A kind of intelligent control system and control method based on rolling type silicone resin light conversion body bonding and packaging LED

An intelligent control system and light conversion technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low production efficiency of packaged LEDs, the influence of thermal overstress, and product consistency problems, so as to improve the light output efficiency and light output. Uniformity, improving the consistency of light and color, and the effect of smoothing and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

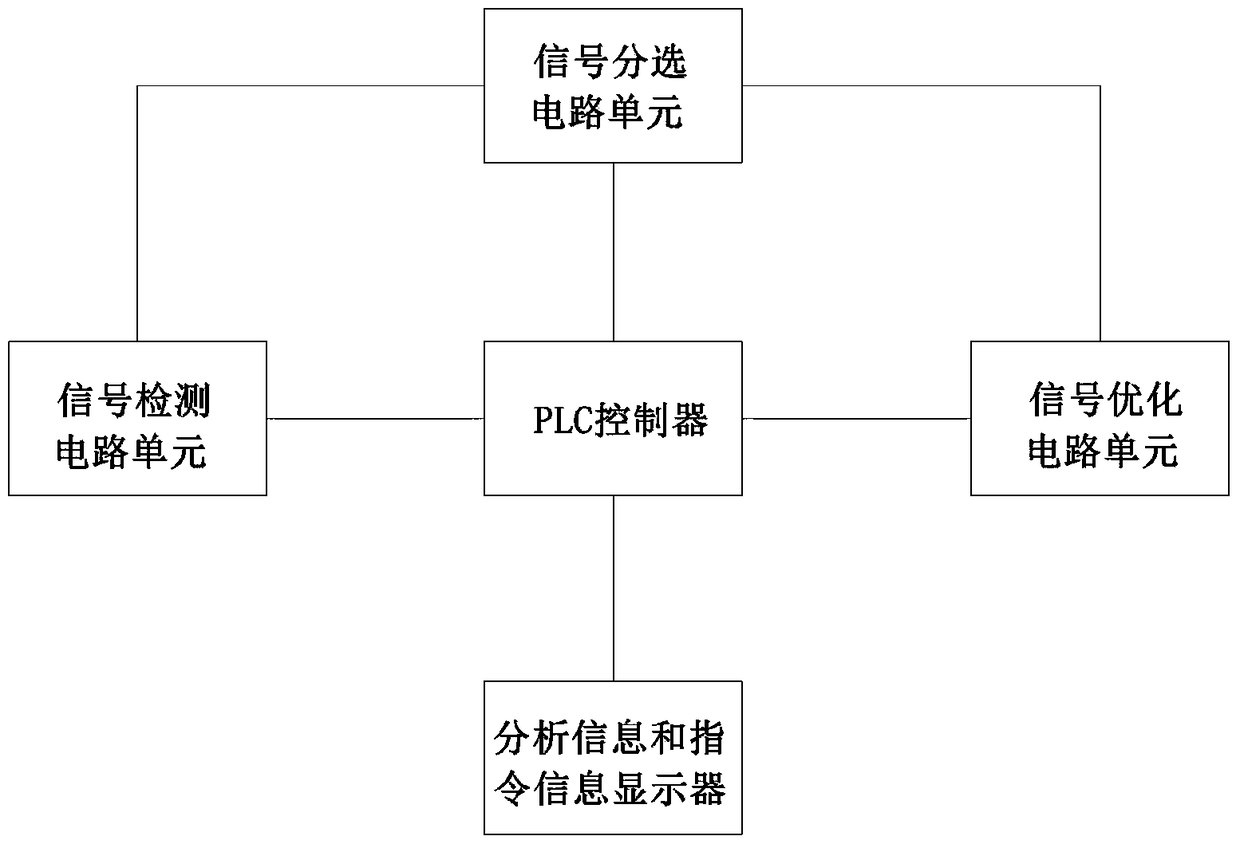

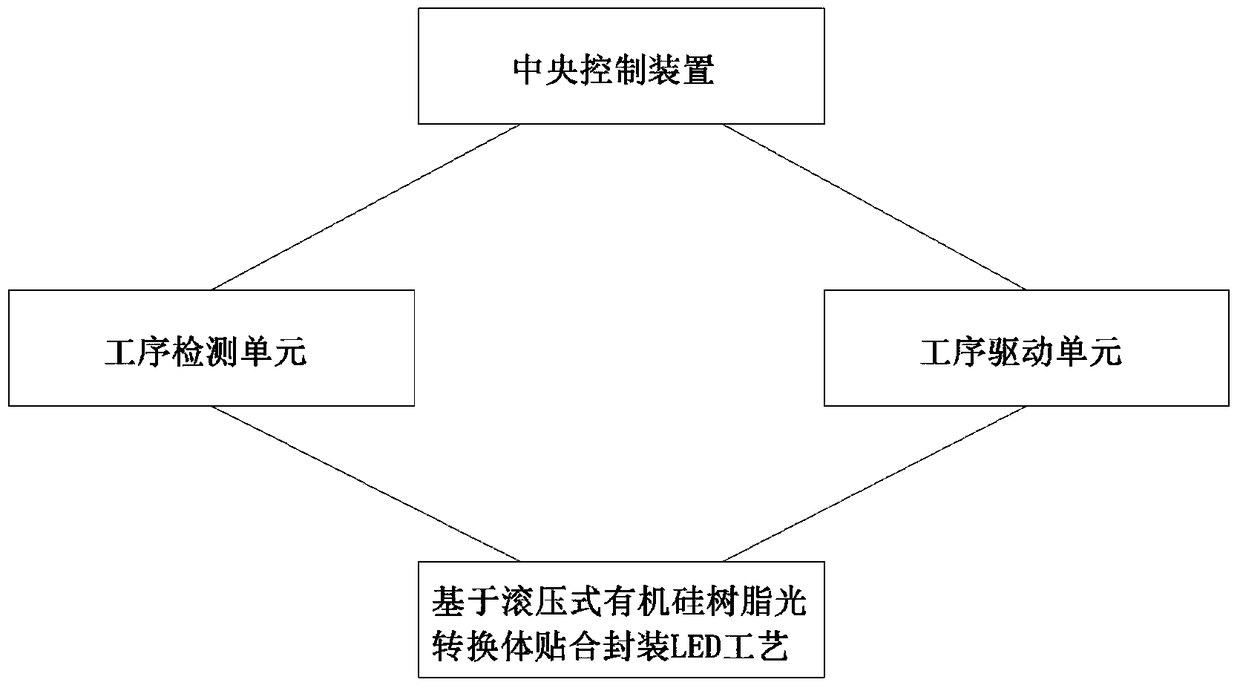

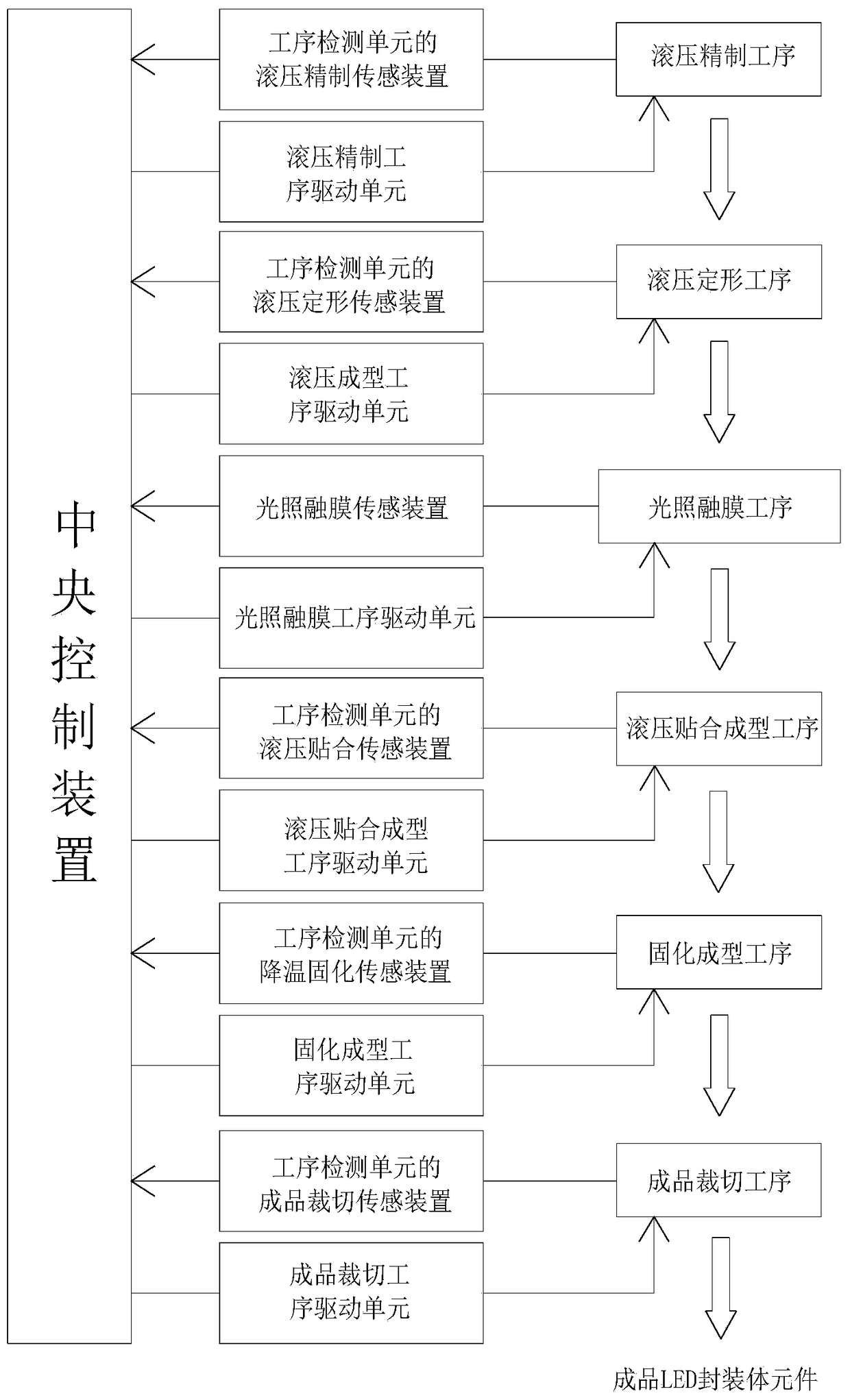

[0024] Example 1. combine figure 1 , an intelligent control system based on a rolling-type organic silicon resin light conversion body for laminating and packaging LEDs, which at least includes a rolling and laminating molding process and a curing molding process for the organic silicon resin light converting body to be rolled and bonded to package LEDs and the process detection unit, central control device and process drive unit of the finished product cutting process; where:

[0025] The process detection unit at least includes a rolling bonding sensing device for detecting that the light conversion film array and the LED flip chip array are formed into an LED package element through a rolling bonding molding process, and is used for detecting that the LED package body The solidification sensing device for the finished LED package component made by the component through the curing molding process, and the cutting sensor device for detecting the finished LED package componen...

Embodiment 2

[0051] Example 2. combine image 3 , Figure 4 with Figure 5, the following is an example of the application of the present invention to the new technology of rolling-type organic silicon resin light conversion body bonding and packaging LEDs to further describe the intelligent control method of the present invention. A rolling-type silicone resin based on the present invention The control method of the intelligent control system of the light conversion body bonding and packaging LED is characterized in that it includes the detection of the rolling and bonding molding process, curing molding process and finished product cutting process of the organic silicon resin light conversion body rolling and bonding packaging LED and regulation; where:

[0052] For the detection and regulation of the rolling and laminating molding process, the vacuum sensor, the light intensity sensor and the time timer in the rolling and laminating sensing device respectively collect the LED flip-ch...

Embodiment 3

[0055] Example 3. combine image 3 , the implementation method of the present invention also includes the detection and regulation of the rolling refining process, by the vacuum sensor in the rolling refining sensing device, the distance sensor between the roller and the roller, the distance sensor between the roller and the plane conveying device, the roller One or more combinations of the rotational speed sensor and the planar conveying device, the forward speed sensor and the workpiece temperature sensor respectively collect the working condition information of the light conversion body diaphragm during the rolling and refining process, and transmit it to the central control device through the data line for real-time analysis And processing, the processed information is fed back to the rolling and refining process drive unit through the data line for real-time regulation.

[0056] The implementation method of the present invention also includes the detection and regulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com