Efficient intelligent LED light source

An intelligent, light source technology, applied in the direction of light source, light source fixing, semiconductor devices of light-emitting components, etc., can solve the problems of poor light color continuity, difficult light path fabrication, reduced light color continuity, etc., and achieves a scale beneficial to lean. Production, solving the effect of mixed light partition layering and light color continuity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

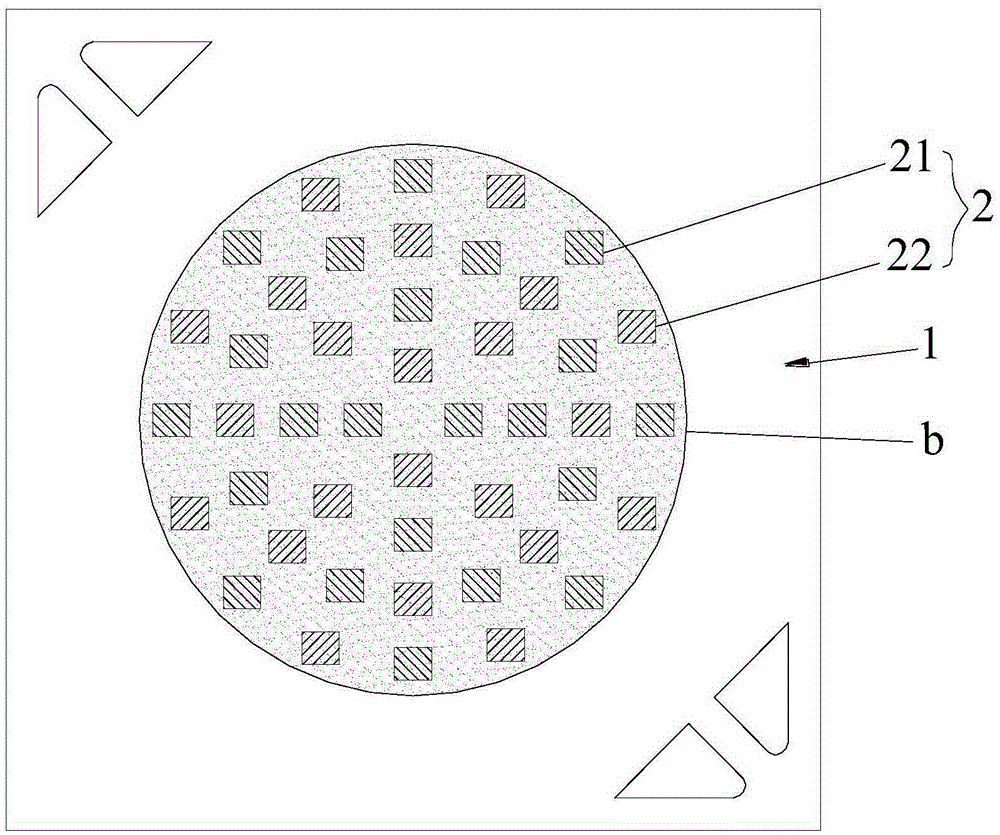

[0020] Please refer to Figure 3-4 , the high-efficiency LED intelligent light source includes a packaging substrate 1 and a chip unit 2 disposed on the packaging substrate 1 . Specifically, the chip unit 2 is divided into a plurality of bare chip units 21 and a plurality of wrapped chip units 22 formed by covering the surface of the bare chip unit 21 with a layer of first fluorescent layer a. The unit 21 is composed of at least one chip, which is usually a blue-ray chip, or a purple-ray chip. More specifically, the color temperature of each bare chip unit 21 is the same, and the color temperature of each wrapped chip unit 22 is the same, but the color temperature of the wrapped chip unit 22 is different from that of the bare chip unit 21 due to the effect of the first fluorescent layer a , the surfaces of the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com