Autonomous-crawling drilling-riveting system and operation method thereof

A technology for drilling riveting and drilling bits, which is used in transportation and packaging, portable drilling rigs, drilling/drilling equipment, etc. It can solve the problems of low joint stiffness and low absolute positioning accuracy, and achieve simplified tooling, stable assembly quality, and flexible application. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

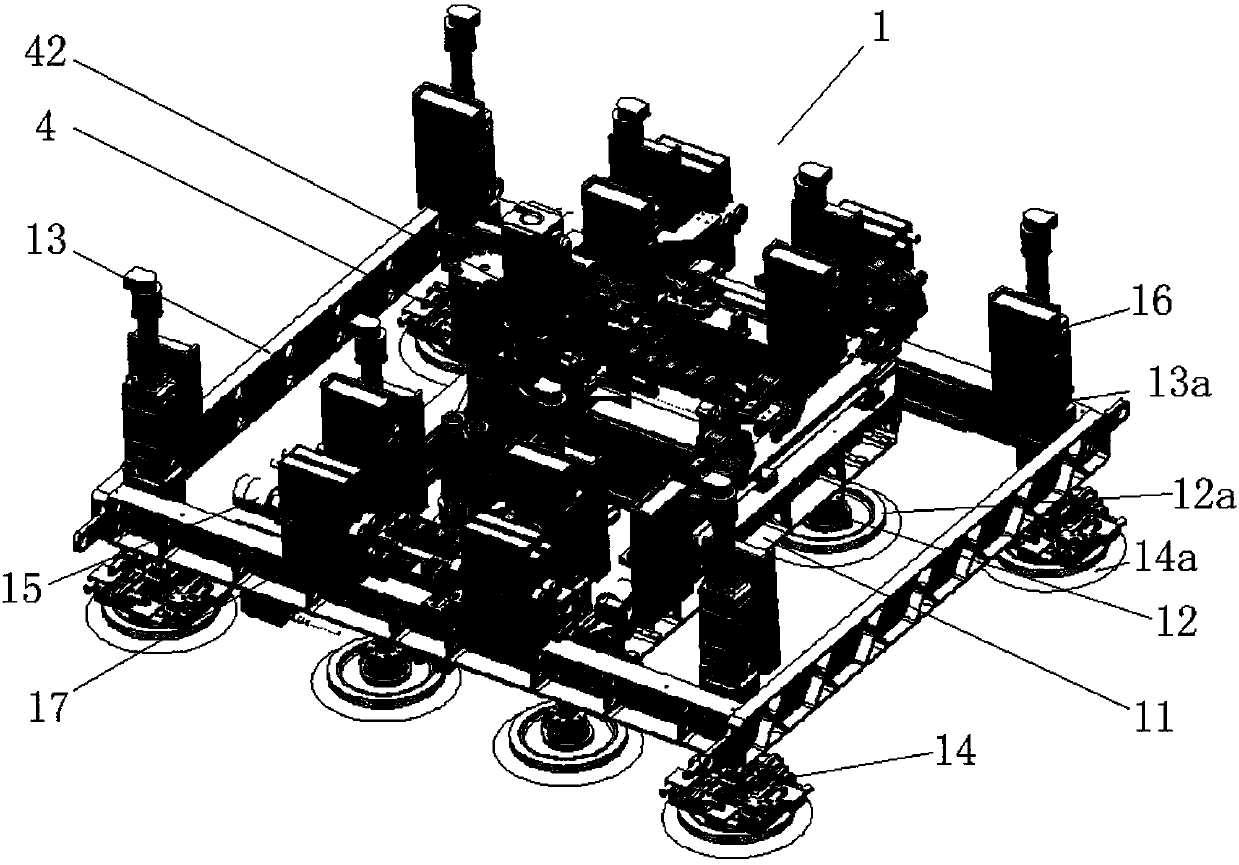

[0074] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments (taking the butt joint assembly drill riveting of the middle section of the fuselage of a large aircraft as an example).

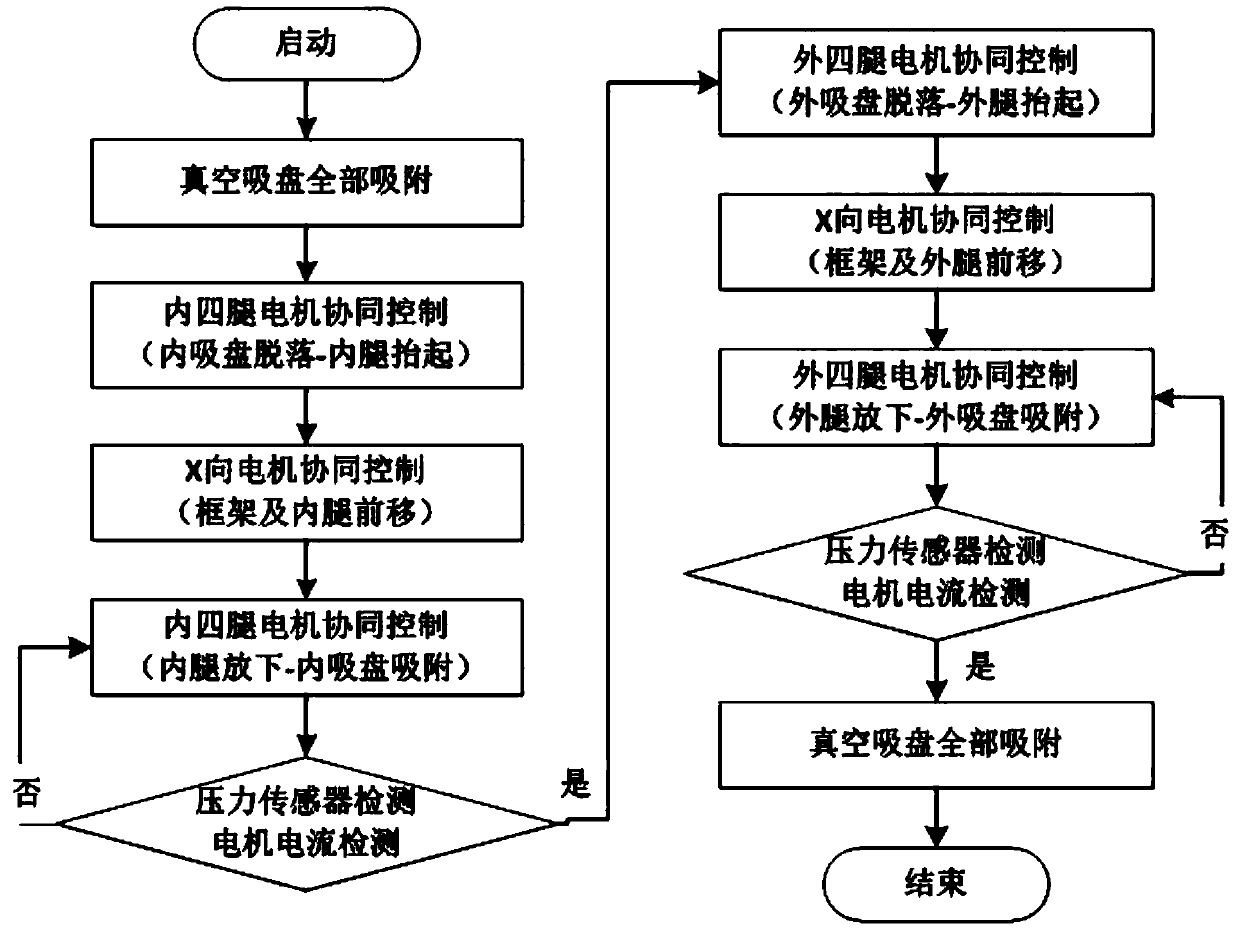

[0075] Specific implementation of robot adsorption walking technology

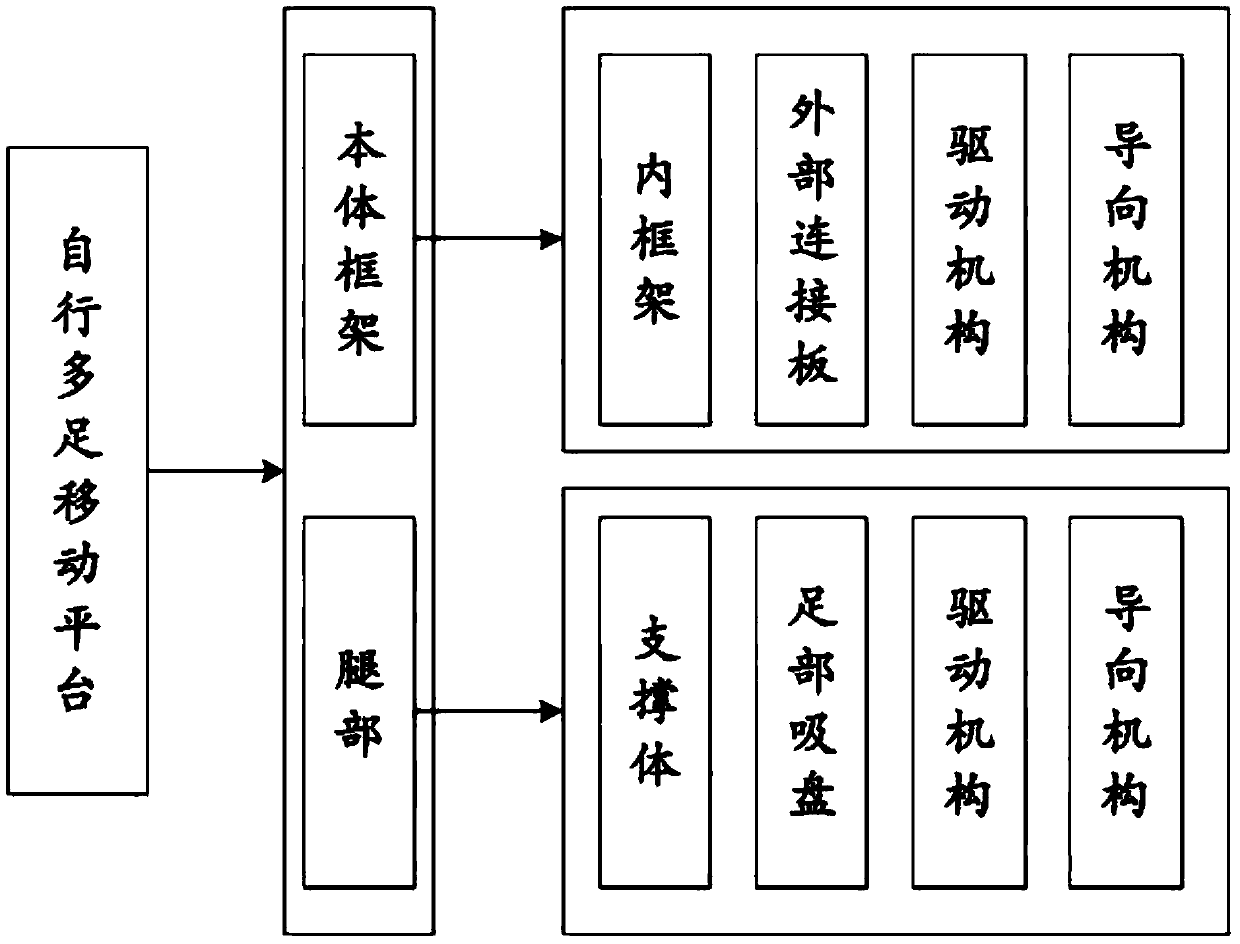

[0076] The autonomous crawling drilling and riveting system of the present invention adopts an inner and outer double-layer structure, and the system as a whole is mainly divided into the following major modules: inner frame 11 and inner leg 12; outer frame 13 and outer leg 14 and inner and outer leg suction cups 14a. Wherein, the inner frame 11 and four inner legs 12 form a group, and the outer frame 13 and four outer legs 14 form a group, which alternately move to realize the self-propelled function; each leg end is equipped with a vacuum suction cup to complete the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com