Light-emitting diode (LED)-exposed waterproof perforated lamp string and manufacturing process thereof

A technology of LED lamp beads and perforated lamps, which is applied in gas/waterproof devices, electric lamp circuit layout, and damage prevention measures of lighting devices, etc., can solve problems such as affecting the service life of LED lamps, poor waterproof performance, and electrical safety accidents. To achieve the effect of good light color consistency, excellent aging resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is a detailed description and illustration of the LED exposed waterproof perforated light string according to the present invention in conjunction with the accompanying drawings. Any additions, subtractions, substitutions and improvements made in violation of the spirit of the present invention are within the technical solutions claimed by the present invention.

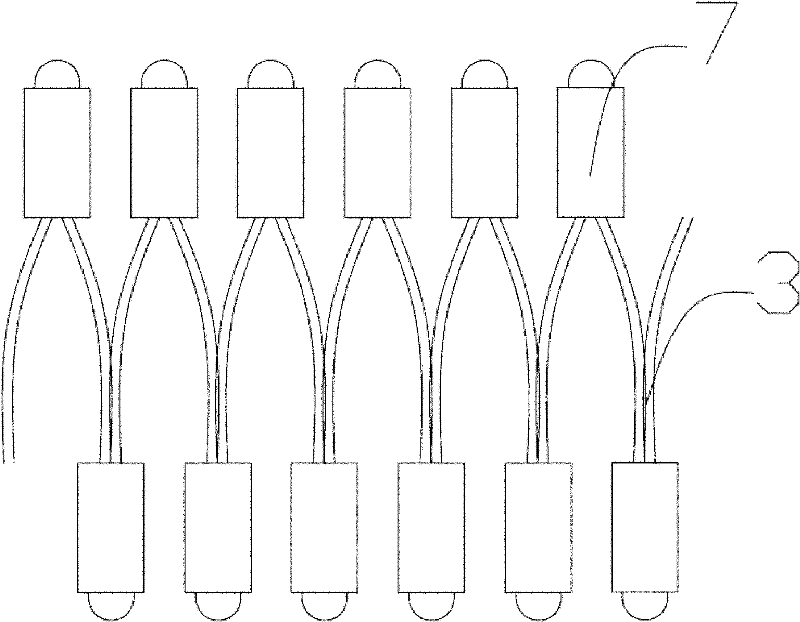

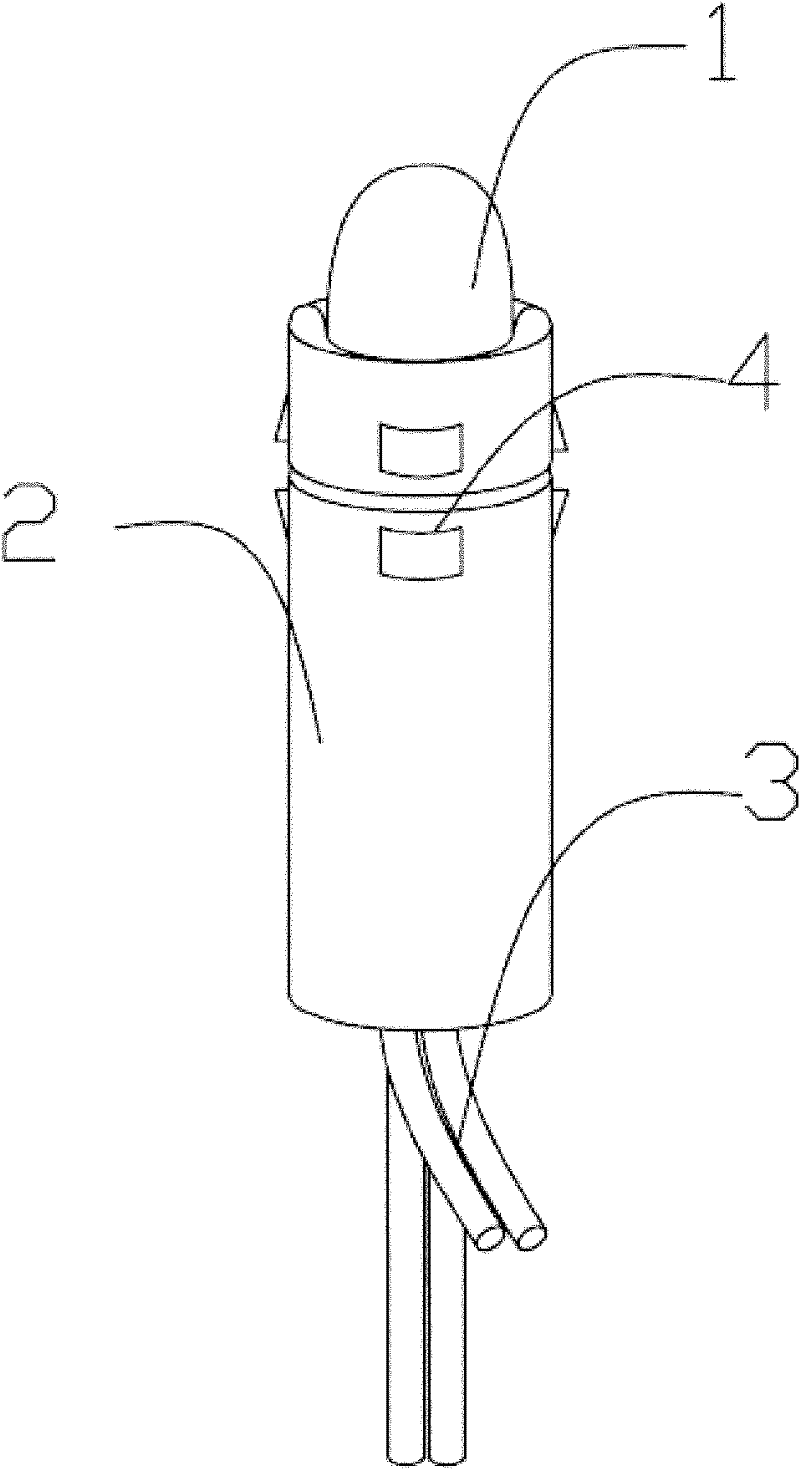

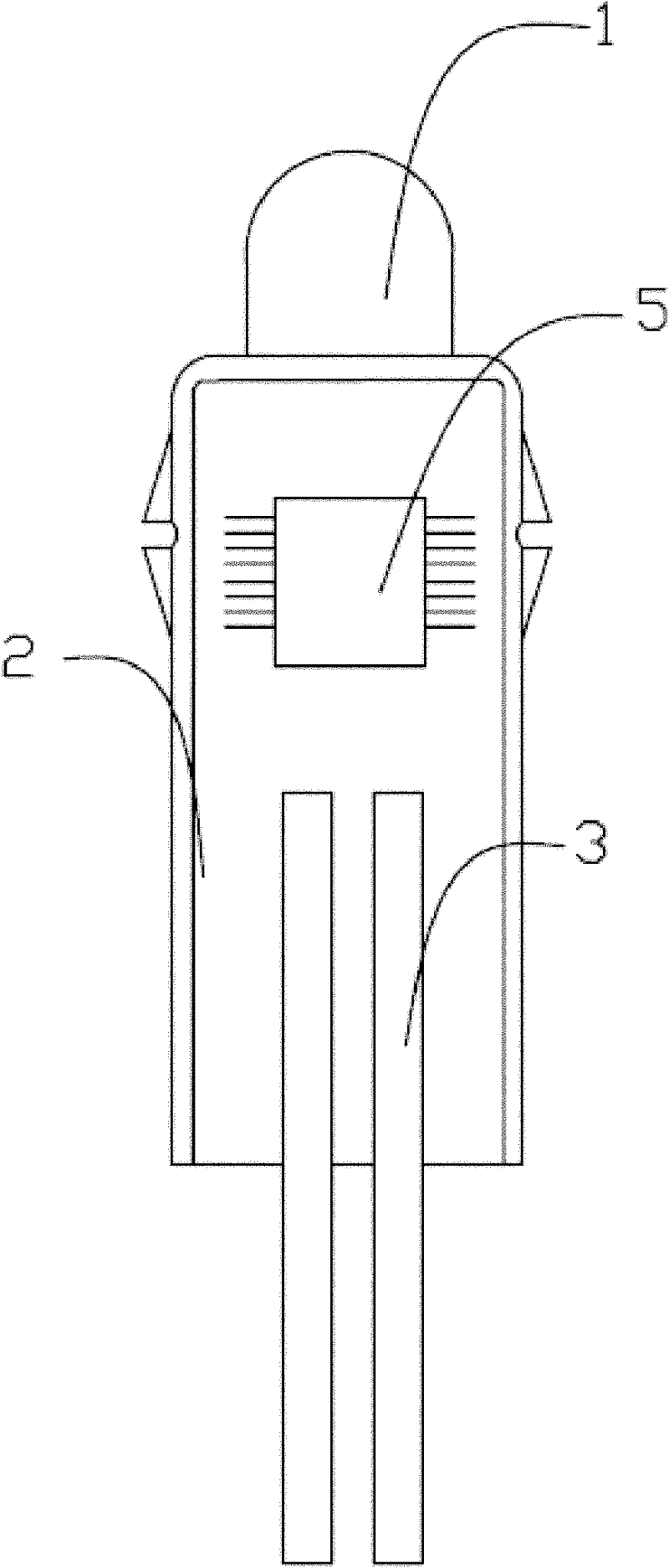

[0041] like Figure 1-3 As shown, the LED exposed waterproof perforated lamp string according to the present invention is composed of a plurality of perforated lamps 7 electrically connected to each other and arranged according to certain rules. Each perforated lamp 7 is composed of LED lamp beads 1, circuit board 5, rubber sleeve 2, The lead wire 3 is formed, wherein, the LED lamp bead 1 is located at the top of the perforated lamp 7, and the shape can be a straw hat shape or a round head shape; the circuit board 5 is provided with a The control circuit of the bead, the lead wire 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com