A water-based zero-formaldehyde ecological board and its manufacturing process

A production process, zero formaldehyde technology, applied in the direction of manufacturing tools, wood processing equipment, wooden veneer joints, etc., can solve the problems of complex ecological board production process, endanger human health, pollute the indoor environment, etc., to achieve the guaranteed size Stability, improvement of deformation, and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

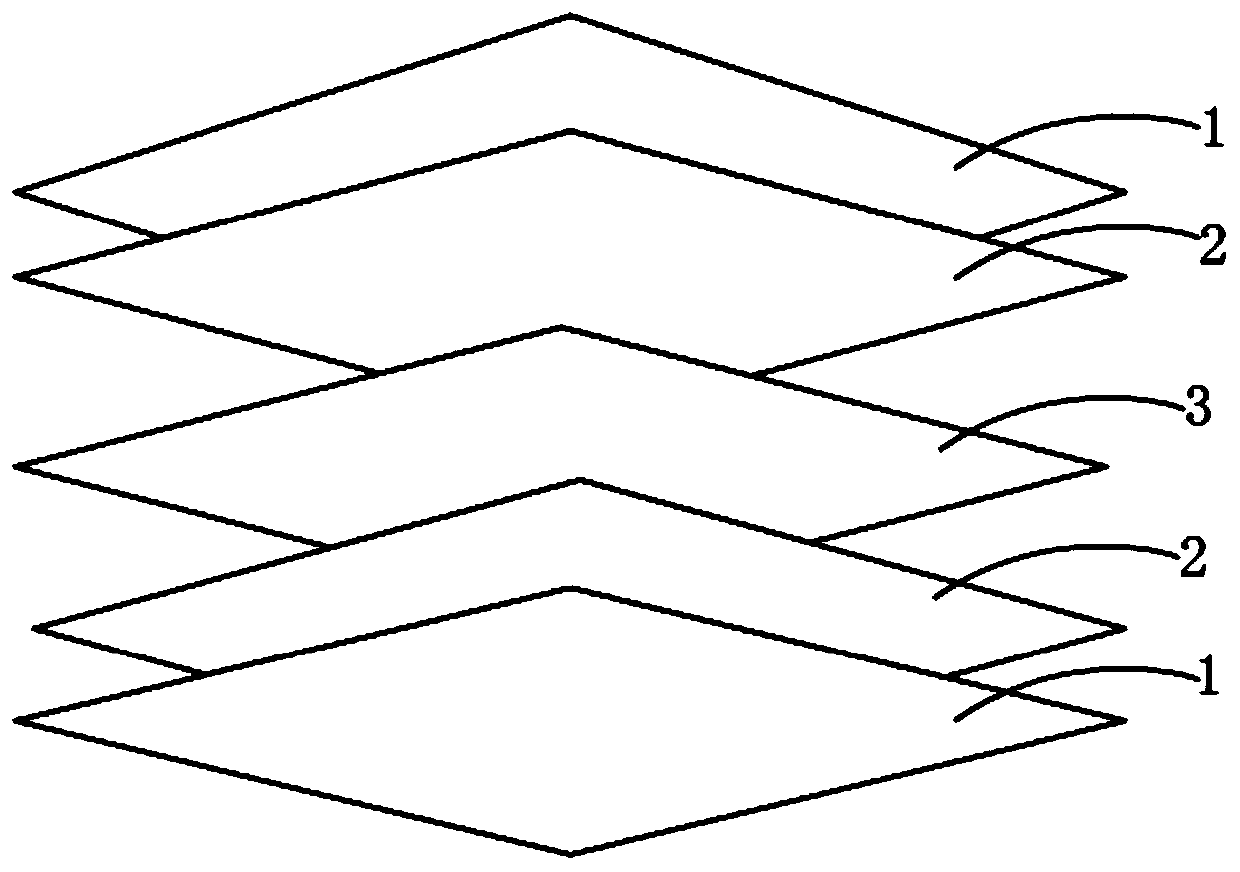

[0030] Such as figure 1 As shown, a water-based zero-formaldehyde ecological board includes facing paper, balancing paper, fiberboard, balancing paper and facing paper adhered in sequence. The outer layers of the two facing papers are all provided with the first water-based polyurethane layer, and the balancing paper The two facing papers are respectively bonded to each other through the second layer of water-based polyurethane, and the balance paper is bonded to the fiberboard through the third layer of water-based polyurethane.

[0031] Wherein, the first water-based polyurethane layer is composed of anionic water-based polyurethane of model KT200. The second water-based polyurethane layer is a composite layer composed of an anionic water-based polyurethane layer of model KT200 and a cationic water-based polyurethane layer of model KT322, and the third water-based polyurethane layer is composed of cationic water-based polyurethane of model KT322.

[0032] The manufacturing ...

Embodiment 2

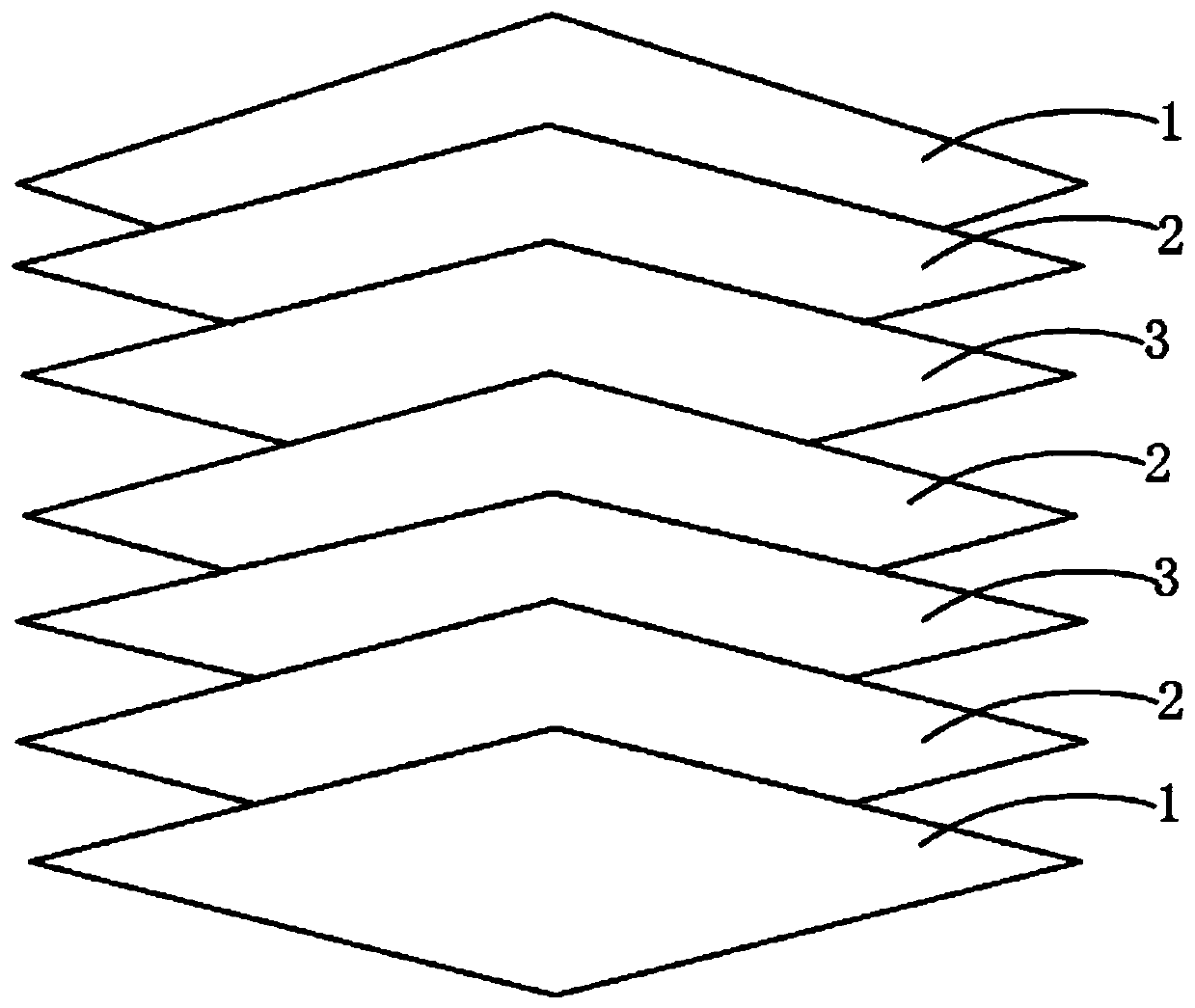

[0037] Such as figure 2 As shown, a water-based zero-formaldehyde ecological board, including decorative paper, balance paper, fiberboard, balance paper, fiberboard, balance paper and decorative paper adhered in sequence, the outer layers of the two decorative papers are provided with the first water-based The polyurethane layer and the balance paper are respectively bonded to the two facing papers through the second water-based polyurethane layer, and the balance paper is bonded to the fiberboard through the third water-based polyurethane layer.

[0038] Wherein, the first water-based polyurethane layer is composed of anionic water-based polyurethane of model KT637. The second water-based polyurethane layer is a composite layer composed of model KT637 anionic water-based polyurethane and model KT322 cationic water-based polyurethane, and the third water-based polyurethane layer is composed of model KT322 cationic water-based polyurethane layer.

[0039] The manufacturing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com