Turbo engine having steam tapping

A technology for turbines and inner shells, which is applied to gas turbine devices, mechanical equipment, engine components, etc., and can solve the problems of axial positioning restrictions of exhaust ports, heat consumption and power reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

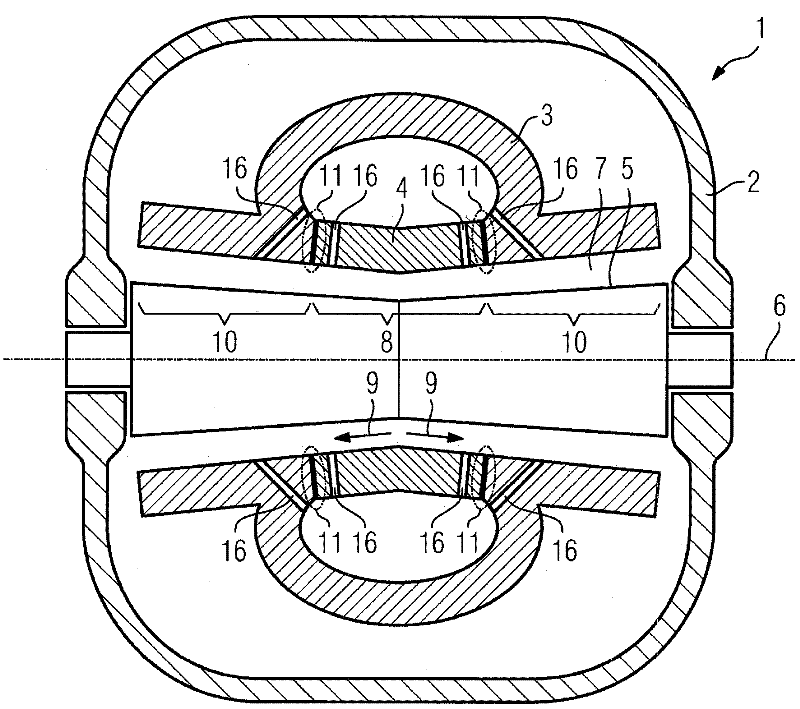

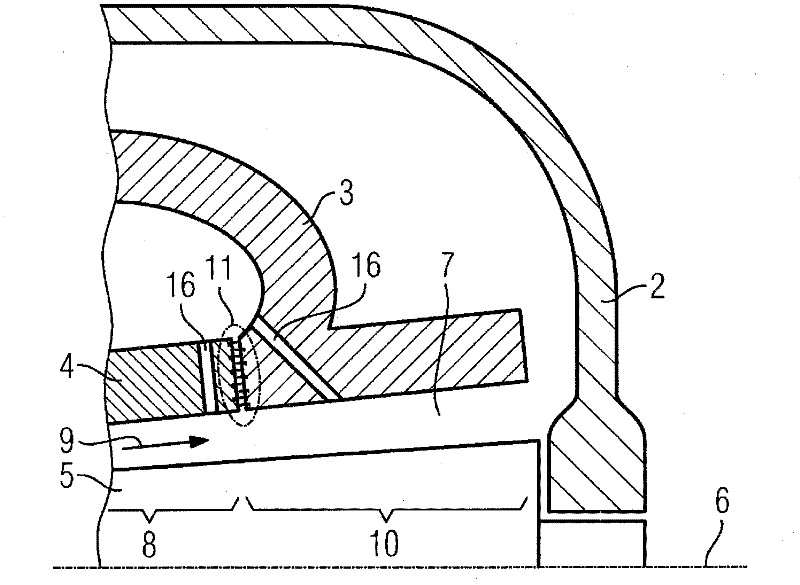

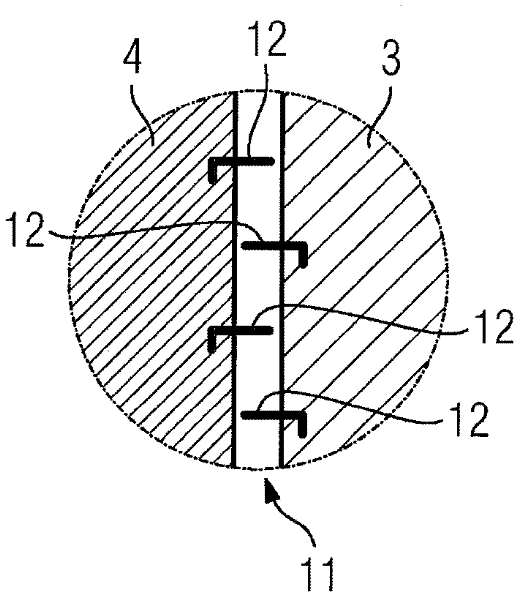

[0020] figure 1 The steam turbine 1 shown as an embodiment of a turbomachine basically comprises an outer housing 2 , an outer inner housing 3 arranged in the outer housing 2 and an inner inner housing 4 arranged in the outer inner housing 3 .

[0021] In the outer inner housing 3 and the inner inner housing 4 , a rotor 5 is mounted rotatably about an axis of rotation 6 . Flow channels 7 are formed between the outer inner housing 3 and the rotor 5 and between the inner inner housing 4 and the rotor 5 . For the sake of clarity, the individual rotor blades and guide blades are not shown in detail. The guide vanes are arranged on the inner inner housing 4 and on the outer inner housing 3 . On the rotor 5 the moving blades are arranged such that in the flow channel 7 the thermal energy of the steam can be converted into rotational kinetic energy. First, steam flows through a steam inlet region (not shown in detail) into the first flow region 8 which is arranged between the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com