Peanut hull graphene compound aerogel oil absorption material and preparation method thereof

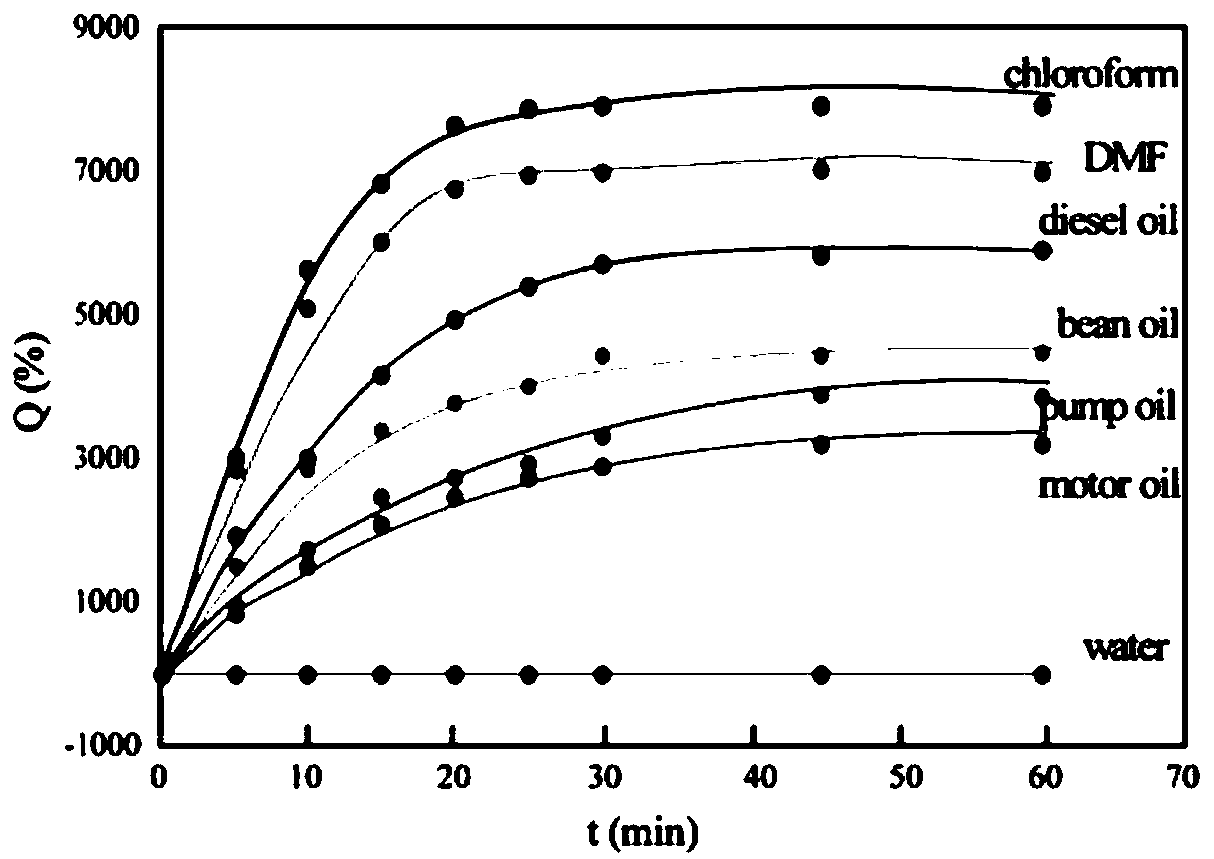

A graphene composite and oil-absorbing material technology, applied in the fields of chemistry and environment, can solve the problems of fragile, waste of resources, poor buoyancy properties, etc., achieve good adsorption performance, and realize the effect of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is achieved through the following technical solutions:

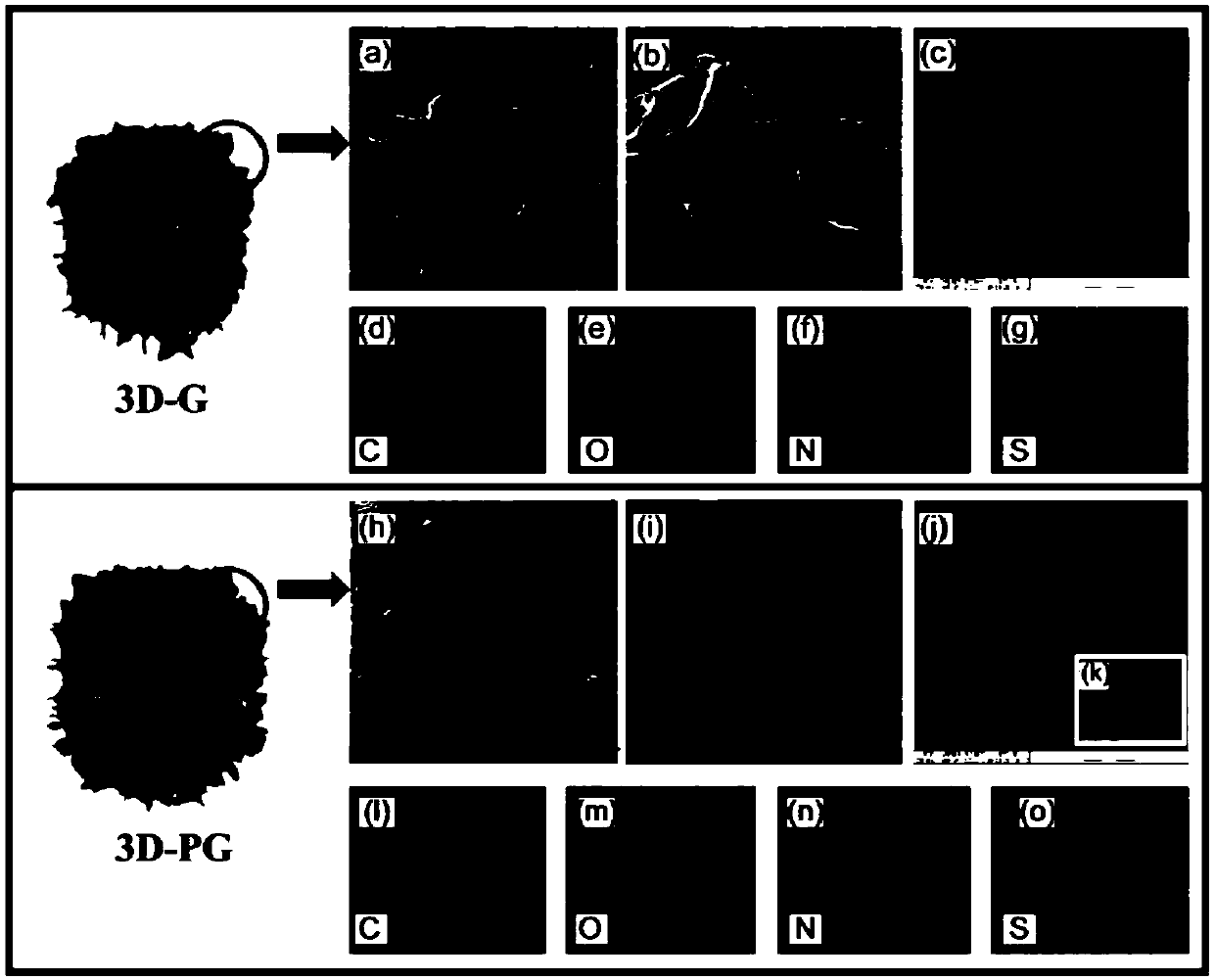

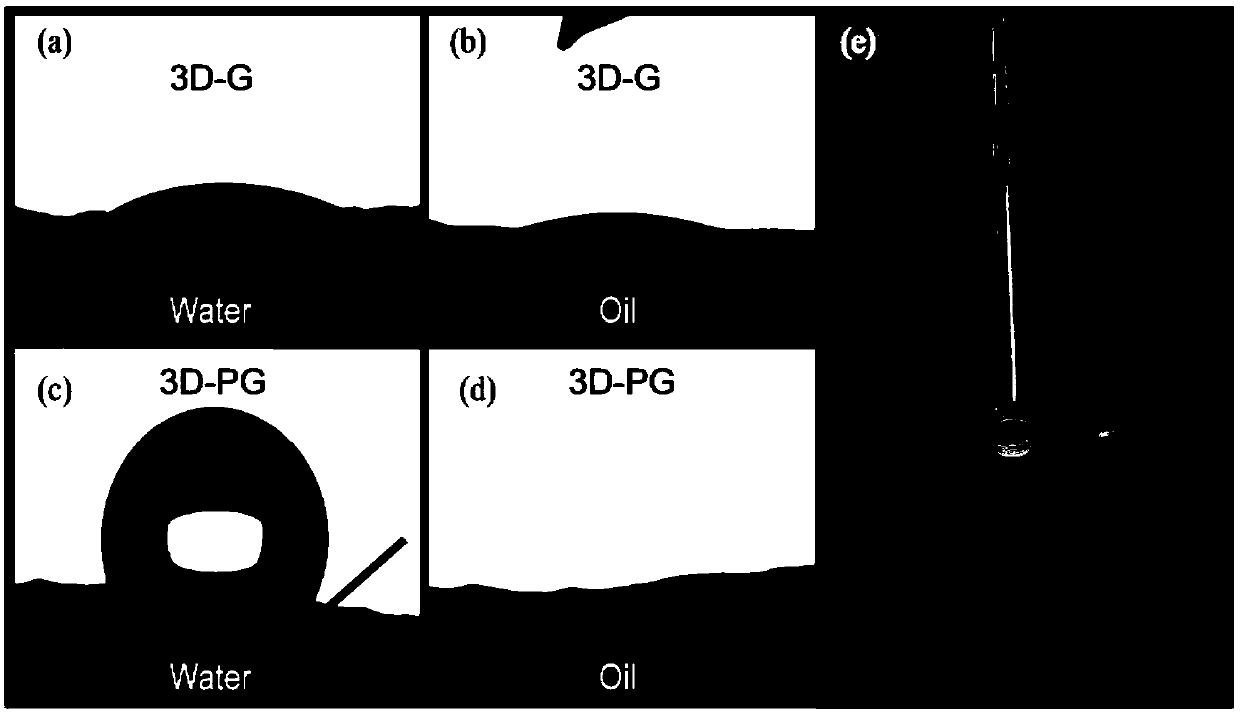

[0011] A peanut shell graphene composite airgel oil-absorbing material. The airgel uses graphene as a carrier, thiourea as a crosslinking agent, and a three-dimensional porous structure formed by peanut shell fibers loaded on the graphene through thiourea.

[0012] Another object of the present invention is to provide a preparation method of peanut shell graphene composite airgel oil-absorbing material.

[0013] The preparation method of the above-mentioned peanut shell graphene composite airgel oil-absorbing material comprises steps:

[0014] The preparation step of graphene oxide aqueous solution;

[0015] The preparation step of graphene oxide and peanut shell mixed dispersion liquid;

[0016] The steps of preparing peanut shell graphene composite hydrogel by hydrothermal reaction;

[0017] Steps for preparing peanut shell graphene composite airgel by freeze-drying.

[0018] Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com