Aramid fiber non-woven paper production process

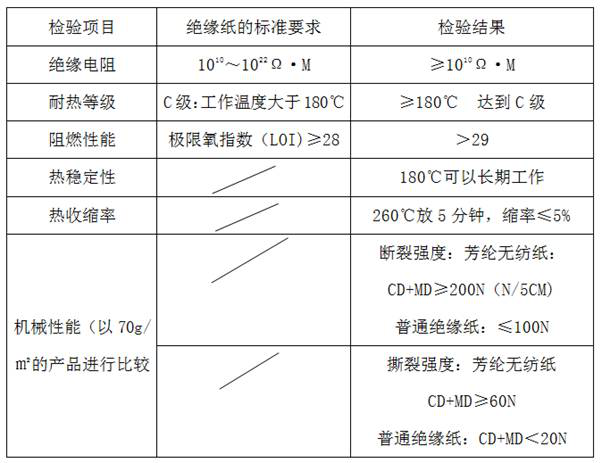

A production process, non-woven paper technology, applied in textiles and papermaking, non-woven fabrics, heating/cooling fabrics, etc., can solve the problems of low heat resistance, easy aging, short service life, etc., and achieve high temperature resistance, Long service life, the effect of service life science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

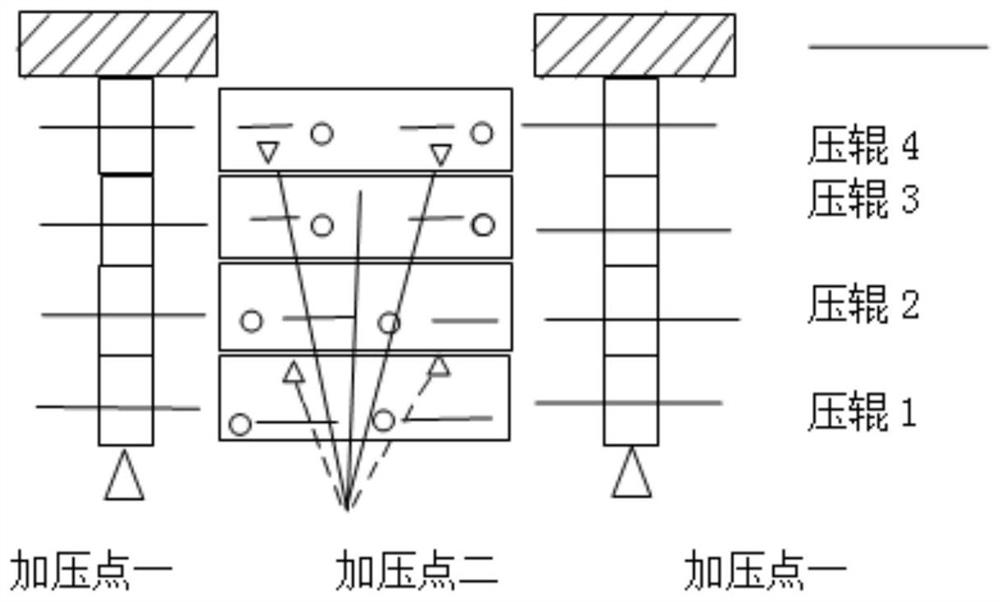

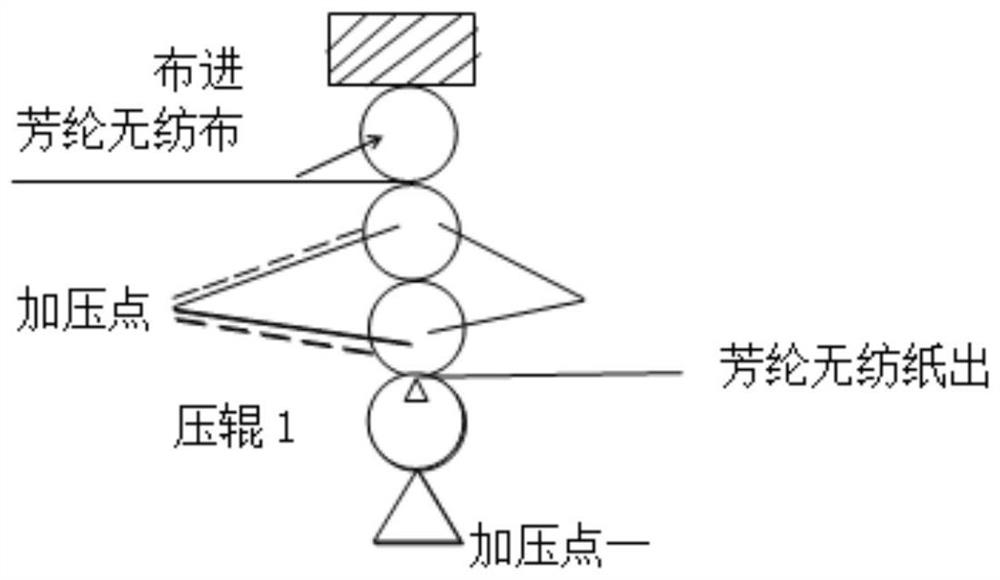

[0017] refer to Figure 1 to Figure 2 A specific embodiment of the production process of aramid non-woven paper of the present invention will be further described.

[0018] A production process for aramid non-woven paper, which uses aramid fiber to make aramid non-woven fabric through hydroentanglement process, and then forms aramid non-woven paper after high-temperature pressurization processing, specifically including the following steps,

[0019] A. Opening and mixing, the aramid fibers are quantitatively weighed and transported to the opening machine, and the fibers are opened and mixed;

[0020] B. Forming a web, sending the opened fibers into a carding machine or an air-laid machine, carding or air-laying the aramid fibers into a web, and according to the unit weight requirements of the finished product, two or more carding machines can also be used Machines are connected in series to form a net, or a net is made by cross-laying;

[0021] C. Spunlace entanglement, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com