Polyether-ether-ketone/polyether sulfone composite fiber and preparation method thereof

A technology of polyether ether ketone and composite fiber, which is applied in the field of polyether ether ketone/polyether sulfone composite fiber, can solve the problems of high cost and unsuitability for promotion, and achieve low raw material cost, good uniformity and wear resistance, The effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

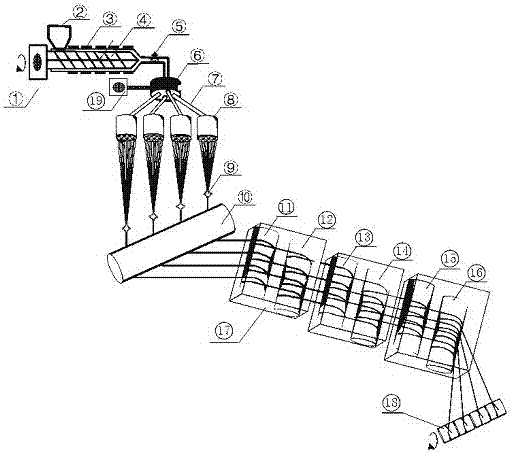

Method used

Image

Examples

Embodiment 1

[0060] Add a dry spinning grade polyetheretherketone / polyethersulfone resin special material (7:3 weight ratio, polyetheretherketone intrinsic viscosity 0.64dL / g, polyethersulfone intrinsic viscosity 0.34dL / g) into the extruder The extruder hopper and the five-stage heating temperature of the extruder are 260°C, 350°C, 360°C, 370°C, and 380°C respectively; the screw pressure is 10MPa, the output speed of the metering pump is 14r / min, the component pressure is 10MPa, and the spinneret specifications It is 36 holes, the temperature of the first group of drafting hot rollers is 150°C, the temperature of the second group of drafting hot rollers is 170°C, the temperature of the third group of shaping hot rollers is 210°C, the primary stretching ratio is 1.4, and the secondary stretching ratio is 1.2 , the relaxation setting ratio is 0.95:1, the winding speed is 700m / min, and the polyetheretherketone / polyethersulfone fiber filament is prepared, the specification is 200dtex / 36f, and t...

Embodiment 2

[0062] As described in Example 1, only the temperature of the drawing hot roller group 1 is 140°C, the temperature of the drafting hot roller group 2 is 160°C, the temperature of the shaping hot roller group 3 is 200°C, the primary draw ratio is 1.2, and the second The grade draw ratio is 1.2, the relaxation setting ratio is 0.95:1, and the winding speed is 500m / min, and the polyetheretherketone / polyethersulfone fiber filament is prepared, the specification is 240dtex / 36f, and the fiber breaking strength is 3.0cN / dtex .

Embodiment 3

[0064] As described in Example 1, the heating temperature of the five stages of the extruder is respectively 270°C, 360°C, 370°C, 380°C, and 390°C, the screw pressure is 10MPa, the output speed of the metering pump is 26r / min, and the component pressure is 10MPa , the size of the spinneret is 72 holes, but the temperature of the stretching hot roller group 1 is 160°C, the temperature of the drawing hot roller group is 180°C, the temperature of the shaping hot roller group 3 is 240°C, and the primary draw ratio is 1.5. The secondary stretching ratio is 1.5, the heat setting ratio is 0.98:1, and the winding speed is 800m / min. The polyetheretherketone / polyethersulfone fiber filament is prepared with a specification of 350dtex / 72f and a fiber breaking strength of 4.0cN / dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com