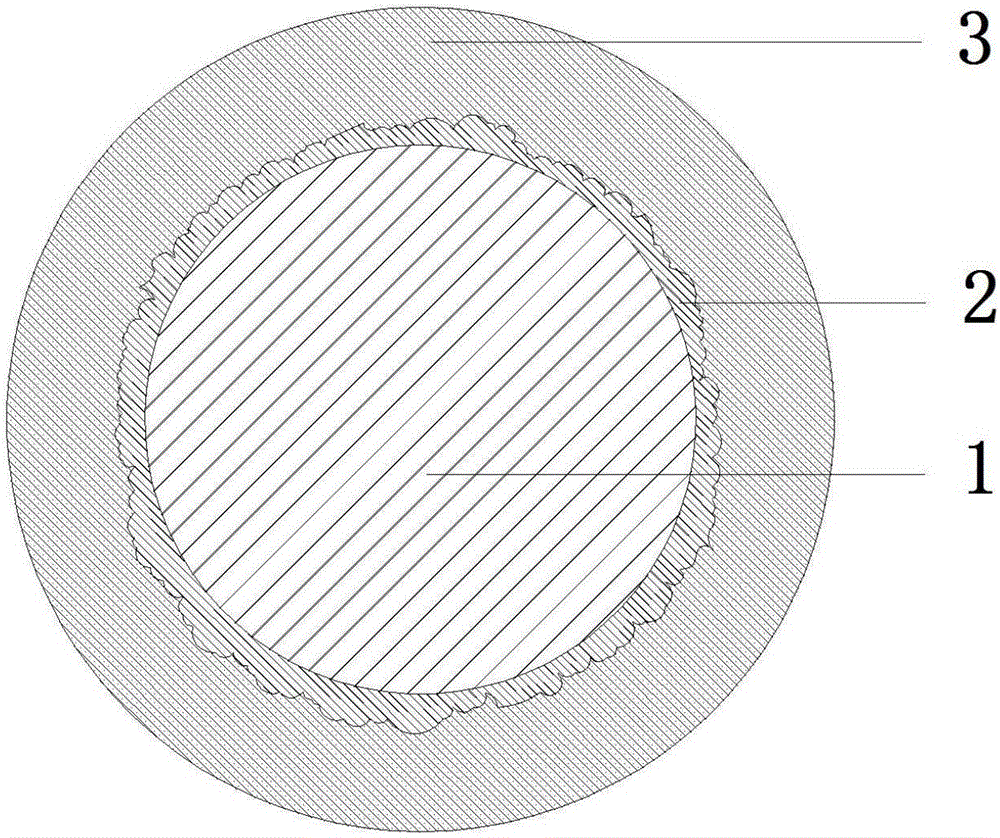

New concept-based phosphor with planting corner angle and penetration and diffusion layer and light-emitting device

A technology of permeation diffusion and phosphor, applied in the field of LED phosphors and light-emitting devices, can solve the problems of poor color consistency of LED finished lamp beads, increased color temperature of LED finished lamp beads, unable to meet the requirements of color temperature stability, etc. Light color consistency, excellent heat absorption/heat dissipation, alleviating the effect of poor light color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

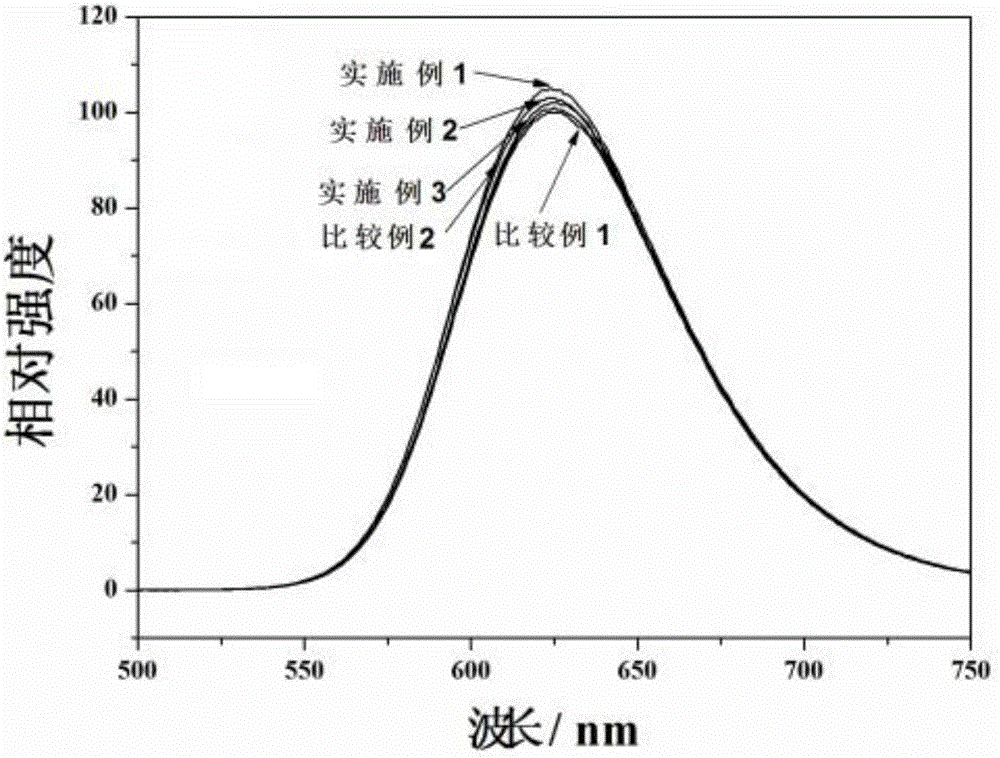

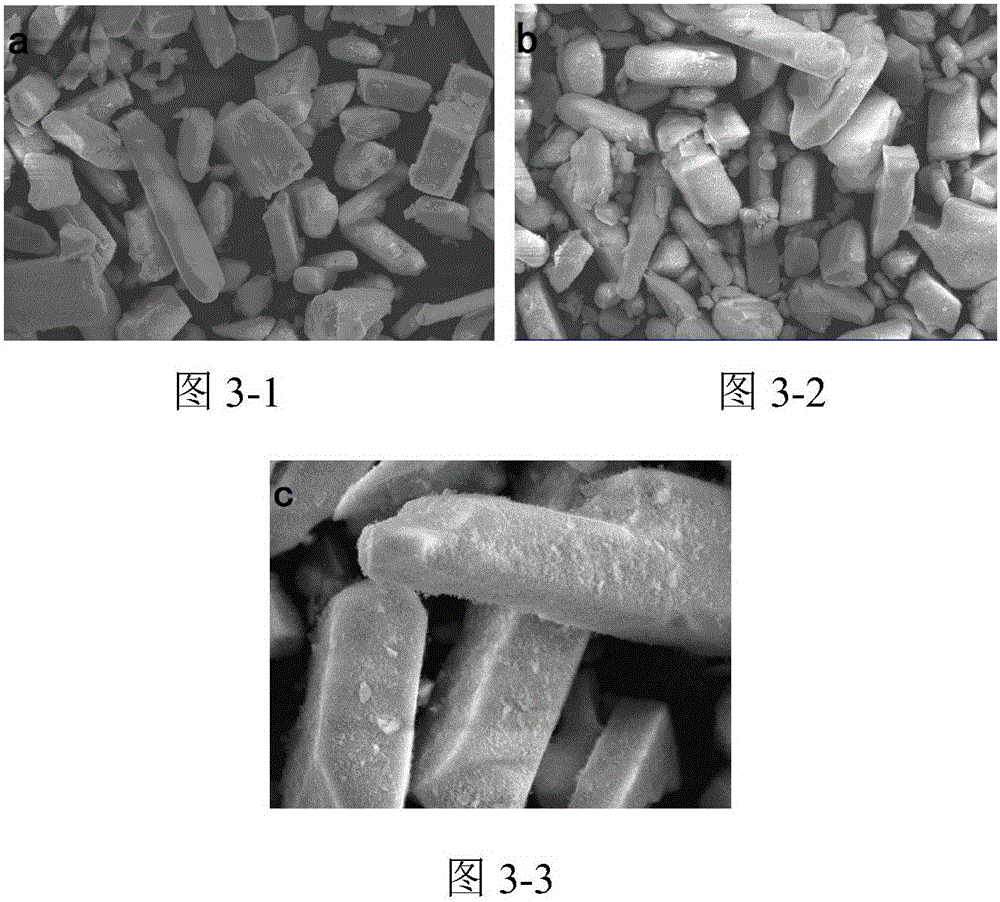

Embodiment 1

[0050] Weigh 100g of (Sr,Ca)AlSiN 3 :Eu 2+ Red phosphor, 0.1g calcium oxide angular planting agent, mix the above raw materials for 3 hours, put them into a molybdenum crucible, then quickly move them into a tube furnace, and then gradually heat up to 200°C under the protection of nitrogen atmosphere, and keep warm for 12 hours , to get (Sr,Ca)AlSiN with planted CaO corners 3 :Eu 2+ Red phosphor; weigh 100g of (Sr,Ca)AlSiN with planted calcium oxide corners 3 :Eu 2+ Red phosphor, 0.5g thermal conductivity 10W / m.k, particle size 2nm, specific surface area 80cm 2 / g of nano-silica and 200mL of absolute ethanol were added to a three-necked flask equipped with a tetrafluoroethylene stirring rod and a thermometer placed in a water bath, stirred and heated to 70°C for 2h, and then the reaction was terminated. After suction filtration, washing with absolute ethanol and drying, (Sr,Ca)AlSiN with planted nano-silica infiltration diffusion layer and calcium oxide corners was obtain...

Embodiment 2

[0052] Weigh 100g of (Sr,Ca)AlSiN 3 :Eu 2+ Red phosphor, 0.2g alumina edge planting agent, mix the above raw materials for 3 hours, put them into a molybdenum crucible, then quickly move them into a tube furnace, and then gradually raise the temperature to 400°C under the protection of nitrogen atmosphere, and keep warm for 12 hours , to get (Sr,Ca)AlSiN with planted alumina corners 3 :Eu 2+ Red phosphor; Weigh 100g of (Sr,Ca)AlSiN with planted alumina corners 3 :Eu 2+ Red phosphor, 1.0g thermal conductivity 20W / m.k, particle size 15nm, specific surface area 150cm 2 / g of nano-magnesium oxide and 200mL of absolute ethanol were respectively added to a three-necked flask equipped with a tetrafluoroethylene stirring rod and a thermometer placed in a water bath, stirred and heated to 70°C for 2h, and then the reaction was terminated. After suction filtration, washing with absolute ethanol and drying, the (Sr,Ca)AlSiN with implanted nano-magnesia infiltration diffusion layer a...

Embodiment 3

[0054] Weigh 100g of (Sr,Ca)AlSiN 3 :Eu 2+ Red phosphor, 0.8g of strontium oxide angular planting agent, mix the above raw materials for 3 hours, put them into a molybdenum crucible, then quickly move them into a tube furnace, and then gradually raise the temperature to 800°C under the protection of a nitrogen atmosphere, and keep it warm for 12 hours , to obtain (Sr,Ca)AlSiN with planted strontium oxide edges 3 :Eu 2+ Red phosphor; Weigh 100g of (Sr,Ca)AlSiN with planted strontium oxide edges 3 :Eu 2+ Red phosphor, 1.8g thermal conductivity 40W / m.k, particle size 50nm, specific surface area 500cm 2 / g of nano-zinc oxide and 200mL of absolute ethanol were respectively added to a three-necked flask equipped with a tetrafluoroethylene stirring rod and a thermometer placed in a water bath, stirred and heated to 70°C for 2h, and then the reaction was terminated. After suction filtration, washing with absolute ethanol and drying, (Sr,Ca)AlSiN with implanted nano-zinc oxide inf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com