Process for encapsulating light-emitting diode

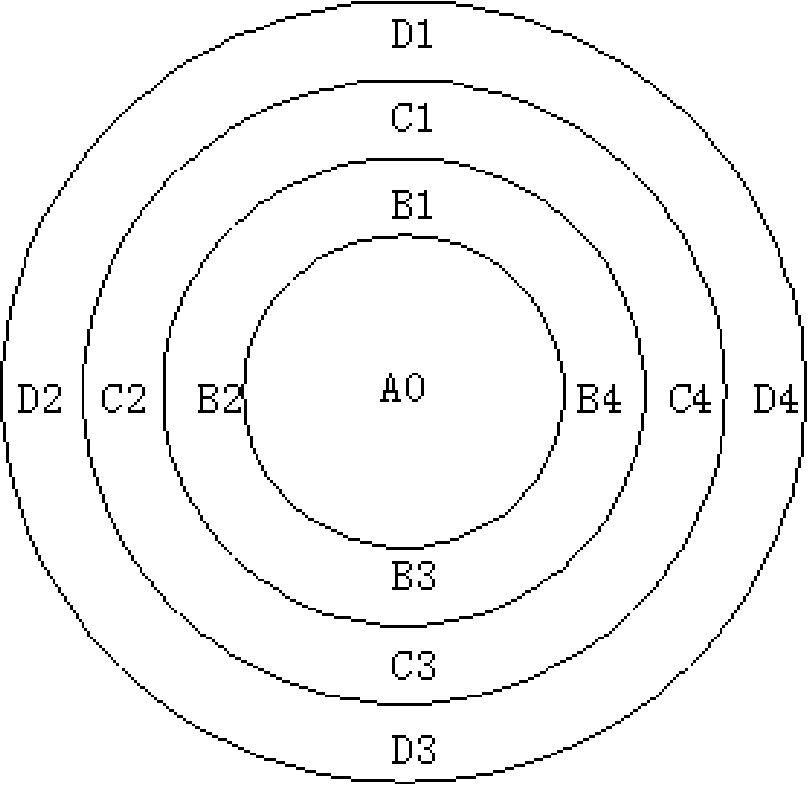

A technology of light-emitting diodes and packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the consistency of light color, inconsistent spacing, yellow circles in the light spot, etc., to improve the consistency and stability of light color, Remove the effect of the aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

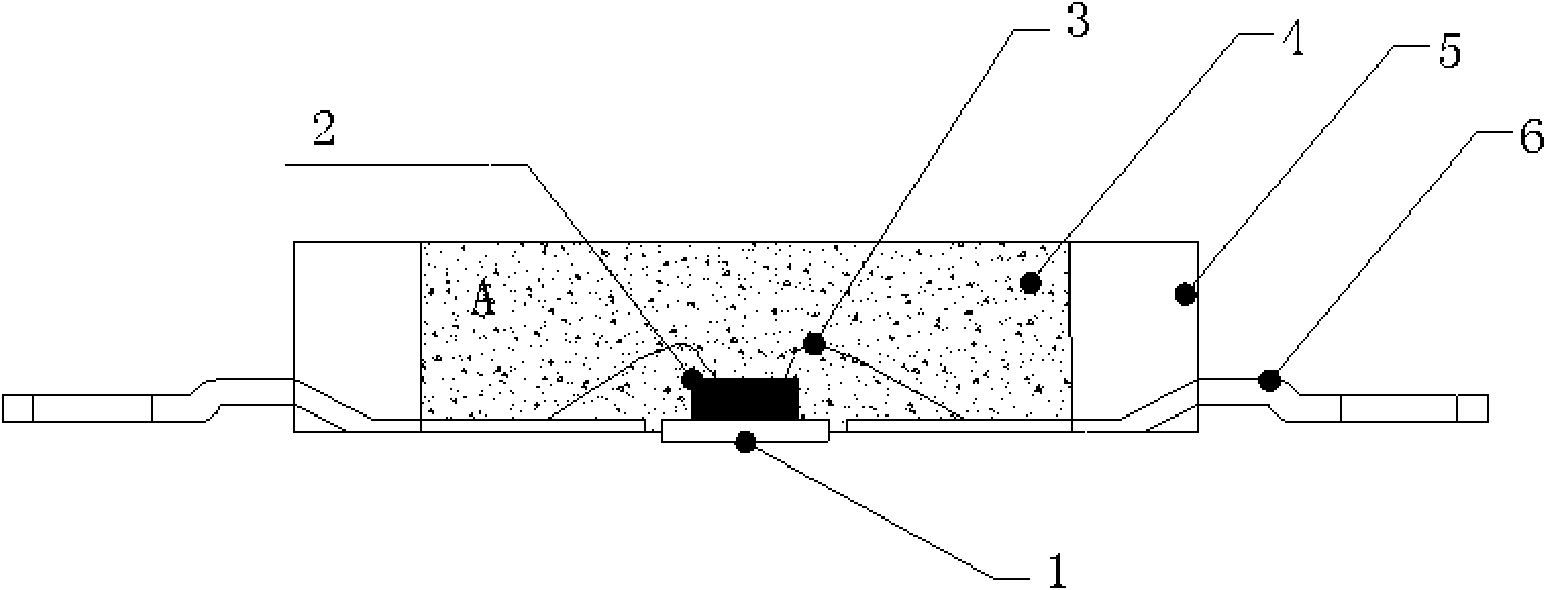

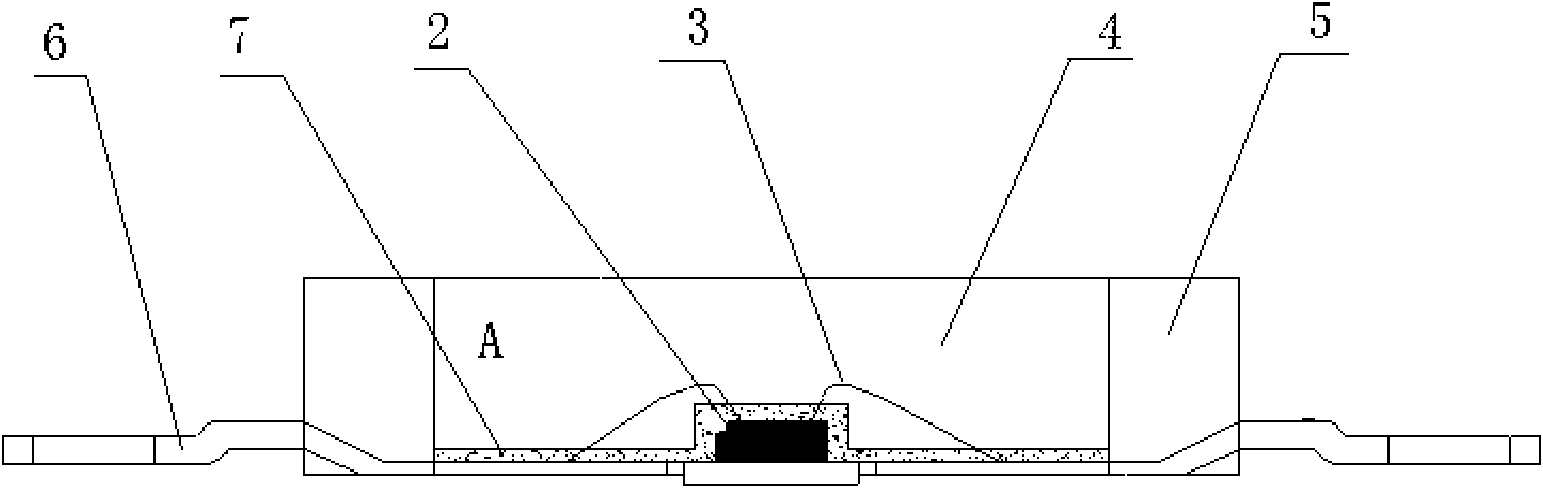

[0028] The LED packaging process of this embodiment includes the following process steps:

[0029] (1) Die-bonding: expand the core of the chip to make it meet the production requirements, bond the chip 2 to the heat-conducting base 1 of the bracket body 5 with crystal-bonding glue, and dry and solidify at a temperature of about 150°C;

[0030] (2) Welding wire: weld the two ends of the gold wire 3 on the electrode pin 6 and the chip 2 respectively, and electrically connect the chip 2 to the electrode pin 6;

[0031] (3) Glue dispensing: apply fluorescent powder glue 4 above the chip 2;

[0032] (4) Precipitation: After dispensing, let stand at 90° C. for 30 minutes to allow the phosphor to precipitate naturally, forming a phosphor layer 7 above the chip 2 ;

[0033] (5) Curing: curing the fluorescent powder glue at a temperature of 150°C;

[0034] (6) Encapsulation: Dot silica gel on the fluorescent powder glue, and cure it at a temperature of 150°C to complete the encapsul...

Embodiment 2

[0039] The LED packaging process of this embodiment includes the following process steps:

[0040] (1) Die-bonding: expand the core of the chip to make it meet the production requirements, bond the chip 2 to the heat-conducting base 1 of the bracket body 5 with crystal-bonding glue, and dry and solidify at a temperature of about 150°C;

[0041] (2) Welding wire: weld the two ends of the gold wire 3 on the electrode pin 6 and the chip 2 respectively, and electrically connect the chip 2 to the electrode pin 6;

[0042] (3) Glue dispensing: dot the fluorescent powder 4 above the chip 2;

[0043] (4) Precipitation: After dispensing, let stand at 30° C. for 4 hours to allow the phosphor to precipitate naturally, forming a phosphor layer 7 above the chip 2 ;

[0044] (5) Curing: curing the fluorescent powder glue at a temperature of 80°C;

[0045] (6) Encapsulation: Dot silica gel on the fluorescent powder glue, and cure it at a temperature of 150°C to complete the encapsulation o...

Embodiment 3

[0050] The LED packaging process of this embodiment includes the following process steps:

[0051] (1) Die-bonding: expand the core of the chip to meet the production requirements, bond the chip 2 to the heat-conducting base 1 of the bracket body 5 with a die-bonding glue, and dry and solidify at a temperature of about 150°C;

[0052] (2) Welding wire: weld the two ends of the gold wire 3 on the electrode pin 6 and the chip 2 respectively, and electrically connect the chip 2 to the electrode pin 6;

[0053] (3) Glue dispensing: apply fluorescent powder glue 4 above the chip 2;

[0054] (4) Precipitation: After dispensing, let stand at 90° C. for 120 minutes to allow the phosphor to precipitate naturally and form a phosphor layer 7 above the chip 2 ;

[0055] (5) Curing: curing the fluorescent powder glue at a temperature of 80°C;

[0056] (6) Encapsulation: Dot silica gel on the fluorescent powder glue, and cure it at a temperature of 150°C to complete the encapsulation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com