Photo-thermal dual-curable adhesive and preparation method thereof

A dual-curing and adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve problems such as poor curing, and achieve the effect of high strength and high temperature and high humidity reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

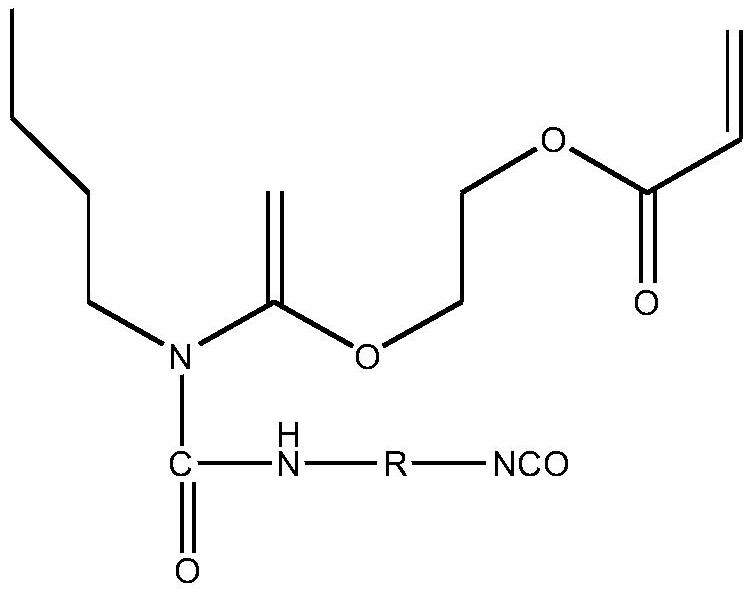

Method used

Image

Examples

Embodiment 1

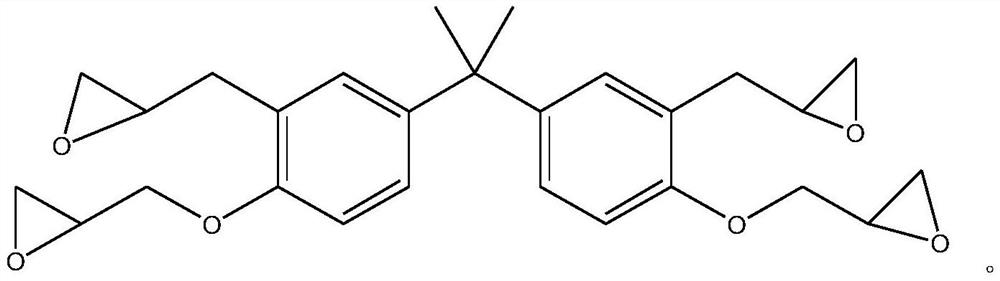

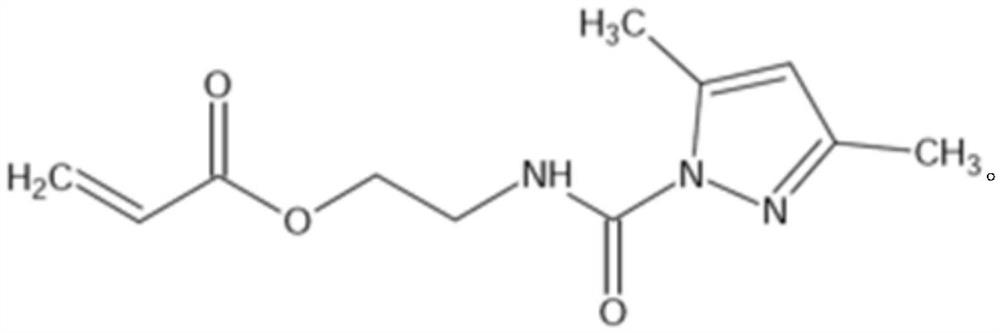

[0030] Accurately weigh the following raw materials, 30g of modified resin with both acrylate groups and isocyanate groups; four-functional special epoxy resin BATG produced by Japan Showa Denko, 30g; THFA, 30g; acrylate monomer of end-blocked isocyanate Japan Showa Denko's AOI-BP, 5g; free radical photoinitiator 184, 3g; special mercaptan Japanese SC organic PEPT, 12g; latent amine curing agent PN-40 7g; add the above components in turn to double planetary power In the mixing mixer, evacuate to a vacuum degree of -0.08MPa, stir at 500 rpm for 2 hours, stir evenly, let it air naturally to room temperature, and obtain a UV-curable adhesive, which can be sealed and packaged.

Embodiment 2

[0032] Accurately weigh the following raw materials, 20g of modified resin with both acrylate groups and isocyanate groups; four-functional special epoxy resin BATG produced by Japan Showa Denko, 20g; IBOA, 30g; acrylate monomer of end-blocked isocyanate Japan Showa Denko's AOI-BP, 10g; free radical photoinitiator TPO, 1g; special mercaptan Japanese SC organic PEPT, 5g; latent amine curing agent PN-50 3g; add the above components in turn to double planetary power In the mixing mixer, evacuate to a vacuum degree of -0.05MPa, stir at 750 rpm for 1 hour, stir evenly, let it air naturally to room temperature, and obtain a UV-curable adhesive, which can be sealed and packaged.

Embodiment 3

[0034] Accurately weigh the following raw materials, 40g of modified resin with both acrylate groups and isocyanate groups; four-functional special epoxy resin BATG produced by Japan Showa Denko, 10g; LA, 10g; end-blocked isocyanate Acrylate monomer Japan Showa Denko's AOI-BP, 3g; free radical photoinitiator 184, 5g; special mercaptan Japanese SC organic PEPT, 17g; latent amine curing agent FXR-1030 7g; add the above components in turn to double planetary power In the mixing mixer, evacuate to a vacuum degree of -0.06MPa, stir at 700 rpm for 1.5 hours, stir evenly, let it air naturally to room temperature, and obtain a UV-curable adhesive, which can be sealed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com