Kinematics calibration method of measurement robot

A technology for measuring robots and kinematics, applied in the field of measurement, can solve the problems of difficult automation, laborious, time-consuming, etc., and achieve the effect of long installation time, low cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

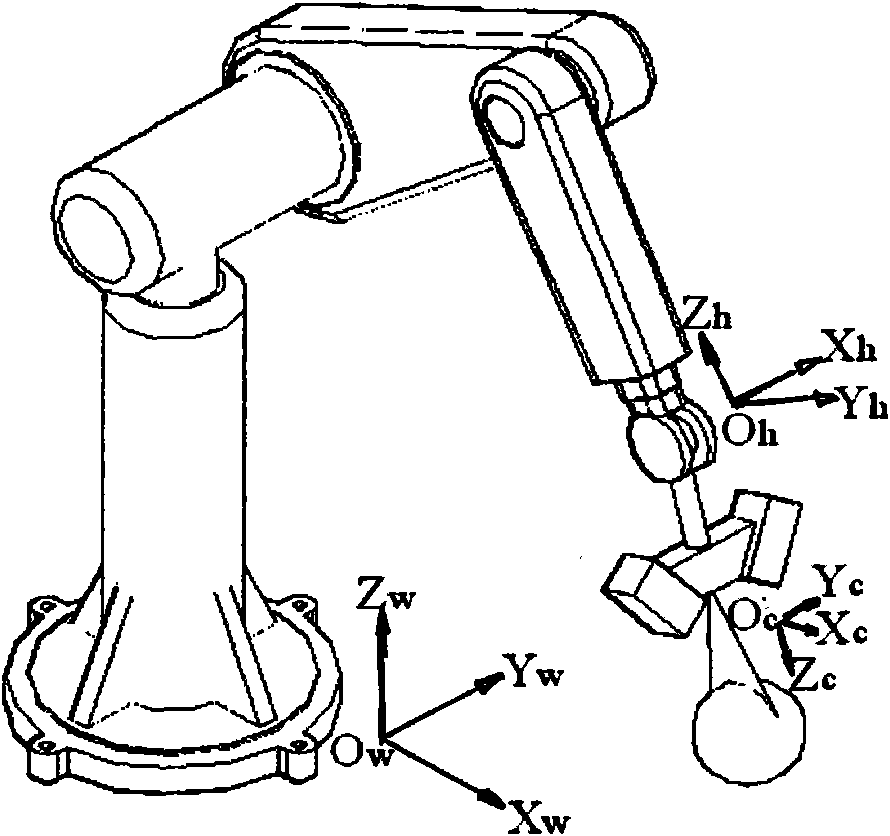

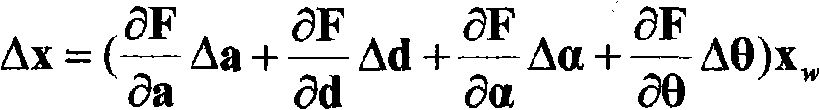

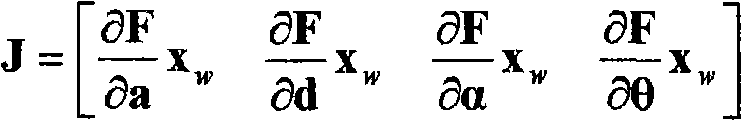

[0009] Industrial robots generally have an open-loop motion structure, and the angle value of each axis can be determined through an angle measuring device. By establishing the corresponding homogeneous equation on each axis and constructing the motion model of the robot, the end position and posture of the robot can be determined. Determining the homogeneous transformation matrix of each axis of the robot requires four parameters: connecting rod length a, connecting rod offset d, connecting rod torsion angle α, and shaft rotation angle θ. By multiplying these homogeneous matrices together, the pose of the end of the robot can be determined. In this article, the structured light sensor is installed at the end of the robot. Suppose the pose matrix of the sensor coordinate system relative to the robot end coordinate system is H, and the pose matrix of the sensor coordinate system relative to the robot base coordinate system

[0010] T=F(a, d, α, θ, H)

[0011] Since the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com