Patents

Literature

68results about How to "Improve light color consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

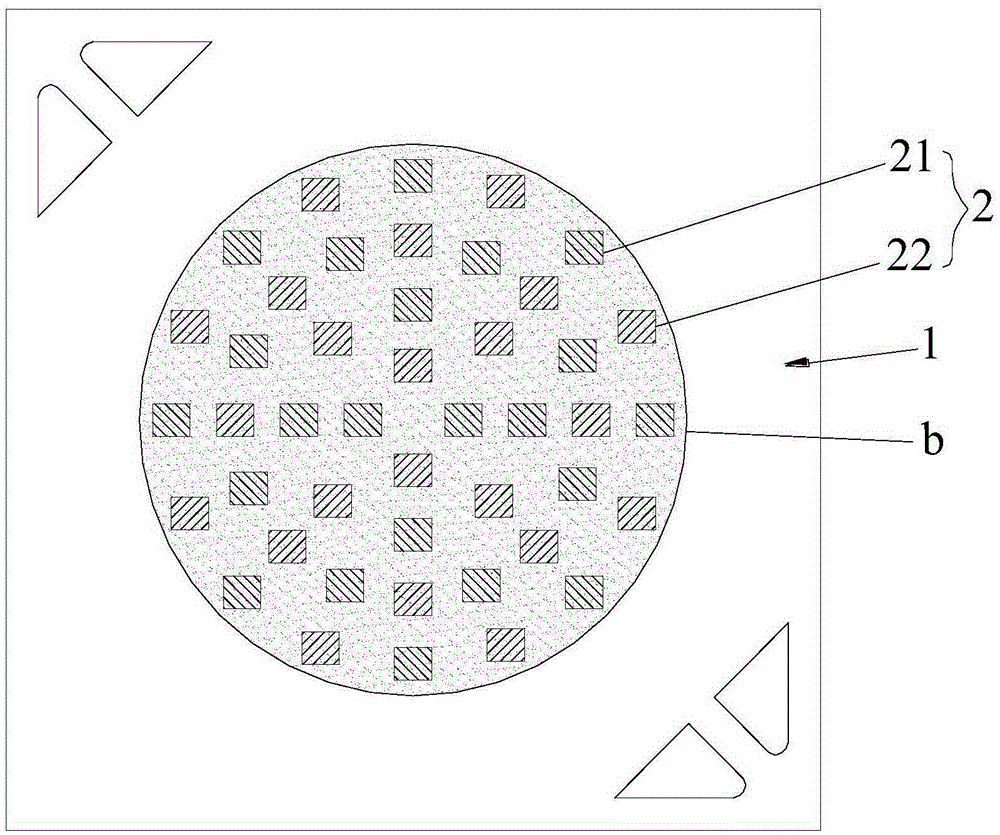

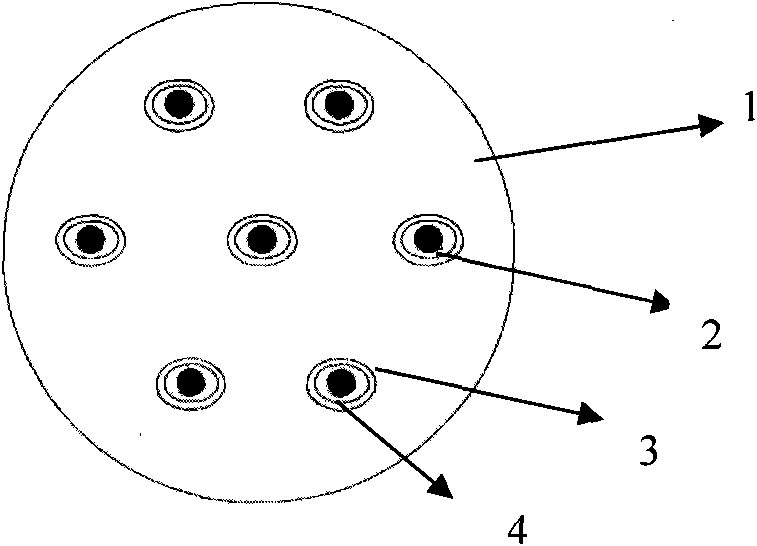

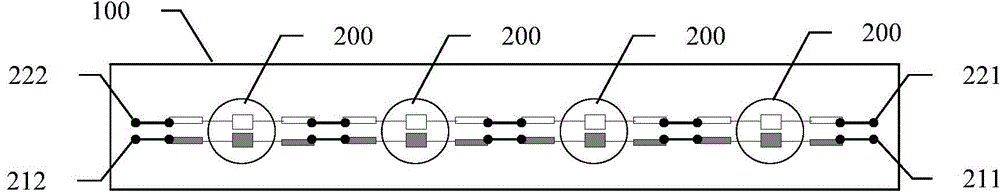

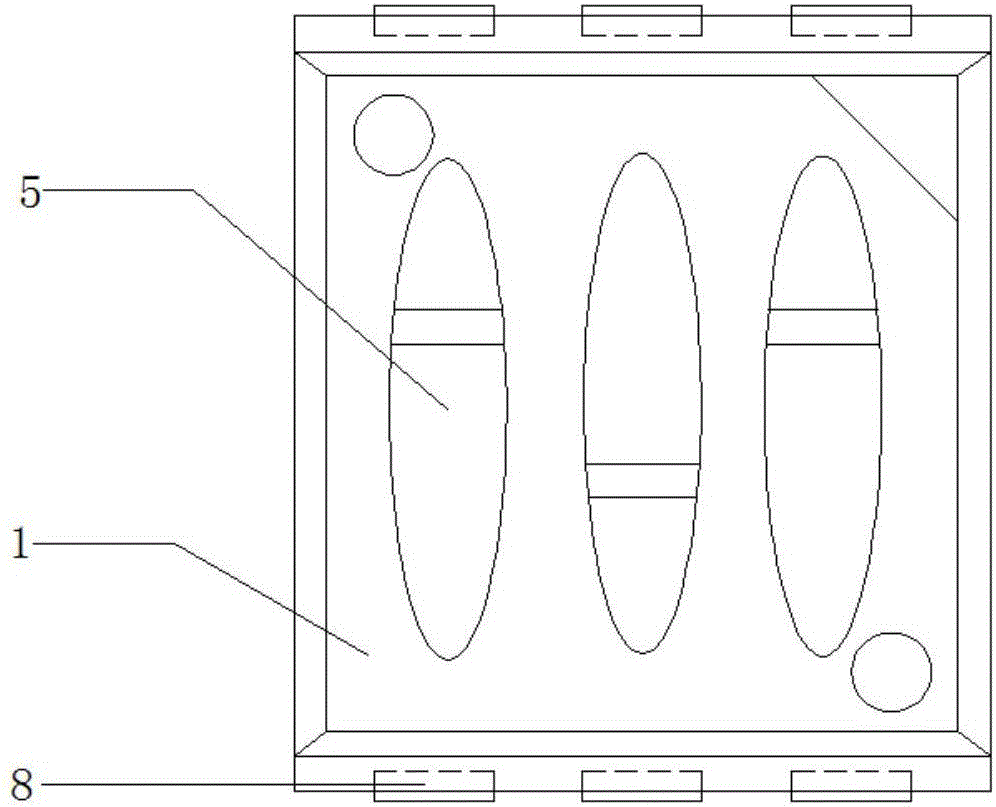

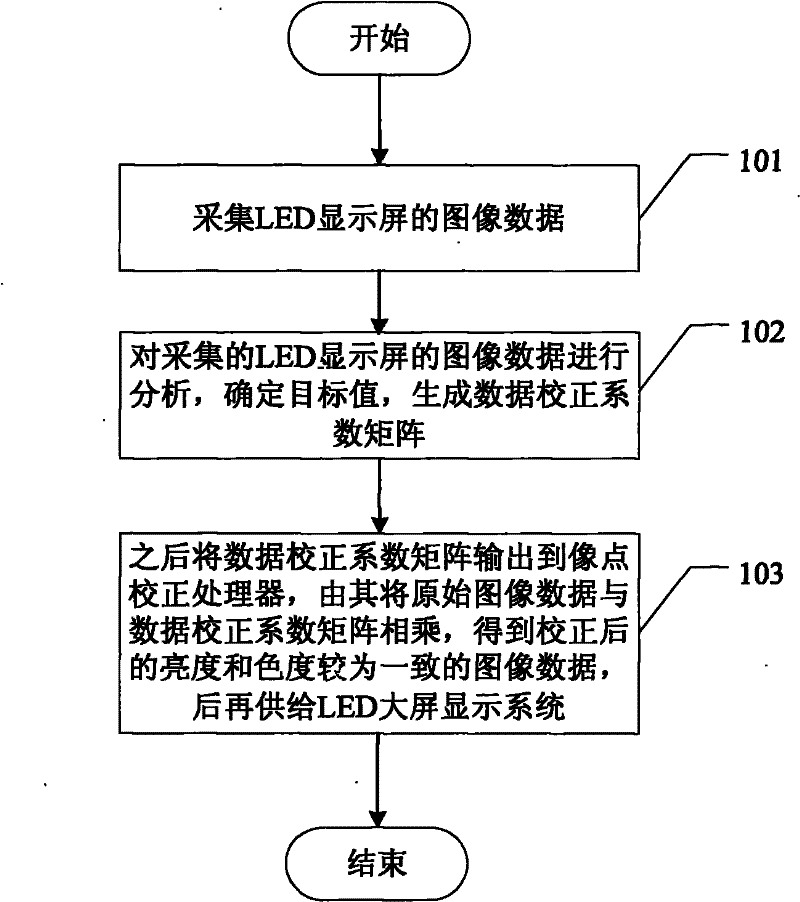

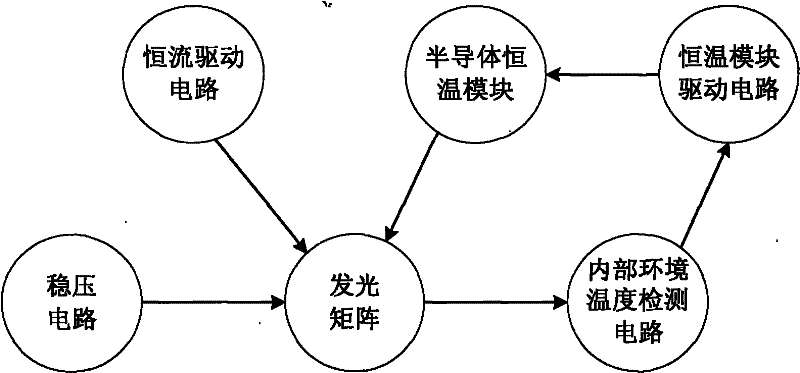

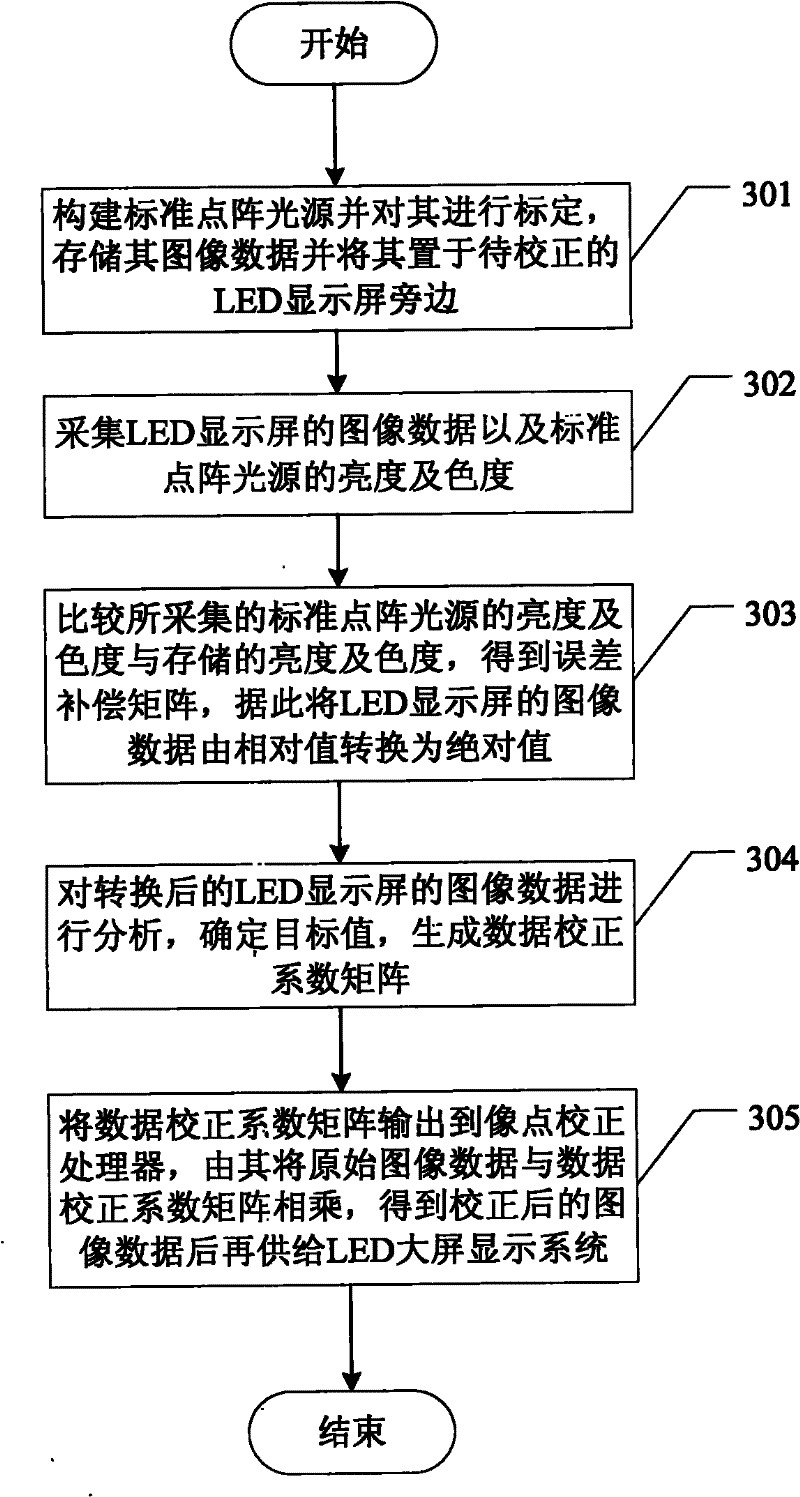

Standard dot matrix light source and image point correction method of LED display screen

InactiveCN102005181AImprove light color consistencyGood white balanceStatic indicating devicesElectric light circuit arrangementDot matrixLight-emitting diode

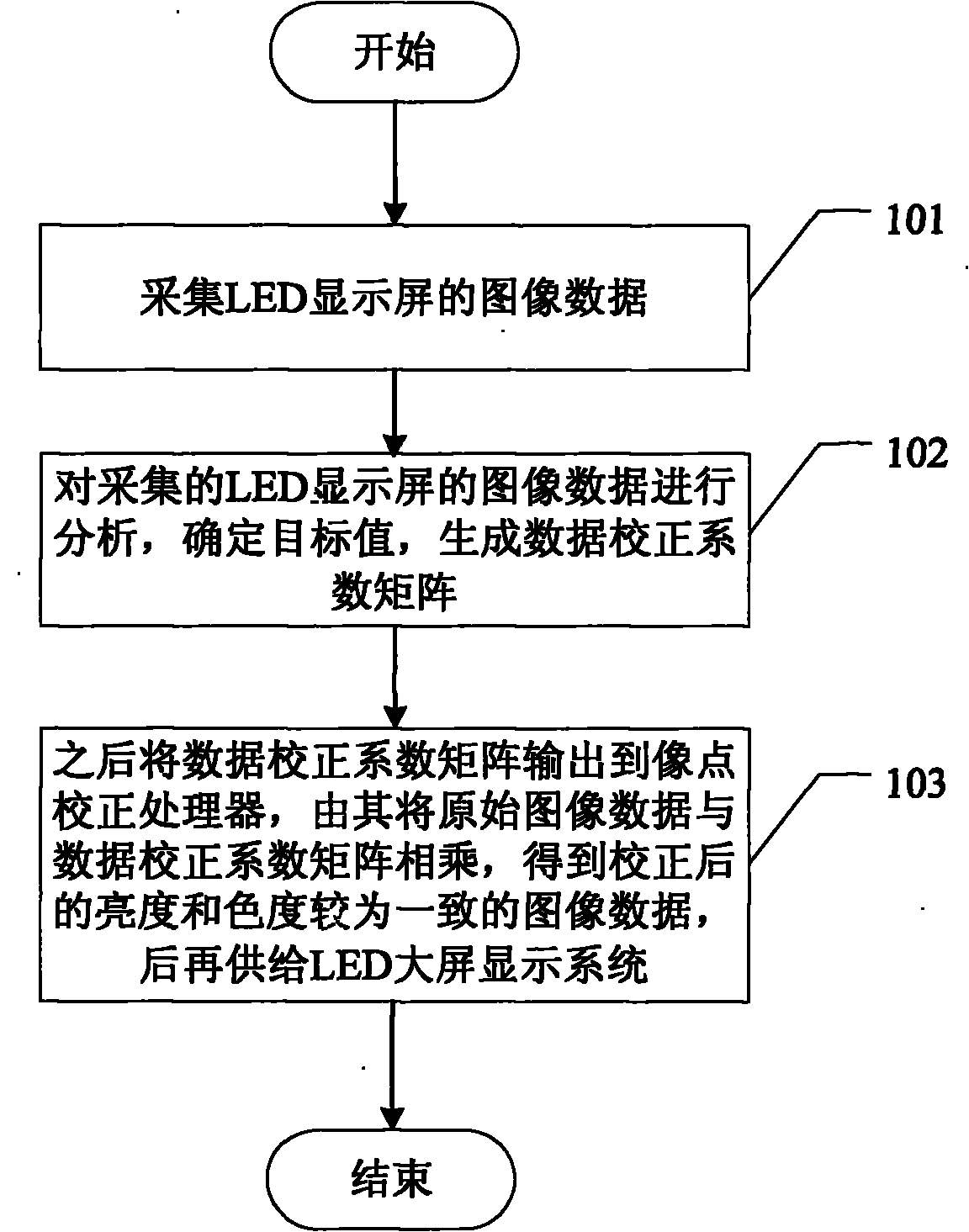

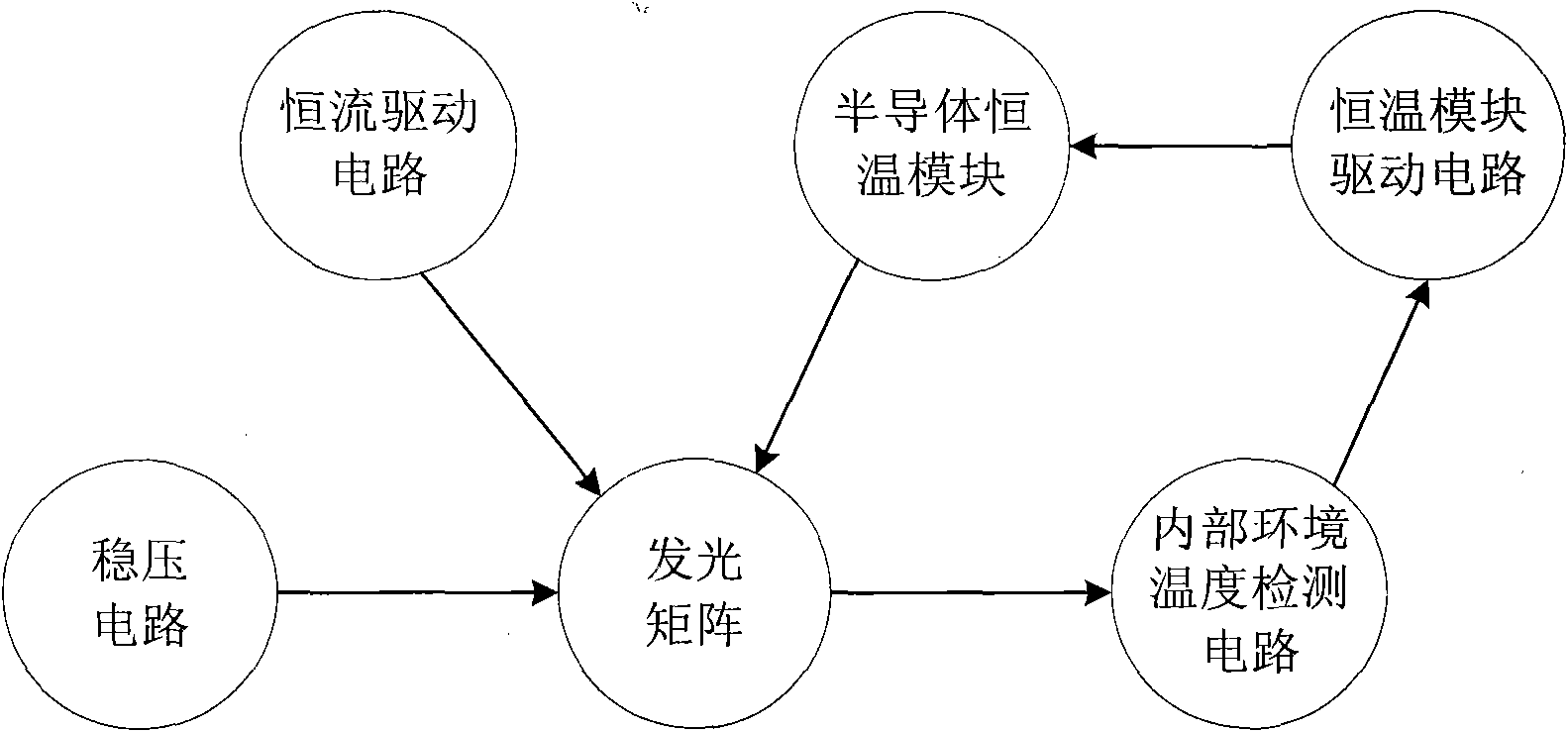

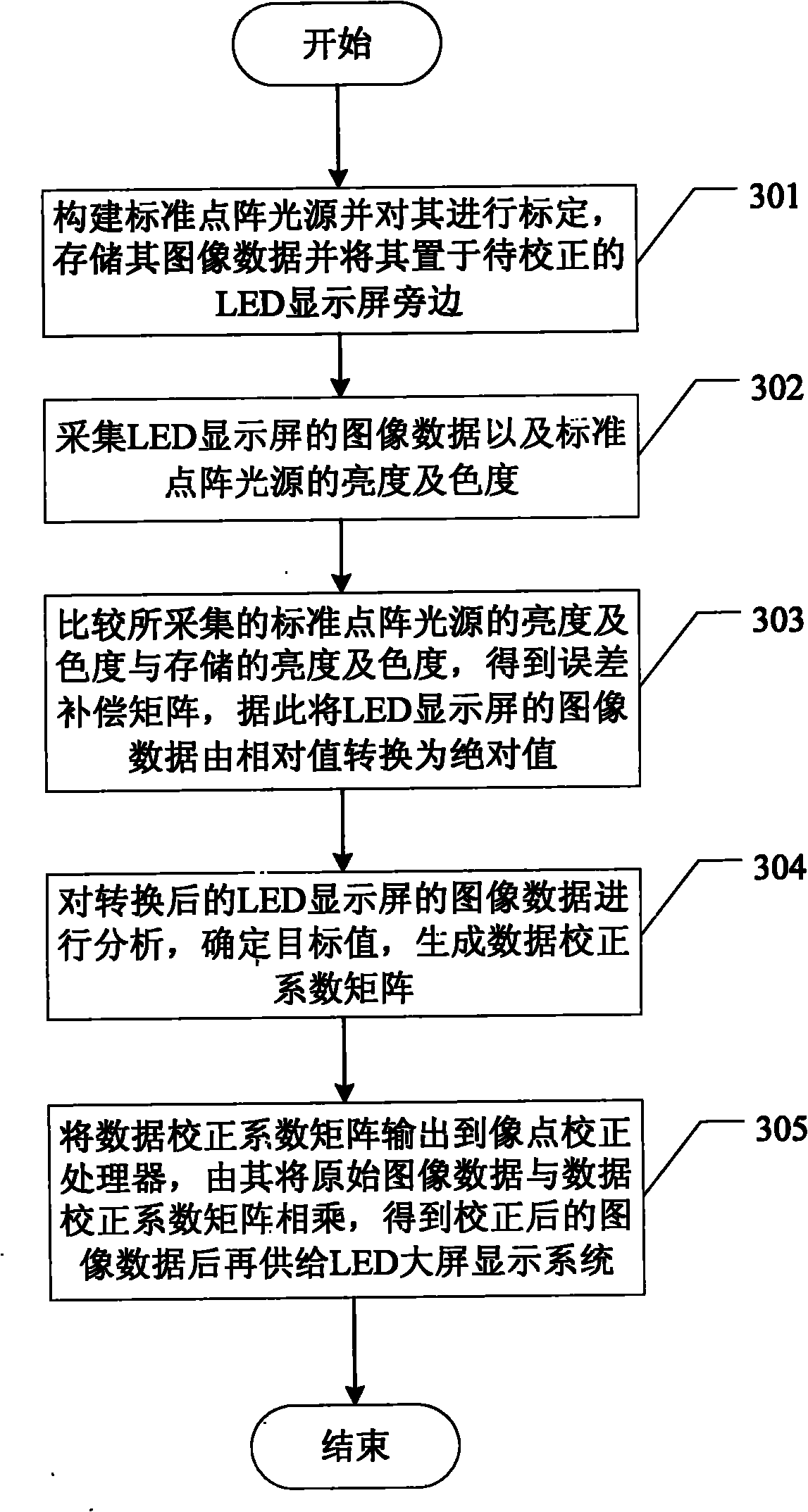

The invention discloses a standard dot matrix light source and an image point correction method of a light-emitting diode (LED) display screen. The method comprises the following steps of: A, constructing the standard dot matrix light source, and calibrating the brightness and the chroma of the standard dot matrix light source; B, acquiring image data of the LED display screen, and the brightness and the chroma of the standard dot matrix light source; C, comparing the acquired brightness and chroma of the standard dot matrix light source with a stored value to obtain an error compensation matrix, and converting the image data of the LED display screen from a relative value into an absolute value; D, analyzing the converted image data of the LED display screen to generate a data correction coefficient matrix; and E, outputting the data correction coefficient matrix to an image point correction processor to perform image data correction processing so as to obtain corrected image data according to the data correction coefficient matrix, and finally outputting the corrected image data to an LED large screen display system. The standard dot matrix light source and the image point correction method can overcome adverse effects caused by working condition drifting of a camera to ensure that the LED display screen has better light-color consistence and white balance after performing the image point correction; and an additional light colorimeter is not needed, and a plurality of times of tests are not performed any more.

Owner:GTEK GRP LTD

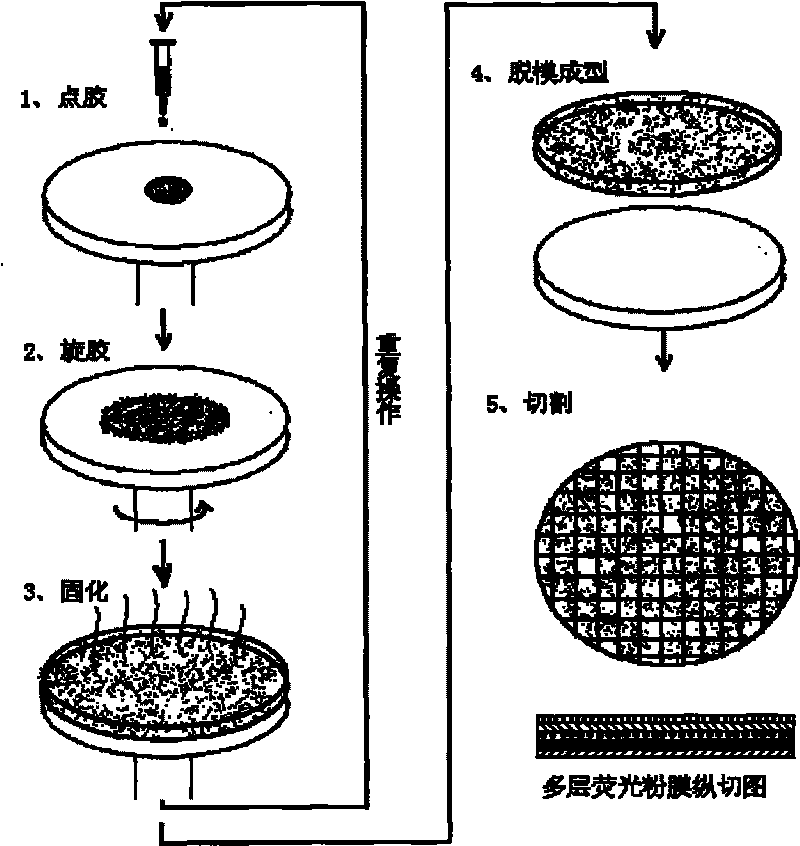

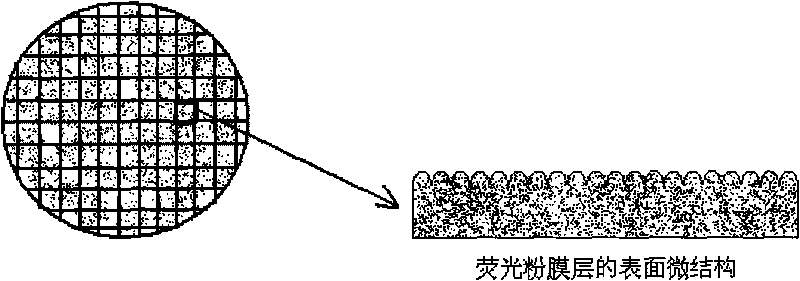

Phosphor powder film making method and obtained phosphor powder film encapsulating method

InactiveCN101699638AStable jobEasy to prepareSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorWhite light

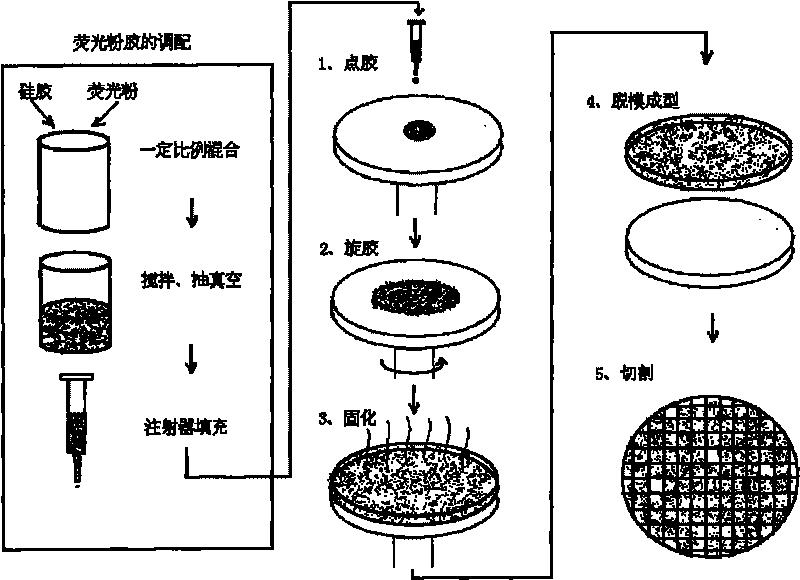

The invention discloses a phosphor powder film making method and obtained phosphor powder film encapsulating method. The invention is characterized in that a method spinning phosphor powder glue is adopted to independently make phosphor powder film in encapsulating process, then the phosphor powder film is covered on an LED chip coated with heat insulating material, and finally the heat insulating material is cured to complete white-light LED phosphor powder coating. The quantity of LED chip is one or more than one. The invention is simple in technology and low in making cost, can accurately control the thickness of phosphor powder film, greatly improves light color consistency of LED product, is applicable to large scale industrialized production and adopts heat insulating encapsulating manner to solve heat dissipation problem of LED and reduce lumens depreciation, so that light color is more stable.

Owner:SUN YAT SEN UNIV

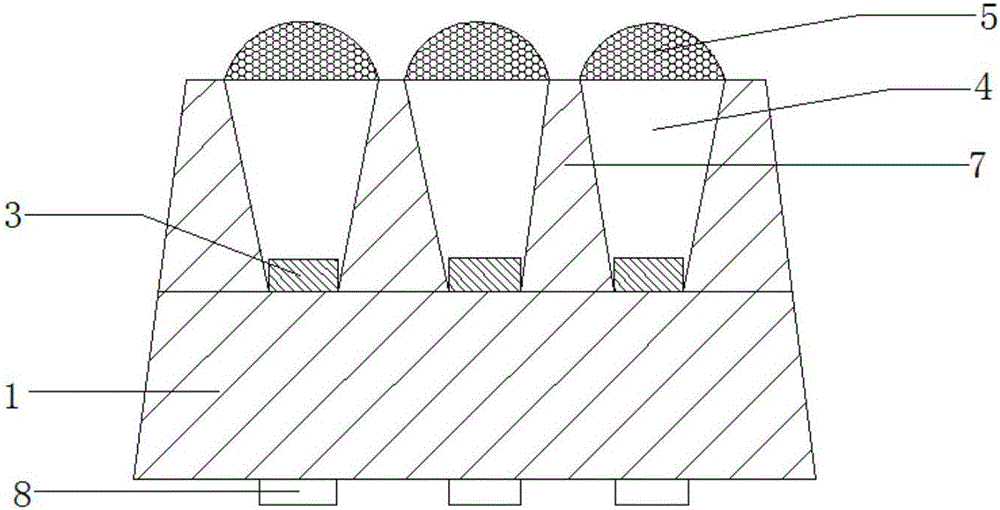

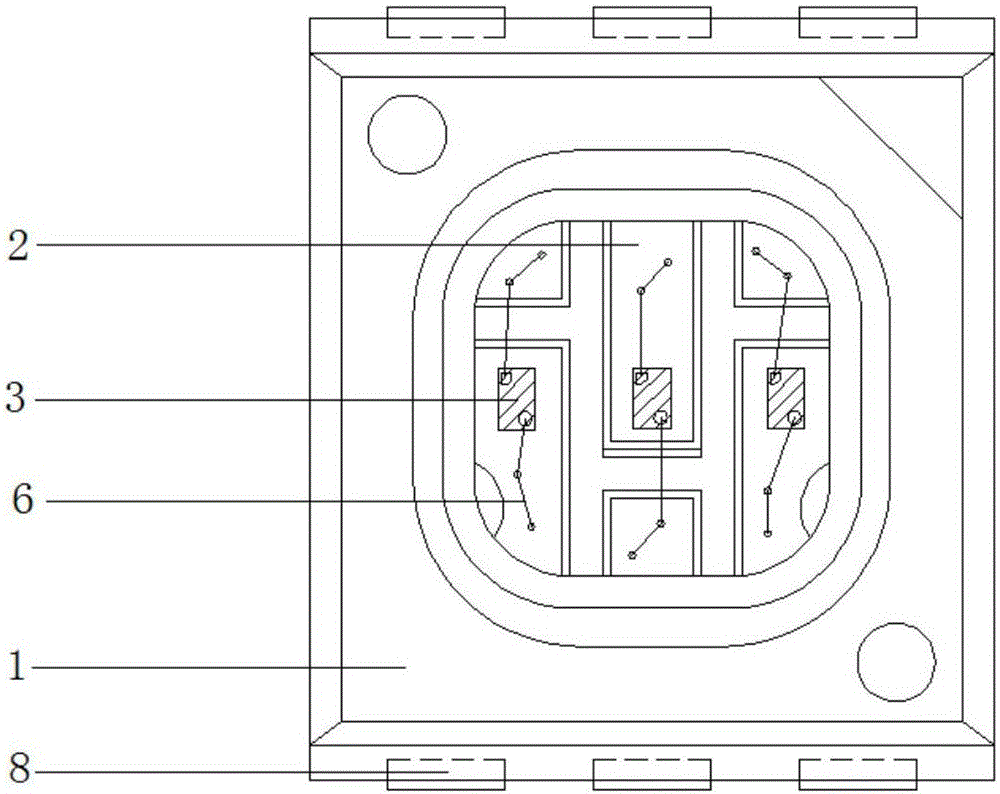

White light emitting diode and white light emitting diode lamp

InactiveCN101881381AGood colorImprove efficiencyPoint-like light sourceElectric circuit arrangementsElectricityHeat conducting

The invention discloses a white light emitting diode with high color rendering property and a white light emitting diode lamp. The white light emitting diode comprises a heat conducting substrate, a light reflecting cup, a light emitting diode chip and a lead wire frame, wherein the light reflecting cup plays a light mixing role, and small protrusions are arranged on the inner wall surface of the light reflecting cup; the light emitting diode chip outputs at least six lights in different colors and is arranged on the heat conducting substrate to carry out electric combination; the lead wire frame is matched with the bottom of a light emitting cup in shape and size, arranged outside the light reflecting cup, and fixed on the upper surface of a base; an electrode of the chip is electrically connected with a lead wire on the lead wire frame, and a transparent optical material is covered on the chip; and polychromatic lights are evenly mixed through the diffuse reflection of a reflecting wall of the light reflecting cup to produce the white light emitting diode with high color rendering property and high efficiency. By applying the white light emitting diode lamp made of the white light emitting diode and a flat light source, the white light emitting diode lamp eliminates the light energy loss of fluorescent powder in the photochromic conversion process, thereby having high electro-optical conversion efficiency, long service life and convenient batched production.

Owner:宁波晶科光电有限公司

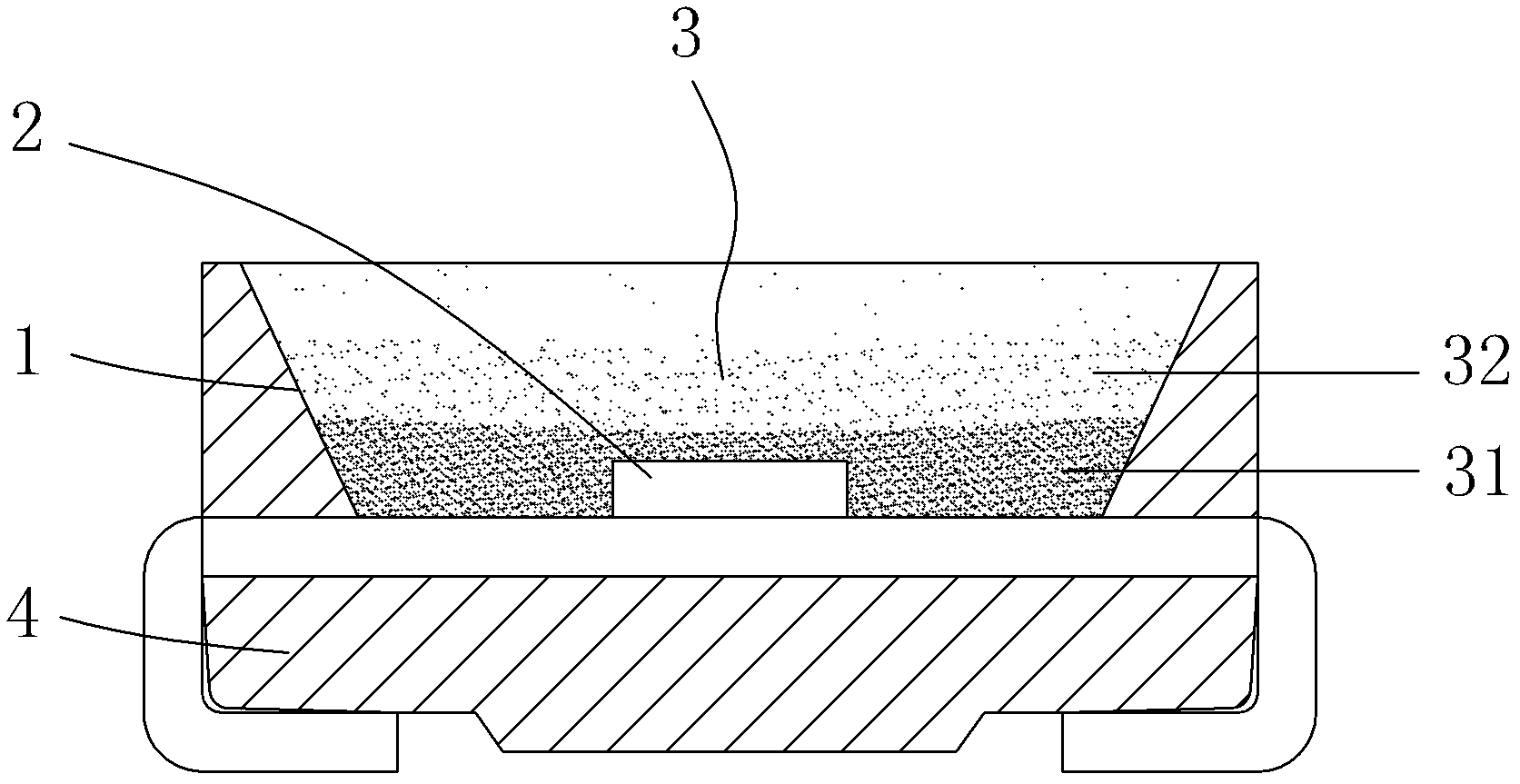

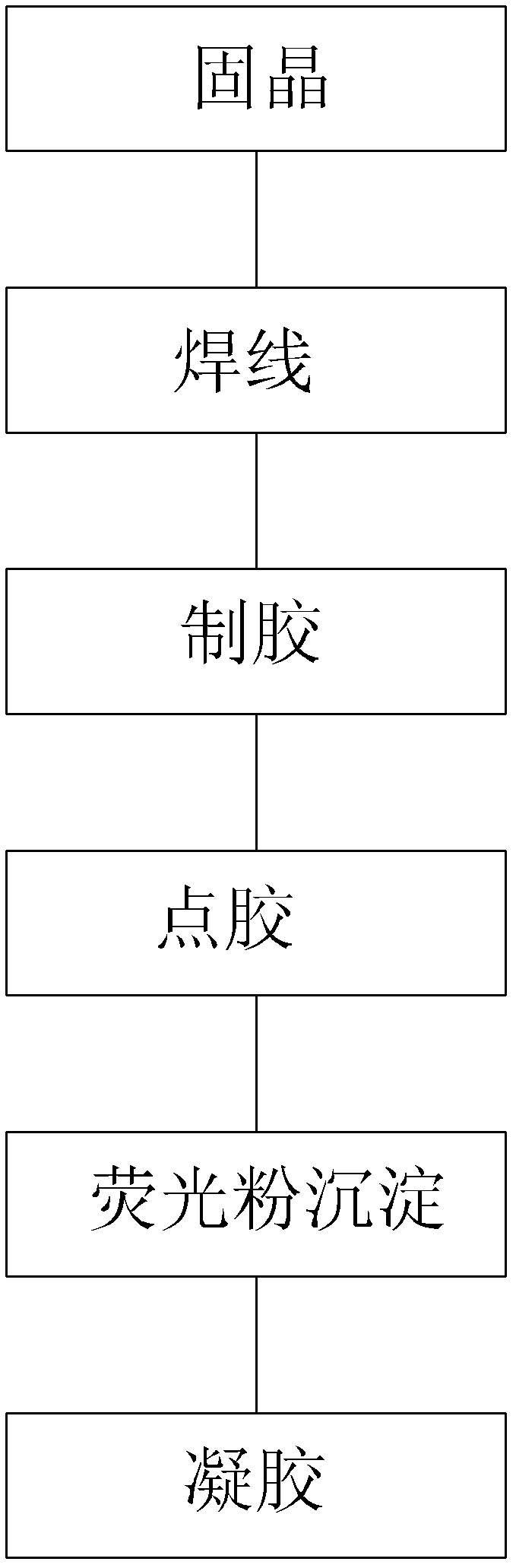

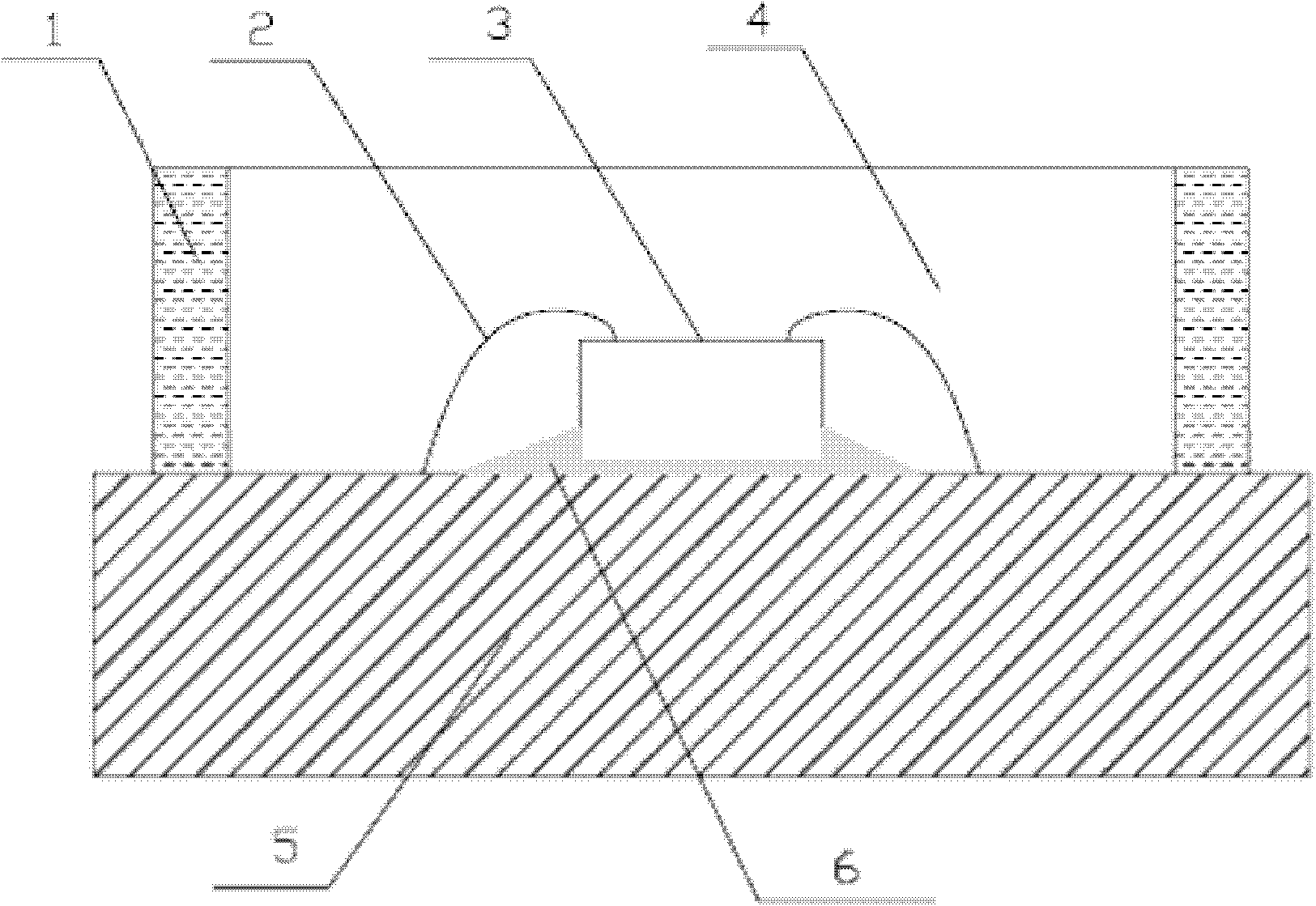

White light LED (light emitting diode) and packaging process thereof

InactiveCN102544322AImprove light color consistencyUniform densitySemiconductor devicesFluorescenceRoom temperature

The invention relates to a packaging process of a white light LED (light emitting diode). The packaging process comprises a die bonding step, a wire bonding step, an adhesive preparing step, a dispensing step, a fluorescent powder precipitating step and an adhesive solidifying step, wherein in the fluorescent powder precipitating step, one of a centrifugal precipitation method, a baking precipitation method or a room temperature natural precipitation method is adopted or more of the centrifugal precipitation method, the baking precipitation method and the room temperature natural precipitation method are combined to ensure fluorescent adhesives to be divided into an upper packaging adhesive layer and a lower fluorescent powder layer covering an LED chip in a reflecting cup to ensure at least most fluorescent powder in the fluorescent adhesives to be precipitated on the fluorescent powder layer; and in the adhesive solidifying step, the reflecting cup after precipitation is continuously put in an oven to be baked to solidify the packaging adhesives in the reflecting cup and the packaging adhesives are taken out of the reflecting cup after being solidified. By adopting the packaging process, the problem that the light colors of the white light LEDs generated by the existing packaging processes of the white light LEDs have poorer consistency is mainly solved and the aim of ensuring the consistency of the light colors of the generated white light LEDs to be better is achieved.

Owner:江西兆驰光元科技股份有限公司

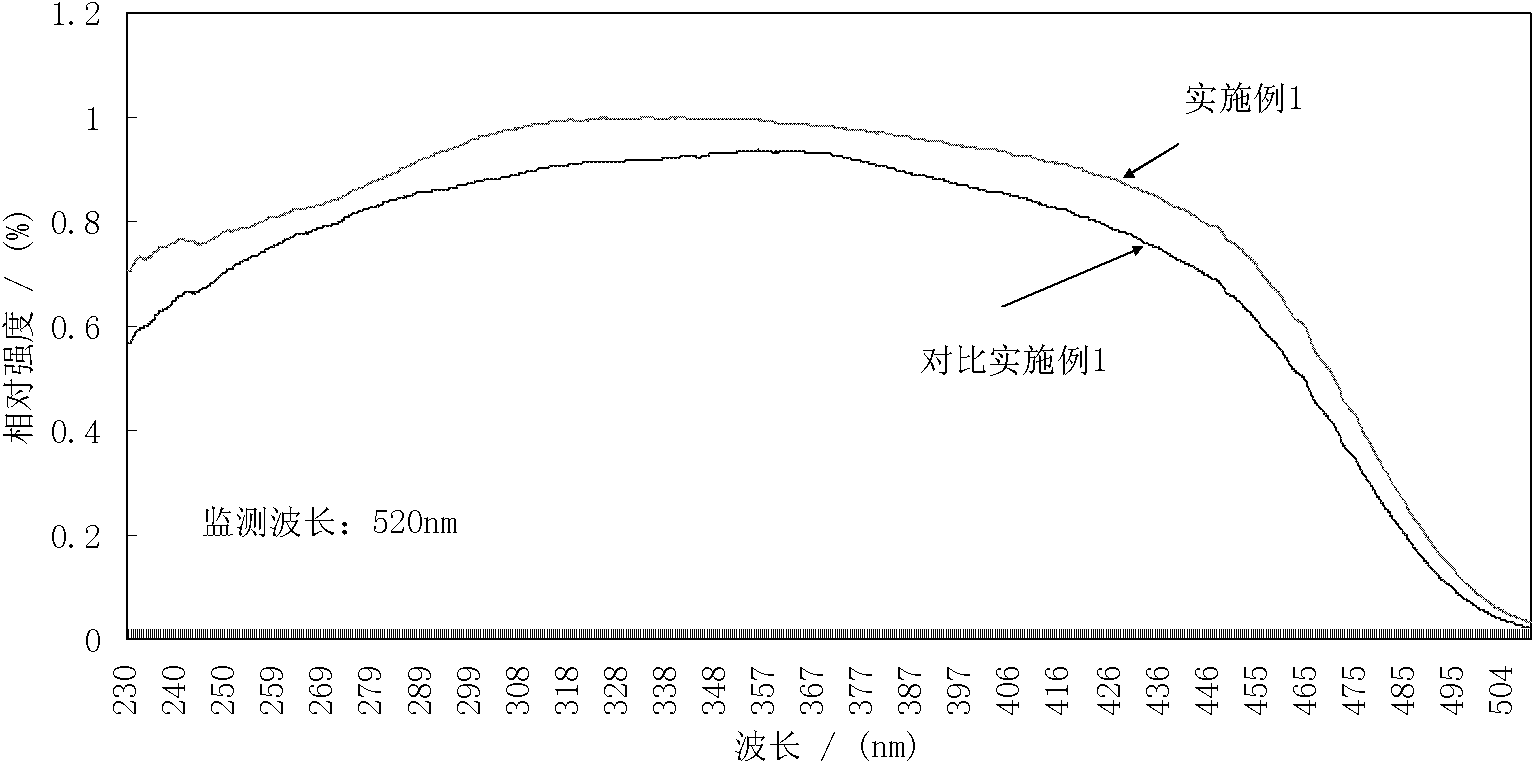

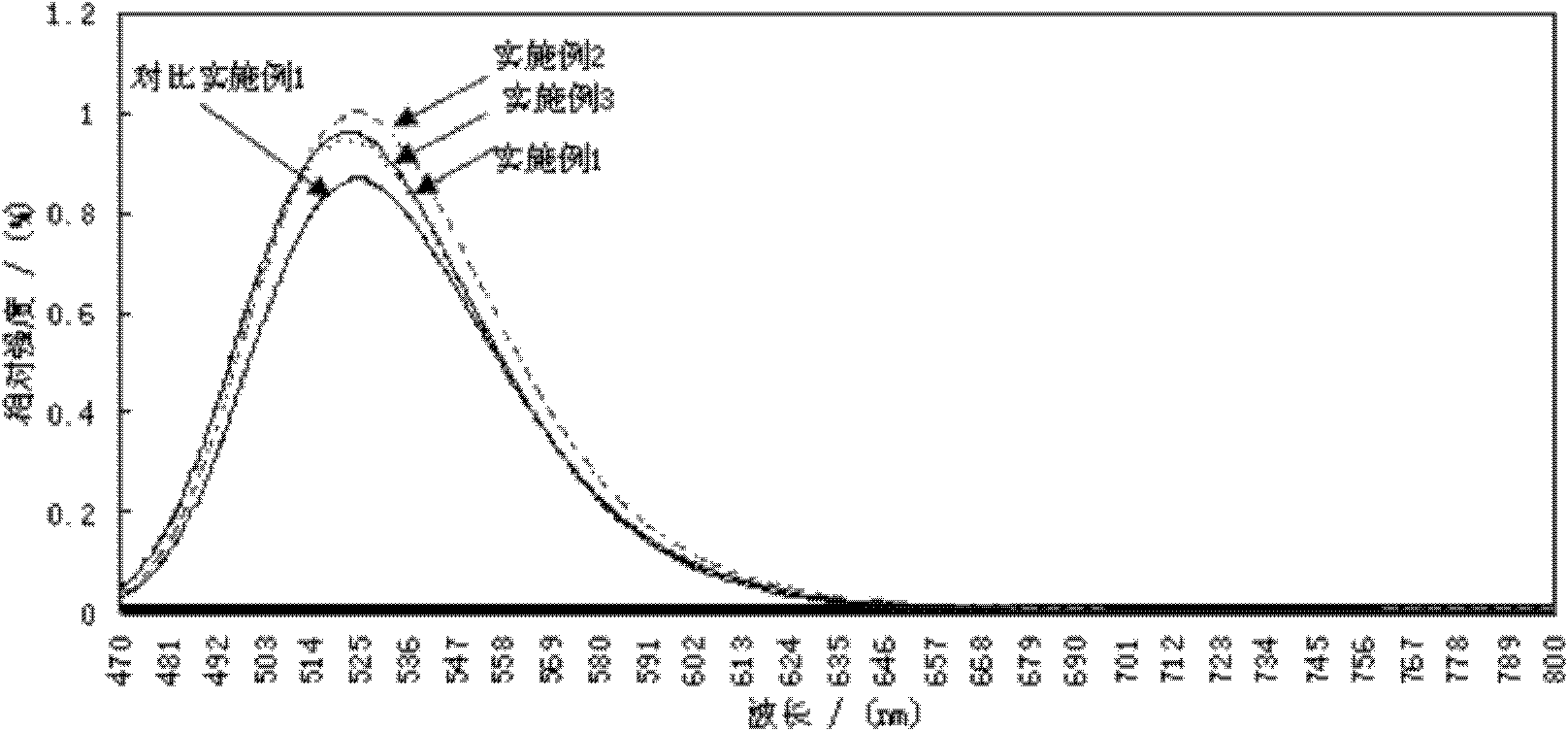

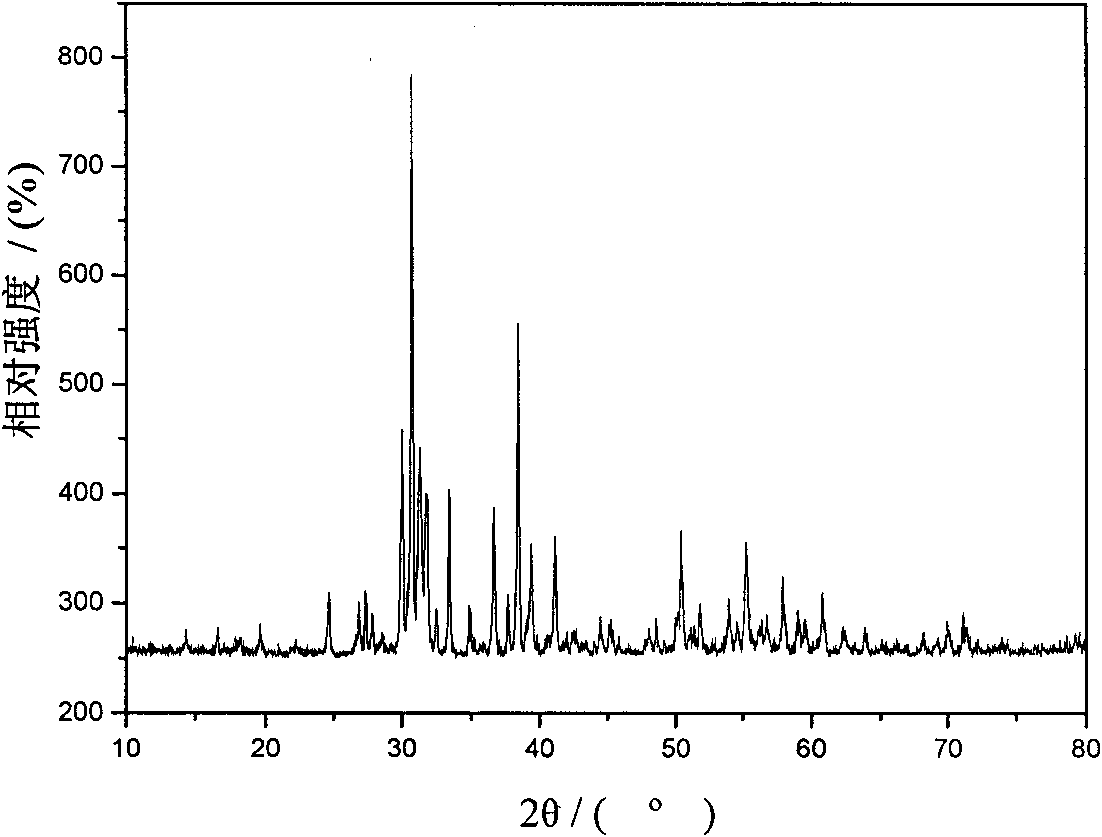

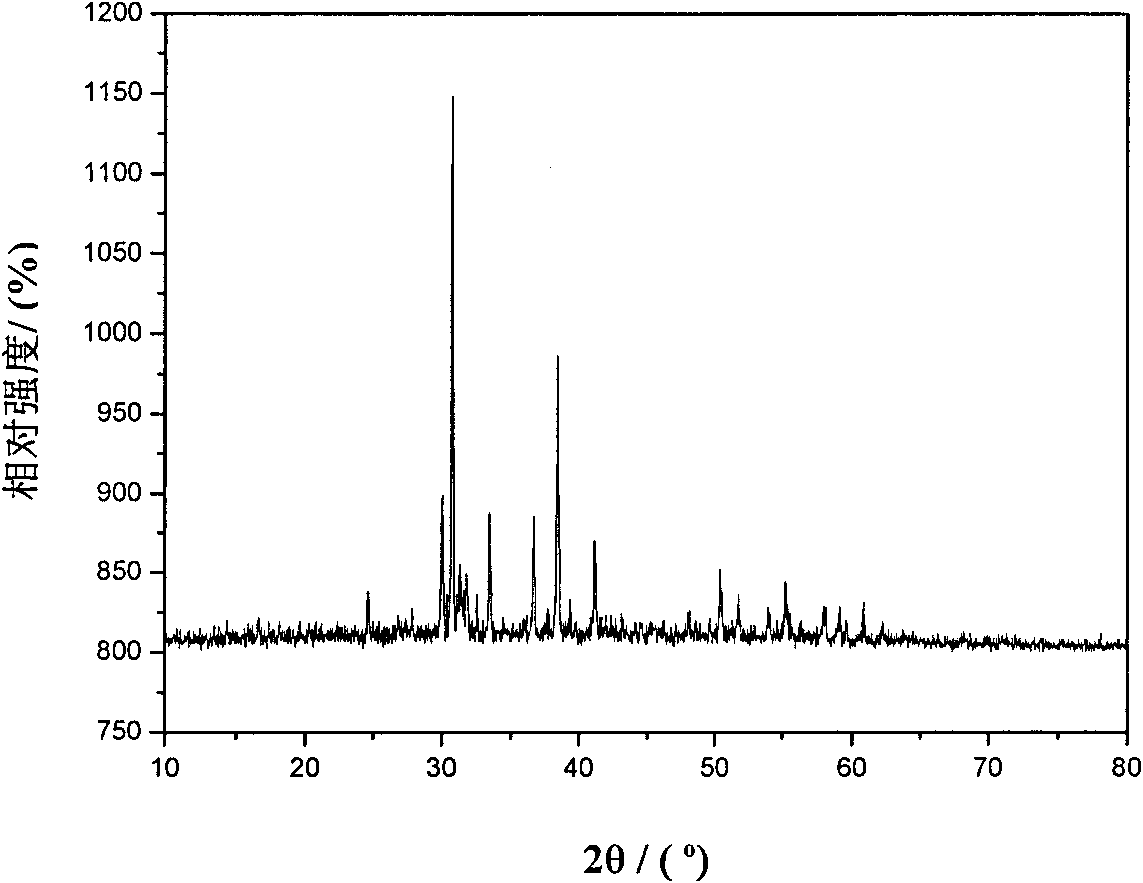

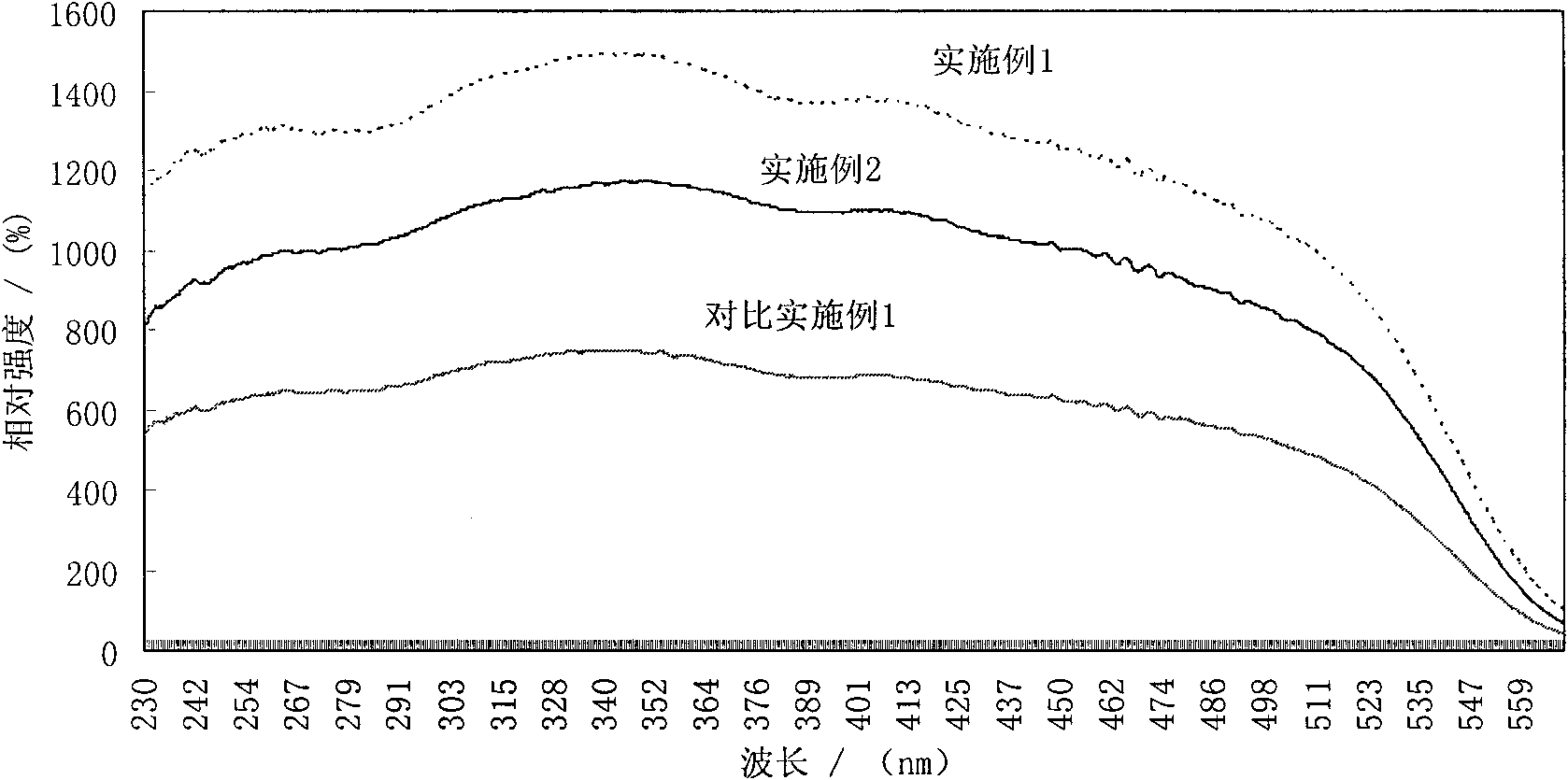

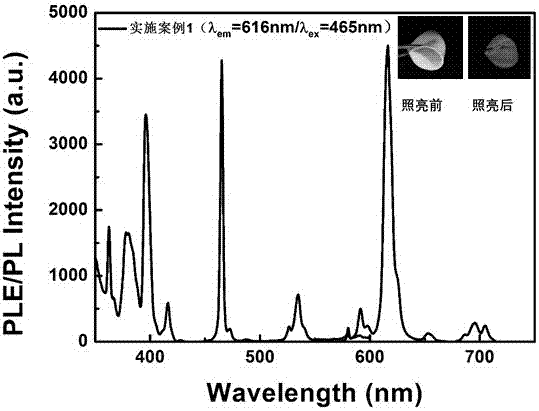

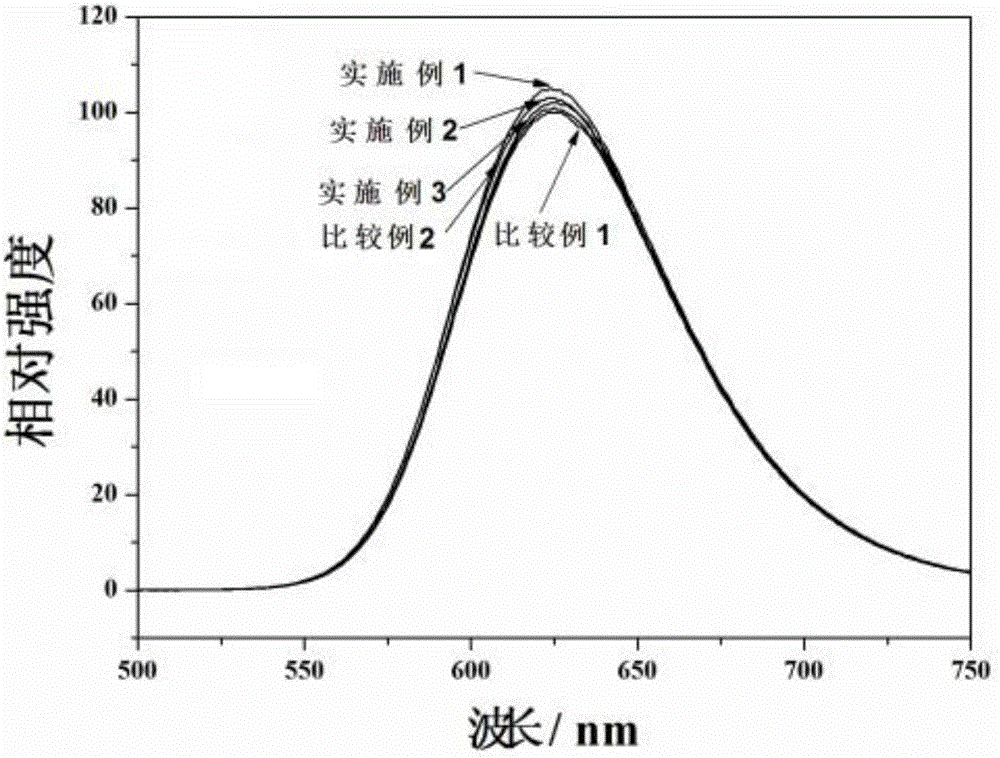

Europium-activated silicate green fluorescent powder and application thereof in white light-emitting diode

ActiveCN101851508AImprove absorption efficiencyImprove transfer efficiencyGas discharge lamp usageLuminescent compositionsTrace elementStructural formula

The invention relates to europium-activated silicate green fluorescent powder and the application thereof in a white light-emitting diode, which as excellent luminous performance and temperature quenching property. The chemical structural formula of the europium-activated silicate green fluorescent powder is shown in a formula (i): Ba(2-x-y-p)SrxMpSiqO(2+2q):Euy(i), wherein M is at least one of Sc, Y, La, Cr or Er; x is more than 0.03 and less than or equal to 0.75; y is more than 0.001 and less than or equal to 0.09; p is more than or equal to 0.0003 or less than or equal to 0.05; and q is more than or equal to 0.75 and less than 1. The europium-activated silicate green fluorescent powder can be widely applied to white light-emitting diodes. In the europium-activated silicate green fluorescent powder, bivalent europium is taken as a main activator, and trace elements, such as Sc, Y and La and / or co-activators, such as Cr and Er are doped, so the emitting intensity of the fluorescent powder is effectively enhanced and the temperature quenching property of the fluorescent powder is remarkably improved.

Owner:JIANGSU BREE OPTRONICS CO LTD

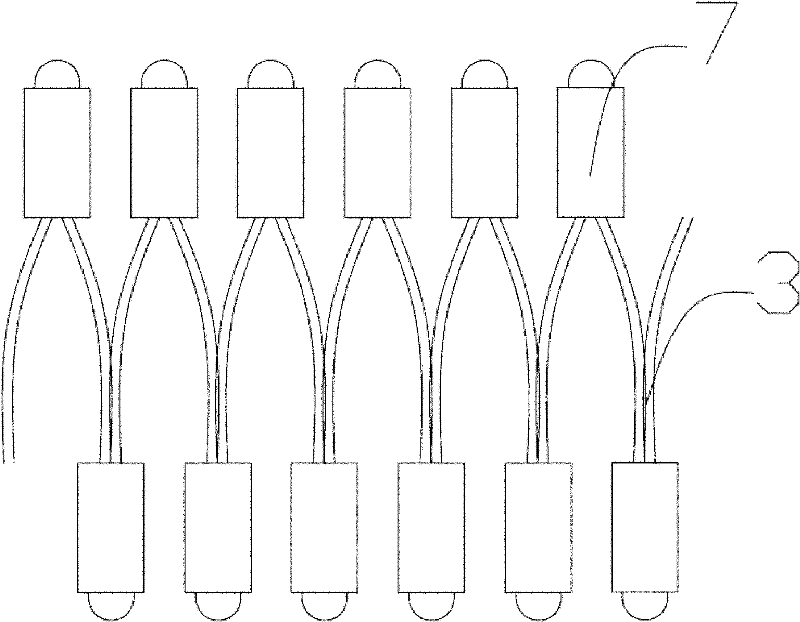

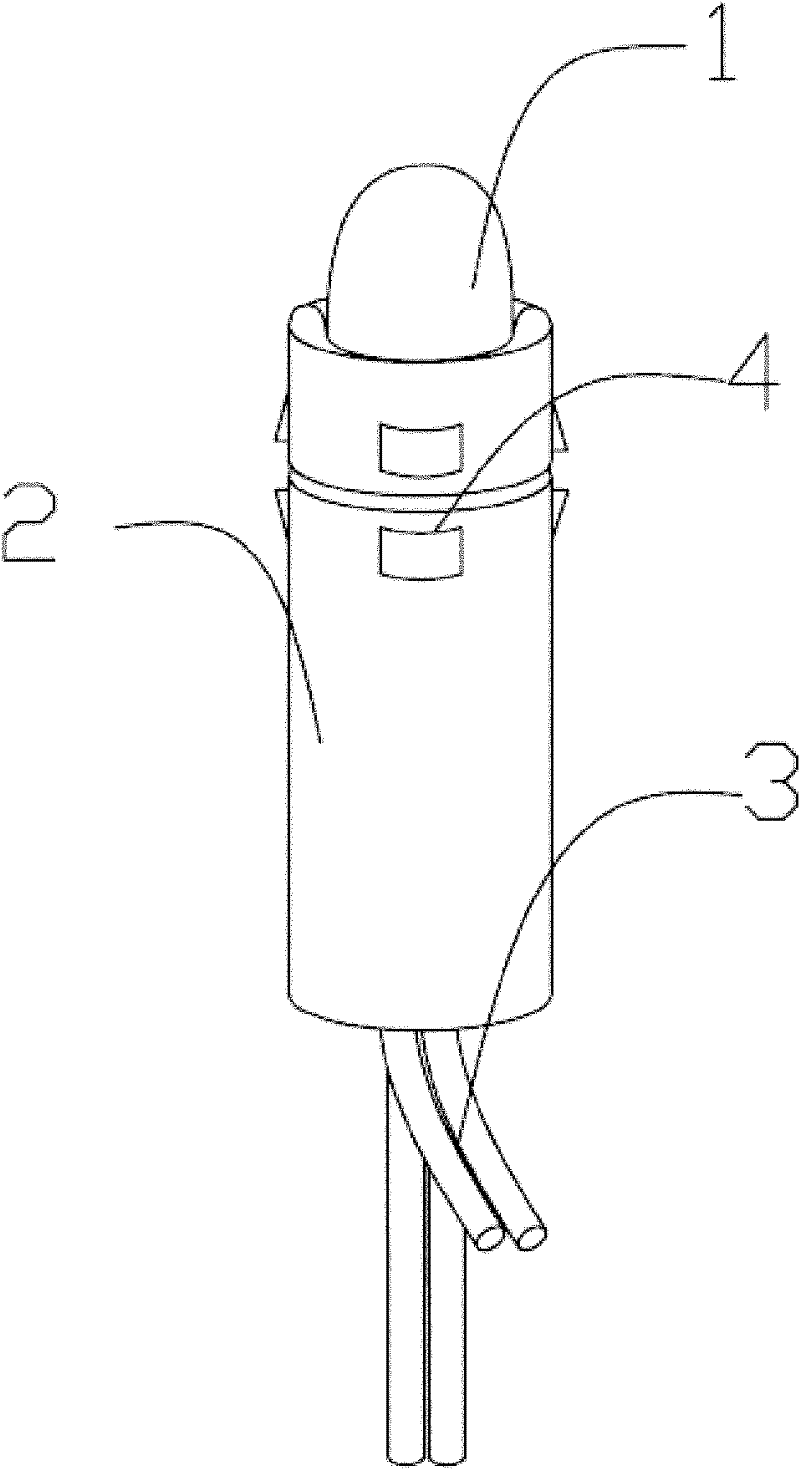

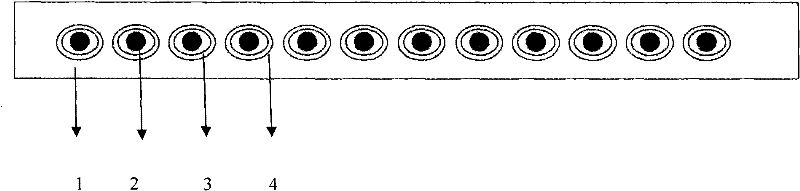

Light-emitting diode (LED)-exposed waterproof perforated lamp string and manufacturing process thereof

InactiveCN102454908AEasy to makeGive full play to the advantages of LED point light sourcePoint-like light sourceElongate light sourcesEpoxyUltraviolet

The invention provides a light-emitting diode (LED)-exposed waterproof perforated lamp string and a manufacturing method thereof. The LED-exposed waterproof perforated lamp string is formed by combining LED lamps, printed circuit boards (PCBs) and anti-ultraviolet (anti-UV) polyurethane (PU) wires together in a welding mode and an epoxy resin glue embedment mode and solidifying at the high temperature of between 50 and 60 DEG C. The problem that modified epoxy resin and polyvinyl chloride (PVC) cables cannot be firmly adhered and the problem of waterproof performance treatment are radically solved. When the LED-exposed waterproof perforated lamp string is actually used, a plurality of perforated lamps are connected together by a parallel circuit according to a certain rule; the LED-exposed waterproof perforated lamp string has the advantages of simple structure, low cost, long service life, large light-emitting angle, low light attenuation, uniform aperture, low power consumption, energy conservation and environment friendliness, is stable in work and safe in use and is driven by direct current (DC) the constant voltage of 5V; and a special bayonet design is adopted, and the perforated lamps are directly mounted after being perforated, so that mounting cost is lowered, the LED-exposed waterproof perforated lamp string is convenient to maintain, and various boards can be used after being perforated. The perforated lamps are designed in a bidirectional disassembling and assembling separated mode, so that the perforated lamps are easier to maintain and have wide application prospects.

Owner:RISHANG OPTOELECTRONICS

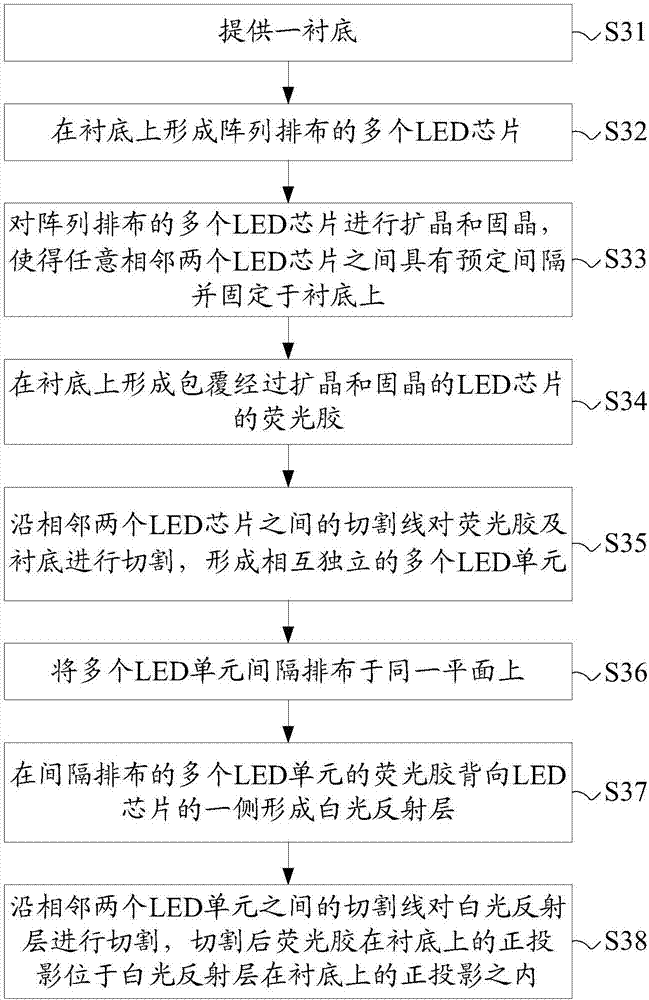

LED (Light Emitting Diode) light source, manufacturing method thereof and backlight module

ActiveCN106932951AIncrease reflective areaImprove light color consistencyNon-linear opticsSemiconductor devicesFluorescenceLED lamp

The invention provides an LED (Light Emitting Diode) light source, a manufacturing method thereof and a backlight module. The LED light source comprises a substrate, an LED chip, fluorescent glue and a white-light reflecting layer, wherein the LED chip is coated and packaged on the substrate by the fluorescent glue; the white-light reflecting layer is used for reflecting light outgoing from the fluorescent glue to the white-light reflecting layer; and the forward projection of the fluorescent glue on the substrate is positioned in the forward projection of the white-light reflecting layer on the substrate. Based on the design, the light-color consistency of light emitted from the four surfaces can be improved, the incoming Bin rate of the LED can be improved and the backlight cost can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

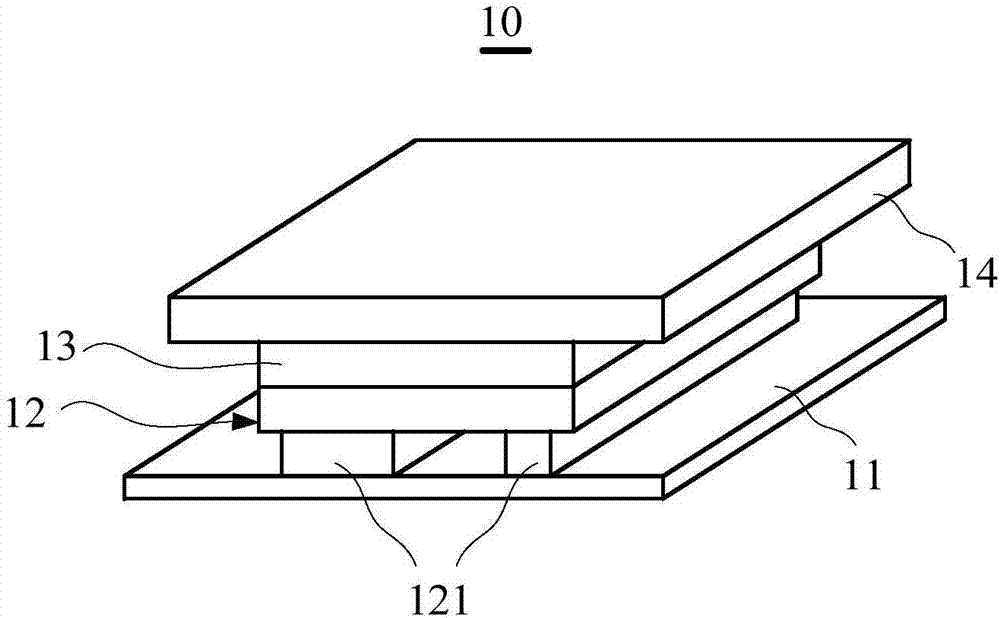

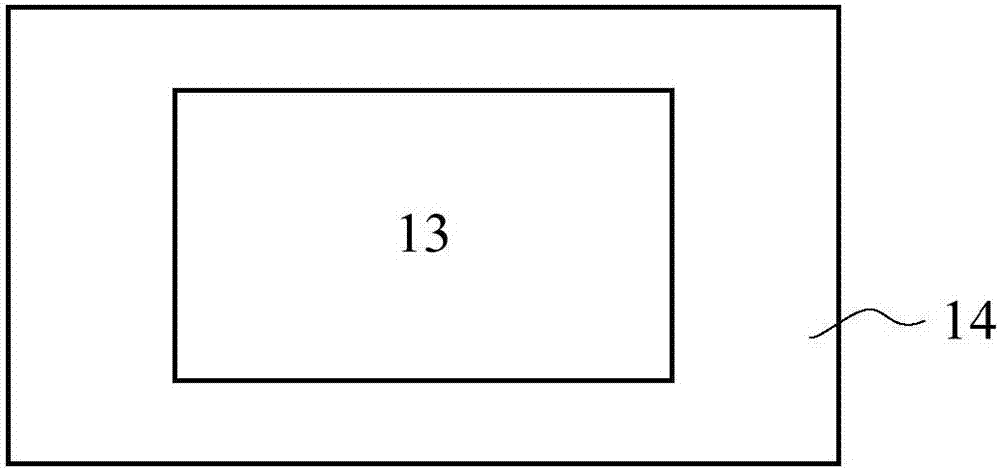

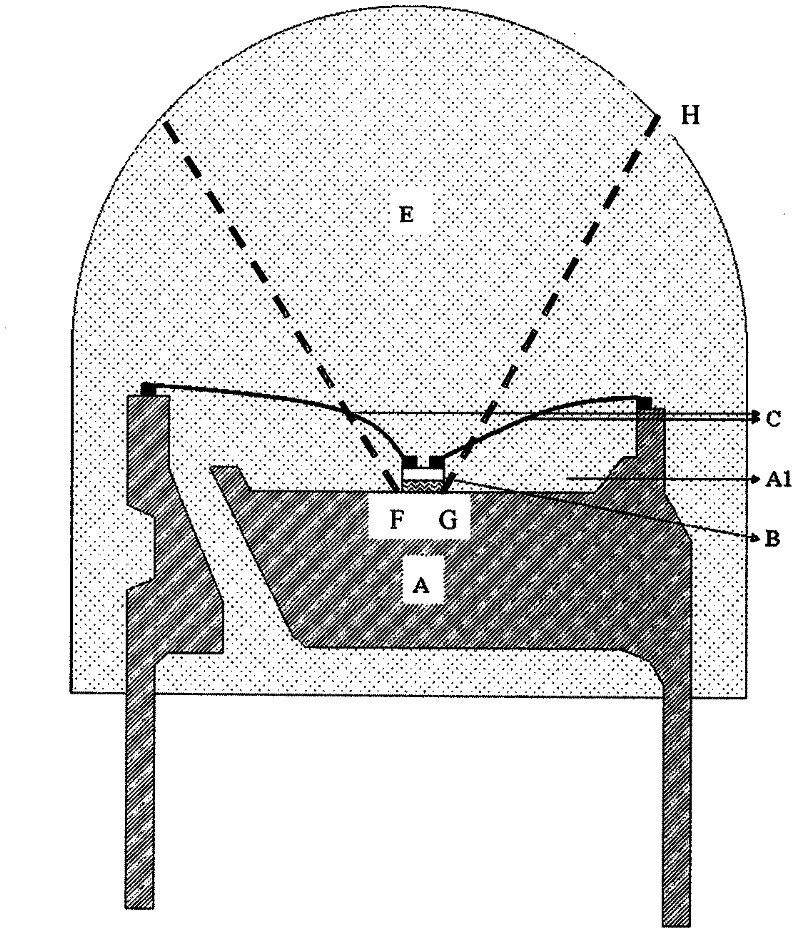

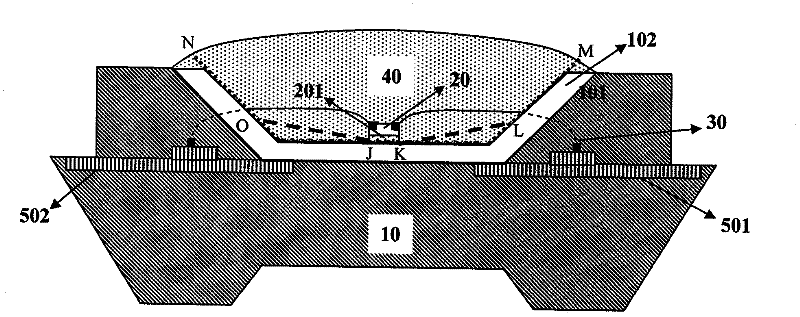

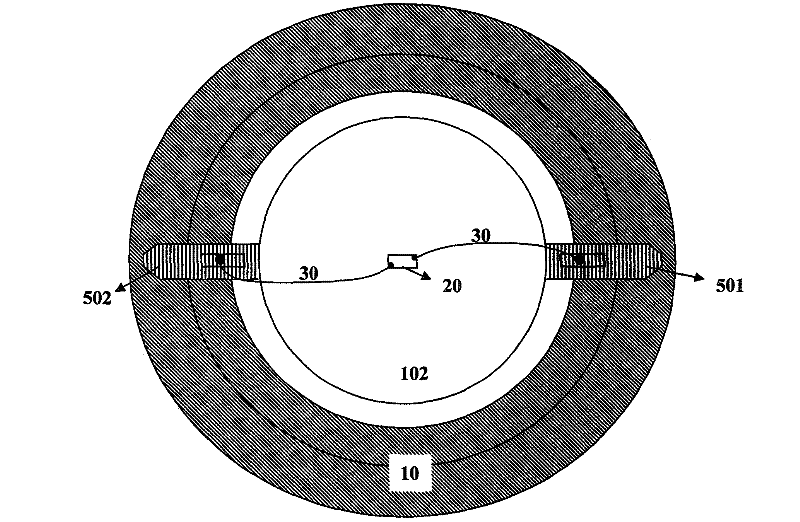

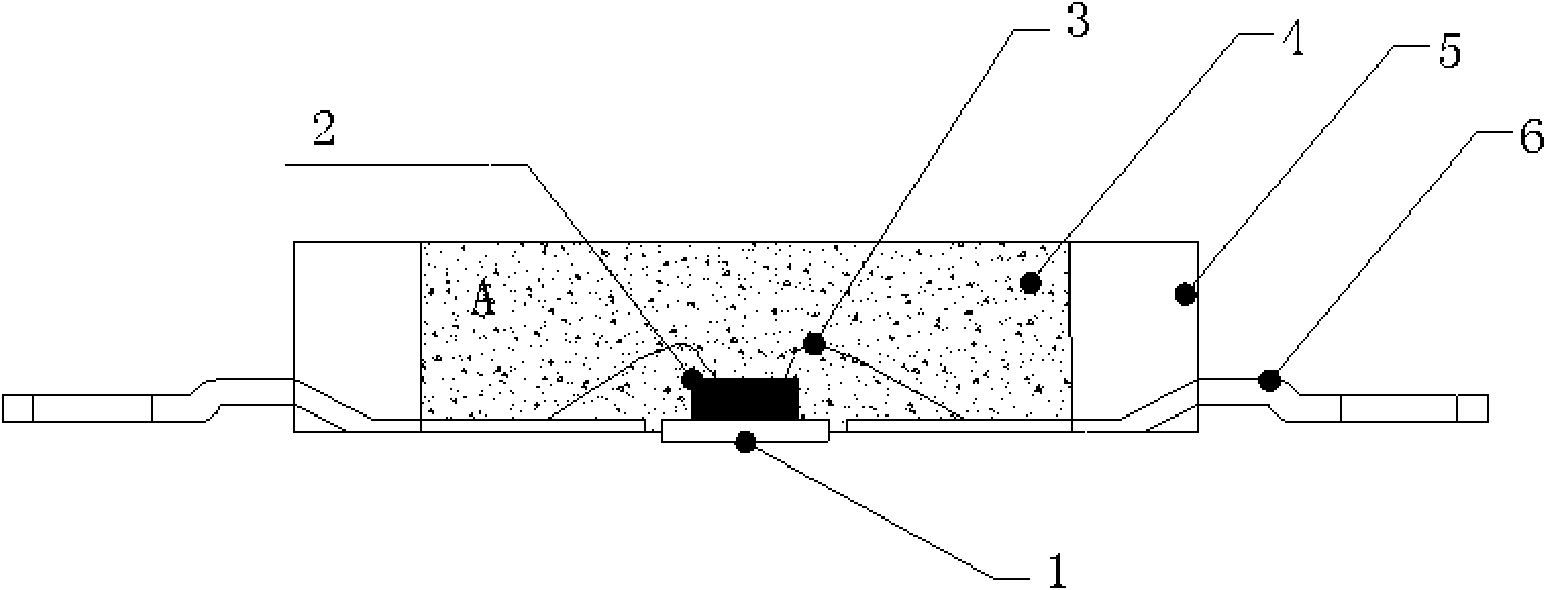

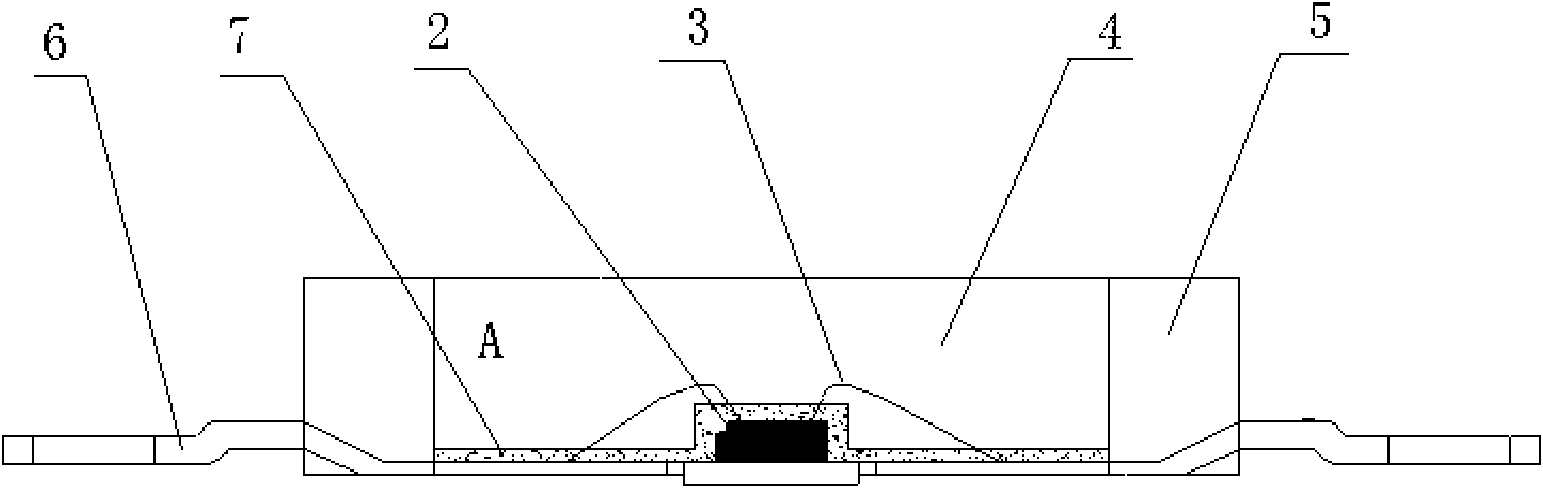

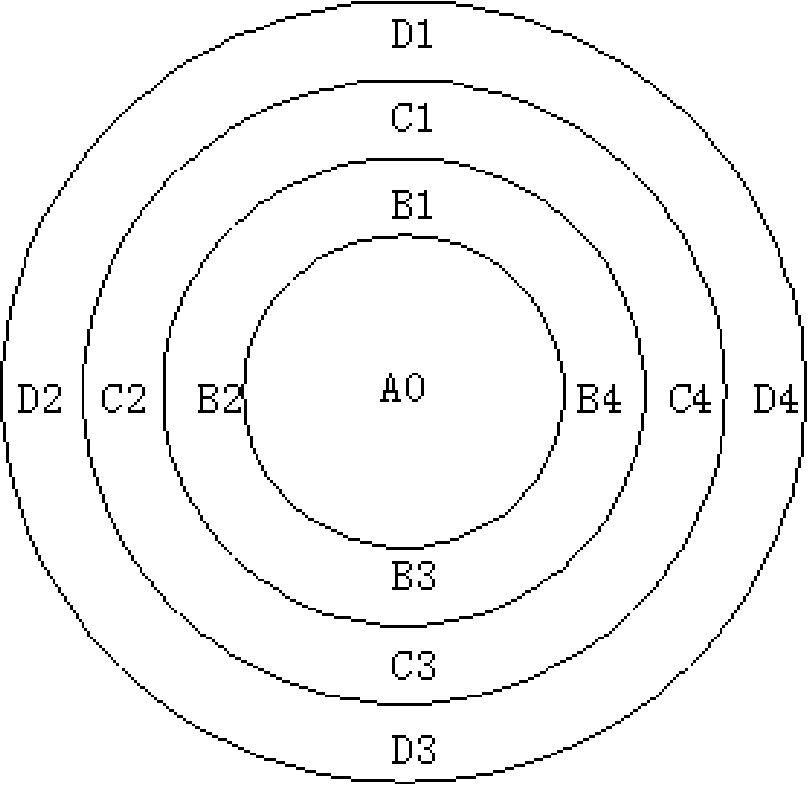

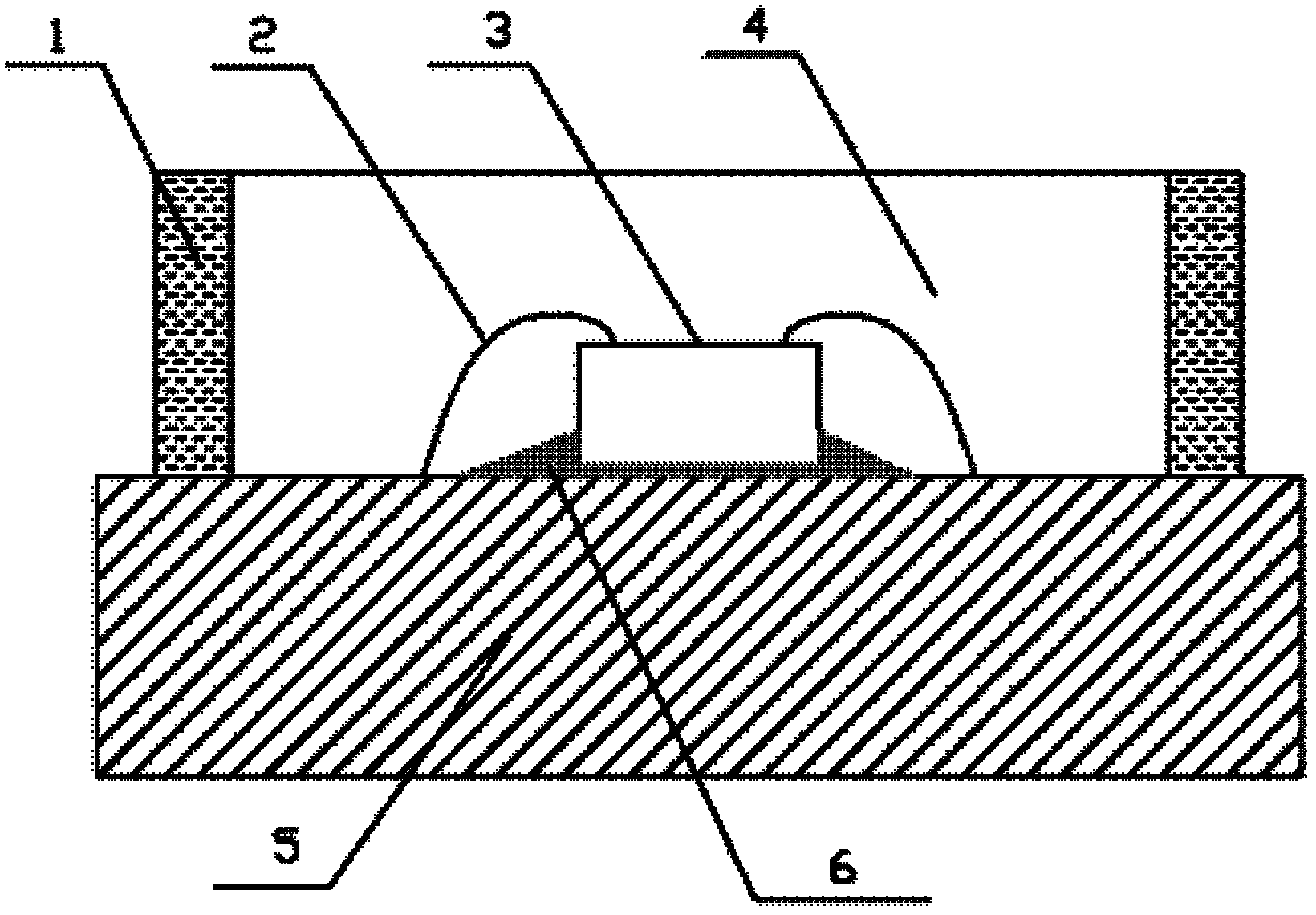

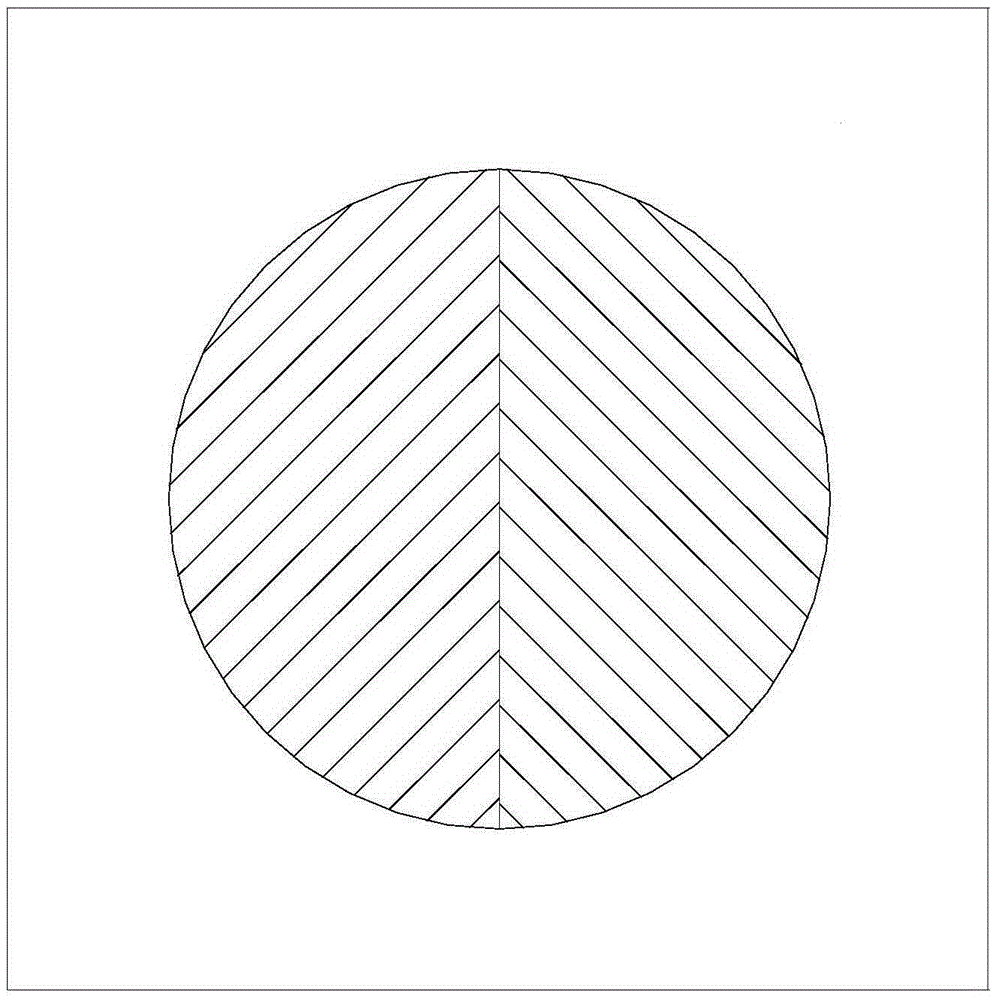

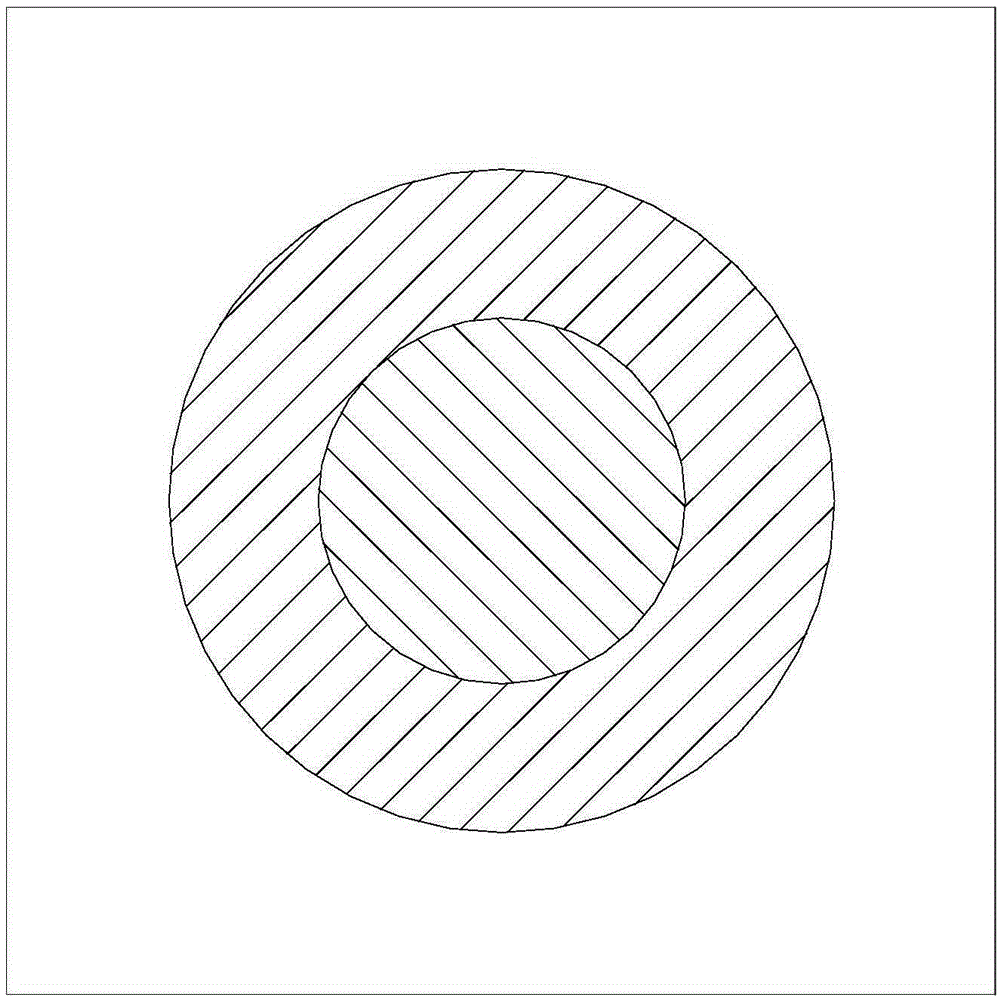

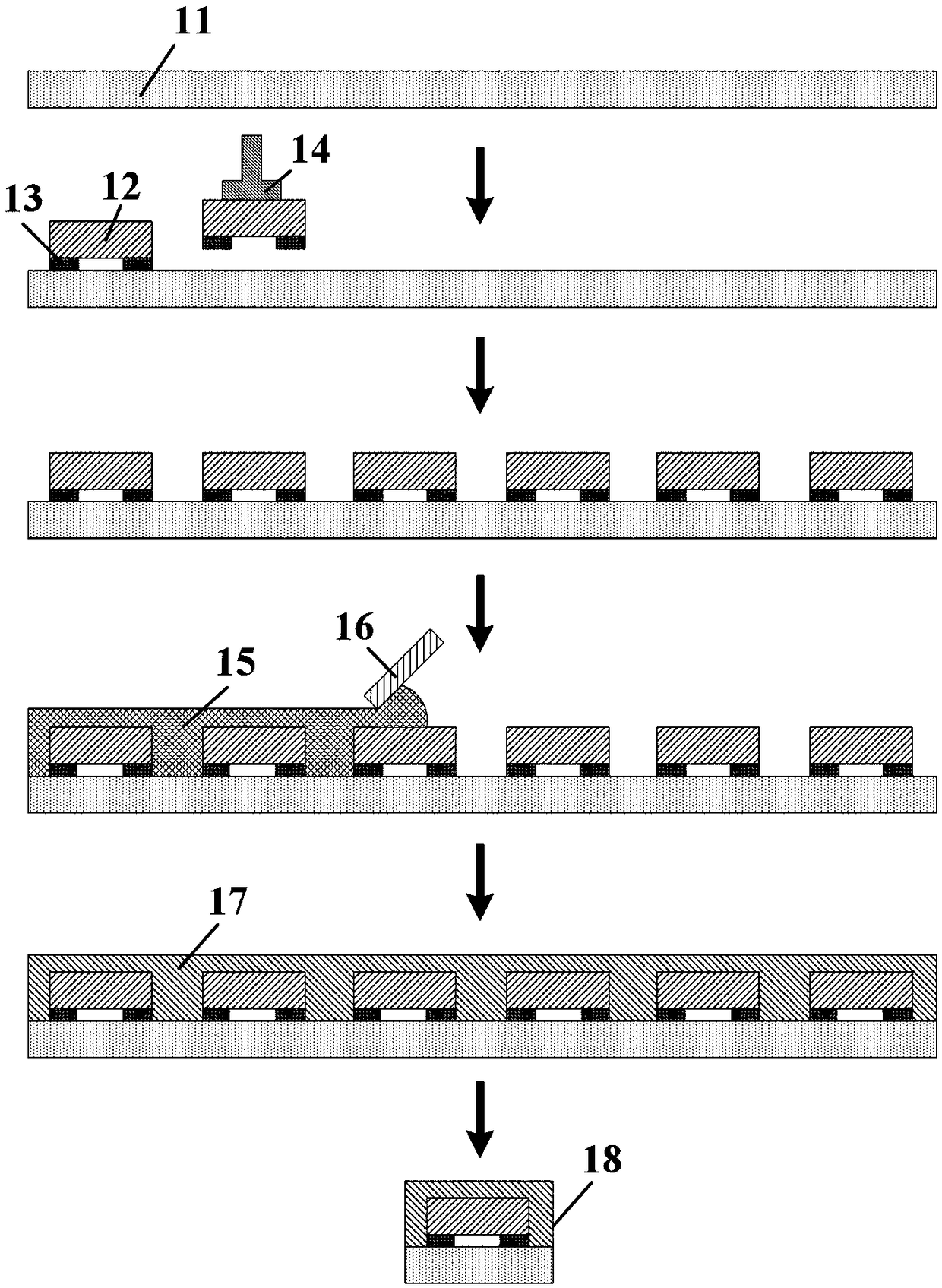

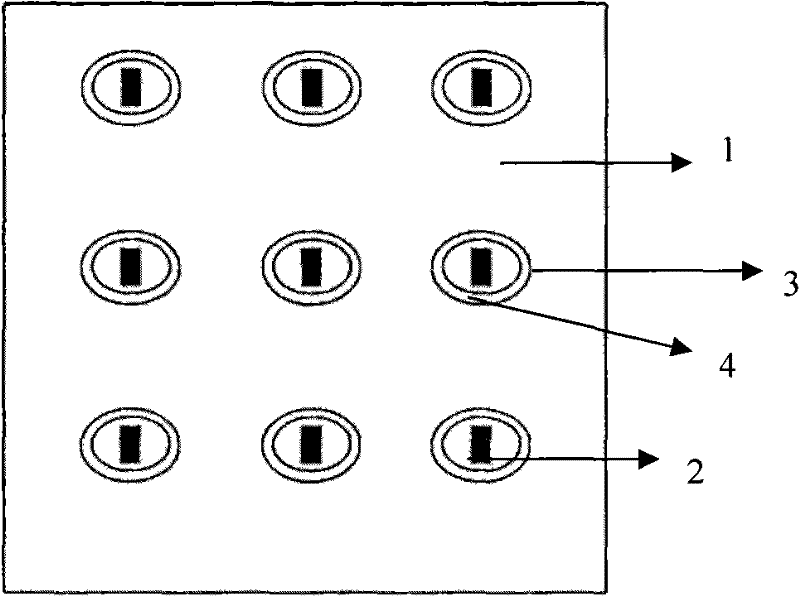

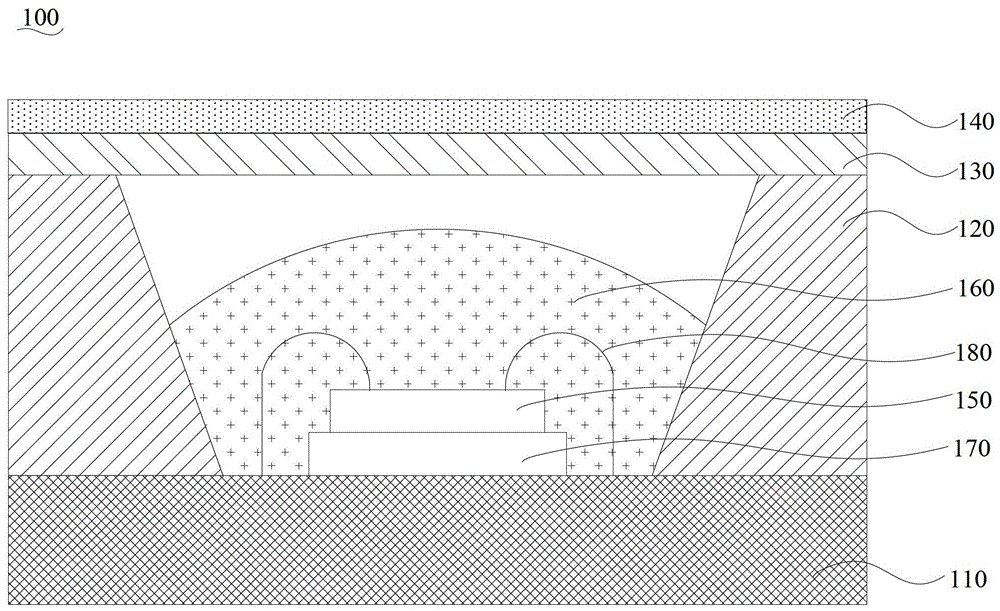

Method for efficiently packaging light-emitting diode (LED) chips by using substrate high diffuse reflection optical design

ActiveCN102544252AFacilitated DiffusionImprove luminous efficiencySemiconductor devicesDiffuse reflectionDie bonding

The invention aims at providing a light-emitting diode (LED) packaging method capable of obtaining high luminous efficiency, low light attenuation and high light color uniformity in LED chip packaging by using a substrate with an optical design and high diffuse reflection (200-760nm waveband reflectivity R>=80%), and the method is applicable to packaging for various LED chips especially white light LED chips of the various LED chips. The substrate 10 for an LED is characterized in that surface treatment is conducted on the substrate 10 and a high diffuse reflection layer 102 is formed on the surface 101 of the substrate 10. An LED packaging structure is characterized by comprising electrodes 501 and 502, an LED chip 20 and sealing objects 40, wherein the electrodes 501 and 502 are formed on the substrate 10, the LED chip 20 is fixed on the high diffuse reflection layer 102 of the packaging substrate in die bonding mode, and the sealing objects cover the LED chip 20 and the high diffuse reflection layer 102. The LED packaging method has the advantages that the reflection cylindrical surface of light coming out from the bottom of the chip is expanded uniformly enough to form a large-angle sector surface (radian close to 170-degree KLMNOJ) through high diffuse reflection of the substrate surface, so that fluorescent powder can be excited and accordingly luminous efficiency higher than that of a traditional silver-plated mirror surface reflection film is obtained, and good light color uniformity is guaranteed.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Process for encapsulating light-emitting diode

InactiveCN101656290AEliminate apertureImprove light color consistencySemiconductor devicesLight spotLight-emitting diode

The invention relates to the technical field of light-emitting diodes, in particular to a process for encapsulating a high-power light-emitting diode. The process for encapsulating a light-emitting diode comprises the following steps: applying glue and then keeping a light-emitting diode static at normal temperature to 102 DEG C for a period of time; depositing fluorescent powder in glue and leading the fluorescent powder to be attached to the surface of a chip. The invention eliminates a yellow aperture formed after the light-emitting diode is projected. Colors of light spots projected by thelight-emitting diode are consistent and even, and the light color quality of the light-emitting diode is improved.

Owner:SICHUAN JIUZHOU OPTOELECTRONIC TECH CO LTD

Novel light-emitting diode (LED) packaging structure and packaging method capable of forming white light

The invention discloses a novel light-emitting diode (LED) packaging structure capable of forming white light. The novel LED packaging structure comprises an LED packaging bracket. The LED packaging bracket comprises a substrate and a border enclosing the upper part of the substrate. An LED die is arranged in an area enclosed by the upper border of the substrate, bonded together with the substrate through a die bonder in which fluorescent powder is doped, connected through gold threads, and communicated to the anode and cathode of the LED packaging bracket. A packaging adhesive is filled in a space formed by the border and the substrate, and covers the LED die. The fluorescent powder is directly doped in the die bonder for bonding the LED die and the substrate of the LED packaging bracket, so that light reflected by the bottom of the LED die can directly contact the fluorescent powder to finish an excitation process, and long-waveband yellow light is emitted and forms the white light together with the blue light of the LED die. Compared with the prior art, the novel LED packaging structure eliminates a subsequent procedure for doping the fluorescent powder in the packaging adhesive and a procedure and equipment for centrifugal precipitation, improves production efficiency and decreases cost. The invention also discloses a novel LED packaging method capable of forming the white light.

Owner:FORYOU MULTIMEDIA ELECTRONICS

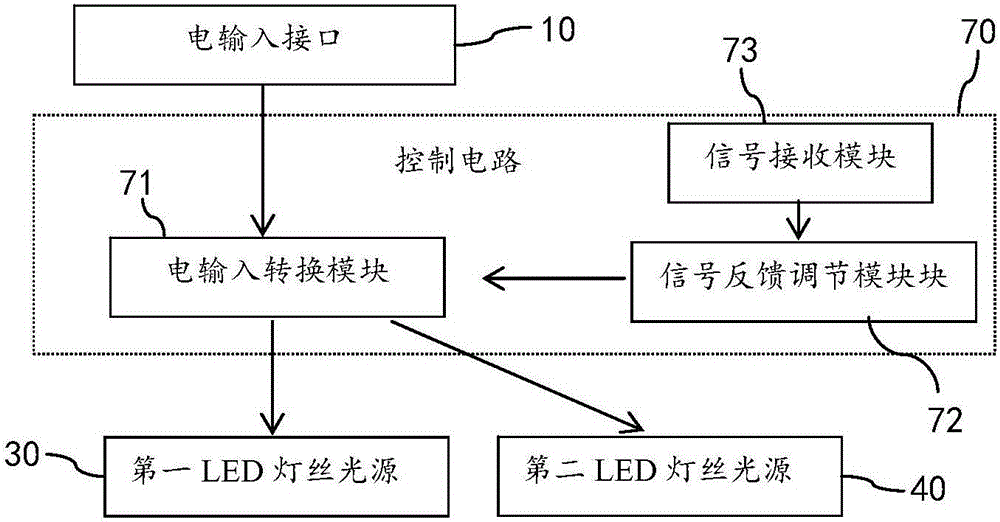

Efficient intelligent LED light source

InactiveCN105423149AImprove air tightnessImprove reliabilitySolid-state devicesLight fasteningsEngineeringAir tightness

The invention discloses an efficient intelligent LED light source which comprises a package substrate and a chip unit arranged on the package substrate. The chip unit is divided into at least one naked type chip unit body and at least one wrapped type chip unit body, wherein the wrapped type chip unit body is formed by covering the surface of the naked type chip unit body with a first fluorescent layer. The color temperature of the naked type chip unit body is different from that of the wrapped type chip unit body. The naked type chip unit body and the wrapped type chip unit body are further covered with a second fluorescent layer. According to the efficient intelligent LED light source, the light-color consistency is good, the light is uniform, the light-color consistency is enhanced after color mixture, the problem that mixed light is partitioned and layered is solved, and the LED light source which is packaged integrally is good in airtightness, high in reliability, high in light-color quality and convenient and fast to manufacture.

Owner:GUAGNZHOU TIANXIN PHOTOELECTRIC CO LTD

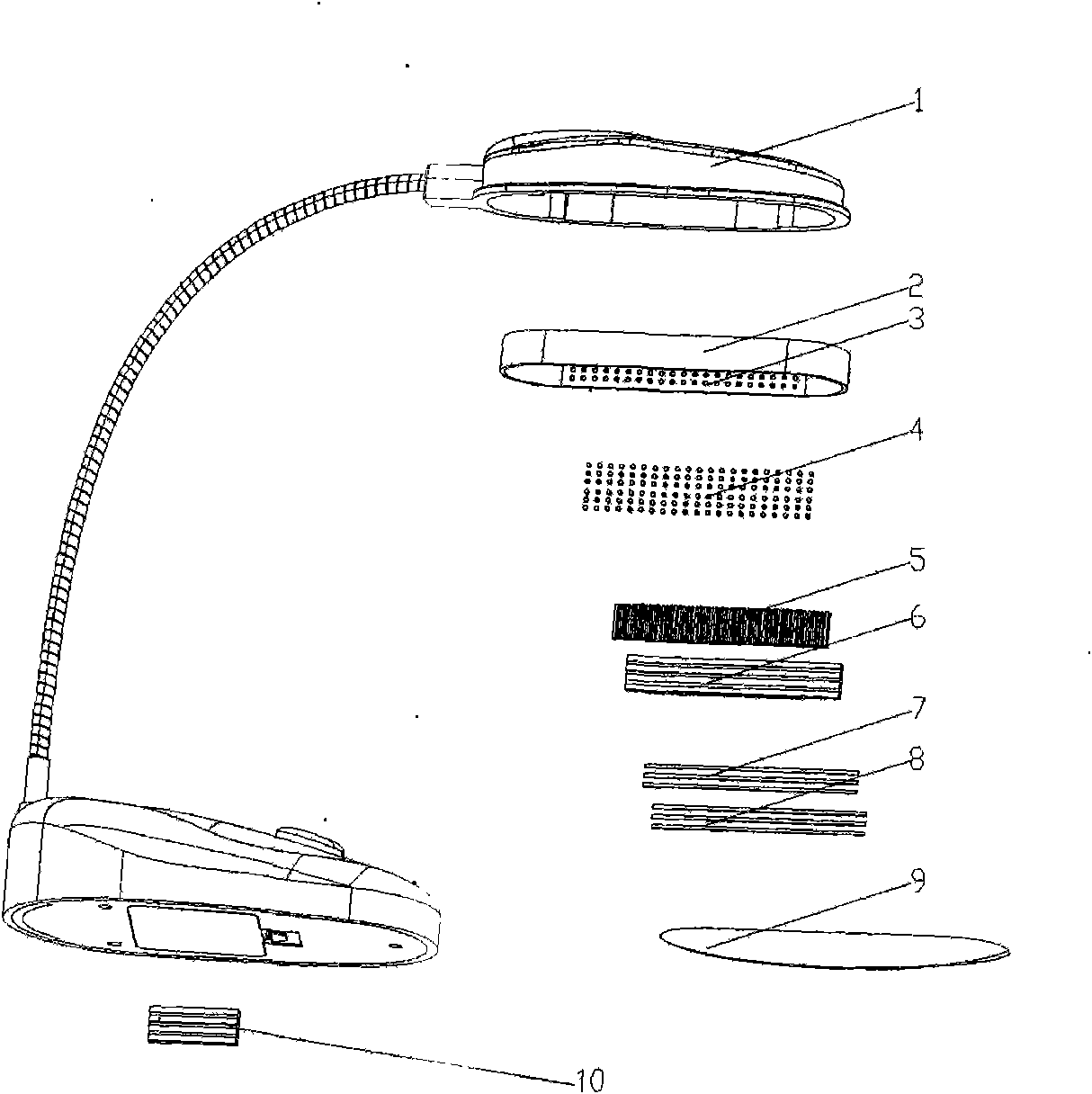

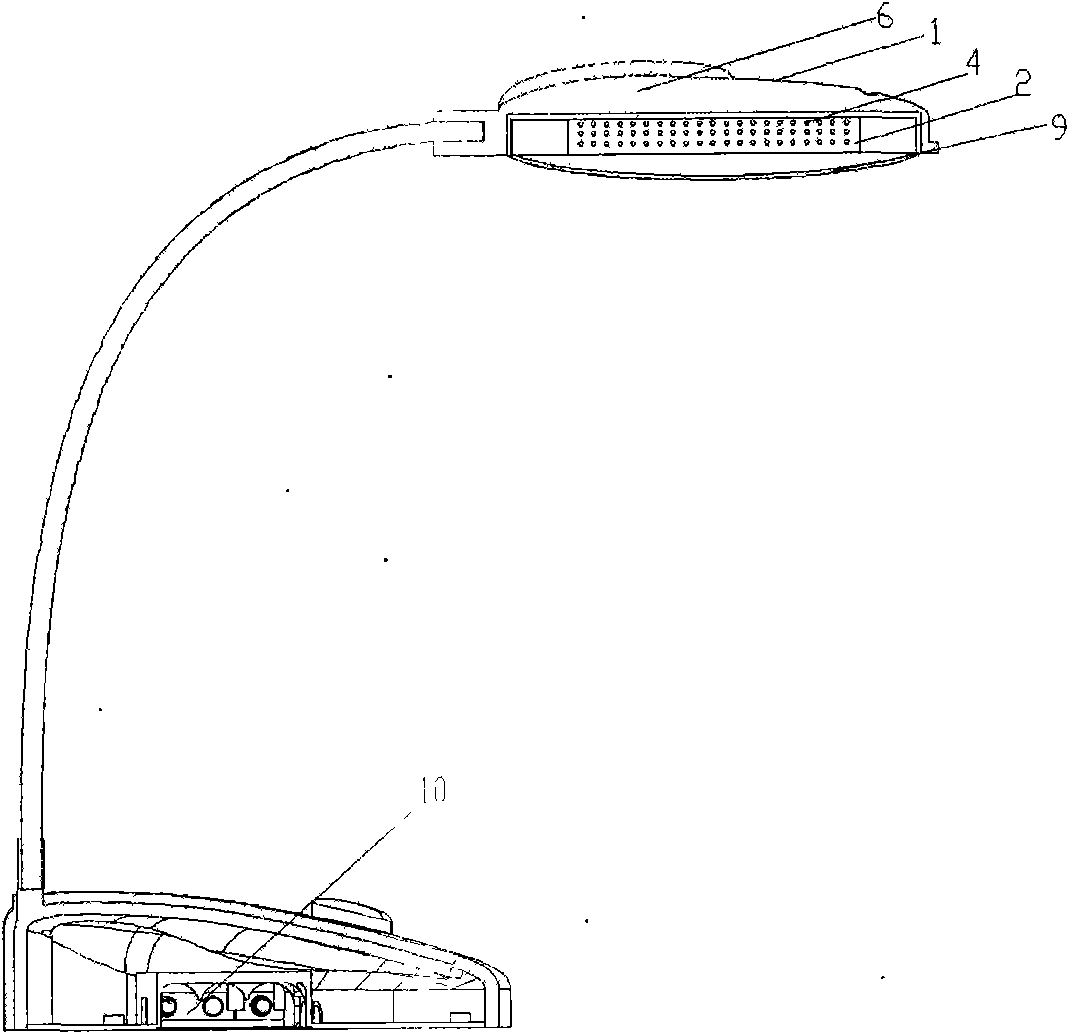

Multi-functional high-power LED lamp

InactiveCN101922642AImprove light color consistencyProtect eyesightMechanical apparatusPoint-like light sourceLight guideLight treatment

The invention relates to a multi-functional high-power LED lamp with illumination and phototherapy, which is assembled by a plurality of high-power RGB (red, green, blue) light sources and adopts an integral type heat radiating structure. The multi-functional high-power LED lamp comprises the light sources, a heat radiating structure, a lamp holder and a driving power supply. The LED light sources are directly fixed on the side surface of a light guide plate by using glues according to a certain proportion, and reflective membranes are uniformly coated on other two sides of the light guide plate and the bottom surface adhered with a lamp body; and when the RGB are all lighted, a uniform white light surface can be formed and has good consistency of light colors without glare or eye irritation; and if any one color of the RGB is independently lighted, emitted light can play different phototherapy roles on human bodies.

Owner:嘉兴嘉尼光电科技有限公司

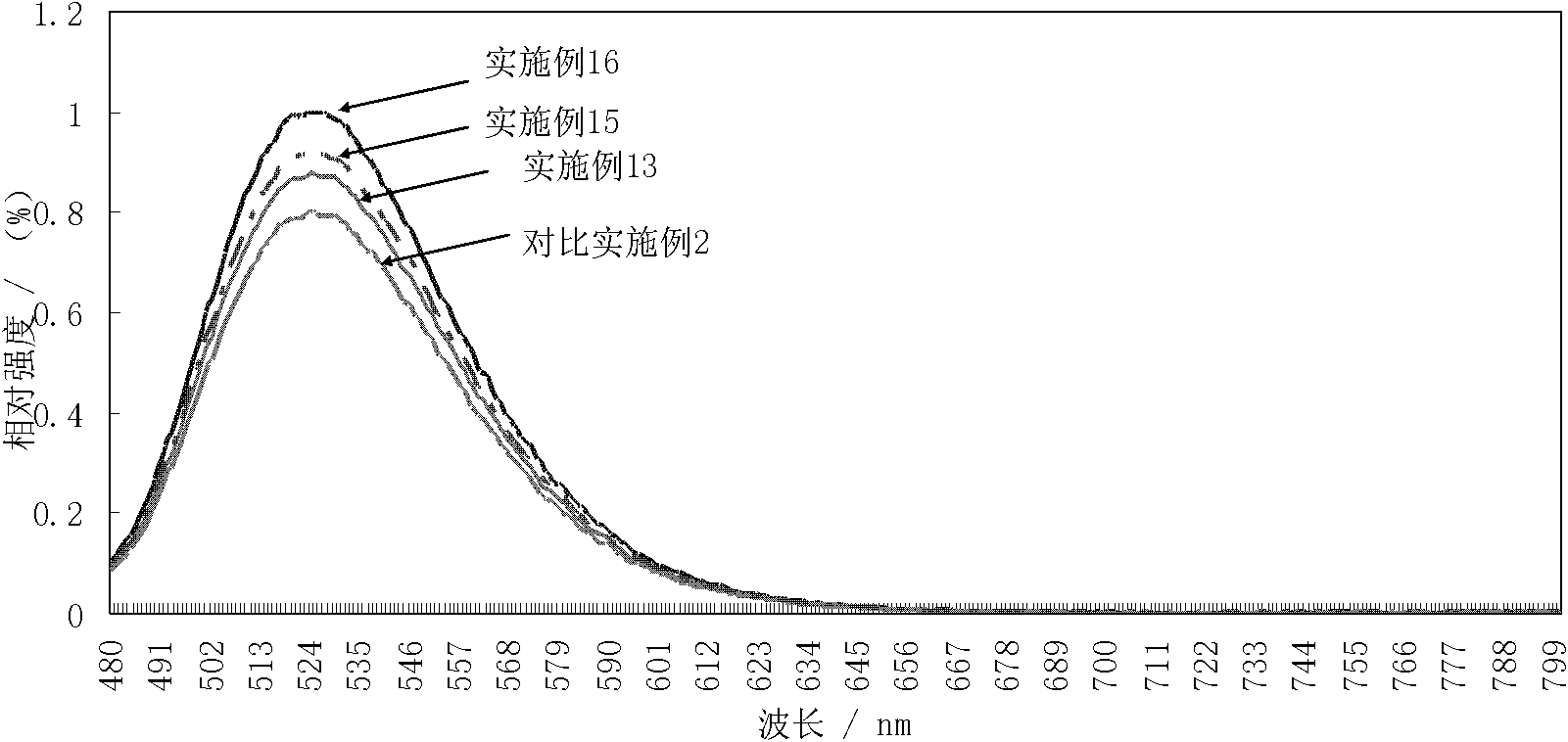

Rare earth fluorescent powder and preparation method thereof

ActiveCN101838535AReduce crystal field strengthImprove the anti-light decay characteristicsGas discharge lamp usageLuminescent compositionsMetallurgyRare earth

The invention provides rare earth fluorescent powder and a preparation method thereof. The chemical structural formula of the rare earth fluorescent powder is Sr(3-x-y-z)BaxMepSiqO(3+2q+p / 2):Euy, Rz, wherein Me is at least one of Li, Na and K; R is at least one of La, Gd and Lu; x is more than or equal to 0.001 and less than or equal to 0.2; y is more than or equal to 0.001 and less than 0.12; z is more than or equal to 0.0001 and less than 0.08; p is more than or equal to 0.001 and less than 0.05; q is more than or equal to 0.65 and less than 1. The method can effectively control the grain diameter of the calcined product; and the prepared fluorescent powder has the advantages of small grain diameter, narrow distribution, high lighting effect, capability of effectively enhancing the lighting effect and light color consistency of a white LED, and high luminous performance, chemical stability and temperature quenching characteristic.

Owner:JIANGSU BREE OPTRONICS CO LTD

Dispensing method applicable to flip chip

InactiveCN102637806AImprove light extraction efficiencyNo wires requiredSemiconductor devicesFluorescenceNitrogen

The invention relates to a dispensing method applicable to a flip chip. The dispensing method applicable to a flip chip comprises the following steps of: A, preparing curing colloidal particles: uniformly mixing AB glue and fluorescent powder accounting for 7-15% of the weight of AB glue, and preparing liquid fluorescent glue; B, defoaming the liquid fluorescent glue prepared in the step A and sealing, and quickly freezing at low temperature below 15 DEG C to obtain solid fluorescent glue; C, cutting the solid fluorescent glue prepared in the step B: putting the solid fluorescent glue in an atmosphere full of low-temperature nitrogen, cutting the solid fluorescent glue into uniform particles, and sealing the particles and storing in an environment below -15 DEG C, wherein the temperature of the low-temperature nitrogen is below -5 DEG C; and D, putting the uniform particles prepared in the step C in a light cup with a fixed flip chip, and roasting for forming.

Owner:厦门多彩光电子科技有限公司

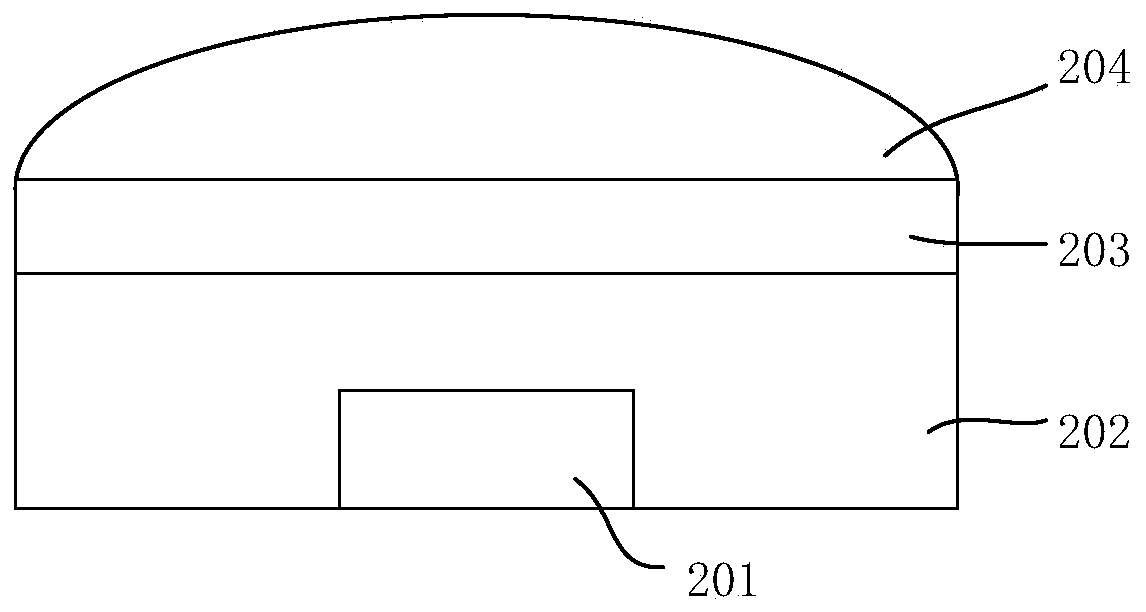

High-thermal stability chip-scale LED (Light Emitting Diode) packaging method and product

ActiveCN109285938AGood heat resistanceStrong thermal reliabilitySemiconductor devicesLed packagingFluorescence

The invention belongs to the related field of semiconductor manufacturing technologies, and discloses a high-thermal stability chip-scale LED (Light Emitting Diode) packaging method. The method comprises the steps of firstly mounting a plurality of LED chips on a ceramic substrate by eutectic bonding, then coating the ceramic substrate with fluorescent glass paste, obtaining a fluorescent glass layer on the top and side surfaces of the chips through low-temperature sintering, and then cutting to obtain LED devices; or firstly, eutectic bonding a plurality of LED chips on a ceramic substrate, then coating the side surfaces of the chips with a light shielding layer, then bonding a prepared fluorescent glass sheet to the top of the chips, and finally cutting to obtain LED devices. The invention further discloses a corresponding LED packaging structure. According to the invention, problems of fluorescent layer aging and carbonization caused by chip heating under high current density are effectively avoided, the thermal stability of the LED devices is improved, and the method is particularly suitable for solving the technical problems such as production efficiency and photochromic consistency in the chip-scale LED packaging process.

Owner:HUAZHONG UNIV OF SCI & TECH

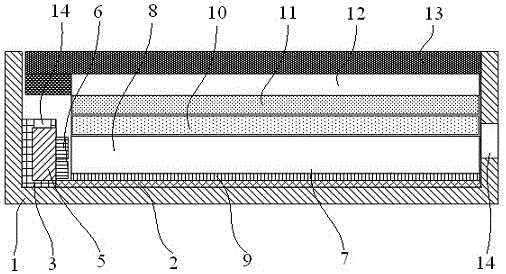

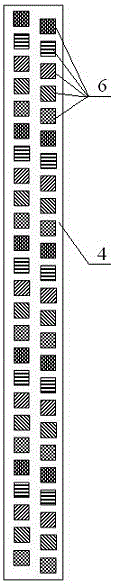

Backlight source used for liquid crystal television

InactiveCN106597745AIngenious structural designEasy to disassemble, assemble, repair and replaceTelevision system detailsColor television detailsLiquid-crystal displayLight guide

The invention relates to a backlight source used for a liquid crystal television. The backlight source comprises a light guide plate assembly, an LED lamp strip, a PMMA diffuser plate, a DBEF light enhancement sheet, a black-white shading double-faced adhesive tape frame, a U-shaped inner glue frame and an outer iron frame, wherein the inner glue frame is arranged inside the outer iron frame, an LED lamp strip clamping groove is arranged at one end, disposed at the inner glue frame, on the inner wall of the outer iron frame, the light guide plate assembly, the PMMA diffuser plate and DBEF light enhancement sheet are successively arranged in the inner glue frame in an attached mode from bottom to top, the LED lamp strip is placed in the LED lamp strip clamping groove, the black-white shading double-faced adhesive tape frame is adhered to the top portion of the DBEF light enhancement sheet, the LED lamp strip clamping groove is completely shielded, and a liquid crystal display screen is adhered to the upper portion of the black-white shading double-faced adhesive tape frame; and the light guide assembly comprises an optical glass light guide plate and a reflective film layer adhered to the bottom of the light guide plate, the LED lamp strip comprises an aluminum-base copper-clad laminate and a plurality of SMD LED lamp beads, the LED lamp beads are welded to the aluminum-base copper-clad laminate, the LED lamp beads and the aluminum-base copper-clad laminate are attached together by use of heat conduction silica gel, and the LED lamp beads are right opposite to the side incident surface of the optical glass light guide plate.

Owner:YANCHENG SANDING ELECTRONICS TECH CO LTD

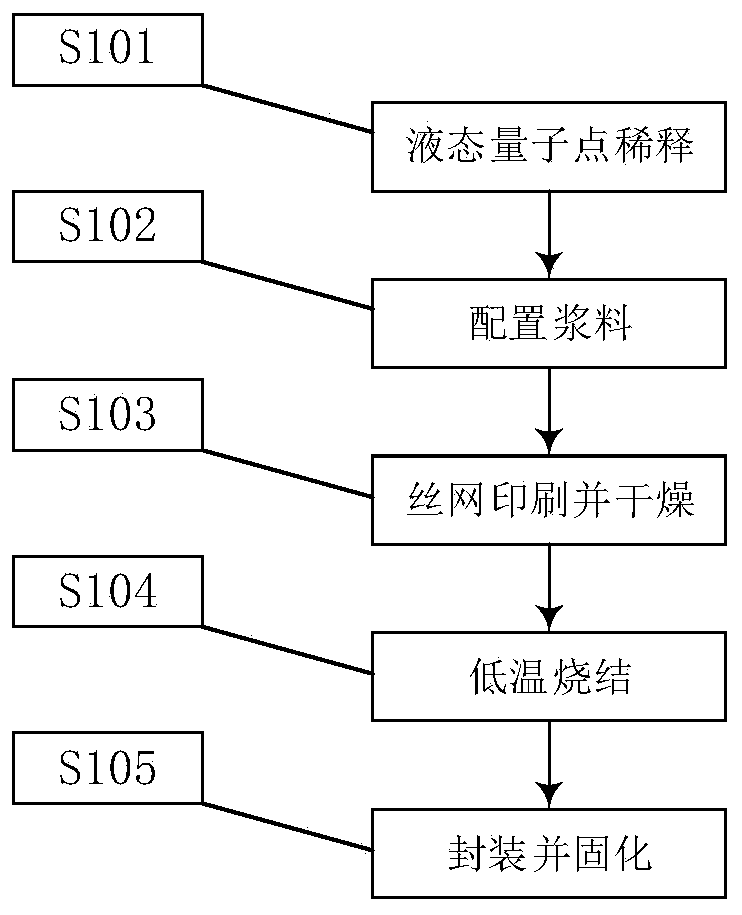

White light LED containing liquid quantum dot and preparation method thereof

ActiveCN109742220AHigh color rendering indexImprove light color consistencySemiconductor devicesColor rendering indexLiquid state

The invention discloses a white light LED containing a liquid quantum dot, and a preparation method thereof. The preparation method of the white light LED containing a liquid quantum dot comprises thefollowing steps: diluting the liquid quantum dot, configuring slurry, printing and drying screen mesh, sintering at low temperature, packaging and solidifying. The invention effectively avoids blue light hazard, obviously improves the color rendering index and the consistency of light color of the white light LED, reduces the color temperature of LED, and effectively slows down light efficiency reduction caused by aging of organic polymer.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

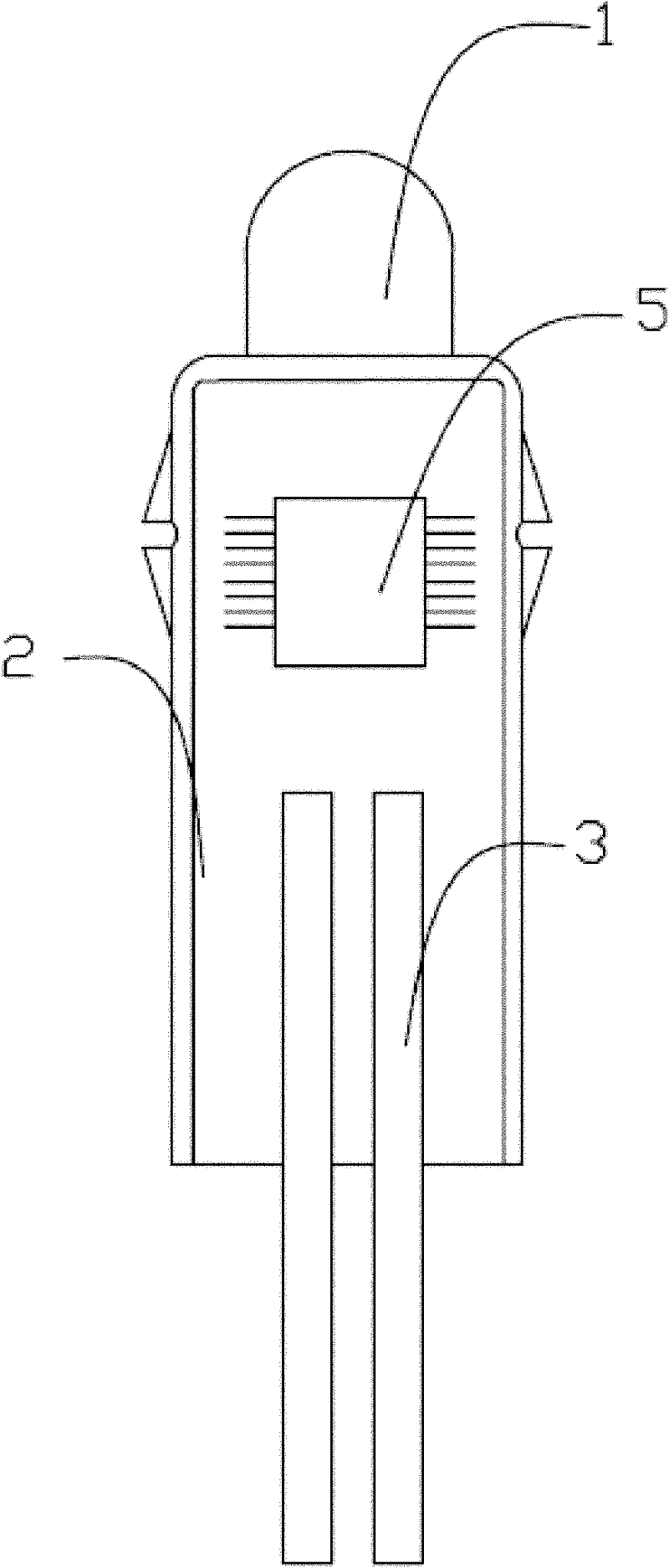

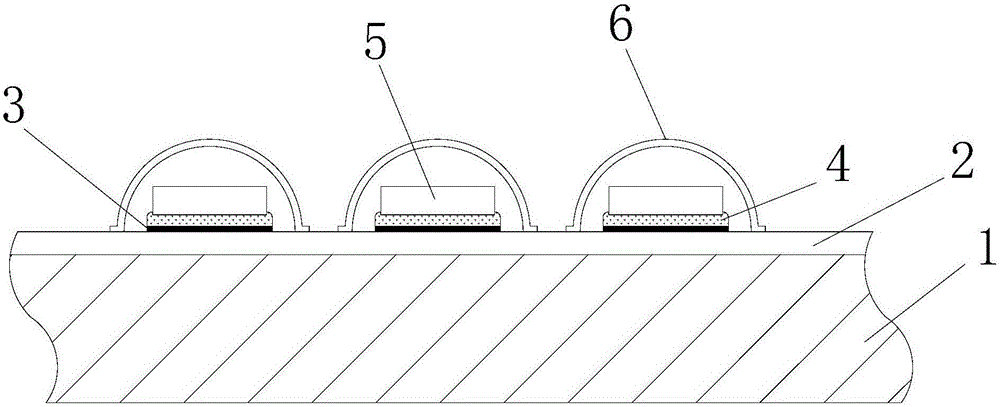

A cob modular led dispensing structure

InactiveCN102270634APrevent outflowStreamlined dispensing materialsPoint-like light sourceSolid-state devicesTemperature controlPhosphor

The invention belongs to LED dispensing technology, in particular to a COB (Chip on Bord) modular LED dispensing technology. The LED structure involved includes: COB consists of four parts: aluminum substrate, LED chip, optical lens, and rubber ring. The rubber ring is fixed on the substrate, and the LED chip is directly solidified on the substrate in the middle of the rubber ring. The ambient temperature is controlled at 15°C-20°C. In the process of dispensing, due to the existence of the surrounding rubber ring and the ambient temperature of 15°C-20°C, it can effectively block the flow of phosphor glue, and at the same time improve the consistency of the phosphor coating to obtain a consistent color temperature. The invention adopts the COB (Chip on Bord) modular LED dispensing technology, which can solve the common color difference problem in the current COB technology.

Owner:JIANGSU SUN & MOON LIGHTING

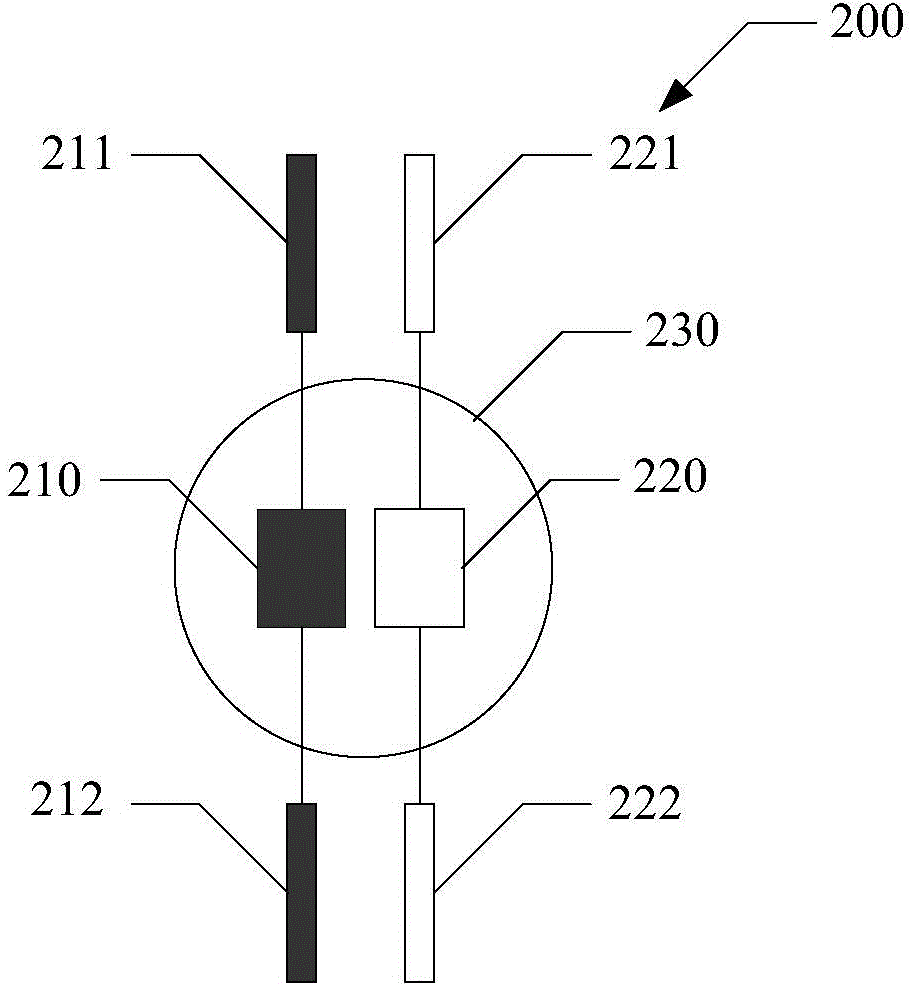

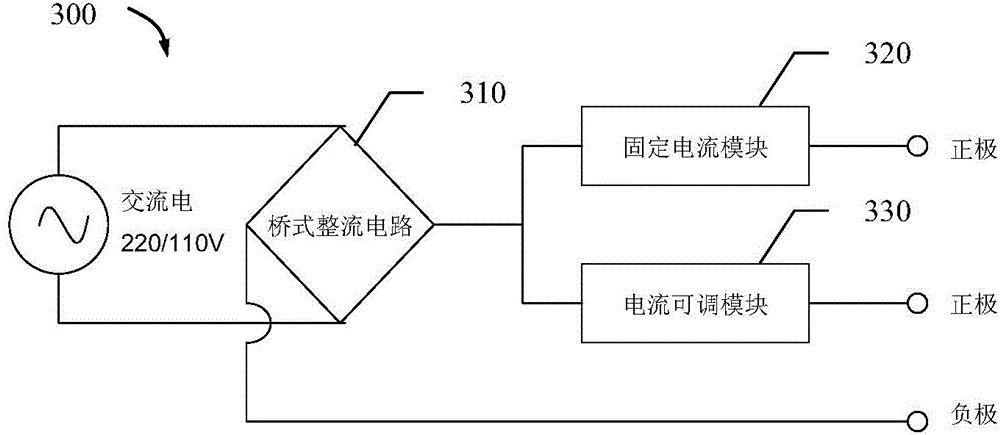

High photosynthetic efficiency high-voltage alternating-current white light LED (light emitting diode) module and white light acquiring method

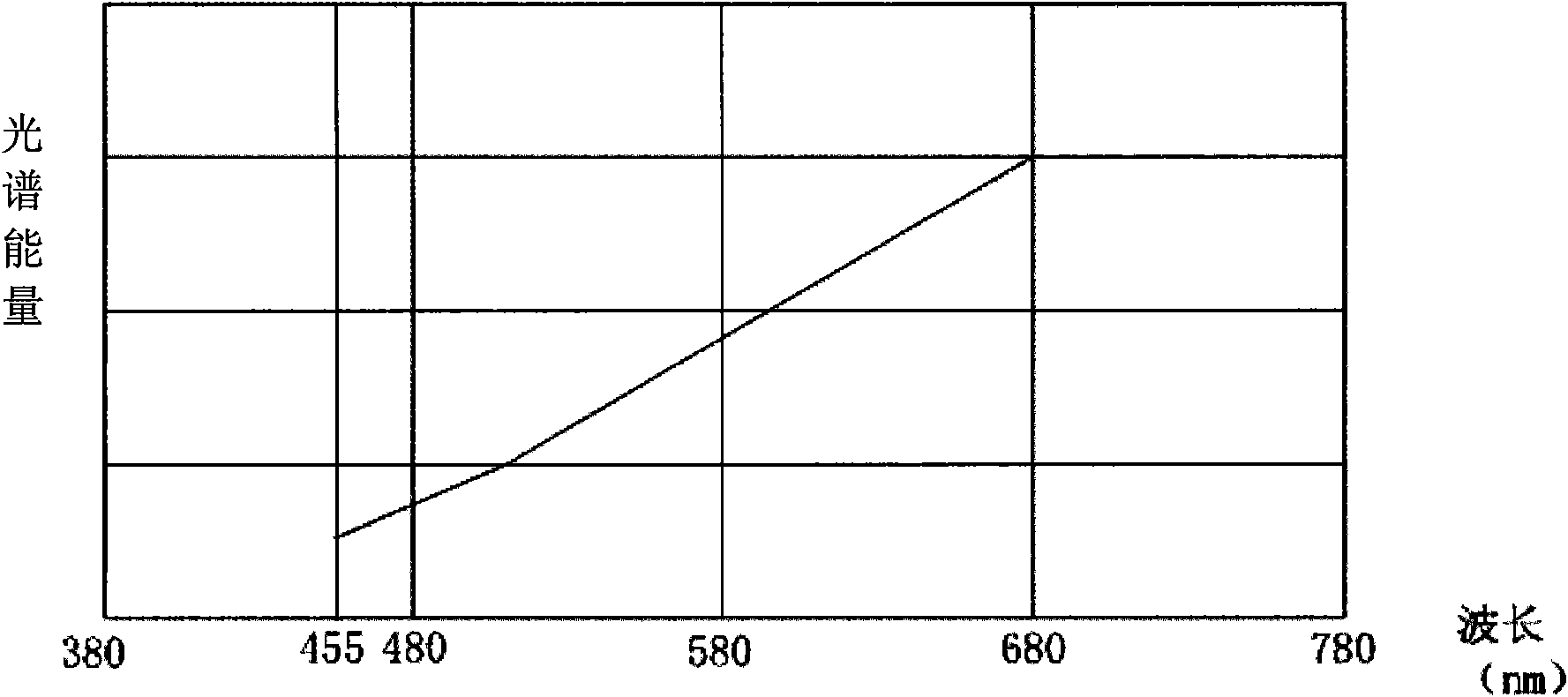

ActiveCN104390162ALow costImprove light color consistencyPlanar light sourcesMechanical apparatusHigh pressureAlternating current

The invention provides a high photosynthetic efficiency high-voltage alternating-current white light LED (light emitting diode) module and white light acquiring method in different mesopic vision environments. The LED module comprises a substrate, high-voltage LEDs and an alternating-current drive control circuit, wherein the high-voltage LEDs of preset quantity which are connected in serial are fixed on the substrate; each high-voltage LED comprises a high-voltage blue light chip, a high-voltage orange light chip and an encapsulation layer which is used for encapsulating the high-voltage blue light chip and the high-voltage orange light chip and contains green fluorescent powder; among the serially-connected high-voltage LEDs, the high-voltage blue light chip and the high-voltage blue light chip are connected in series to form a blue light group, and the high-voltage orange chip and the high-voltage orange light chip are connected in series to form an orange group; the alternating-current drive control circuit comprises a bridge-type rectifying circuit, a constant current module and a current adjustable module; the current provided by an alternating-current power supply is divided by the bridge-type rectifying circuit into two circuits, the two circuits of current are respectively supplied to the constant current module to be used as the drive of the blue light group and to the current adjustable module to be used as the drive of the orange light group so as to independently adjust the drive current of each high-voltage orange light chip; the module has ultrahigh mesopic vision light efficiency in different mesopic vision environments.

Owner:SHANGHAI YAMING LIGHTING

Lens type SMD packaging device

InactiveCN105702670AIncrease brightnessImprove light color consistencySolid-state devicesSemiconductor devicesEngineeringBrightness perception

The invention discloses a lens-type SMD packaging device, which includes a bracket, at least two welding pads are arranged on the inner bottom of the bracket, a light-emitting chip is correspondingly arranged above the welding pads, and welding pads are arranged between the welding pads. Isolated baffles. The pads are independent of each other, and the pads are separated by a partition, so that the luminous angle of the light emitted by the light-emitting chip above each pad is consistent with the optical curve and does not affect each other, and there will be no cross-lighting. High light overlap and good light color consistency. There is also an encapsulation lens above the light-emitting chip, which greatly improves the brightness of the LED device, and the curvature of the lens can be adjusted according to different needs to adjust the light-emitting angle and light-emitting curve of the device, so that the product can meet the requirements of high brightness, good light color consistency, Energy-saving market demand.

Owner:SHENZHEN JIUZHOU OPTOELECTRONICS TECH

Standard dot matrix light source and image point correction method of LED display screen

InactiveCN102005181BImprove light color consistencyGood white balanceStatic indicating devicesElectric light circuit arrangementDot matrixLight-emitting diode

The invention discloses a standard dot matrix light source and an image point correction method of a light-emitting diode (LED) display screen. The method comprises the following steps of: A, constructing the standard dot matrix light source, and calibrating the brightness and the chroma of the standard dot matrix light source; B, acquiring image data of the LED display screen, and the brightnessand the chroma of the standard dot matrix light source; C, comparing the acquired brightness and chroma of the standard dot matrix light source with a stored value to obtain an error compensation matrix, and converting the image data of the LED display screen from a relative value into an absolute value; D, analyzing the converted image data of the LED display screen to generate a data correctioncoefficient matrix; and E, outputting the data correction coefficient matrix to an image point correction processor to perform image data correction processing so as to obtain corrected image data according to the data correction coefficient matrix, and finally outputting the corrected image data to an LED large screen display system. The standard dot matrix light source and the image point correction method can overcome adverse effects caused by working condition drifting of a camera to ensure that the LED display screen has better light-color consistence and white balance after performing the image point correction; and an additional light colorimeter is not needed, and a plurality of times of tests are not performed any more.

Owner:GTEK GRP LTD

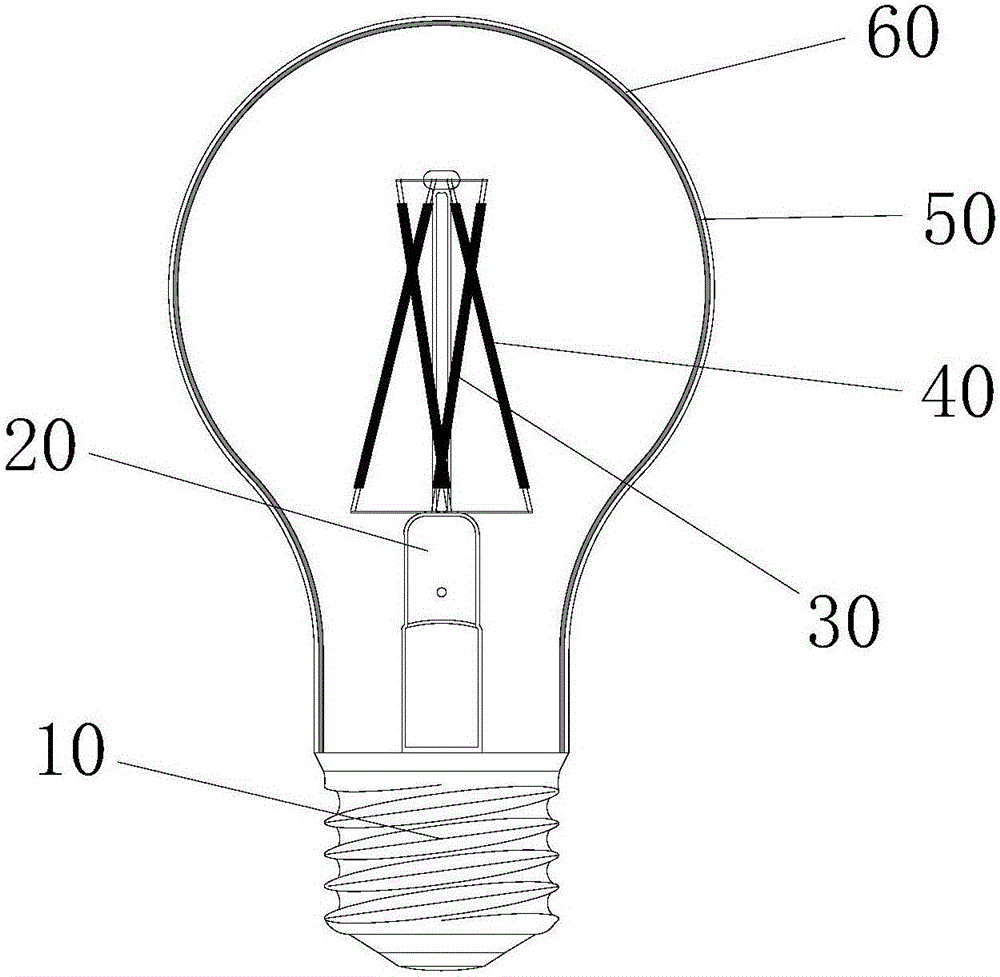

LED filament light source, LED filament bulb lamp and production method thereof

InactiveCN106159062AImprove reliabilityImprove cooling effectElectric circuit arrangementsLighting heating/cooling arrangementsInsulation layerSolder paste

The invention discloses an LED filament light source, an LED filament bulb lamp and a manufacturing method thereof. The LED filament light source comprises a tungsten-copper metal composite heat dissipation substrate, and a high heat-conducting insulating substrate formed on the surface of the tungsten-copper metal composite heat dissipation substrate by magnetron sputtering. layer, several conductive copper layers arranged in an array on the surface of the high thermal conductivity insulating layer generated by magnetron sputtering and electroplating, a solder paste layer arranged on each conductive copper layer, eutectic soldering on the solder paste layer, and microlenses capped on the flip chip. The present invention adopts flip-chip, tungsten-copper metal composite heat-dissipating substrate, high thermal conductivity insulating layer, combined with flip-chip welding and eutectic technology to realize the high current and low thermal resistance channel between the flip-chip and the substrate, and has good heat dissipation performance; Materials with high thermal conductivity are used between the center point of the heat source of the flip chip and the heat dissipation substrate, which greatly reduces the thermal resistance and improves the reliability of the LED filament light source.

Owner:SHENZHEN HOYOL OPTO ELECTRONICS

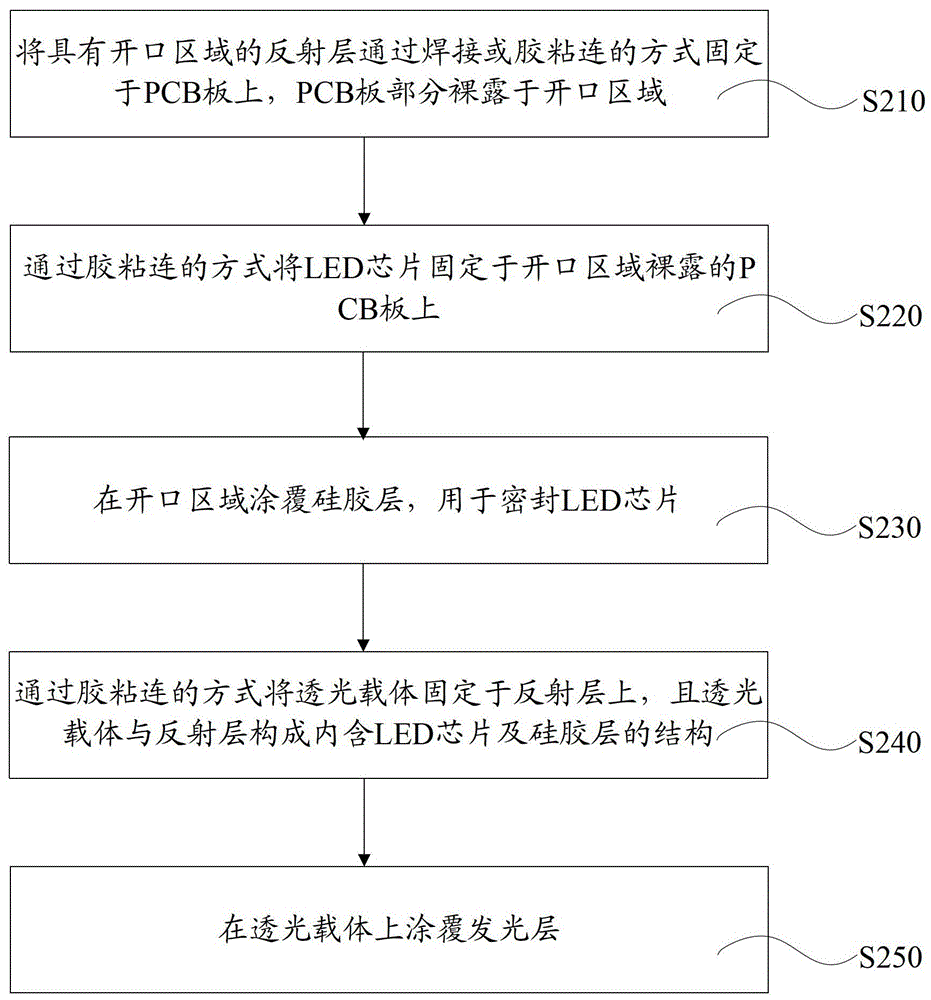

LED packaging structure and LED packaging method

ActiveCN103219449BSimple processImprove luminous efficiencySolid-state devicesSemiconductor devicesEngineeringSilica gel

Owner:东莞帝光智能显示有限公司

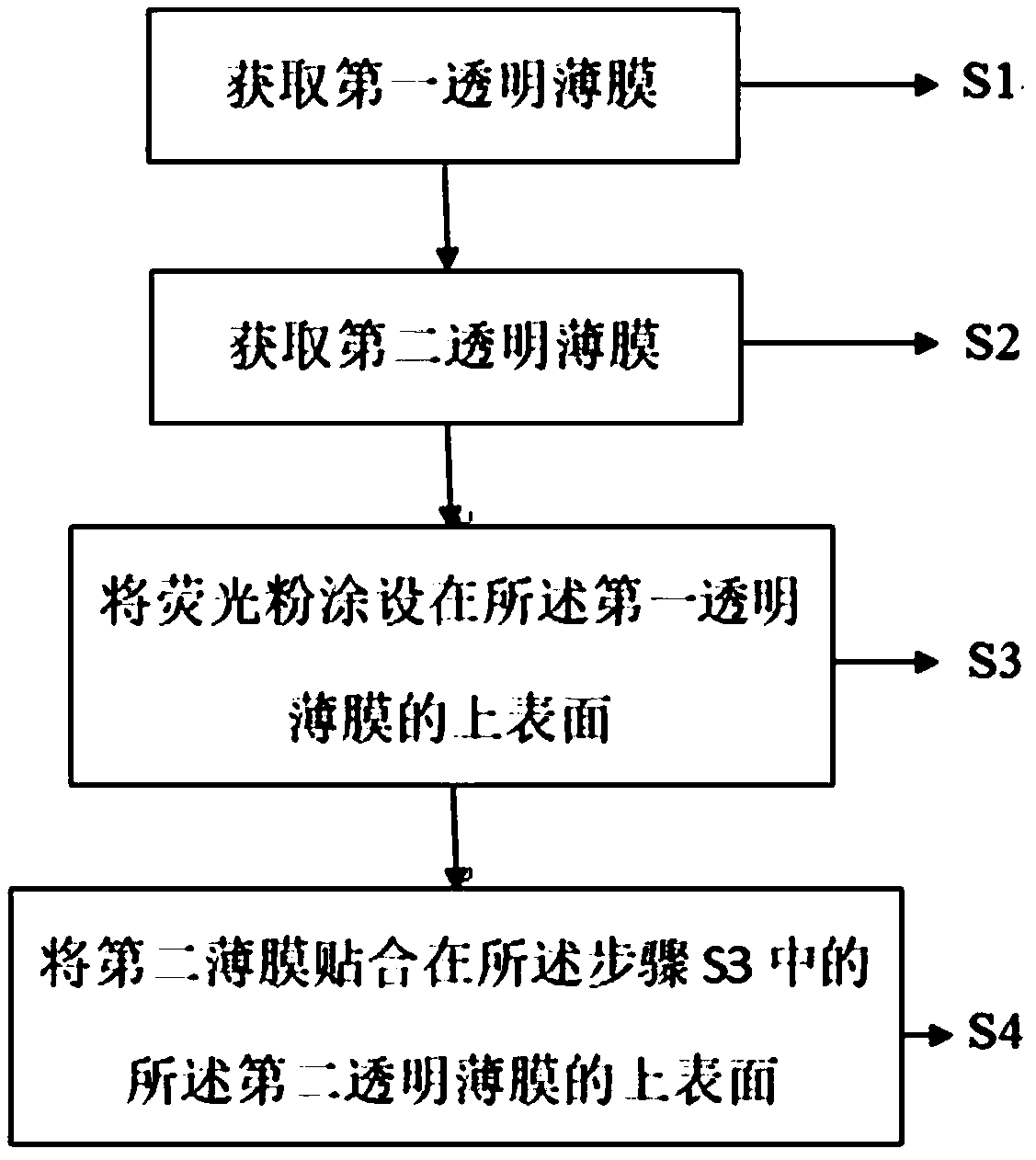

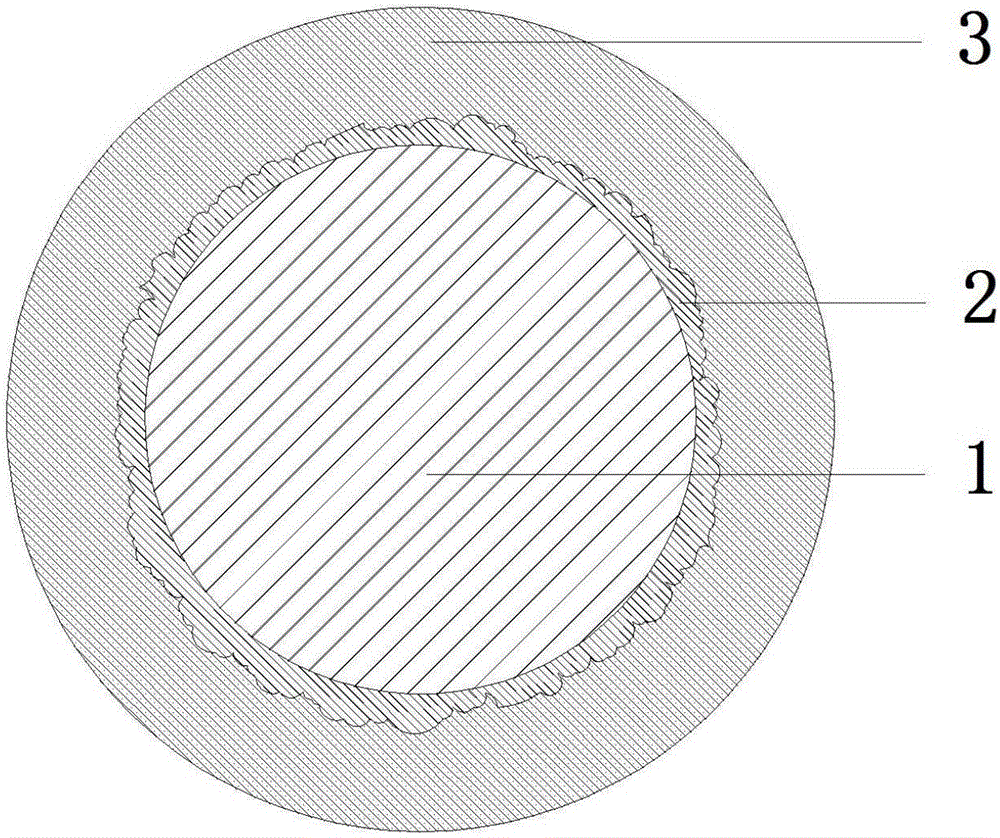

Fluorescent thin film structure for LED, preparation method thereof and light-emitting light source

ActiveCN109390454AGood optical performanceAvoid direct mixingSemiconductor devicesPhosphorFluorescence

The invention relates to a fluorescent thin film structure for an LED, a preparation method thereof and a light-emitting light source. The fluorescent thin film structure for an LED comprises a firsttransparent thin film, phosphor powder applied on the upper surface of the first transparent thin film and a second transparent thin film bonded to the first transparent thin film coated with the phosphor powder. The preparation method of the fluorescent thin film structure for an LED includes: obtaining a first transparent thin film, obtaining a second transparent thin film, applying phosphor powder on the upper surface of the first transparent thin film, and bonding the second transparent thin film to the upper surface of the first transparent thin film coated with the phosphor powder. An LED light-emitting light source includes the fluorescent thin film structure for an LED. The invention solves the problems of fluorescent powder precipitation and poor consistency of light and color inthe packaging process, meanwhile shortens the packaging process and reduces the production cost.

Owner:NINGBO LONGER LIGHTING

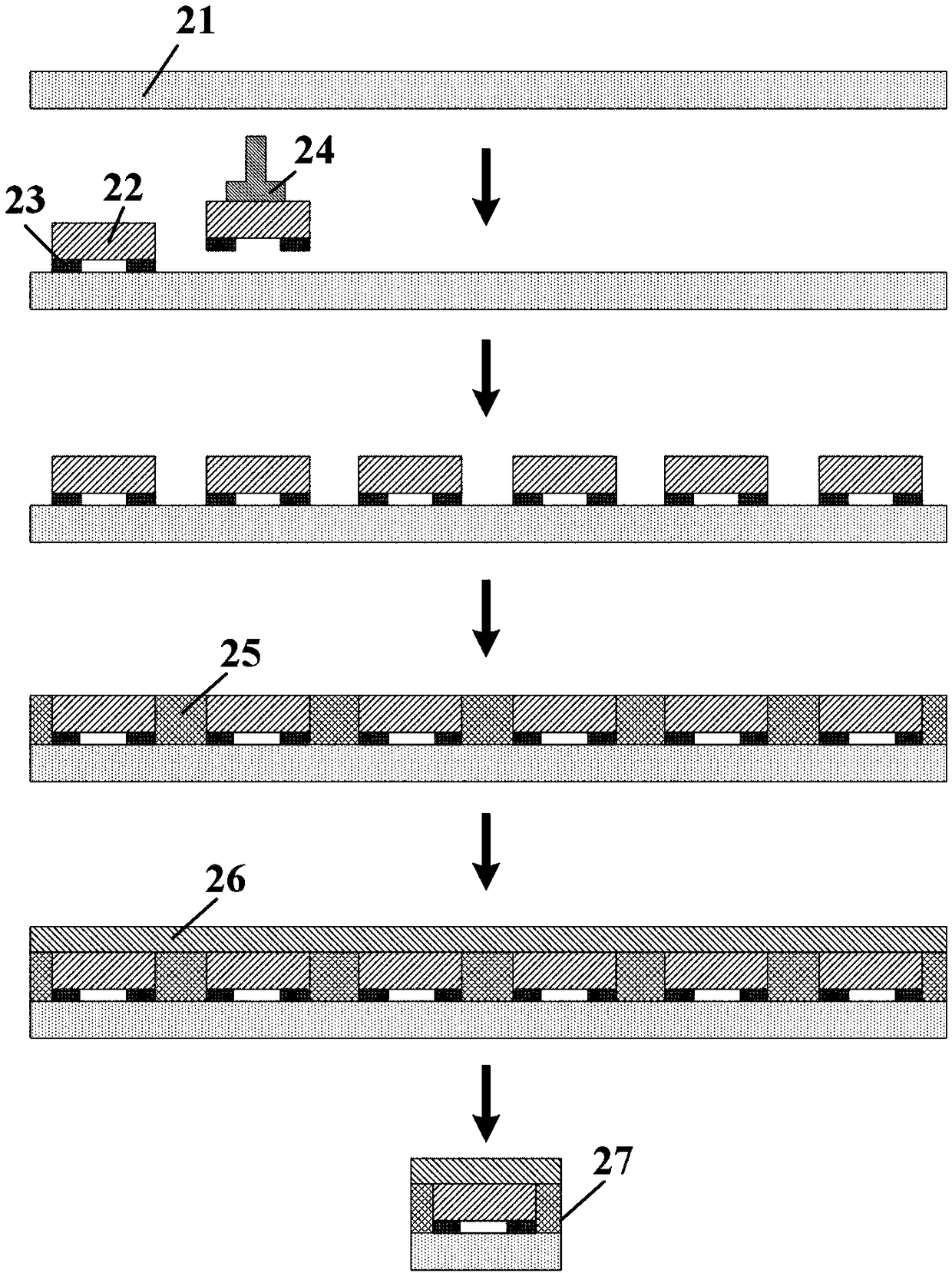

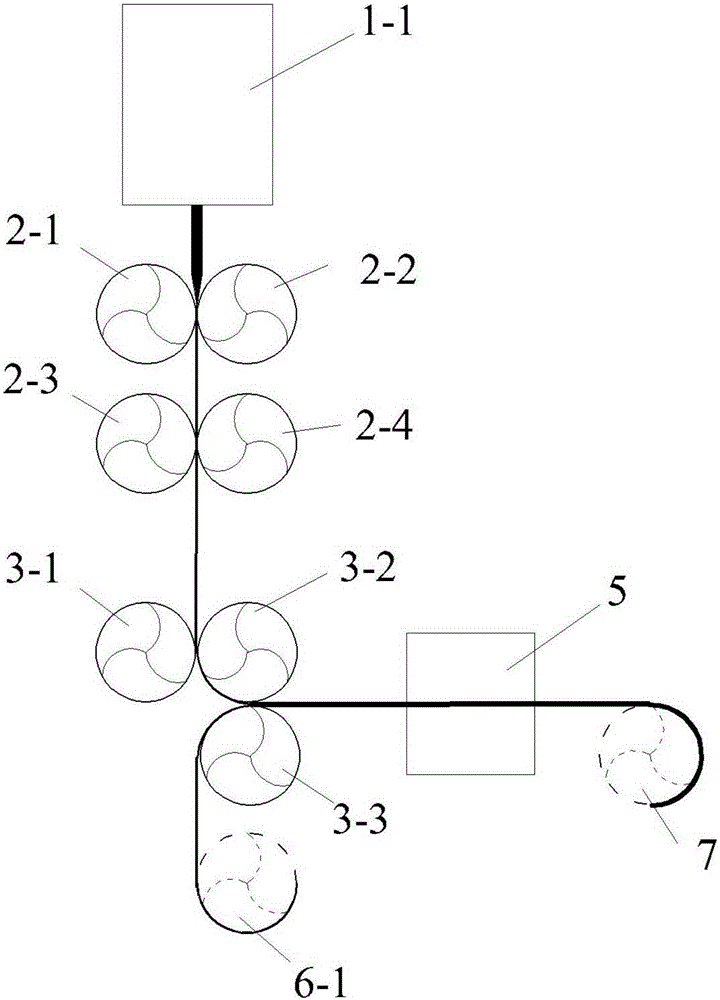

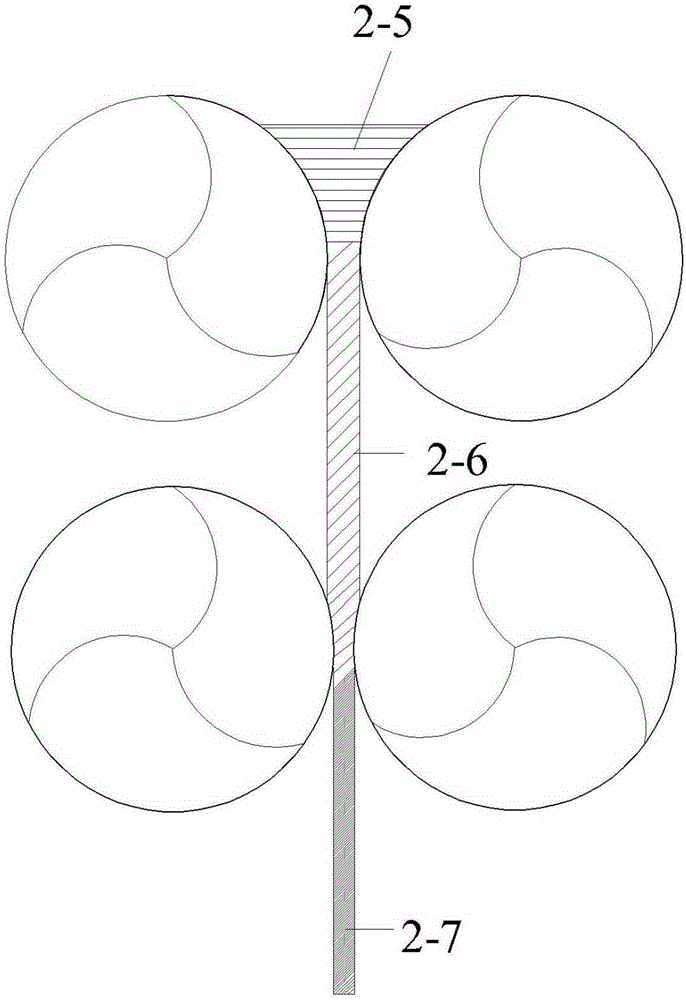

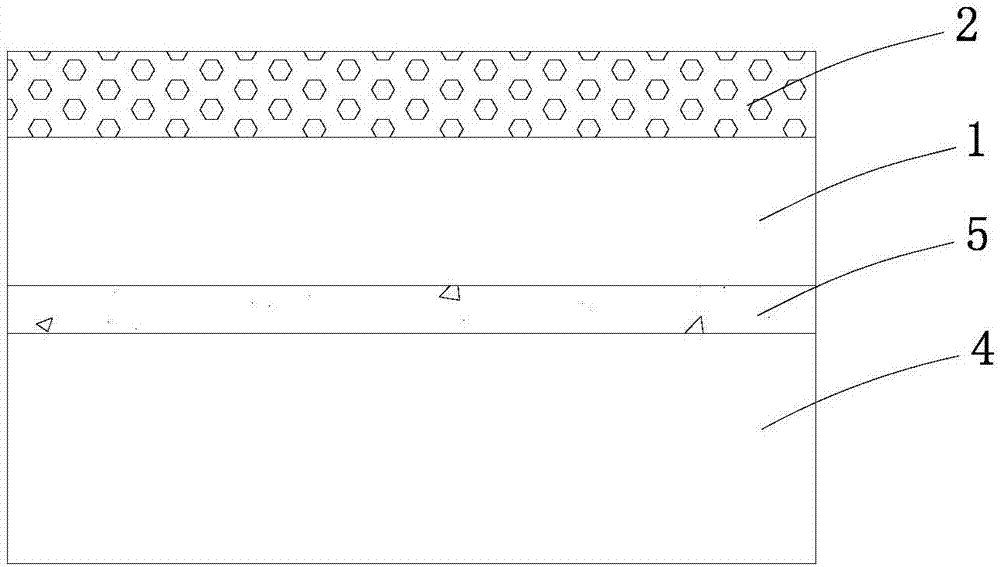

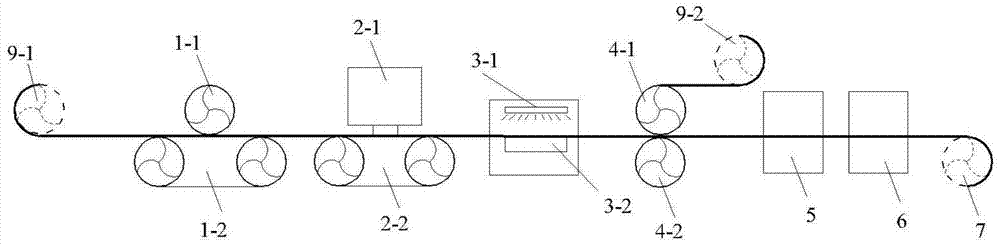

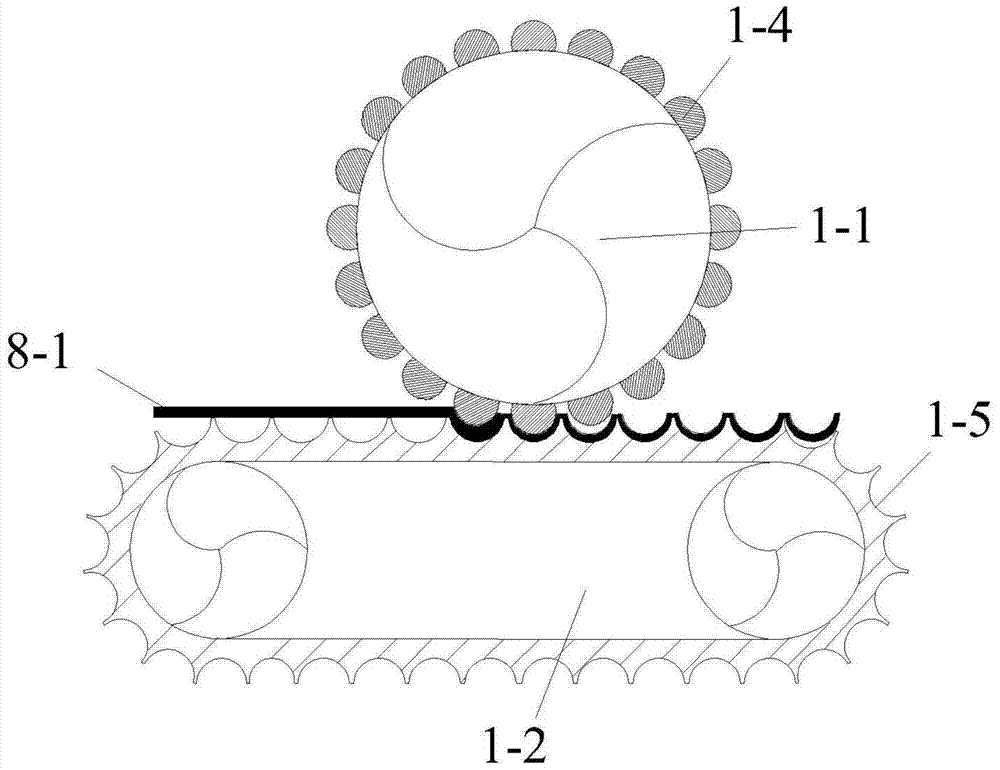

Equipment system for laminating and packaging LED based on rolling type thermoplastic resin light conversion body

ActiveCN106469774AOvercoming light extraction efficiencyOvercome the excellent rateSemiconductor devicesProcess equipmentMechanical engineering

The invention relates to an equipment system for laminating and packaging an LED based on a rolling type thermoplastic resin light conversion body. The characteristics lie in that the equipment system comprises a collaborative rolling shape-fixing and cutting device used for performing rolling shape-fixing and rolling cutting on a light conversion diaphragm so as to form a light conversion diaphragm array and a rolling laminating device used for laminating the light conversion diaphragm array and an LED flip chip array; the collaborative rolling shape-fixing and cutting device and the rolling laminating device sequentially form collaborative linkage process equipment; the collaborative rolling shape-fixing and cutting device comprises a rolling device 1 with a bump array and a rolling device 2 with a groove array which are oppositely arranged in an aligned manner; and the rolling laminating device comprises a rolling device 4 with a groove array and a rolling device 3 with the rolling surface being a smooth surface which are oppositely arranged in an aligned manner. The equipment system meets requirements of a technological method suitable for laminating and packaging the LED based on the thermoplastic resin light conversion body, so that the production efficiency and the superior quality product rate of industrial batch LED packaging are improved.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

Flexible red fluorescent film

InactiveCN107141805AEvenly distributedControl thicknessLuminescent compositionsFluorescenceMass ratio

The invention discloses a flexible red fluorescent film which is formed by powder and organic matter. The powder and the organic matter are in the mass ratio of (0.1-0.3):1, and the organic matter is polydimethylsiloxane; in the powder, in terms of the mass percentage of an oxide, the total content of 0%<Na2O+Li2O+K2O is smaller than 6.65%, the total content of 30%<WO3+M0O3 is smaller than 49.75%, the total content of 5%<Gd2O3+La2O3+Y2O3 is smaller than 34.95%, and the total content of 0%<Eu2O3 is smaller than 22.28%. The invention further provides a preparation method of the flexible red fluorescent film. The flexible red fluorescent film is simple in operation and low in cost, and problems about consistency and heat dissipation of fluorescent powder coating can be improved, and the flexible red fluorescent film is suitable for remote fluorescent powder LED packaging and large-scale, quantitative industrial production.

Owner:SHANGHAI INST OF TECH

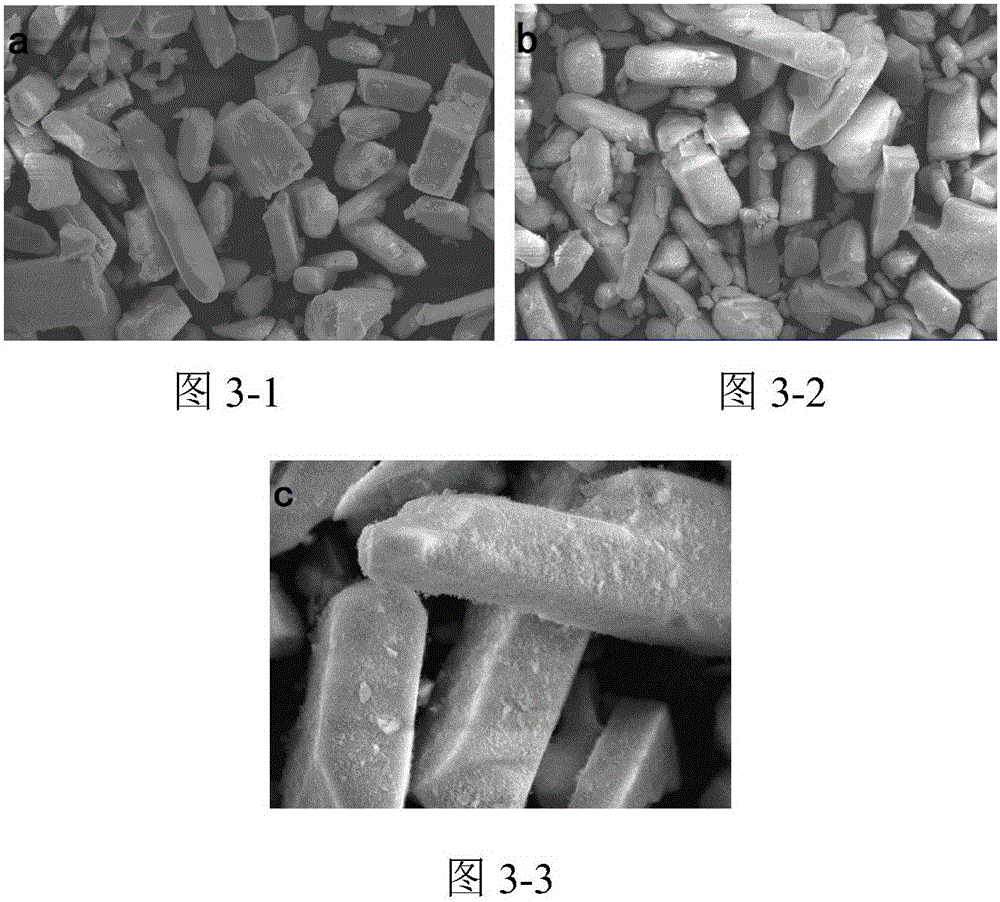

New concept-based phosphor with planting corner angle and penetration and diffusion layer and light-emitting device

ActiveCN106025043AGood chemical stabilityReduce temperature riseLuminescent compositionsSemiconductor devicesPhosphorInorganic compound

The invention relates to a new concept-based phosphor with a planting corner angle and a penetration and diffusion layer. The phosphor is characterized by comprising an inorganic compound phosphor, a corner angle planting agent and a penetration planting agent, wherein primary bonding of the corner angle planting agent and the surface of the inorganic compound phosphor is carried out to form the inorganic compound phosphor with the planting corner angle; and secondary bonding of the penetration planting agent and the surface of the inorganic compound phosphor with a corner angle shape is carried out to form the phosphor with the planting corner angle and the penetration and diffusion layer. The phosphor with the planting corner angle and the penetration and diffusion layer has excellent cold-to-hot state performance and good chemical stability and is suitable for various light-emitting devices. The preparation method provided by the invention is simple, convenient and reliable, and is suitable for industrialized mass production and manufacturing.

Owner:JIANGSU BREE OPTRONICS CO LTD

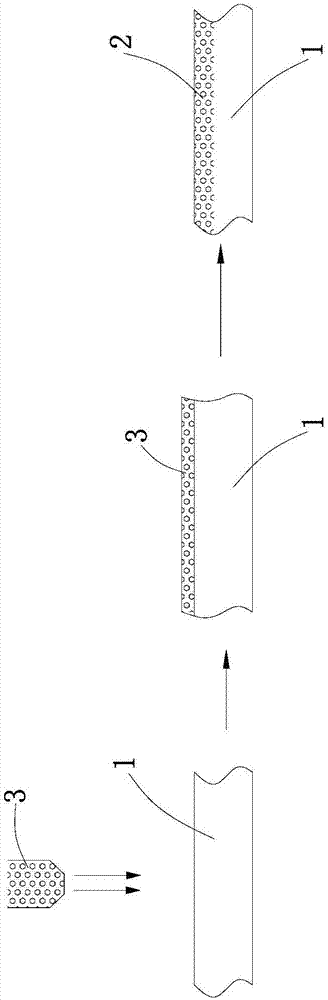

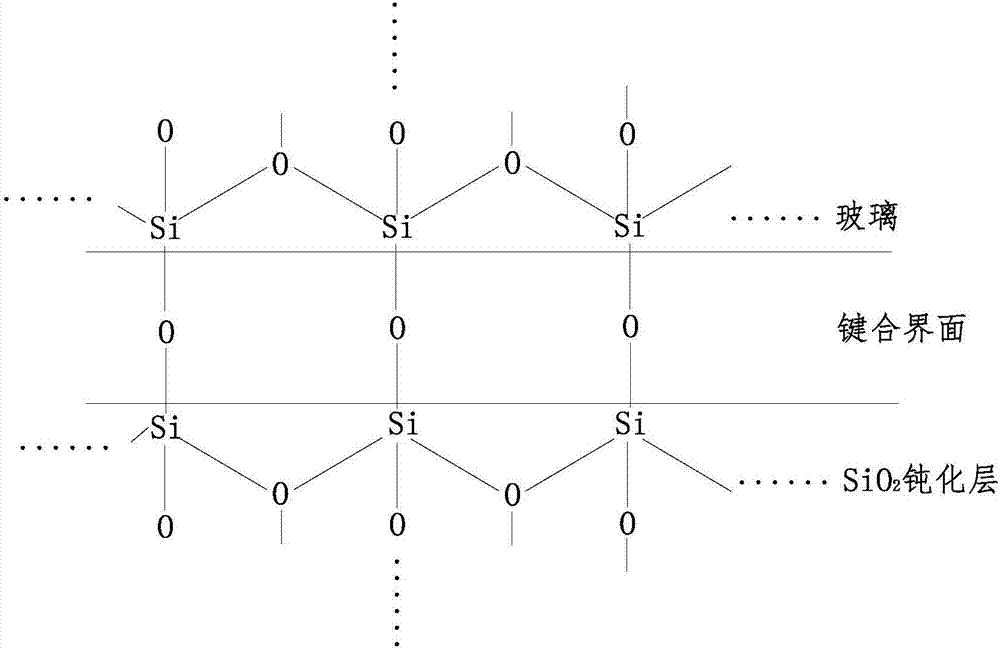

Non-organic-glue wafer-level package method and LED flip chip package body

InactiveCN107331759AImprove light color consistencyHigh light transmittanceSemiconductor devicesFluorescenceWafer-level packaging

The invention relates to a non-organic-glue wafer-level package method and an LED flip chip package body. The package method enables glass having a phosphor layer to be directly bonded to a light output surface of an LED flip chip in a low-temperature bonding manner, so that the whole LED package body is free from organic glue package, and the defects of organic glue package are avoided.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

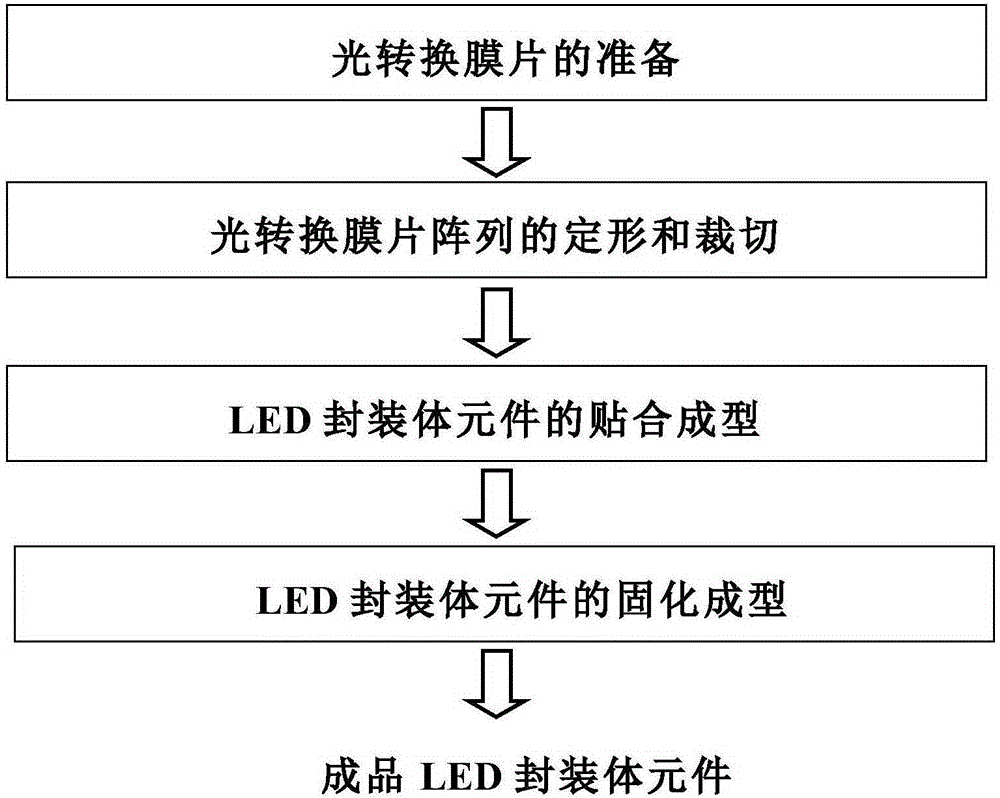

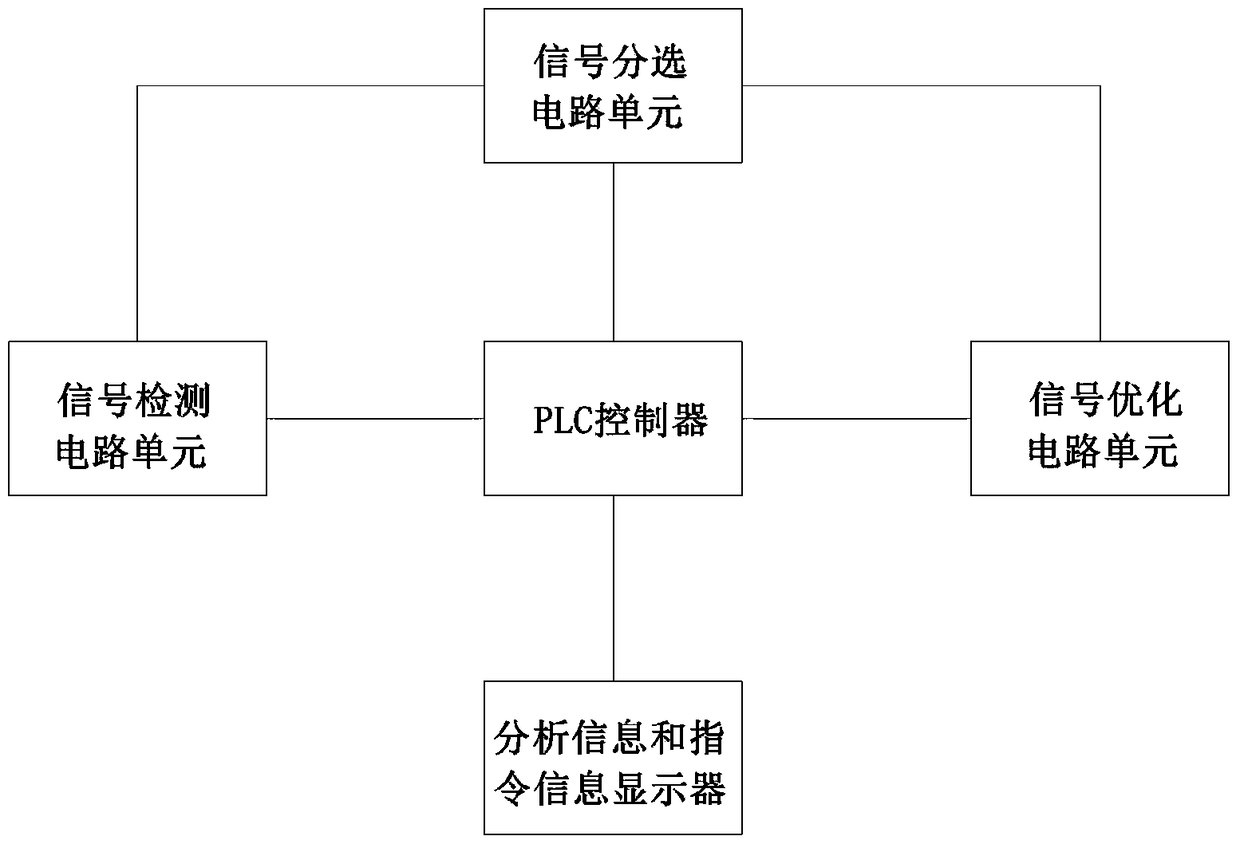

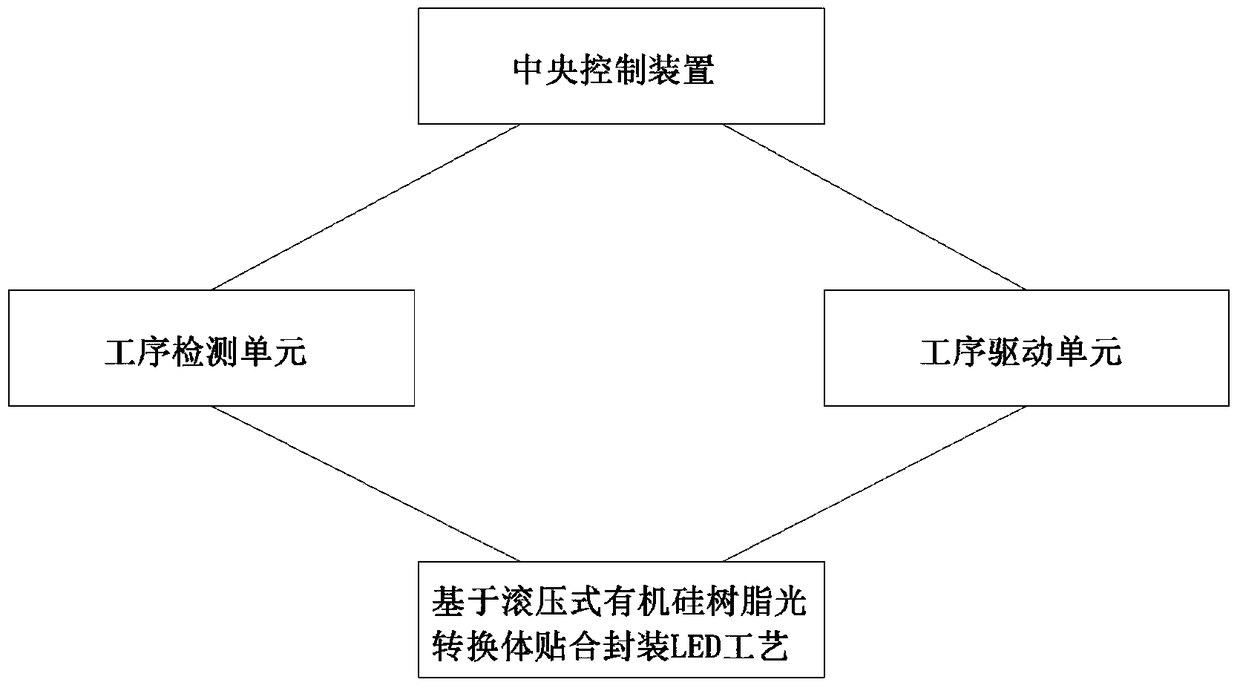

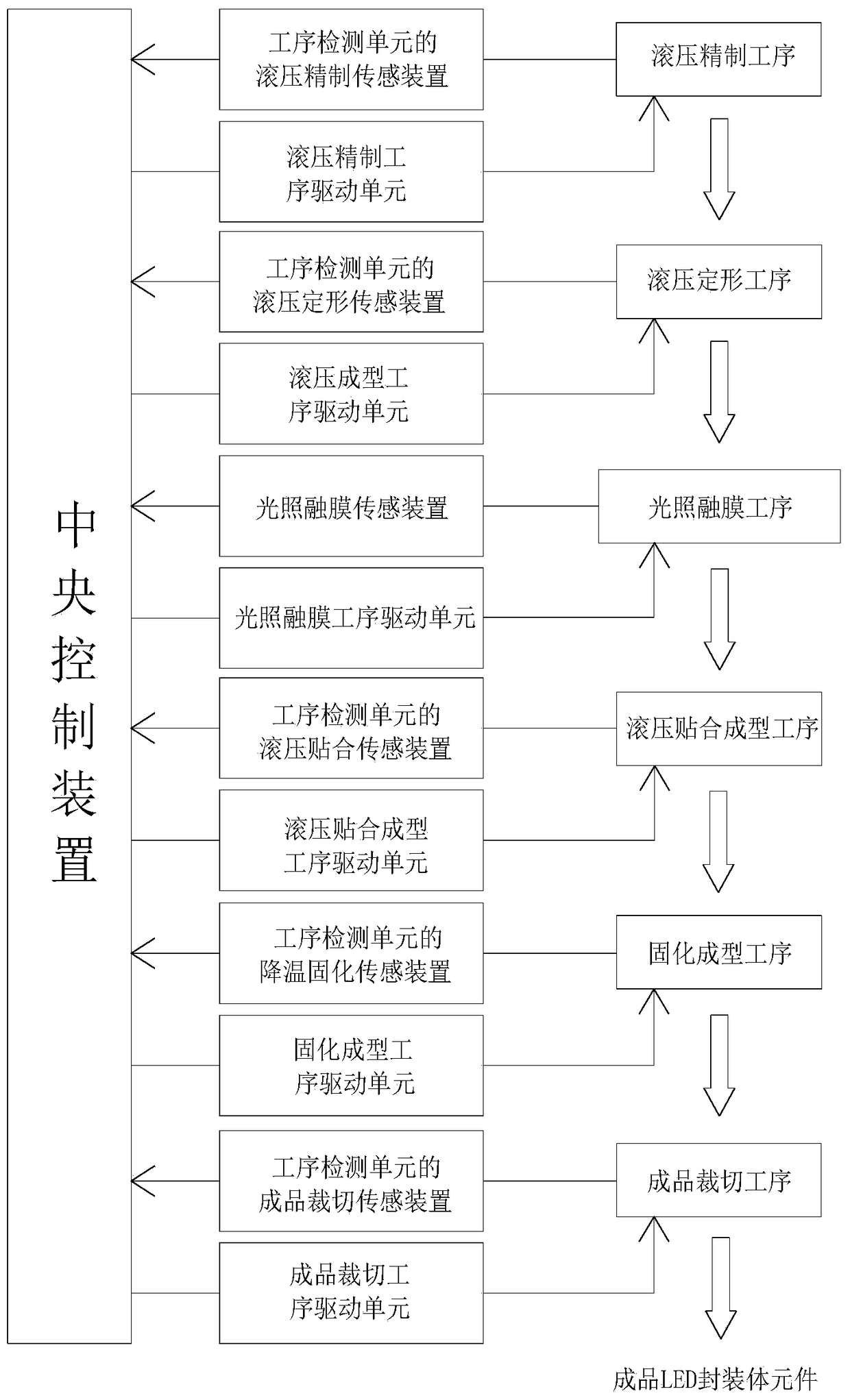

A kind of intelligent control system and control method based on rolling type silicone resin light conversion body bonding and packaging LED

The invention relates to an intelligent control system of fitted packaging of an LED by an organic silicone resin light conversion body based on rolling. The system is characterized in that the system at least comprises process detection units used for a rolling fitted molding process, a curing molding process, and a finished product cutting process of rolling fitted packaging of the LED by the organic silicone resin light conversion body, a central control device, and process driving units; and the central control device is connected with the process detection units and the process driving units in a signal manner, and used for receiving state information of each process detection unit in real time and processing operation information for real-time regulation and control of the process driving units. The system is advantageous in that the process of rolling fitted packaging of the LEDs can be detected and controlled, the requirement of the process and an equipment system applicable to fitted packaging of the LEDs by the organic silicone resin light conversion body can be met, and the production efficiency and the yield of industrial and batch packaging of the LEDs are increased.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

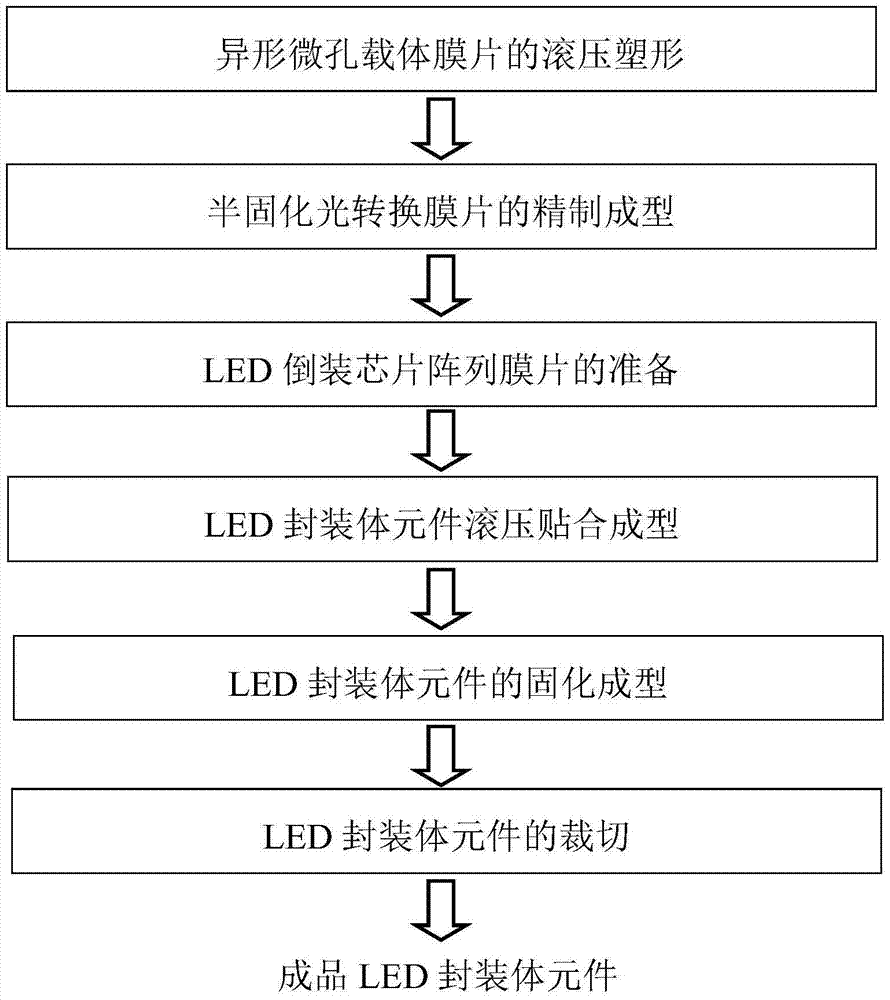

A process method and refining equipment system for a refined light conversion body to fit and package an LED

ActiveCN106558642BIncrease productivityImprove the quality rateSemiconductor devicesContinuous flowEngineering

The invention relates to a refining light conversion body fitting packaging LED process method and refining equipment system. The process method comprises the continuous flow process formed by rolling molding of a special-shaped micropore carrier film, refining molding of a semi-curing light conversion film, preparation of an LED flip chip array film, rolling and fitting molding of LED packaging body elements, curing molding of the LED packaging body elements and the cutting process of the LED packaging body elements. The method has the substantial advantage of the refining light conversion body, and especially the method can meet the requirements of the continuous flow process of the organic silicon resin light conversion body fitting packaging LED so that the production efficiency and the superior product rate of industrial batch LED packaging can be enhanced.

Owner:JIANGSU CHERRITY OPTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com