Light emitting diode structure

A technology of light emitting diodes and conductive structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of unsatisfactory light extraction efficiency, and achieve the effect of improving light extraction efficiency and increasing reflective area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

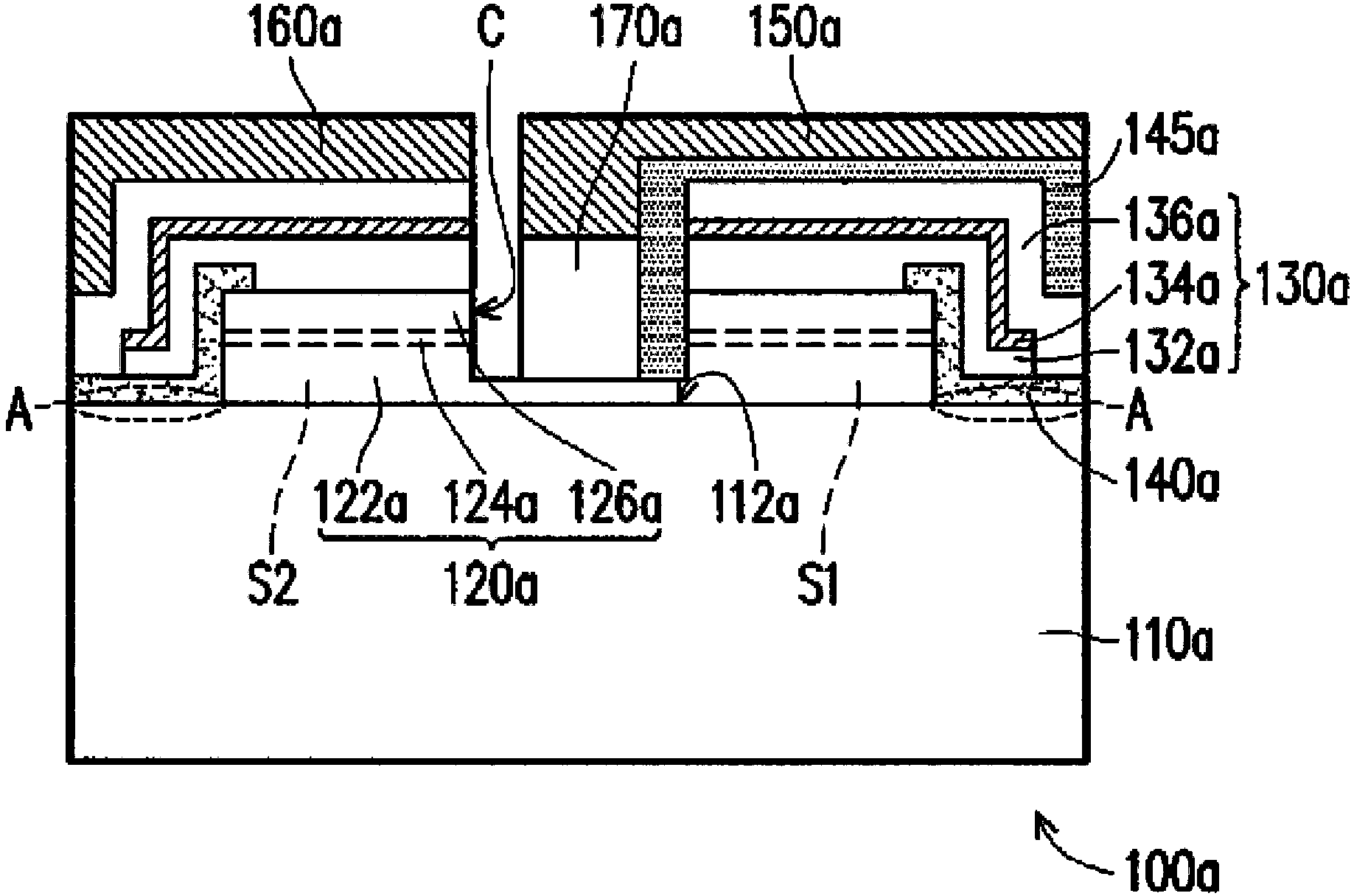

[0048] figure 1 It is a schematic cross-sectional view of a light emitting diode structure according to an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the light emitting diode structure 100a includes a substrate 110a, a semiconductor epitaxial layer 120a and a reflective conductive structure layer 130a. The semiconductor epitaxial layer 120a is disposed on the substrate 110a, and exposes a part of the substrate 110a ( figure 1 in the imaginary circle A). The reflective conductive structure layer 130a is disposed on the semiconductor epitaxial layer 120a, wherein the reflective conductive structure layer 130a covers part of the semiconductor epitaxial layer 120a and the portion of the substrate 110a exposed by the semiconductor epitaxial layer 120a.

[0049] More specifically, in this embodiment, the substrate 110a is, for example, a sapphire substrate, but not limited thereto, wherein the substrate 110a has an upper surface 112a. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com