PPS (Poly-Phenylene Snlfide)/PPO (Poly-Phenylene Oxide)/PA (Poly-Amide) alloy with high temperature resistance and high heat conductivity and preparation method of PPS/PPO/PA alloy

A technology of high temperature resistance and high thermal conductivity, applied in the field of high temperature resistance and high thermal conductivity PPS/PPO/PA alloy and its preparation, it can solve the problems of low elongation and impact strength, reduce the physical properties of PPS, limit the application of PPS, etc. Thermal conductivity, effect of good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

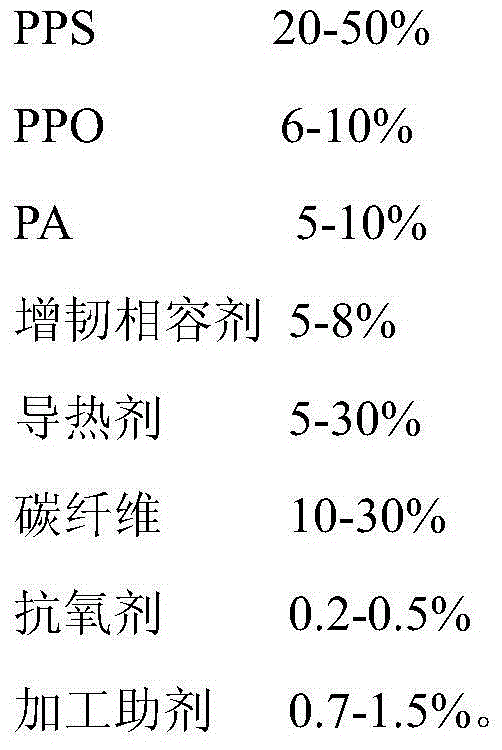

Method used

Image

Examples

Embodiment Construction

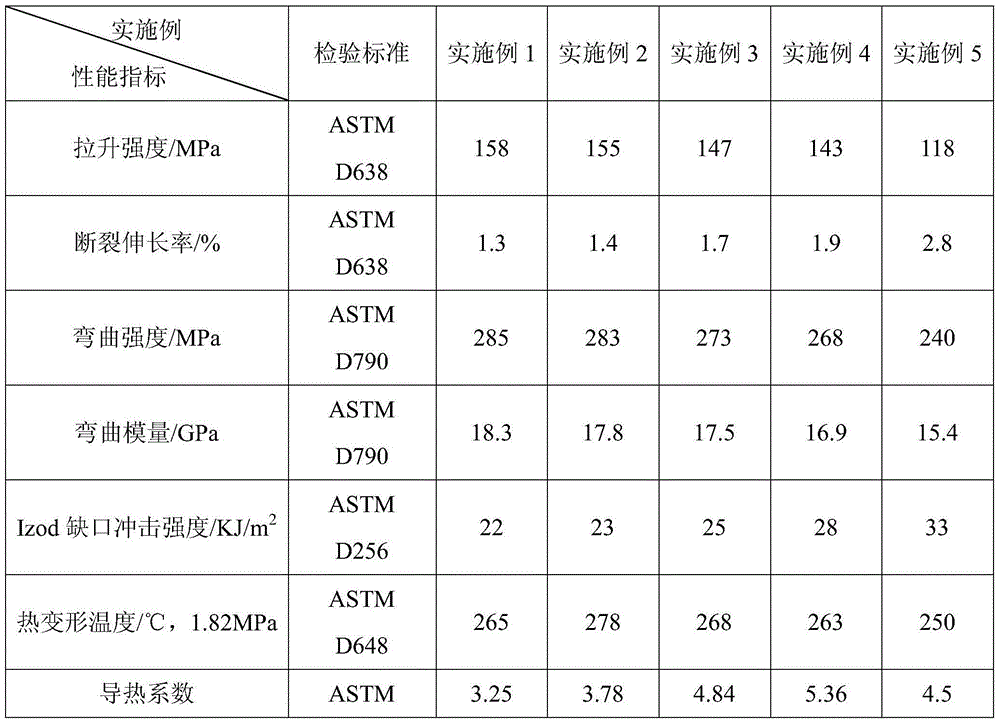

[0028] In order to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with examples, which do not constitute any form of limitation to the present invention.

[0029] According to the raw material formulation scheme of each embodiment in Table 1, weigh according to the weight fraction, pretreat the heat conduction agent, add the heat conduction agent into the high-speed mixer in different proportions, perform silane coupling agent treatment, mix evenly, and set aside ; The carbon fiber short fiber is surface treated, and made into uniform particles with a binder; PPS, PPO, PA, toughening compatibilizer, thermal conductivity agent and other additives are added to a high-speed mixer and mixed uniformly; after mixing The material is extruded and granulated in a twin-screw extruder. The extruder is divided into 10 zones. The screw combination is the best combination that can obtain the maximum ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com