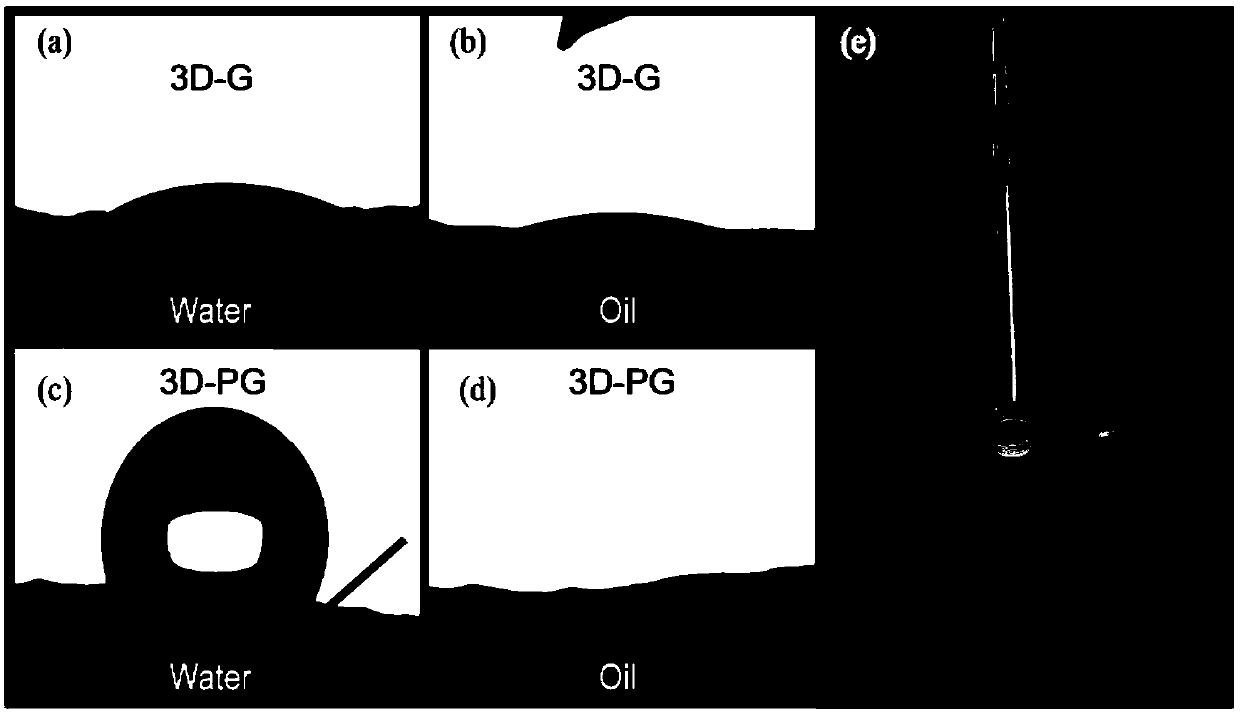

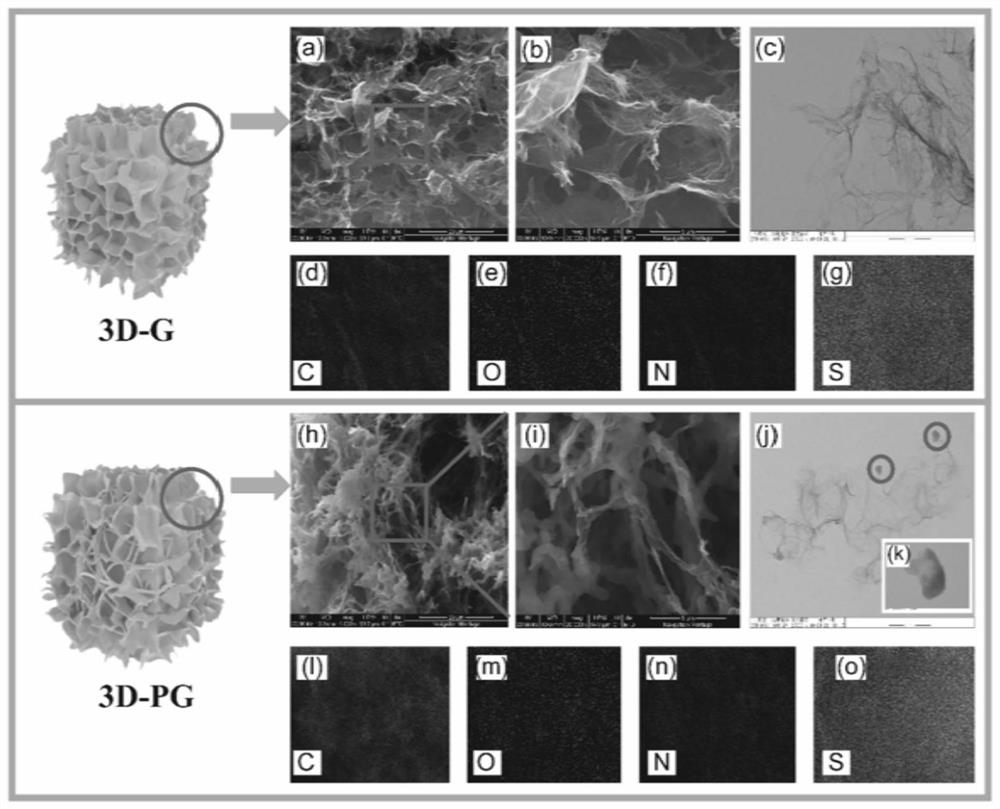

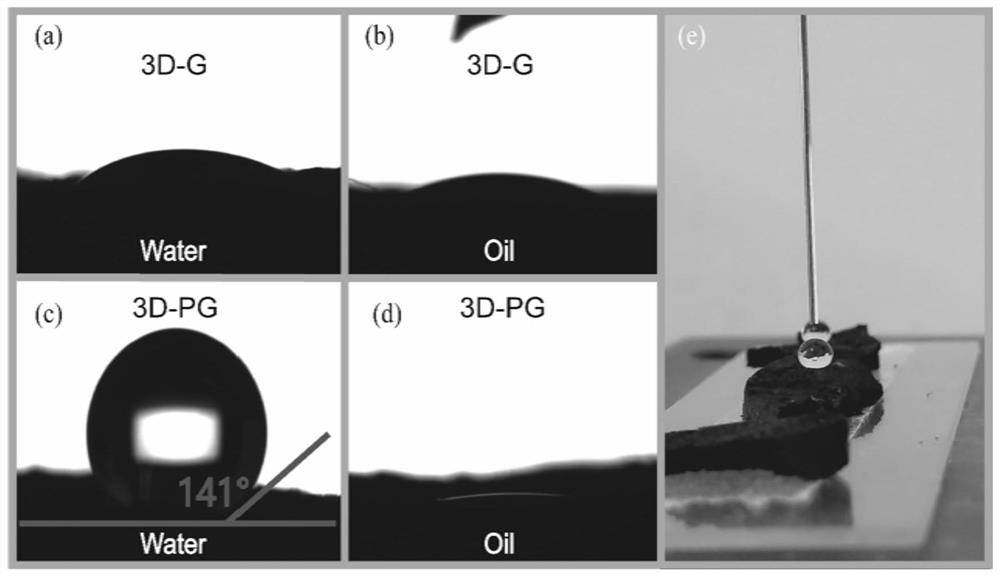

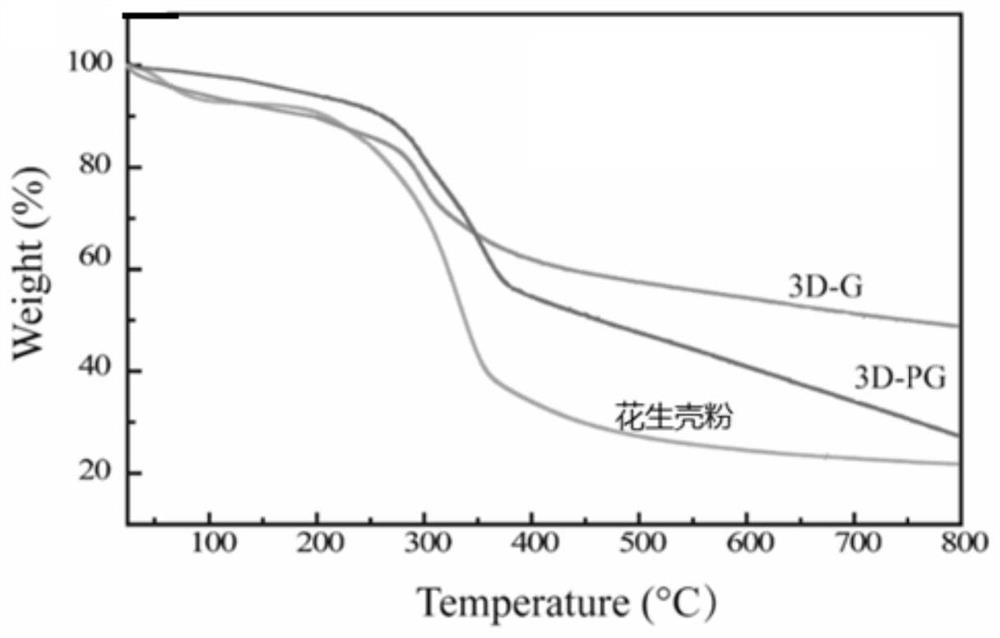

Peanut hull graphene compound aerogel oil absorption material and preparation method thereof

ActiveCN109513425ARaw materials are easy to getLow priceOther chemical processesAlkali metal oxides/hydroxidesThioureaHigh pressure

The invention relates to a peanut hull graphene compound aerogel oil absorption material and a preparation method thereof. The compound aerogel is prepared by using peanut hulls and graphene oxide asraw materials and thiourea as crosslinker, graphene slices are separated through gas generated by thiourea under high temperature and high pressure and form a three-dimensional porous structure with the peanut hulls. According to the preparation method, graphene oxide slices are separated by utilizing the gas generated by thiourea under high temperature and high pressure through a hydrothermal method; and the surface of the graphene slices are modified with functional groups, so that the graphene slices can be better combined with the peanut hull powder and form the three-dimensional porous network structure due to interaction. The three-dimensional porous network structure has large toughness and high strength, cannot be easily broken even being saturated and adsorbed, the graphene is further reamed by the peanut hulls, the specific surface area of a material is increased, and the oil absorption performance is greatly reinforced.

Owner:SHANDONG UNIV

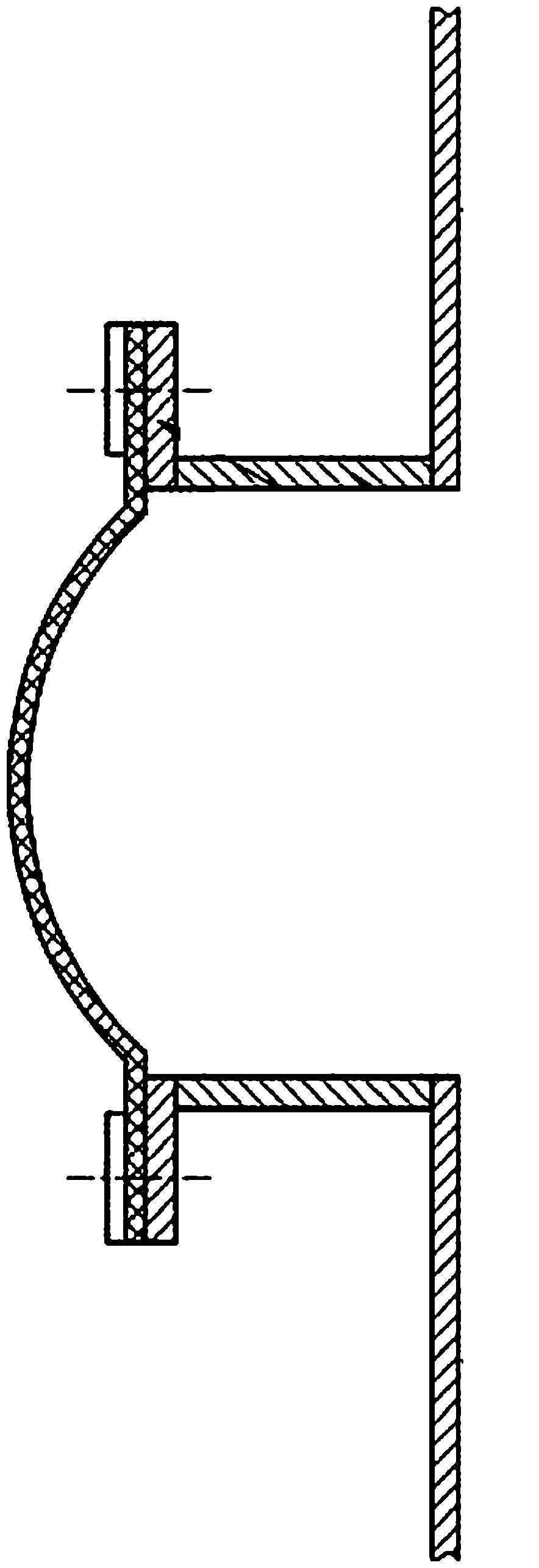

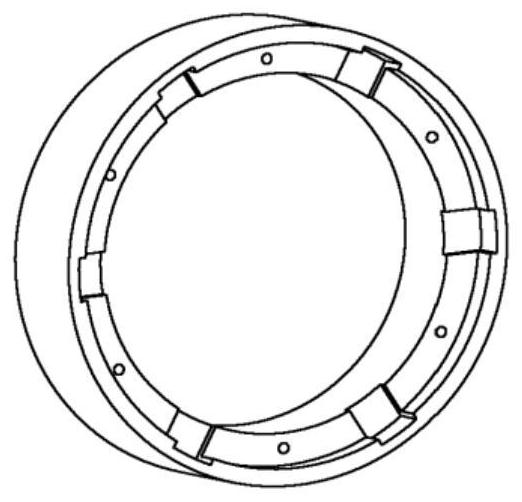

Chimney expansion joint

InactiveCN103075602AAvoid direct flushingAvoid scourPipeline expansion-compensationCorrosion preventionEngineeringExpansion joint

The invention discloses a chimney expansion joint. The technical scheme is that the chimney expansion joint comprises a steel inner cylinder, a flange rack part and a seal ring, wherein the seal ring is fixedly connected with the steel inner cylinder through the flange rack part; the flange rack part comprises an upper taper angle flange, a lower taper angle flange, an upper pressing flange, a lower pressing flange and a bolt component; inner rings of the upper taper angle flange and the lower taper angle flange are welded with the steel inner cylinder; mounting surfaces at the two ends of the seal ring are fixedly pressed between the upper taper angle flange and the lower taper angle flange through the upper pressing flange and the lower pressing flange; the mounting surfaces at the two ends of the seal ring are positioned between corresponding upper and lower taper angle flanges and upper and lower pressing flanges respectively; the upper and lower taper angle flanges and the upper and lower pressing flanges tilt upwards at an angle of 9-16 degrees; and anti-corrosion parts are arranged on corresponding welding parts of the upper and lower taper angle flanges and the inner side of the steel inner cylinder. By using the scheme, the manufacturing cost can be reduced, the construction period can be shortened, the maintenance is convenient, and the service life is prolonged.

Owner:山东龙泰电站技术有限公司

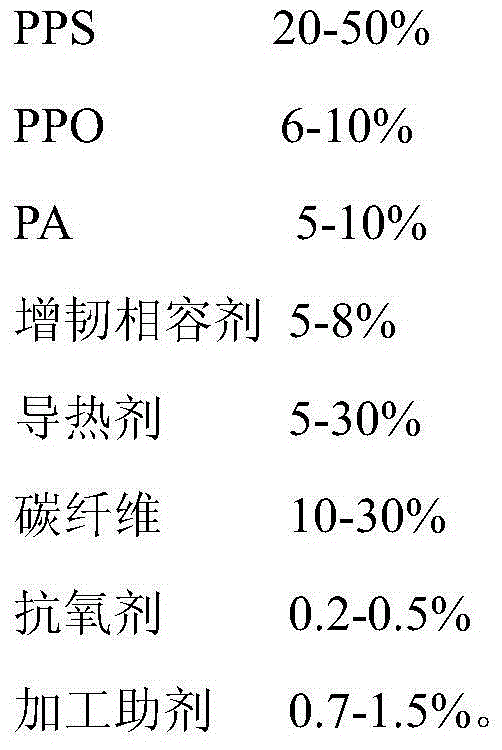

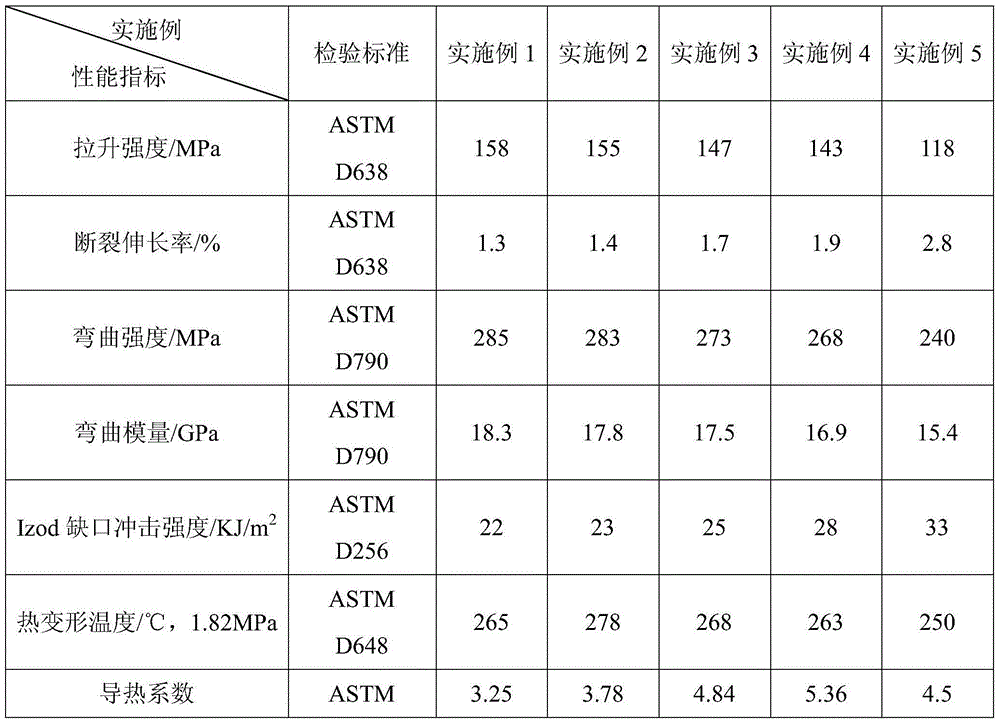

PPS (Poly-Phenylene Snlfide)/PPO (Poly-Phenylene Oxide)/PA (Poly-Amide) alloy with high temperature resistance and high heat conductivity and preparation method of PPS/PPO/PA alloy

The invention discloses a PPS (Poly-Phenylene Snlfide) / PPO (Poly-Phenylene Oxide) / PA (Poly-Amide) alloy with high temperature resistance and high heat conductivity and a preparation method of the PPS / PPO / PA alloy, which belongs to the technical field of high molecular materials. The PPS / PPO / PA alloy is prepared from PPS, PPO, PA, a toughening compatilizer, a heat conduction agent, carbon fibers, an antioxidant and processing additives. The preparation method of the PPS / PPO / PA alloy comprises the following steps: firstly coupling main components of the heat conduction agent, jointly stirring and mixing the main components of the heat conduction agent with other raw materials except the carbon fibers, adding the mixed materials into a zone 1 of total 10 zones of a twin-screw extruder, adding the granulated carbon fibers after being subjected to surface treatment into a zone 10, extruding, granulating, drying and carrying out injection molding to obtain the PPS / PPO / PA alloy. The PPS / PPO / PA alloy with high temperature resistance and high heat conductivity is high in heat conduction coefficient and has the characteristics of high strength, high impact, good processing property and the like.

Owner:广东道生科技股份有限公司

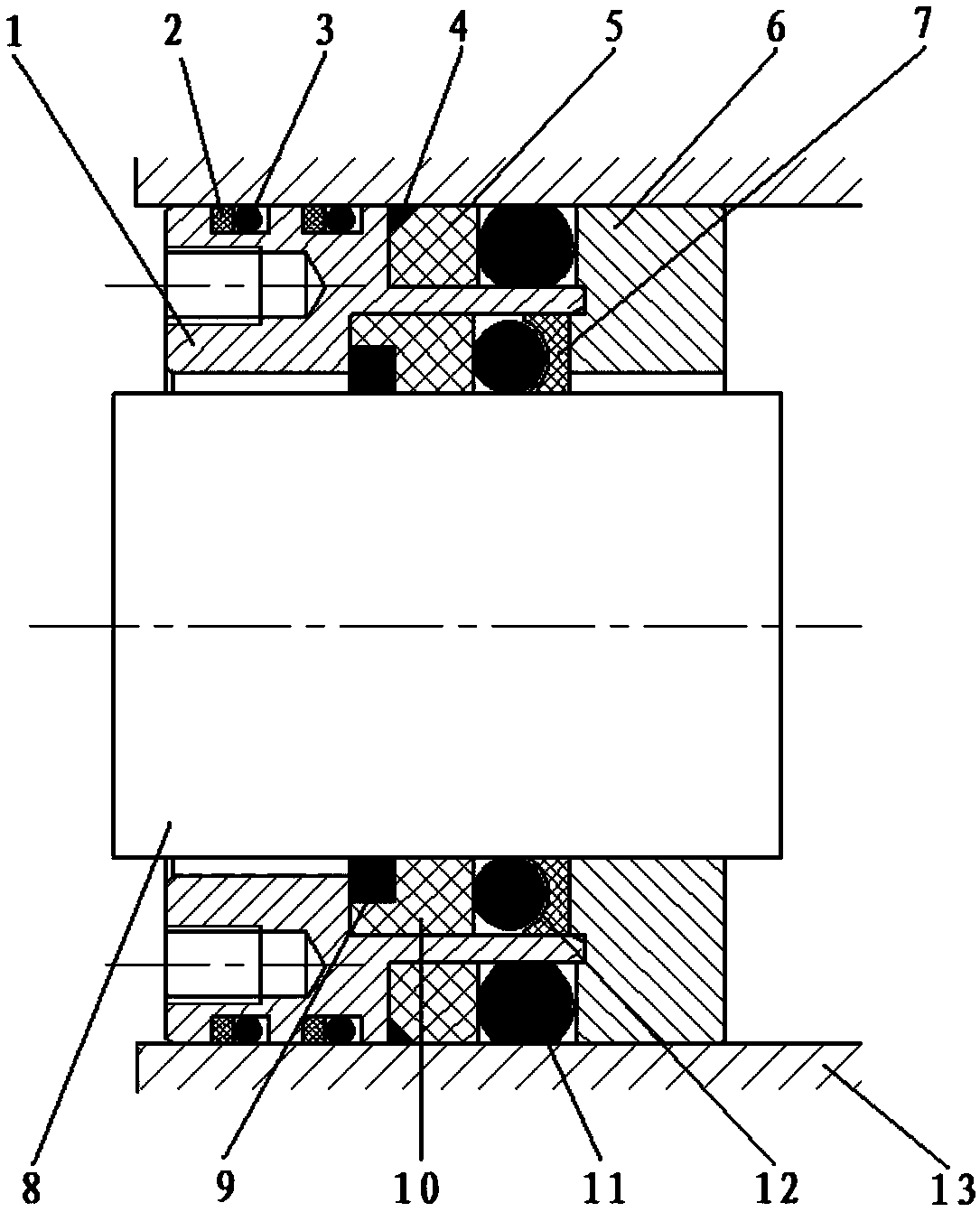

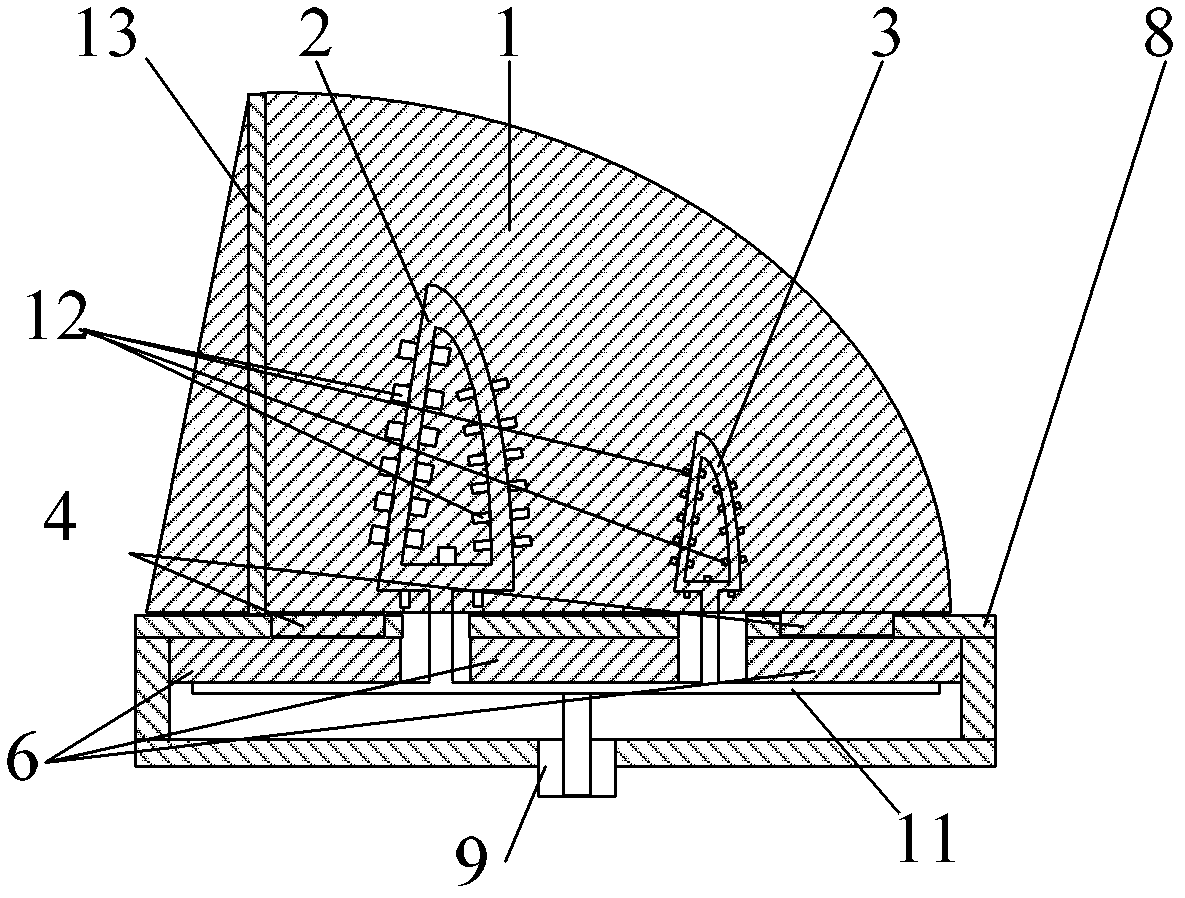

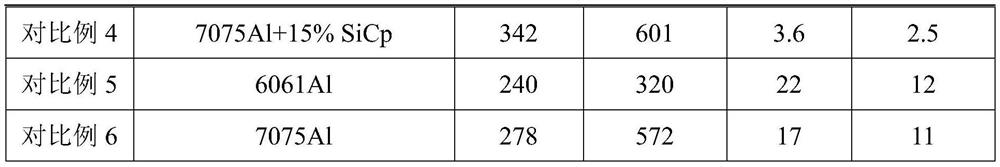

High temperature and high pressure kettle large gap compensation type sealing device

ActiveCN108050256AHigh fatigue requirementsHigh strengthEngine sealsRough surfaceUltra high pressure

The invention belongs to steel pipe ultra high temperature and high pressure testing technologies, and relates to a high temperature and high pressure kettle large gap compensation type sealing device. The sealing device includes a sealing groove-shaped piece, a baffle, an assistant O-shaped sealing combination, an outer side main sealing structure and an inner side sealing structure. The sealinggroove model piece plays a role of mounting and fixing a sealing ring. The baffle plays a role of limiting and pre-tightening. The assistant O-shaped sealing combination is composed of an outer side assistant PTFE baffle ring and a fluororubber O-shaped ring and plays a role of assistant sealing. The outer side main sealing structure includes an outer tapered aluminum anti-flowing ring, an outer side PTFE baffle ring and an outer side large line diameter O-shaped ring. The inner side sealing structure is composed of an one-sided U-shaped PTFE baffle ring and an inner side large line diameter O-shaped ring, wherein the one-sided U-shaped PTFE baffle ring and the inner side large line diameter O-shaped ring integrate with a compensation type sealing structure. The high temperature and high pressure kettle large gap compensation type sealing device is suitable for sealing environments such as ultra high temperature and high pressure, large gap, inching and rough surfaces, and solves the technical problem of simulation of oil casing pipe deep well environments in a testing field at home and abroad.

Owner:CHINA AIRPLANT STRENGTH RES INST

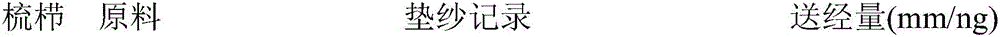

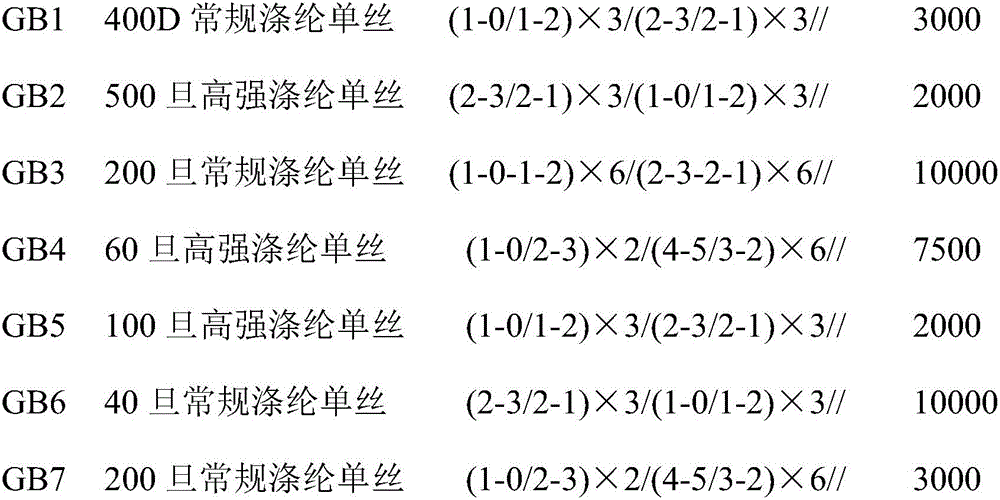

A warp knitting spacer fabric composite sole

The invention relates to a warp knitting spacer fabric composite sole. A production method of the sole is characterized by performing, with general polyester monofilaments and high-tenacity polyester monofilaments as raw materials, warp knitting by using a two-needle bar warp knitting machine based on a three-dimensional screen cloth warp knitting method to prepare elastic screen cloth through warping, warp knitting and after-finishing. Based on the method of three-dimensional warp knitting of warp knitting spacer fabric characterized by integral forming, a sole has excellent structural strength, elasticity and light weight; the warp knitting spacer fabric composite sole has excellent moisture conductivity and breathability performance of three-dimensional fabric; the polyester filaments with an antibacterial function and high tenacity are used as the screen cloth materials for the sole, so that the sole has the functions of bacteria resistance and bacteriostasis; a multi-step chain extension and tackifying process can be performed by using a tackifying chain extender with epoxy functional groups, so that the problems that conventional powdery tackifying is low in efficiency and micro-molecules are hard to remove in a tackifying process are solved. The prepared warp knitting spacer fabric composite sole has a broad application prospect in the field of shoe materials.

Owner:FUJIAN JINJIANG HUAYU WEAVING

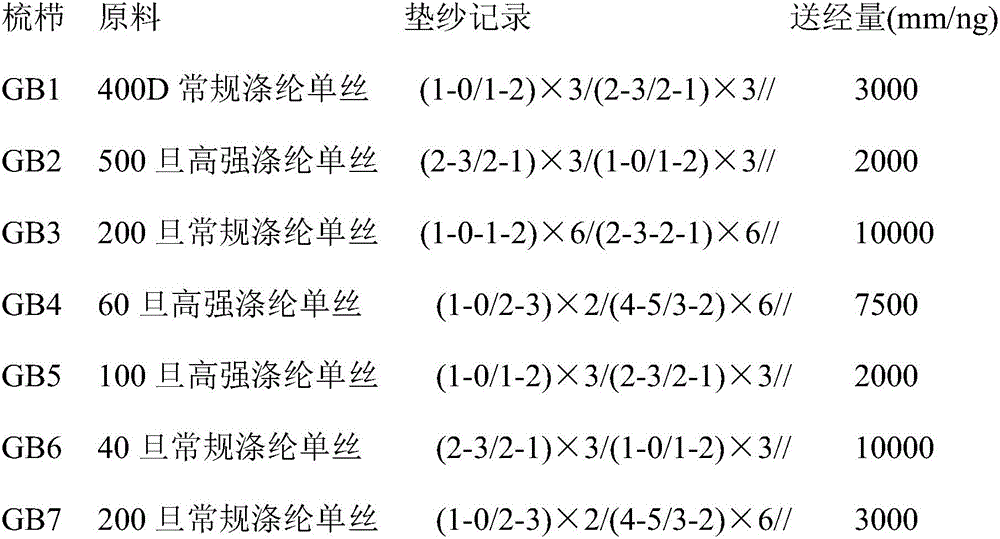

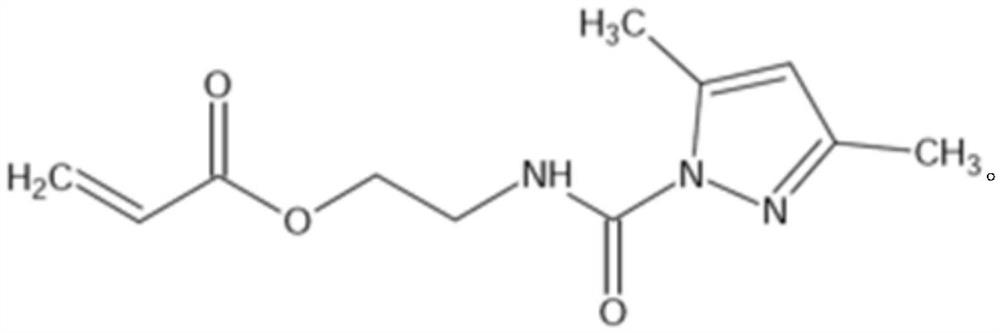

Photo-thermal dual-curable adhesive and preparation method thereof

ActiveCN113493654AFully curedWith light curingOrganic non-macromolecular adhesivePolymer scienceAdhesive

The invention relates to a photo-thermal dual-curable adhesive. The adhesive of the invention is prepared from the following raw materials in percentage by weight: 15-40% of modified resin with an acrylate group and an isocyanate group on one molecule, 10-30% of four-functionality special epoxy resin, 10-30% of an acrylate monomer, 3-10% of an acrylate monomer of blocked isocyanate, 1-5% of a free radical photoinitiator, 5-17% of special thiol and 3-10% of a latent amine curing agent. The photo-thermal dual-curable adhesive prepared by the invention has better storage stability, high bonding strength, better high-temperature and high-humidity resistance and wide application range.

Owner:YANTAI DARBOND TECH

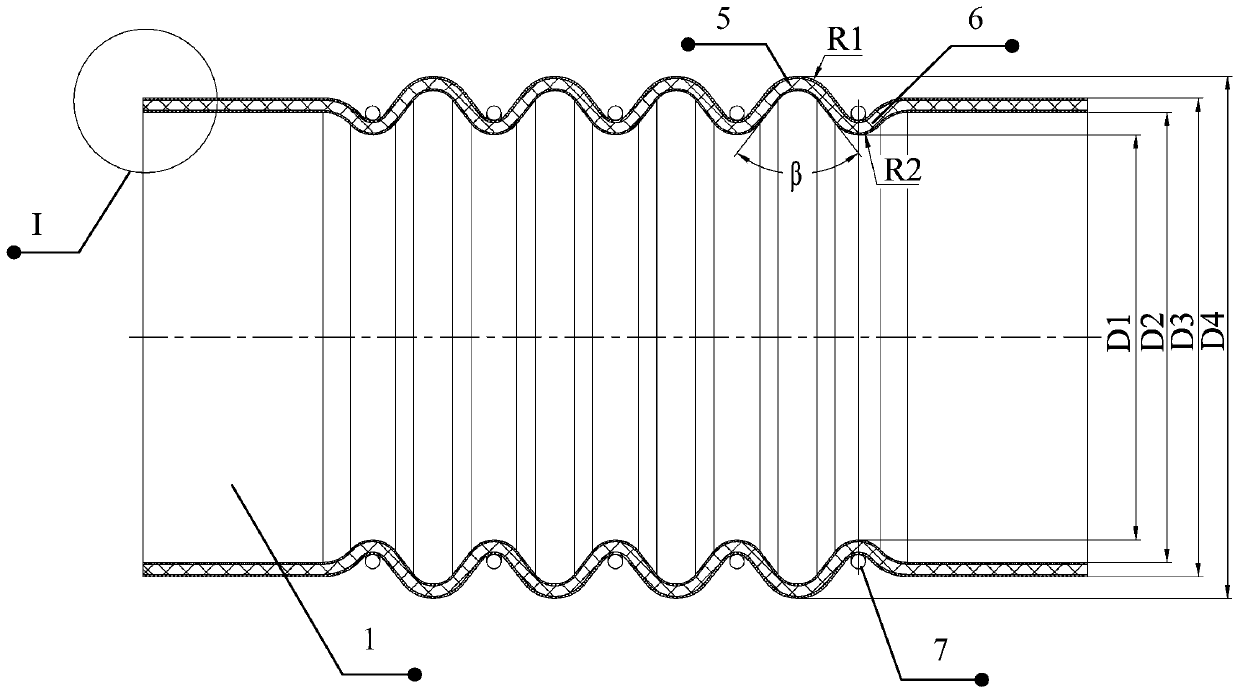

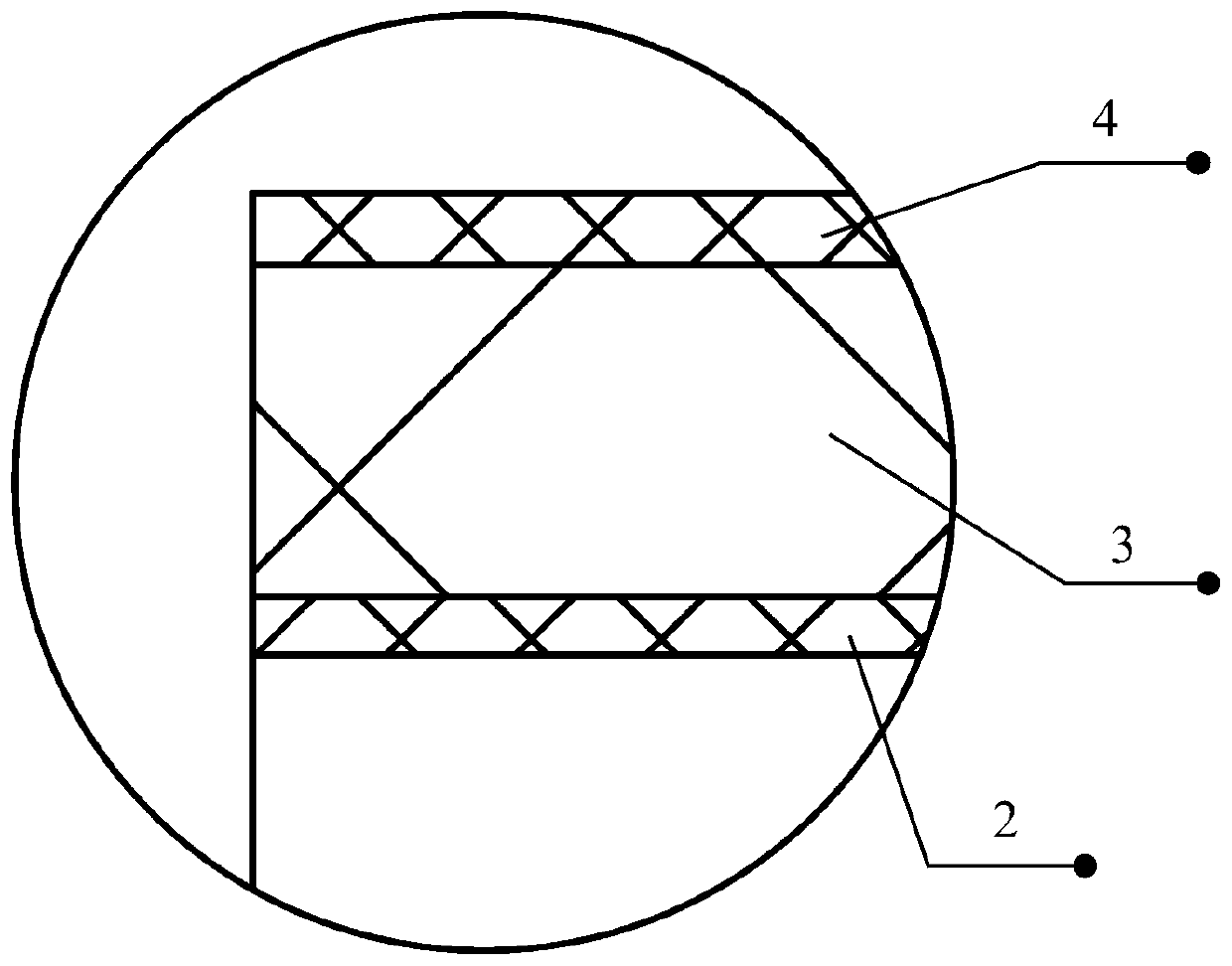

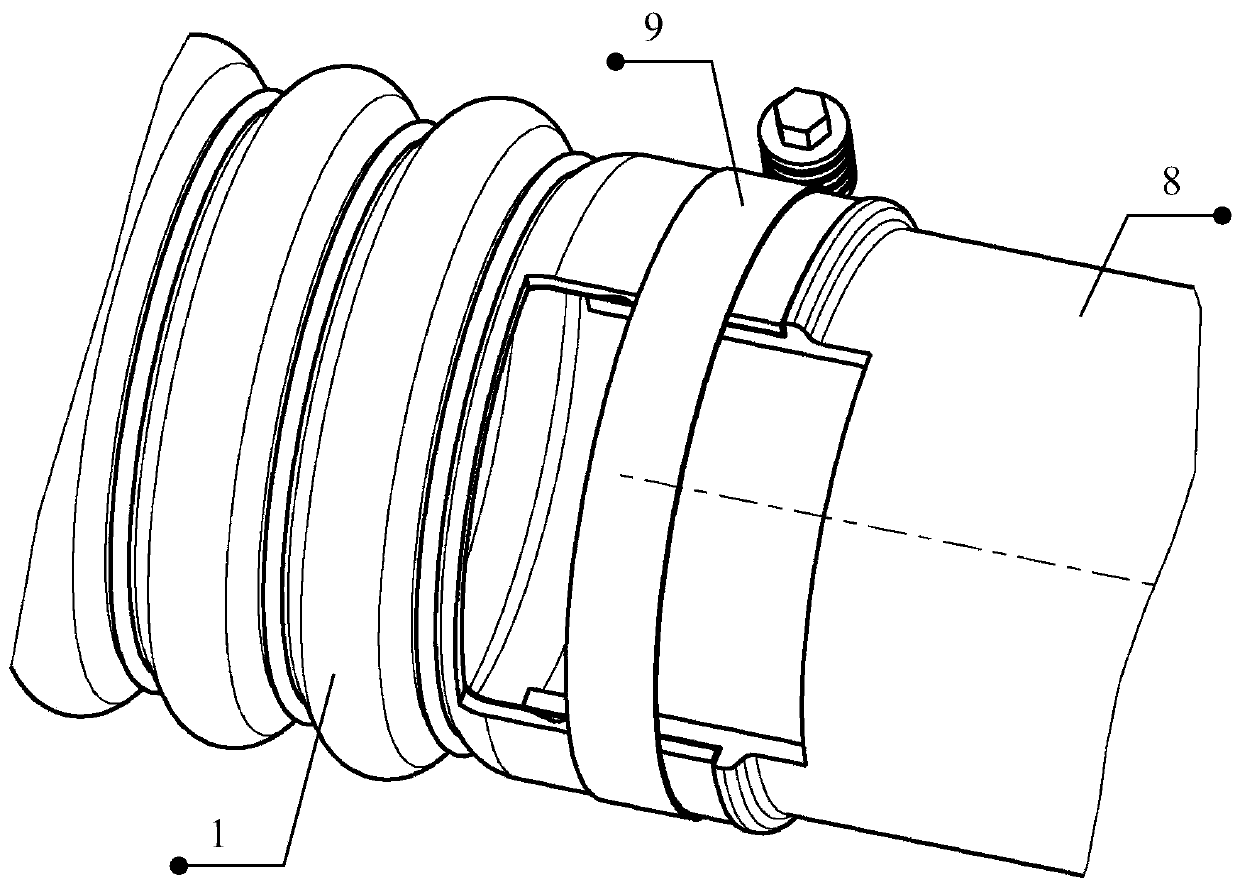

Thin-walled high-temperature-resistant high-pressure-resistant intercooler corrugated pipe

InactiveCN110608320AReduce weightHigh temperature resistance hasSleeve/socket jointsInternal combustion piston enginesIntercoolerEngineering

The invention belongs to the technical field of cooling systems for commercial vehicles and particularly relates to a thin-walled high-temperature-resistant high-pressure-resistant intercooler corrugated pipe. The corrugated pipe is of a three-layer structure, and the three layers include the rubber pipe inner rubber layer, the rubber pipe reinforcement layer and the rubber pipe outer rubber layer; the rubber pipe inner rubber layer is made from fluorinated silicone, the rubber pipe reinforcement layer is a high-temperature-resistant four-layer aramid cloth, and the rubber pipe outer rubber layer is made from silicone; the two ends of the corrugated pipe are straight line segments, and the middle of the corrugated pipe is a corrugated segment; the corrugated segment is provided with a wavepeak structure and a wave trough structure; the included angle beta between the two sides of the wave peak is 75-105 degrees, the corner radius R1 of the outer surface of the wave peak is 8-11 millimeters, the corner radius R2 of the inner surface of the wave trough is 5-7 millimeters, the diameter D4 of the tangent circle of the outer surface of the wave peak is equal to the outer diameter D3 ofthe straight line segments and 9-11 millimeters, and the diameter D1 of the tangent circle of the inner surface of the wave peak is equal to the inner diameter D2 of the straight line segments minus8-12 millimeters. The corrugated pipe is low in weight, and the burst pressure at the normal temperature is larger than 2 MPa; the corrugated pipe has the advantages of being resistant to high temperature, high in strength and modulus, stable in size, low in shrinking percentage, resistant to heat and chemical corrosion, good in flexibility and dielectricity and the like.

Owner:FAW JIEFANG AUTOMOTIVE CO

Polyether-ether-ketone/polyether sulfone composite fiber and preparation method thereof

ActiveCN108004617APoor transparencyOptimal Blend ModificationArtificial thread manufacturing machinesFilament/thread formingFiberPolymer science

The invention relates to a polyether-ether-ketone / polyether sulfone composite fiber and a preparation method thereof, and belongs to the technical field of special organic fibers. The composite fiberis mainly prepared from, by mass, 1-99 parts of polyether-ether-ketone and 1-99 parts of polyether sulfone. The polyether-ether-ketone and the polyether sulfone are put into a ball mill mixing machinefor stirring and mixing, and then extruded, cut off and granulated by a screw extruder after drying; the mixed granules are drie, fed into a high-temperature spinning machine for melting and plasticizing, then conveyed by a metering pump into a filter system and a component system, and extruded by a multihole spinneret plate to form polyether-ether-ketone / polyether sulfone fiber melt slivers; filaments obtained after stretching and setting are introduced by a negative-pressure filament suction gun into a winding system and then wound into a filament cylinder, and the finished product is obtained. According to the polyether-ether-ketone / polyether sulfone composite fiber and the preparation method thereof, the technology is simple, the production efficiency is high, the fiber prepared by using the method is good in performance, and various indexes can meet subsequent weaving requirements. The polyether-ether-ketone is blended with the polyether sulfone, the cost of the blend fiber is effectively reduced, and great support is provided for market-oriented popularization of polyaryletherketone fibers.

Owner:CHANGZHOU CHUANGYING NEW MATERIAL TECH

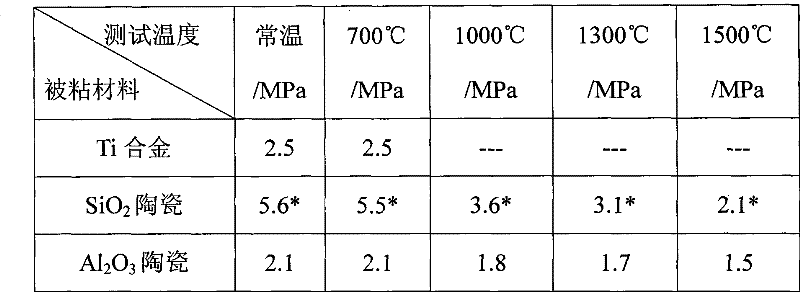

Phosphates adhesive and preparation method thereof

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

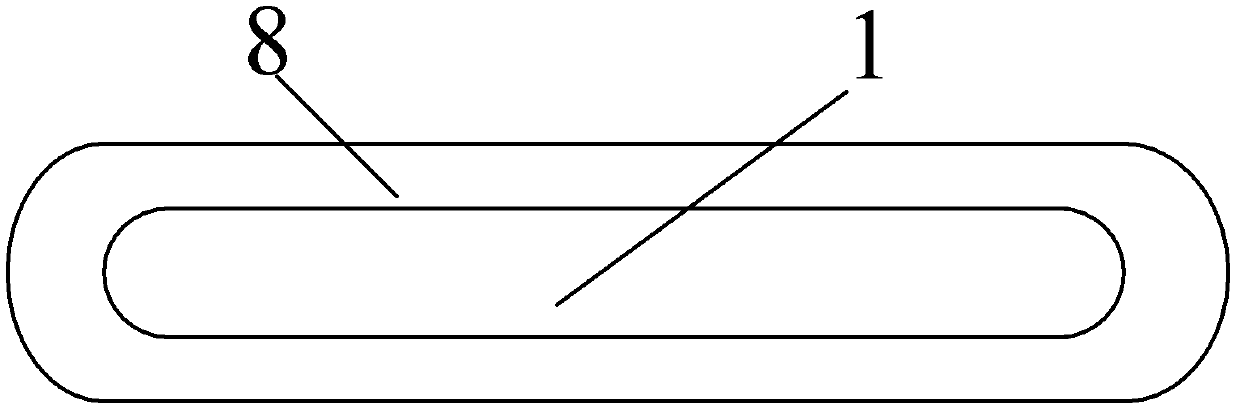

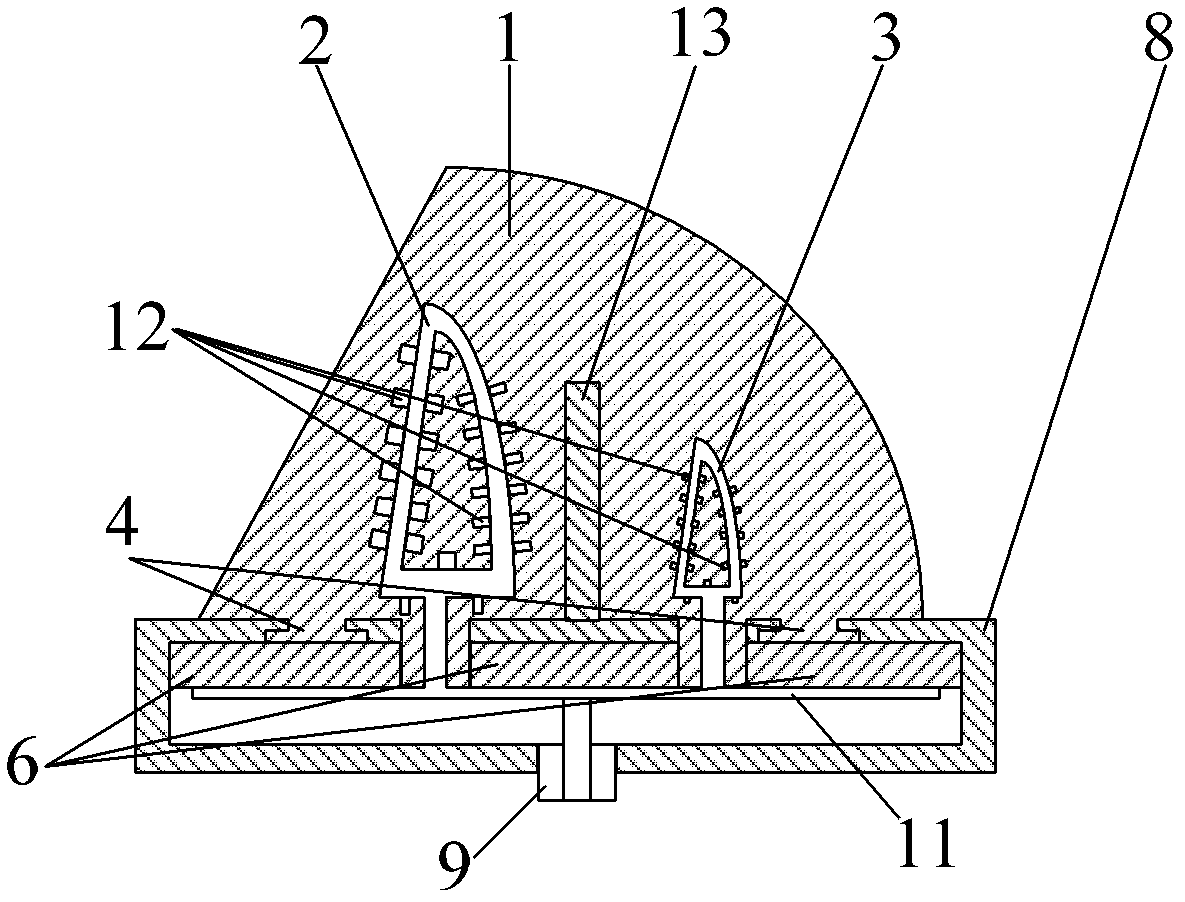

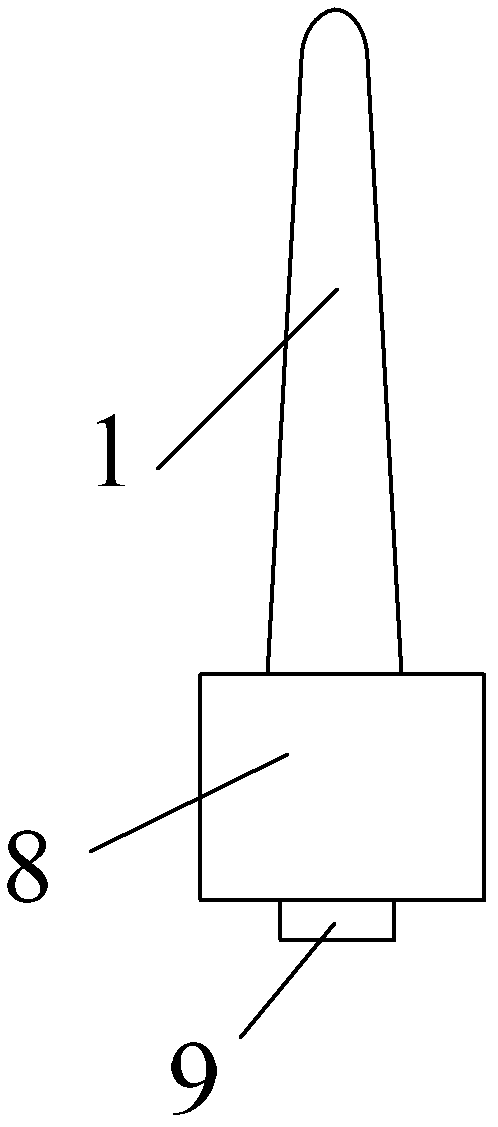

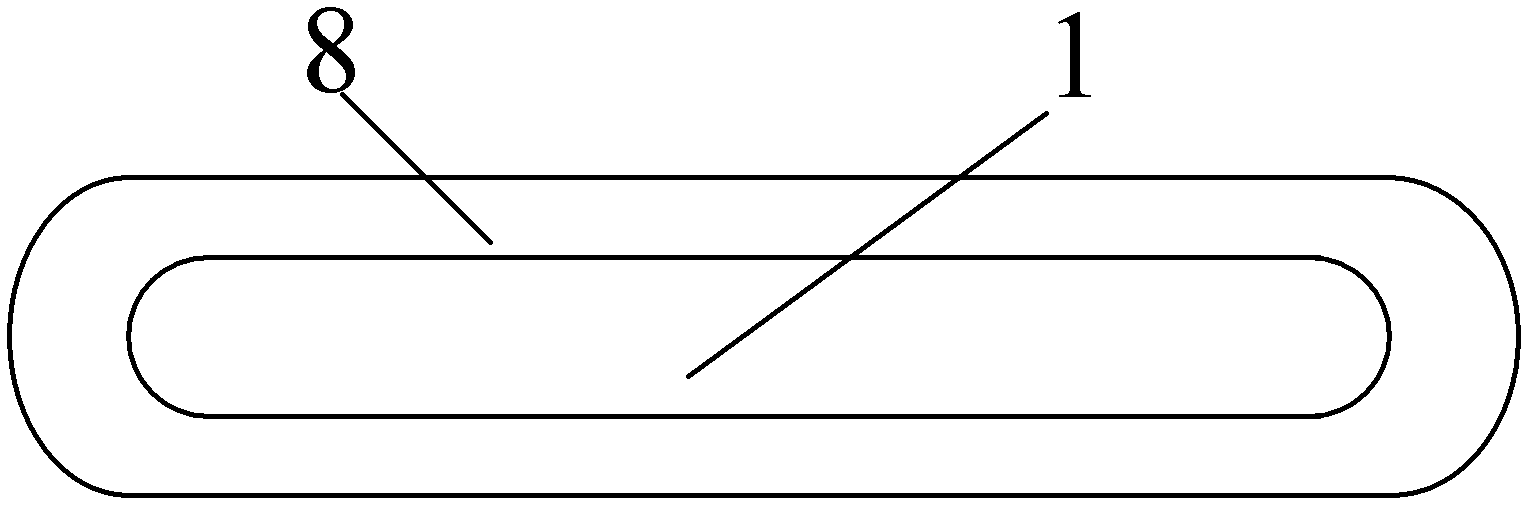

Lightning-protection reflection type high-strength dual-waveband directional antenna

InactiveCN102637947AHigh bandwidthImprove structural strengthSimultaneous aerial operationsRadiating elements structural formsMetal stripsCoaxial cable

The invention relates to a lightning-protection reflection type high-strength dual-waveband directional antenna. The lightning-protection reflection type high-strength dual-waveband directional antenna comprises a metallic reflection cavity, wherein microstrip plates are arranged in the metallic reflection cavity; a multiplexer is arranged on the microstrip plates; a coaxial cable is connected onto a main circuit of the multiplexer; a first radiation oscillator and a second radiation oscillator are respectively connected onto a first branch and a second branch of the multiplexer; a solid antenna housing covers on the first radiation oscillator and the second radiation oscillator; the solid antenna housing is provided with a lightning-protection reflection oscillator; the lightning-protection reflection oscillator is located at the same side of the first radiation oscillator and the second radiation oscillator; the first radiation oscillator and the second radiation oscillator adopt hollow sail-shaped unipolar metal oscillators; the hollow sail-shaped unipolar metal oscillators consist of first metallic straight strips, second metallic straight strips and arc-shaped metallic strips; the first metallic straight strips, the second metallic straight strips and the arc-shaped metallic strips are connected with one another in an end-to-end manner; angles formed by the first metallic straight strips, the second metallic straight strips and the arc-shaped metallic strips are acute angles; and metal blocks are arranged or directly welded on the hollow sail-shaped unipolar metal oscillators so as to form an inner-and-outer embattlement type structure.

Owner:SOUTHEAST UNIV +2

Superfine polyester carpet yarn

The invention relates to superfine polyester carpet yarn belonging to the technical field of carpet yarn. The invention is characterized that the superfine polyester carpet yarn is formed by doubling and twisting 346dtex polyester low-elastic yarn or 2267dte polyester low-elastic yarn, adopts a first technical scheme by once doubling three pieces of 346dtex polyester low-elastic yarn into one, twisting S, twice doubling two pieces of twisted yarn into one and twisting Z, and a second technical scheme by doubling three pieces of 2267dte polyester low-elastic yarn into one, twisting S, twice doubling two pieces of twisted yarn into one and twisting Z. The invention needs to dye at high temperature and pressure, but has less production procedures, easy operation, high spinning yield rate and low production cost, much stronger strength than carpet yarn produced by other short fibers and good resilience; and a textured carpet has soft foot feeling and good crease resistance and is easy to clean.

Owner:浙江义乌金汇化纤有限公司

Guiding high-strength dual-waveband directional antenna

ActiveCN102646863AHigh bandwidthImprove structural strengthSimultaneous aerial operationsAntenna adaptation in movable bodiesMetal stripsCoaxial cable

A guiding high-strength dual-waveband directional antenna comprises a metal reflection cavity. A micro-strip plate is arranged in the metal reflection cavity, a multiplexer is arranged on the micro-strip plate, a coaxial cable is connected to a main path of the multiplexer, a first radiation oscillator and a second radiation oscillator are connected to a first branch and a second branch of the multiplexer respectively and covered by a solid antenna cover, and the first radiation oscillator and the second radiation oscillator are hollow sail-shaped monopole metal oscillators. Each hollow sail-shaped monopole metal oscillator comprises a first metal straight strip, a second metal straight strip and an arc metal strip, which are in end-to-end connection and form three acute angles, metal blocks are arranged on or directly welded to the hollow sail-shaped monopole metal oscillators to form inner and outer battlement structures.

Owner:CETC YANGZHOU BAOJUN ELECTRONICS +2

High temperature resistance high heat conduction PPS/PPO alloy and preparation method thereof

The present invention discloses a high temperature resistance high heat conduction PPS / PPO alloy and a preparation method thereof, and belongs to the technical field of polymer materials. The PPS / PPO alloy comprises the following raw materials, by weight, 20-50% of PPS, 8-10% of PPO, 5-8% of a toughening compatibilizing agent, 5-48% of a heat conduction agent, 20-30% of carbon fibers, 0.2-0.5% of an antioxidant, and 0.8-1.5% of a processing aid. The PPS / PPO alloy preparation method comprises: uniformly stirring the heat conduction agent, carrying out stirring mixing on the heat conduction agent and other raw materials (except the carbon fibers), adding the obtained mixture to a zone 1 of a twin-screw extruder (divided into 10 zones), adding the carbon fibers to a zone 10, and carrying out extrusion granulation, drying and injection molding to obtain the product. The high temperature resistance high heat conduction PPS / PPO alloy has characteristics of high heat conduction coefficient, high impact strength, good processing property and the like.

Owner:GUANGDONG WAYLAM ENG PLASTICS

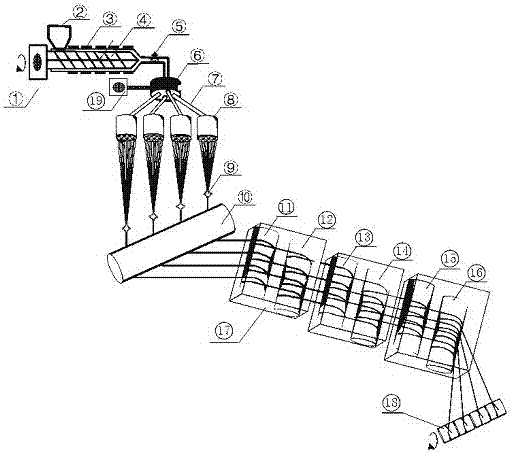

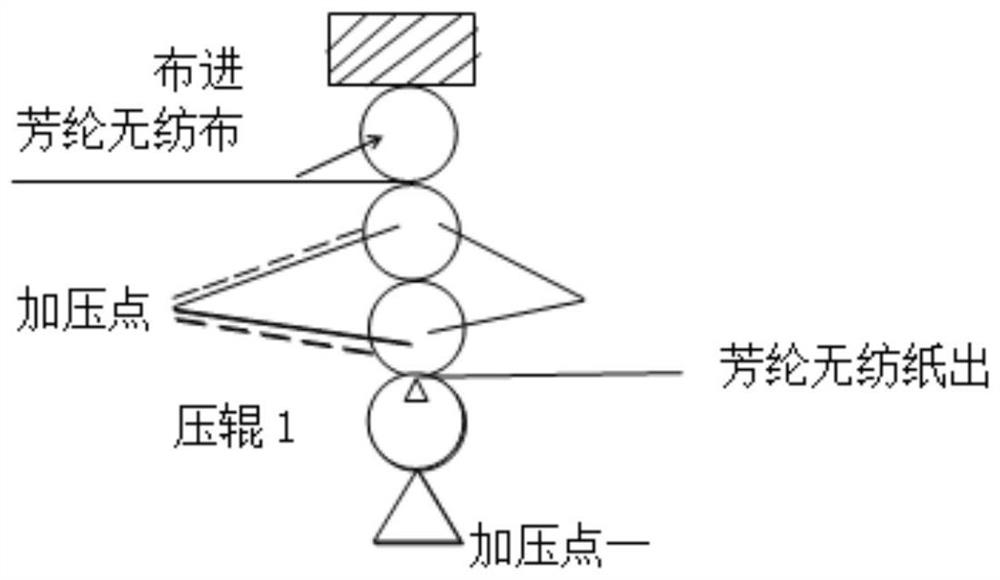

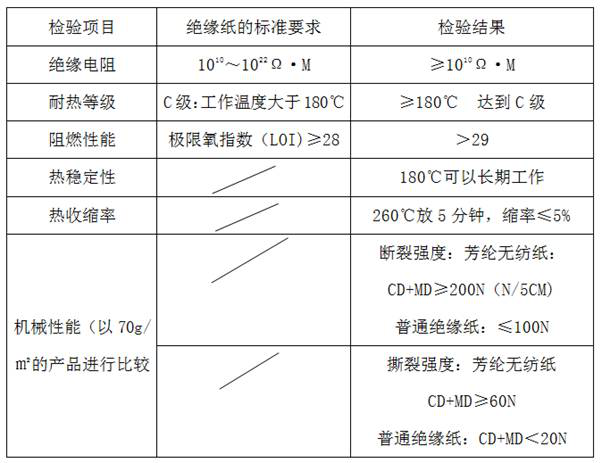

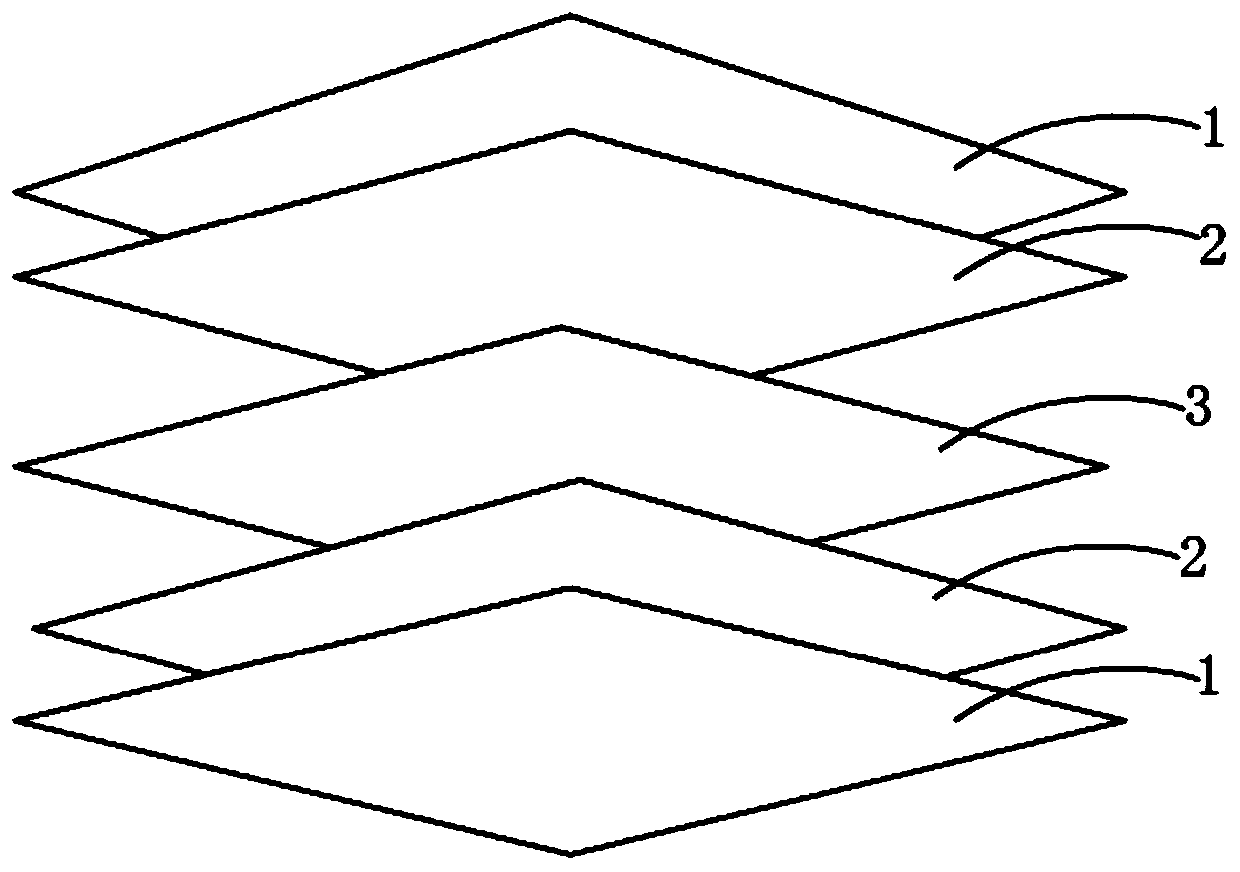

Aramid fiber non-woven paper production process

PendingCN113914012AHigh strengthHigh temperature high strengthHeating/cooling textile fabricsNon-woven fabricsPolymer scienceNew energy

The invention discloses an aramid fiber non-woven paper production process. The production process comprises the following steps of firstly preparing aramid fiber non-woven fabric from aramid fibers through a spunlace entanglement process, and then carrying out high-temperature pressurization processing to form the aramid fiber non-woven paper. The aramid fiber non-woven paper is prepared from the aramid fibers at high temperature and high pressure, and the aramid fibers have excellent performances of ultrahigh strength, high temperature resistance, insulation, aging resistance, long service life and the like, so that the aramid fiber non-woven paper prepared from the aramid fibers has the characteristics of high temperature resistance grade, high strength and long service life; and the use requirements of novel voltage transformation and new energy automobile driving motors can be met.

Owner:SHAOXING HENGRUI NONWOVEN TECH

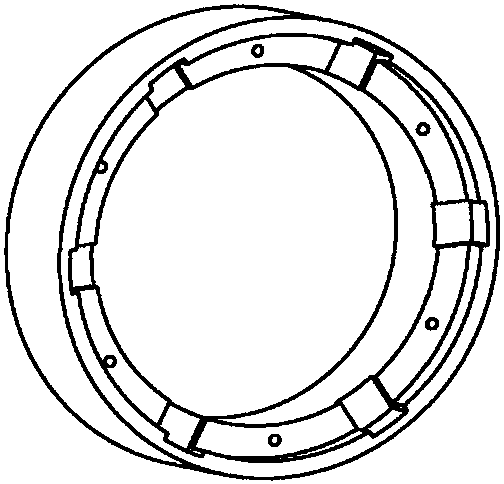

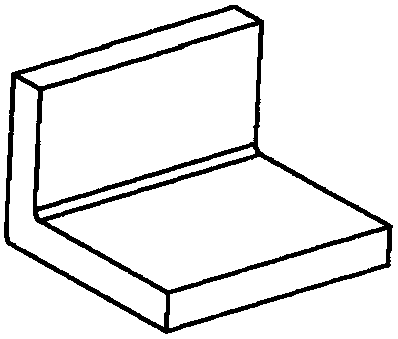

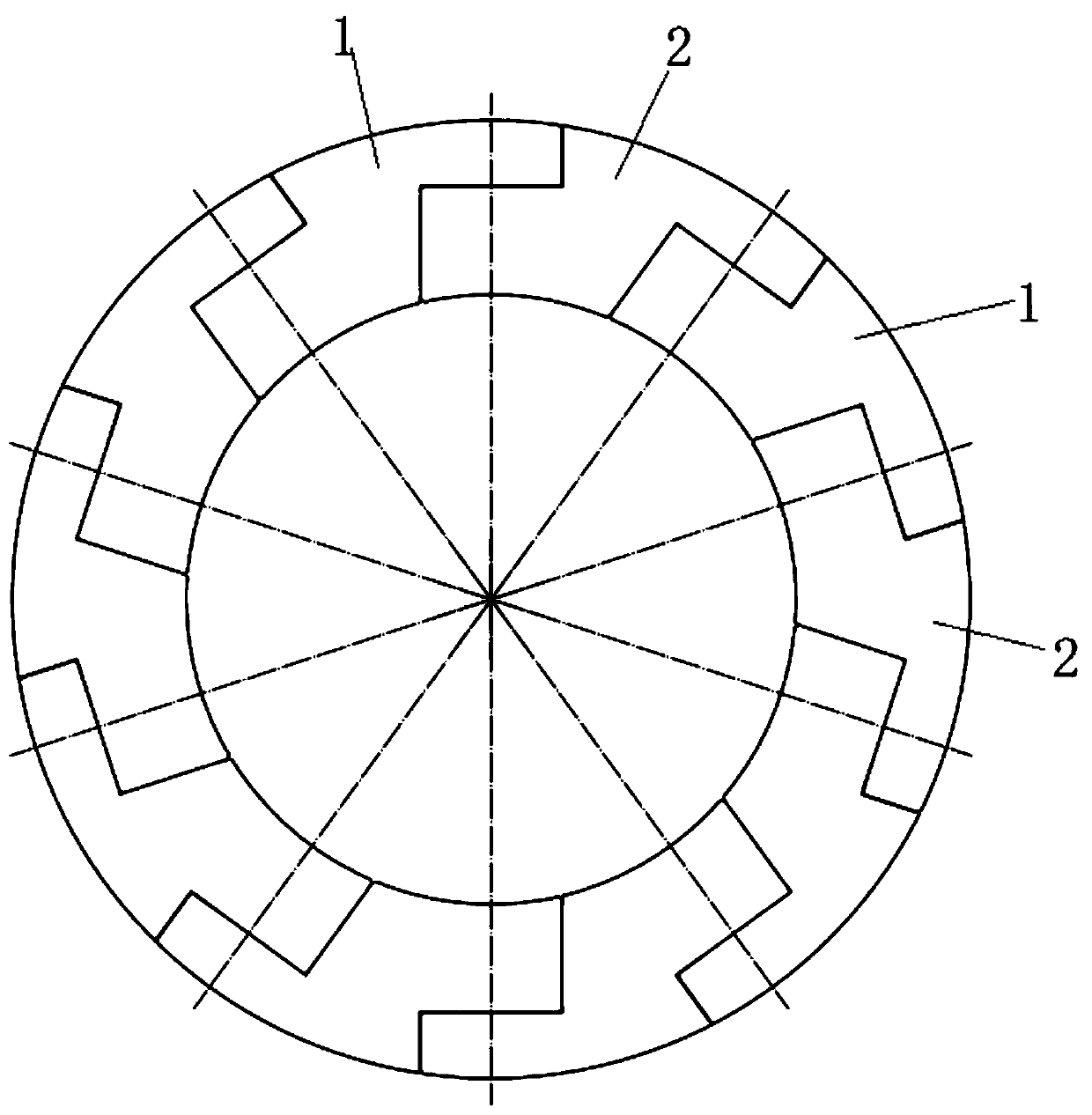

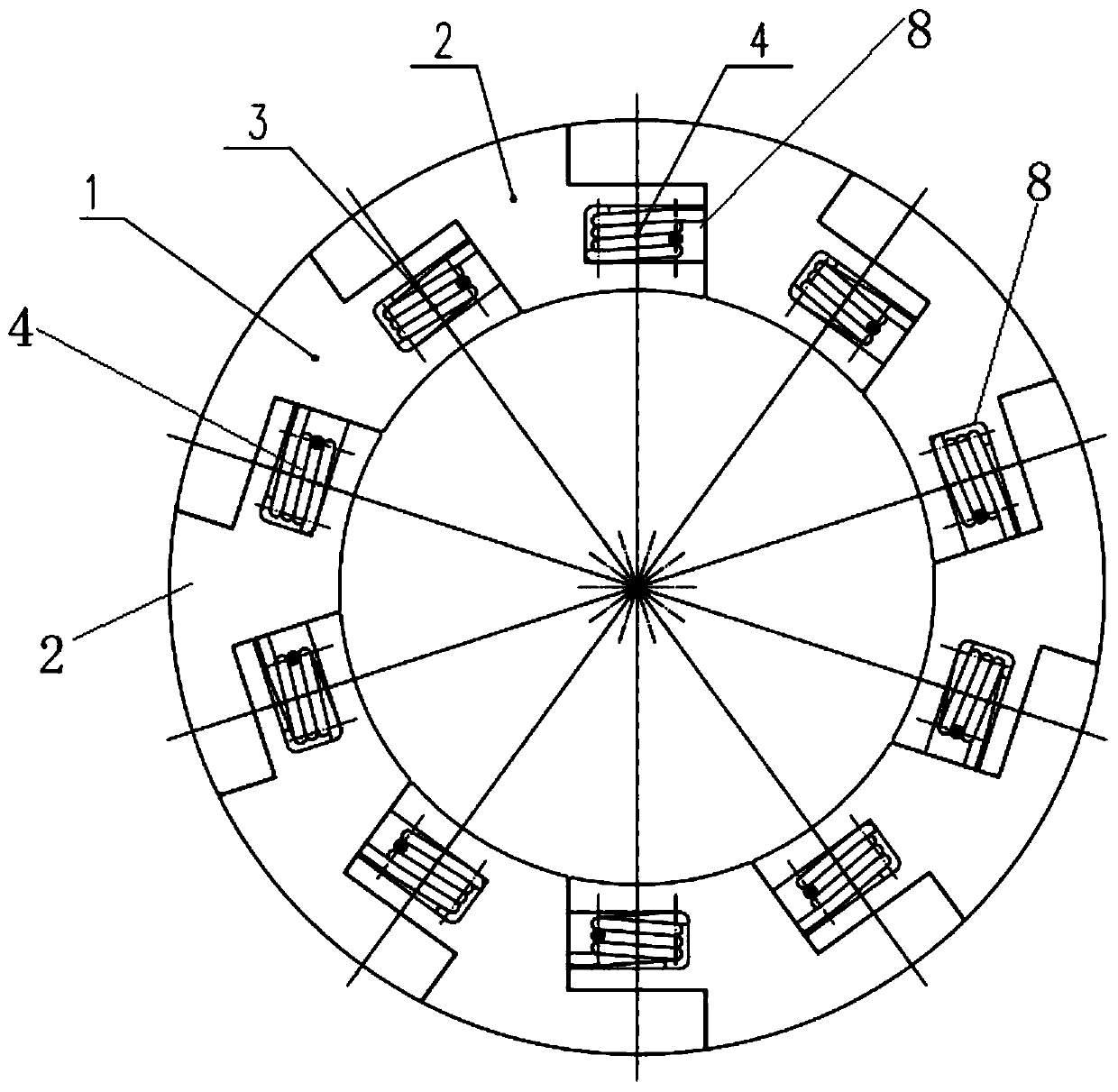

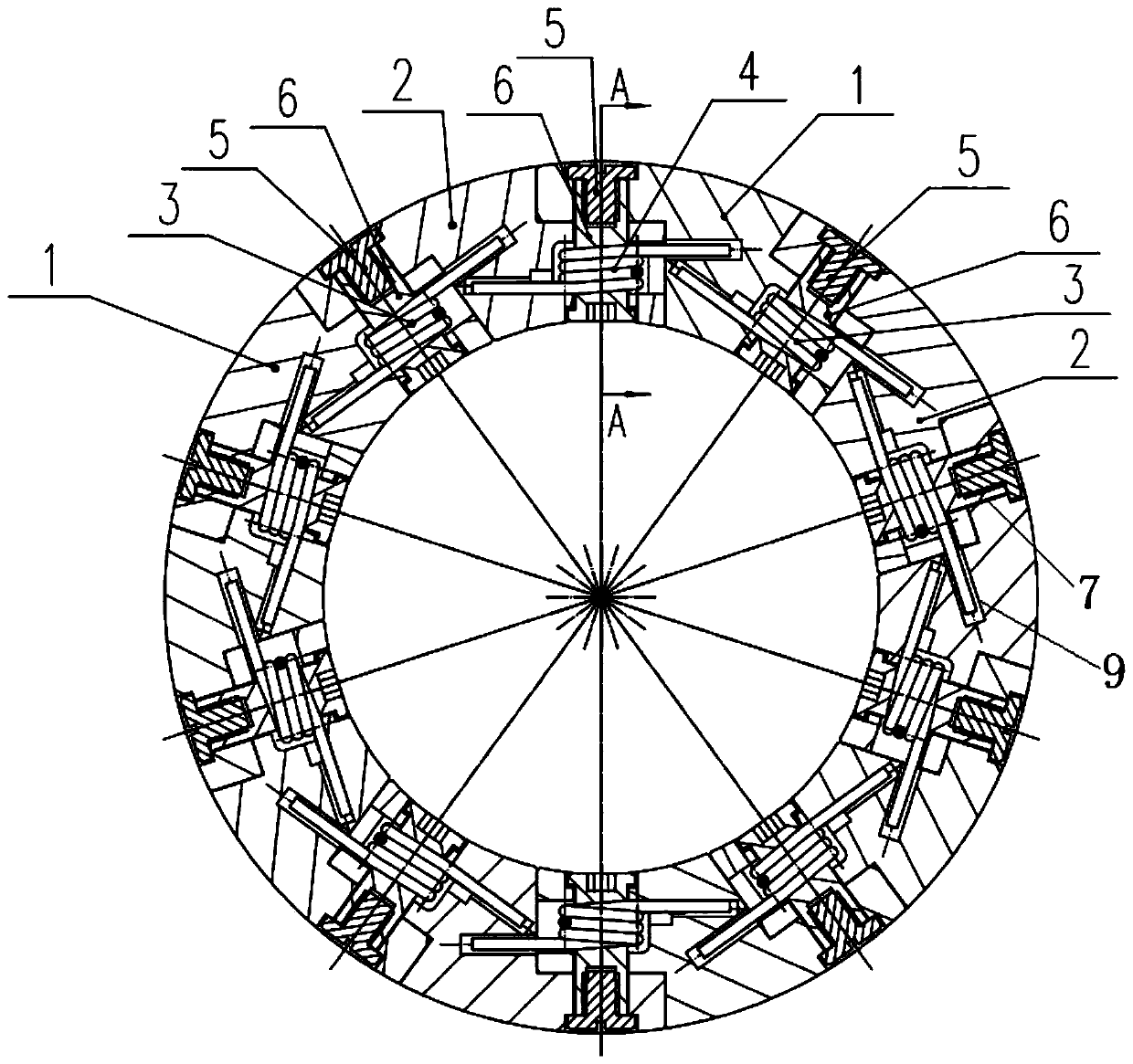

Retrievable rubber sleeve anti-protrusion mechanism used under high temperature and high pressure

PendingCN111322030AMeet the needs of unblockingPlay a role in anti-burstSealing/packingWorking pressureEngineering

The invention discloses a retrievable rubber sleeve anti-protrusion mechanism used under high temperature and high pressure. The retrievable rubber sleeve anti-protrusion mechanism comprises supporting blocks and limiting supporting blocks, wherein the supporting blocks and the limiting supporting blocks are hinged alternately in sequence to form a ring. The supporting blocks and the limiting supporting blocks on two sides of the supporting blocks are jointly penetrated by a guide rod so as to be hinged, and the parts, located on two sides of each supporting block, of the guide rod are sleevedwith a left-handed cylindrical helix torsion spring and a right-handed cylindrical helix torsion spring respectively. Torsion arms at one ends of the left-handed cylindrical helix torsion springs andthe right-handed cylindrical helix torsion springs are located in the supporting blocks, while torsion arms at the other ends are located in the limiting supporting blocks on two sides of the supporting blocks, and the left-handed cylindrical helix torsion springs and the right-handed cylindrical helix torsion springs are alternately distributed in sequence on the ring. The retrievable rubber sleeve anti-protrusion mechanism used under high temperature and high pressure can achieve outer-diameter contraction and expansion, and solves the problems that a retrievable rubber sleeve in the priorart protrudes and is pricked to leak during high-temperature and high-pressure sealing, and working pressure of a retrievable packer is increased.

Owner:宝鸡市元亨石油设备有限责任公司

Lightning-protection reflection type high-strength dual-waveband directional antenna

InactiveCN102637947BHigh bandwidthImprove structural strengthSimultaneous aerial operationsRadiating elements structural formsMetal stripsCoaxial cable

The invention relates to a lightning-protection reflection type high-strength dual-waveband directional antenna. The lightning-protection reflection type high-strength dual-waveband directional antenna comprises a metallic reflection cavity, wherein microstrip plates are arranged in the metallic reflection cavity; a multiplexer is arranged on the microstrip plates; a coaxial cable is connected onto a main circuit of the multiplexer; a first radiation oscillator and a second radiation oscillator are respectively connected onto a first branch and a second branch of the multiplexer; a solid antenna housing covers on the first radiation oscillator and the second radiation oscillator; the solid antenna housing is provided with a lightning-protection reflection oscillator; the lightning-protection reflection oscillator is located at the same side of the first radiation oscillator and the second radiation oscillator; the first radiation oscillator and the second radiation oscillator adopt hollow sail-shaped unipolar metal oscillators; the hollow sail-shaped unipolar metal oscillators consist of first metallic straight strips, second metallic straight strips and arc-shaped metallic strips; the first metallic straight strips, the second metallic straight strips and the arc-shaped metallic strips are connected with one another in an end-to-end manner; angles formed by the first metallic straight strips, the second metallic straight strips and the arc-shaped metallic strips are acute angles; and metal blocks are arranged or directly welded on the hollow sail-shaped unipolar metal oscillators so as to form an inner-and-outer embattlement type structure.

Owner:SOUTHEAST UNIV +2

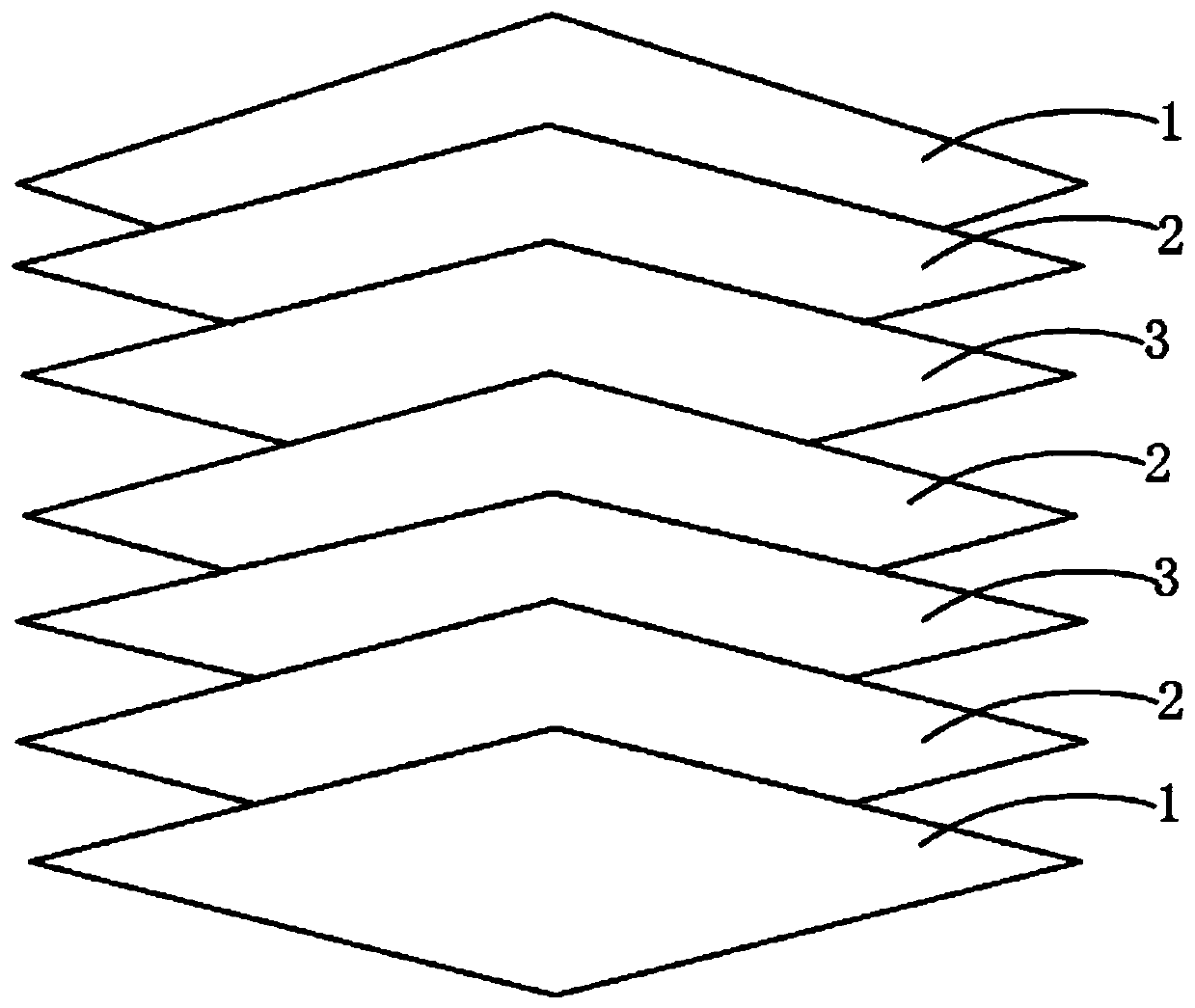

A water-based zero-formaldehyde ecological board and its manufacturing process

ActiveCN107060252BGuaranteed dimensional stabilitySimple manufacturing processCovering/liningsWood veneer joiningFiberManufacturing technology

The invention provides a zero formaldehyde ecological board and a manufacturing technology thereof. The waterborne zero formaldehyde ecological board comprises two pieces of facing paper, balancing paper and a fiber board body. The two pieces of facing paper are located on the upper surface layer and the lower surface layer correspondingly, the balancing paper and the fiber board body which are sequentially alternated are arranged between the two pieces of facing paper, and the two pieces of facing paper are adhered to the adjacent balancing paper correspondingly; and the outer surface layers of the two pieces of facing paper are each provided with a first waterborne polyurethane layer, the balancing paper is adhered to the two pieces of facing paper through second waterborne polyurethane layers correspondingly, and the balancing paper is adhered to fiber board body through third waterborne polyurethane layers. According to the zero formaldehyde ecological board and the manufacturing technology thereof, environment-friendly waterborne polyurethane layers are adopted, and therefore the formaldehyde density of the ecological board can be released to be 0.1 mg / L or below; and the manufacturing technology of the ecological board is simplified, and production efficiency is greatly improved.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

High-strength dual-band directional antenna

InactiveCN102610902BHigh bandwidthImprove structural strengthSimultaneous aerial operationsRadiating elements structural formsMetal stripsCoaxial cable

The invention relates to a high-strength dual-band directional antenna, which comprises a metal reflection cavity. A microstrip plate is arranged in the metal reflection cavity. A multiplexer is arranged on the microstrip plate. A coaxial cable is connected onto the main circuit of the multiplexer. A first radiation oscillator and a second radiation oscillator are respectively connected onto a first branch circuit and a second branch circuit of the multiplexer. Solid antenna domes respectively cover the first radiation oscillator and the second radiation oscillator. The first radiation oscillator and the second radiation oscillator are of hollow sail-shaped monopole metal oscillators. Each hollow sail-shaped monopole metal oscillator consists of a first metal straight strip, a second metal straight strip and an arc-shaped metal strip, wherein the first metal straight strip, the second metal straight strip and the arc-shaped metal strip are head-to-tail connected, three angles formed by the first metal straight strip, the second metal straight strip and the arc-shaped metal strip are acute angles, and metal blocks are arranged or directly welded on the hollow sail-shaped monopole metal oscillators to form internal and external battlement structures.

Owner:SOUTHEAST UNIV +2

Strong-strength broadband antenna for flying carrier and preparation process thereof

InactiveCN102157781BHigh bandwidthHigh gainAntenna adaptation in movable bodiesRadiating elements structural formsDielectricEngineering

The invention discloses a strong-strength broadband antenna for a flying carrier, which comprises a metallic reflective ground with a central hole. A solid antenna housing is connected to the metallic reflective ground. A radiation oscillator is embedded in the solid antenna housing, and comprises a columnar monopole metallic oscillator on which at least one side wing is arranged. The columnar monopole metallic oscillator is extended from the interior of the solid antenna housing, and passes through the central hole on the metallic reflective ground until reaching the outside of the solid antenna housing. The part, exposed outside the solid antenna housing, of the columnar monopole metallic oscillator is connected with an N terminal. The preparation process of the strong-strength broadband antenna for the flying carrier comprises the following specific steps of: reserving a mould according to the solid antenna housing and the reflective ground structure of the antenna, arranging the reflective ground and radiation oscillator of the antenna in the mould, simultaneously injecting a fluidic solid antenna housing dielectric material into the mould through a small hole, performing cooling after the whole mould is filled with the material, and finally removing the mould to obtain the integrated antenna.

Owner:CETC YANGZHOU BAOJUN ELECTRONICS

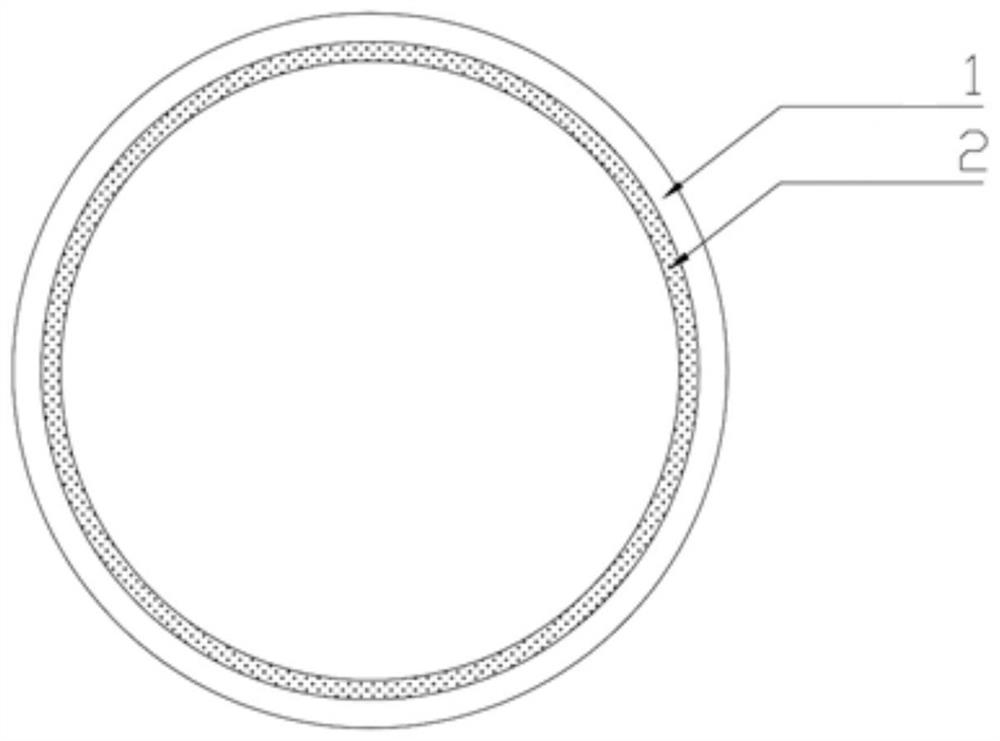

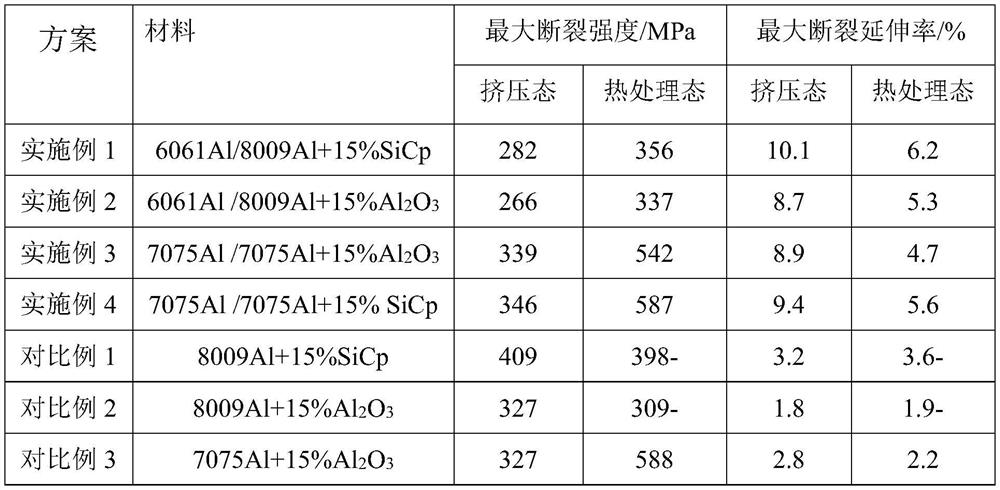

A kind of preparation method of hybrid aluminum matrix composite material pipe

The invention discloses a method for preparing a hybrid aluminum-based composite material pipe, which includes loading particle-reinforced aluminum-based composite materials with different volume fractions into an aluminum alloy tube billet for pre-compacting, vacuuming, heating, perforating and hot extrusion compounding, Heat treatment (including annealing, quenching and aging) and other processes rely on high temperature and high pressure during extrusion to densify the particle-reinforced aluminum matrix composite material, and at the same time improve the composite strength of the interface between the particle-reinforced aluminum matrix composite material and the outer aluminum alloy matrix, and Improve the deformation ability of particle reinforced aluminum matrix composites, and solve the problems of poor plasticity and toughness of single particle reinforced aluminum matrix composites and difficulties in extrusion and manufacturing of hybrid aluminum matrix composites.

Owner:HUNAN GOLDHORSE ALUMINUM IND

High-temperature resistant high-strength alloy steel and thermal treatment process thereof

The invention discloses high-temperature resistant high-strength alloy steel and a thermal treatment process thereof. The high-temperature resistant high-strength alloy steel comprises the following raw materials in percentage by weight: 0.02-0.05% of carbon, 3-6% of aluminum, 0.1-0.5% of thallium, 0.03-0.08% of rubidium, 0.1-0.4% of tin, 0.05-0.1% of niobium, 0.1-0.5% of lithium, 5-12% of titanium, 10-15% of gypsum whiskers, 10-18% of yttrium oxide, 6-11% of a tungsten carbide powder and the balance of iron. The high-temperature resistant high-strength alloy steel disclosed by the invention is prepared from carbon, aluminum, thallium, rubidium, tin, niobium, lithium, titanium, gypsum whiskers, yttrium oxide, the tungsten carbide powder and iron through five steps of thermal treatment processes, the obtained high-temperature resistant high-strength alloy steel has the advantages of being high in strength, high in temperature resistance, good in toughness, and the like, is long in service life and capable of well meeting production and use requirements, and in addition, a component made of the steel is not easy to break or deform, and is worthy of popularization.

Owner:山东雨辰知识产权有限公司

A large gap compensation type sealing device for high temperature and autoclave

ActiveCN108050256BHigh fatigue requirementsHigh strengthEngine sealsRough surfaceUltra high pressure

The invention belongs to the ultra-high pressure and high temperature test technology of steel pipes, and relates to a large-gap compensation type sealing device for high-temperature and high-pressure kettles. The invention includes a sealing groove, a baffle, an auxiliary O-shaped sealing combination, an outer main sealing structure, and an inner sealing structure; the sealing groove plays the role of installing and fixing the sealing ring; the baffle plays the role of limiting and pre-tightening; The auxiliary O-ring seal combination is composed of an outer auxiliary PTFE retaining ring and a fluororubber O-ring, which acts as an auxiliary seal; the outer main seal structure includes an outer conical aluminum anti-flow ring, an outer PTFE retaining ring, and an outer large-diameter O-ring ; The inner sealing structure is composed of a single-side concave PTFE retaining ring integrated with a compensating sealing structure and an inner large-diameter O-ring. The high-temperature and autoclave large-gap compensation type sealing device of the present invention is suitable for sealing environments such as ultra-high pressure high temperature, large gap, fretting, rough surfaces, etc., and solves technical problems in the field of simulating oil casing deep well environment tests at home and abroad.

Owner:CHINA AIRPLANT STRENGTH RES INST

A kind of peanut shell graphene composite airgel oil-absorbing material and preparation method thereof

ActiveCN109513425BRaw materials are easy to getLow priceOther chemical processesAlkali metal oxides/hydroxidesThioureaGraphene flake

The invention relates to a peanut shell graphene composite airgel oil-absorbing material and a preparation method thereof. The composite airgel uses peanut shells and graphite oxide as raw materials, uses thiourea as a crosslinking agent, and passes thiourea under high temperature and high pressure The generated gas separates the graphene sheets and forms a three-dimensional porous structure with the peanut shell. The present invention utilizes thiourea to generate gas under high temperature and high pressure through a hydrothermal method to help the sheet separation of graphene oxide, and at the same time, functional groups are modified on the surface of graphene sheet, so that it can be better combined with peanut shell powder and interact with each other. The three-dimensional porous network structure is formed by the action. The three-dimensional porous network structure has high toughness and high strength, and it is not easy to break even after saturated adsorption. The peanut shell further expands the pores of graphene, increases the specific surface area of the material, and greatly enhances the oil absorption capacity.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com