Thin-walled high-temperature-resistant high-pressure-resistant intercooler corrugated pipe

A high-temperature-resistant, bellows technology, used in hoses, pipes, machines/engines, etc., can solve the problems of reduced shock absorption, increased stiffness, and high cost, and achieves easy assembly, good flexibility, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

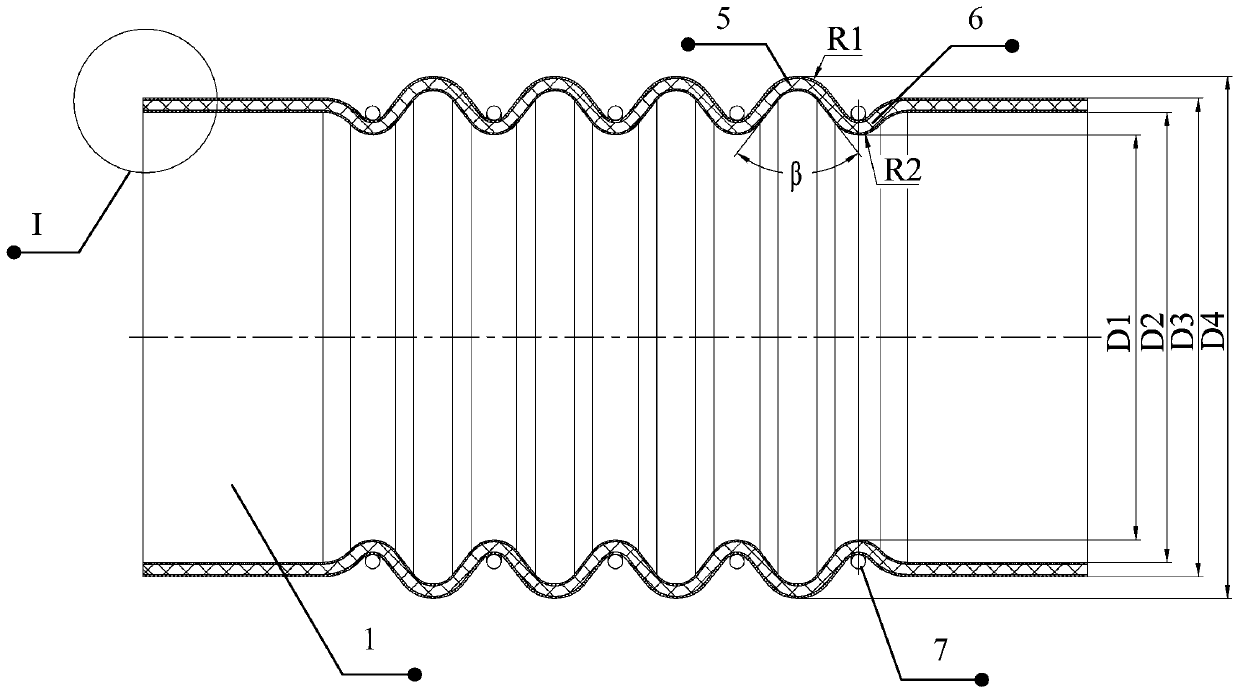

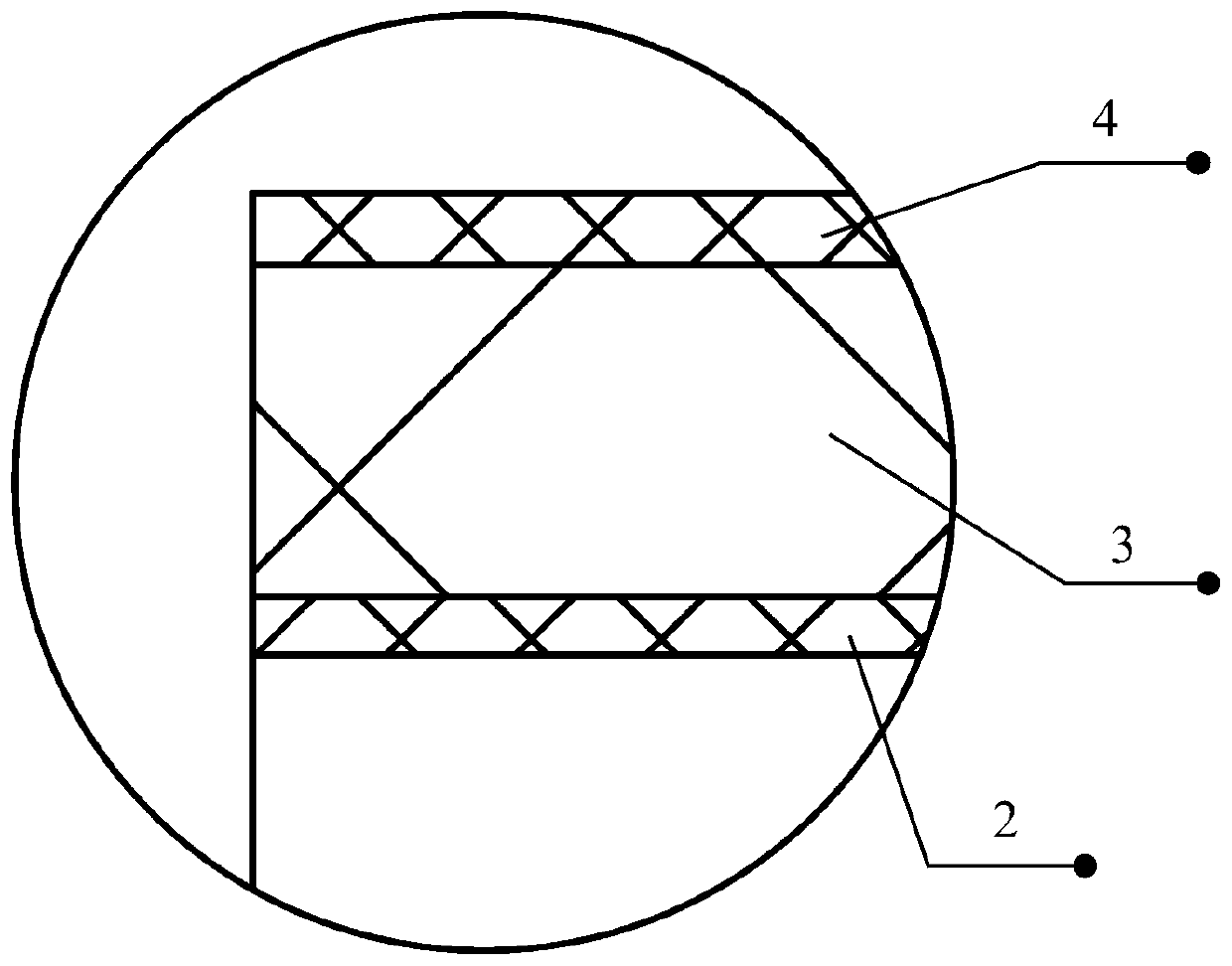

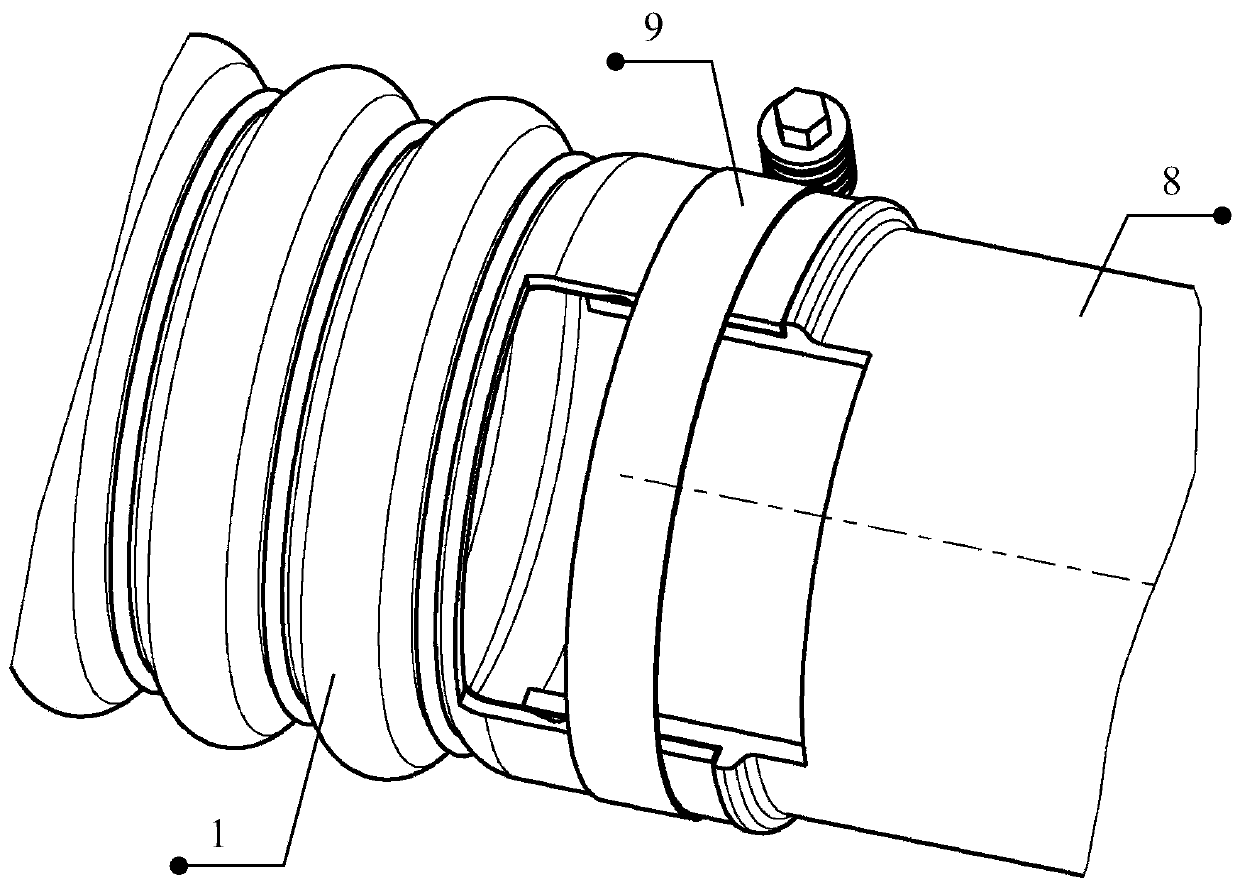

[0027] A thin-walled corrugated pipe for high temperature and high pressure intercooler, which consists of: the inner rubber layer of the rubber hose is made of oil-resistant, high and low temperature resistant fluorinated silica gel as the isolation layer, and the rubber hose reinforcement layer is made of four layers of high temperature resistant aramid cloth, so that the product has Superior high temperature resistance and excellent pressure resistance, the outer rubber layer of the hose is made of silica gel; the corrugated tube hose body is formed by automatic winding technology, the thickness of the inner rubber layer of the hose is controlled at 0.65mm, and the thickness of the outer rubber layer of the hose is controlled at 0.9mm. The overall wall thickness is 3.2mm, and the overall wall thickness of the hose refers to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com