Retrievable rubber sleeve anti-protrusion mechanism used under high temperature and high pressure

A high-temperature, high-pressure, rubber cartridge technology, applied in wellbore/well components, earthwork drilling, sealing/package, etc., can solve puncture leaks, retrievable rubber cartridge protrusions, and increase the working pressure of retrievable packers and other problems to achieve the effect of improving sealing performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

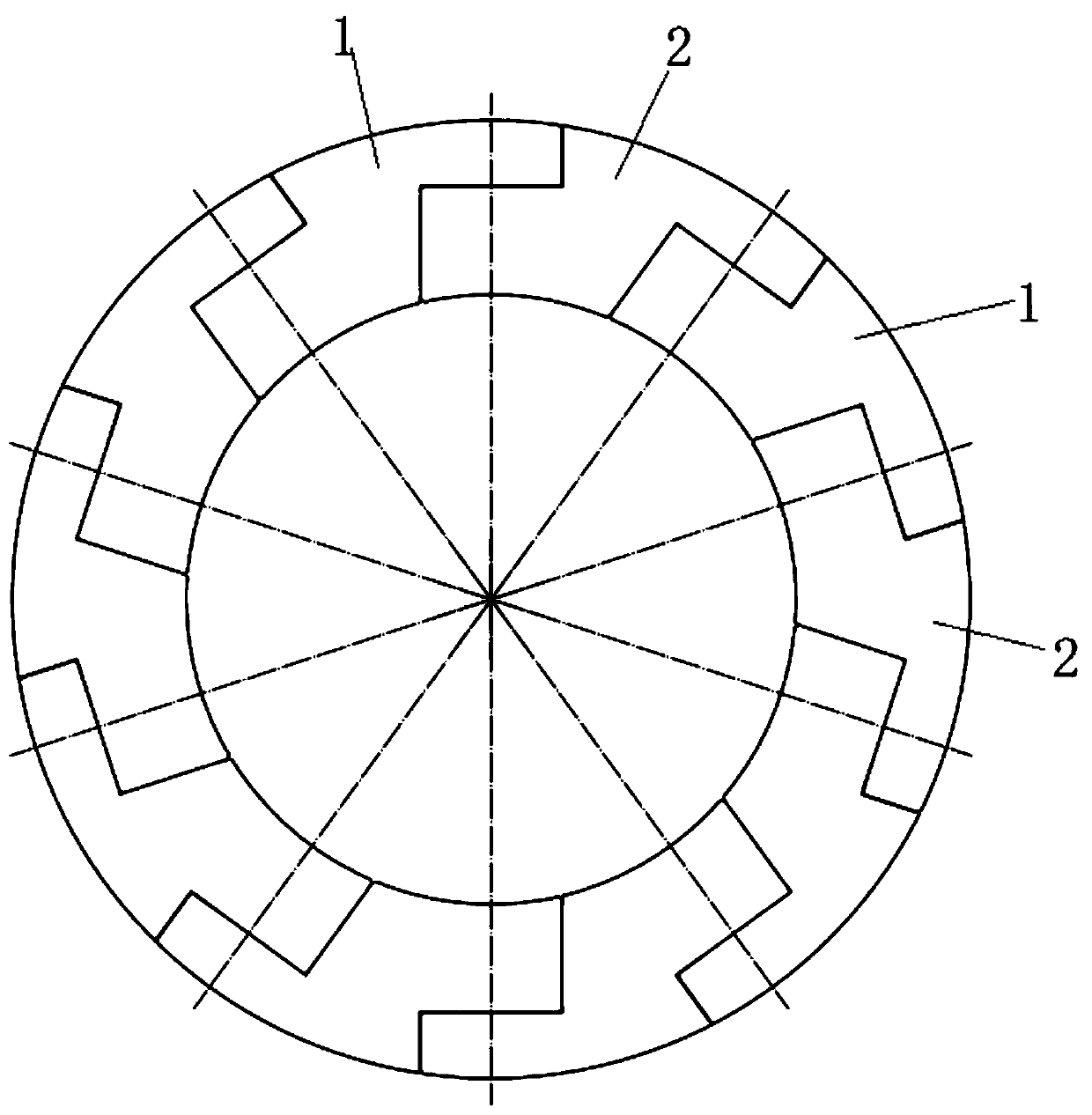

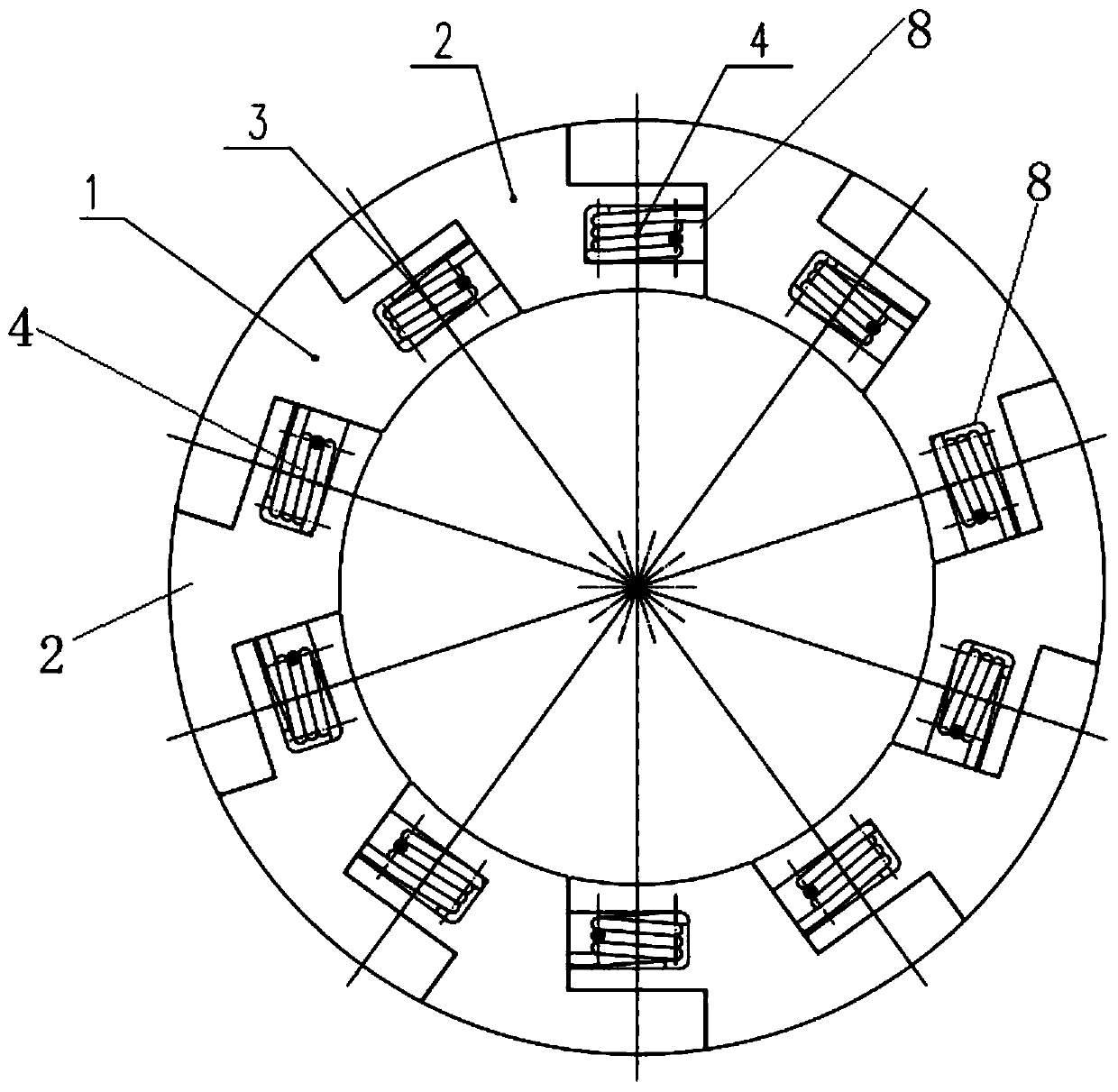

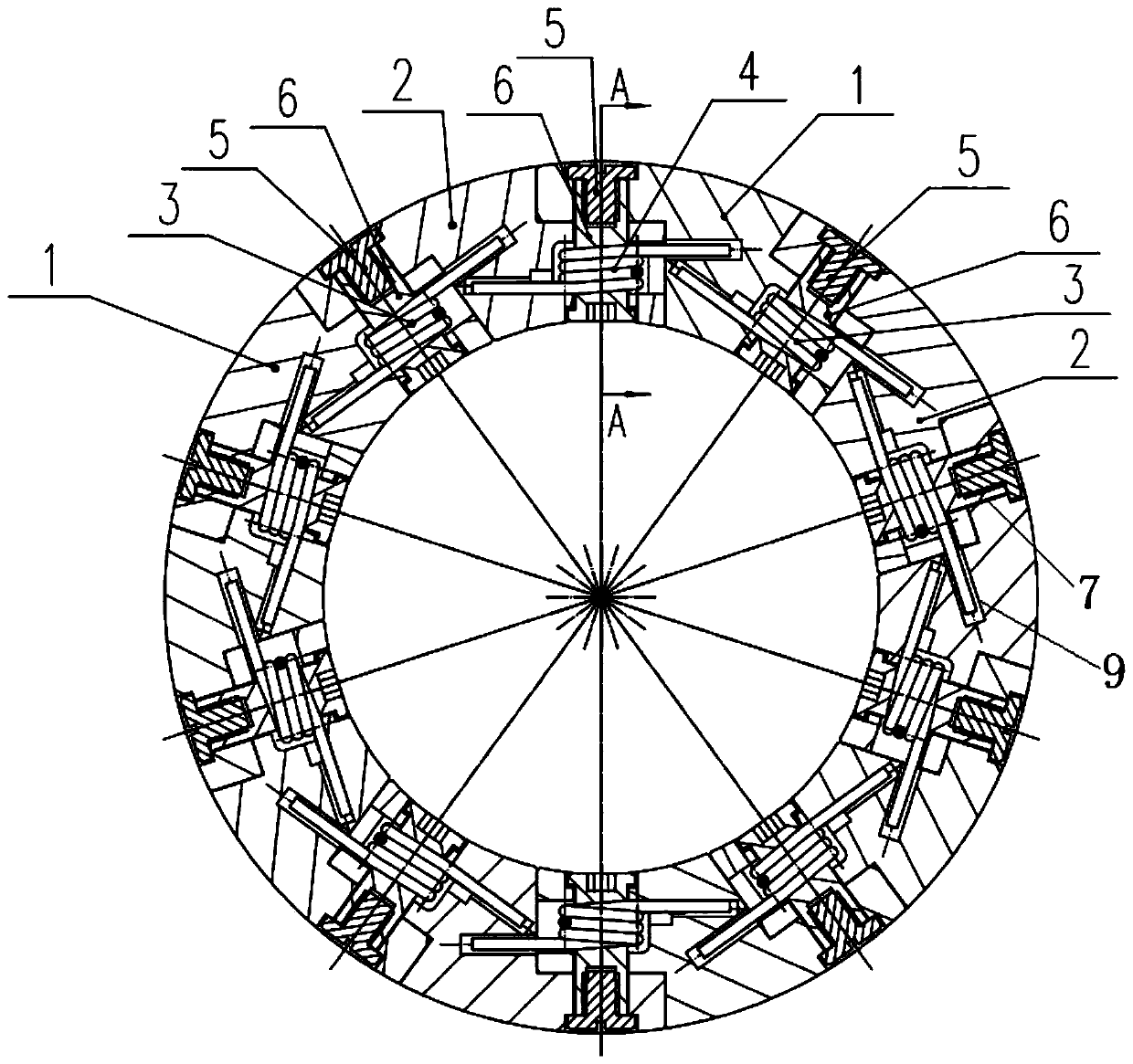

[0030] The present invention is a recyclable rubber cartridge anti-burst mechanism for high temperature and high pressure. Its structure is as follows: Figure 1-5 As shown, it includes a support block 1 and a limit support block 2 that are hinged at intervals in turn and forms a ring, and the support block 1 and the limit support blocks 2 on both sides of the support block 2 are hinged by a guide rod 6 that is threaded together, as Figure 10-11 As shown, the guide rods 6 on both sides of the support block 1 are respectively sleeved with a left-handed cylindrical helical torsion spring 3 and a right-handed cylindrical helical torsion spring 4, and one end of the left-handed cylindrical helical torsion spring 3 and right-handed cylindrical helical torsion spring 4 is located on the support In the block 1, the other end is located in the limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com