LED (Light Emitting Diode) light source, manufacturing method thereof and backlight module

A backlight module, LED chip technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high backlight cost, low input bin rate light acceptance rate, poor light color consistency, etc., to improve light color. Consistency, improve the Bin rate, increase the effect of light reflection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions of each exemplary embodiment provided by the present invention with reference to the accompanying drawings in the embodiments of the present invention. In the case of no conflict, the following embodiments and technical features thereof can be combined with each other.

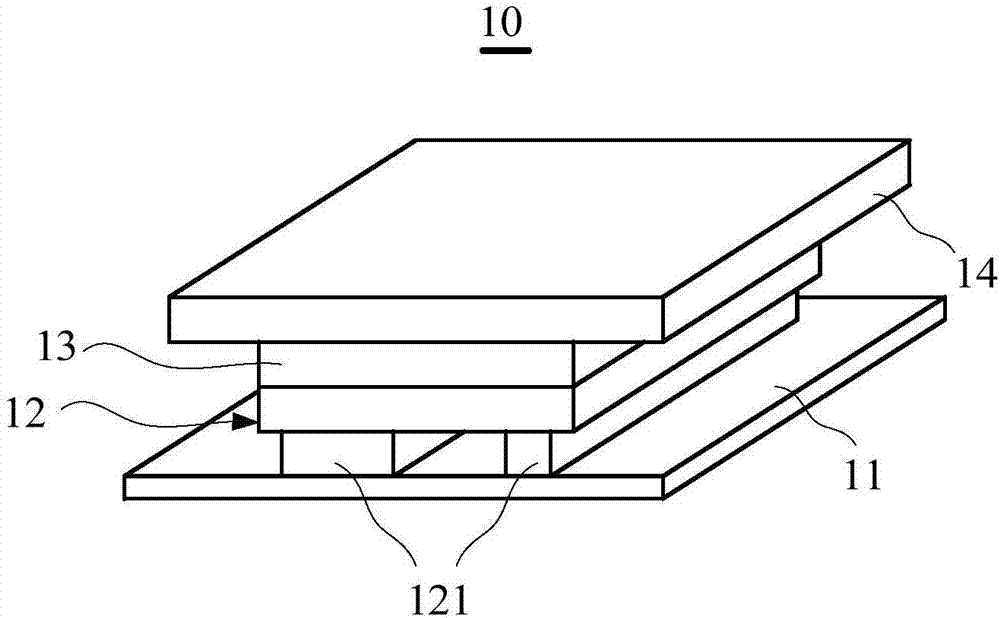

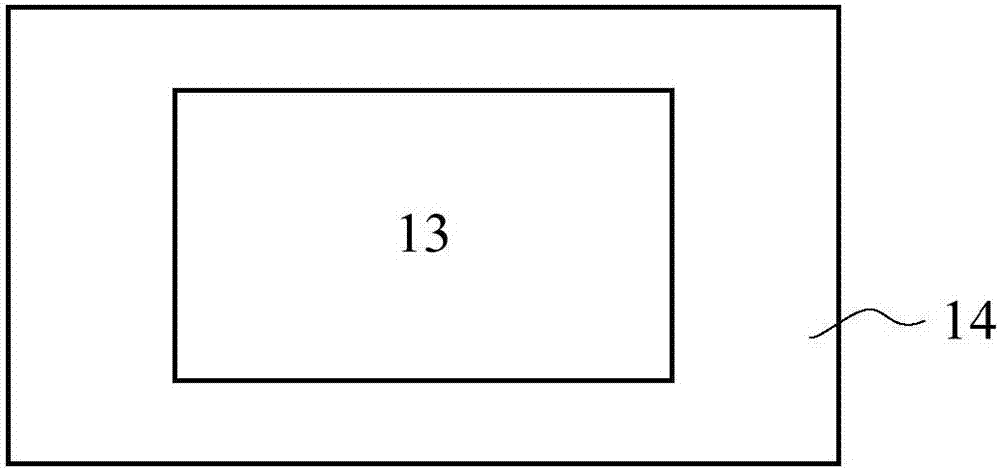

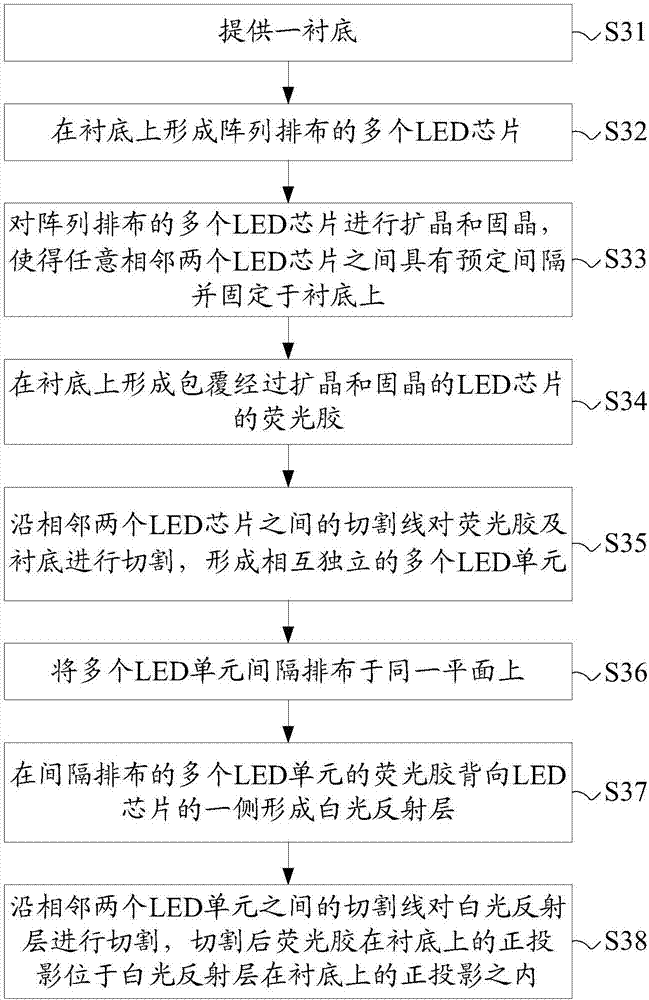

[0024] see figure 1 , is an LED light source according to an embodiment of the present invention. The LED light source 10 includes a substrate 11 , an LED chip 12 fixed on the substrate 11 , fluorescent glue 13 and a white light reflection layer 14 . The substrate 11 may be sapphire. The LED chip 12 is a flip chip provided with a metal electrode 121 , which is connected to electricity through the metal electrode 121 and emits blue light. The fluorescent glue 13 wraps and packages the LED chip 12 on the substrate 11 , and the fluorescent glue 13 has a rectangular structure as a whole, so that the packaged LED light source 10 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com