A process method and refining equipment system for a refined light conversion body to fit and package an LED

A process method and LED package technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of product consistency, low production efficiency of packaged LEDs, and the influence of thermal overstress, so as to improve production efficiency and optimize The product rate, the removal of the external bonding layer process, and the effect of improving the consistency of light and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

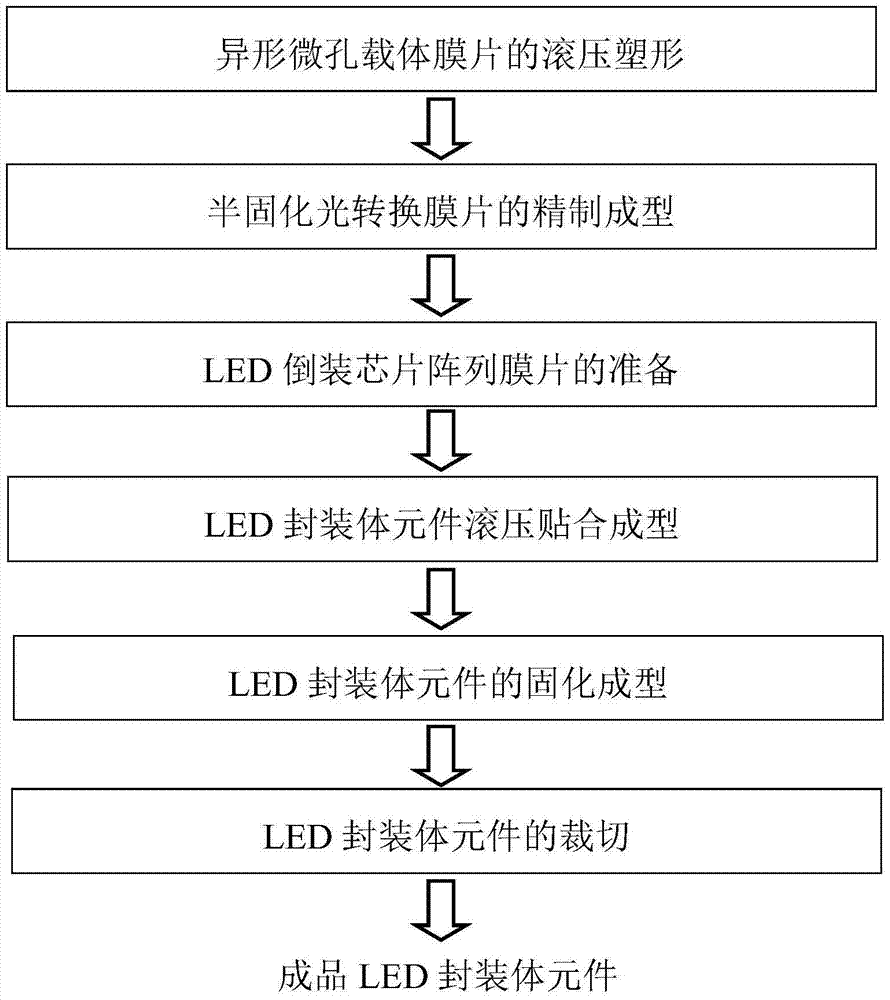

[0063] Example 1. see figure 1 , figure 2 and Figure 6 As shown, the present invention proposes a process for bonding and packaging LEDs with a refined light conversion body, which includes rolling molding of special-shaped microporous carrier membranes, refined molding of semi-cured light conversion membranes, and LED flip-chip array membranes. The preparation of the sheet, the rolling and bonding of the LED package components, the curing and molding of the LED package components and the cutting process of the LED package components are a flow-type continuous process. The specific steps include the following:

[0064] Step 1, rolling shaping of the special-shaped microporous carrier membrane: the microporous carrier membrane is passed through the first rolling device with a bump array and the second rolling device with a groove array that are aligned to each other. Rolling and molding to obtain a special-shaped microporous carrier membrane with a groove array; wherein: t...

Embodiment 2

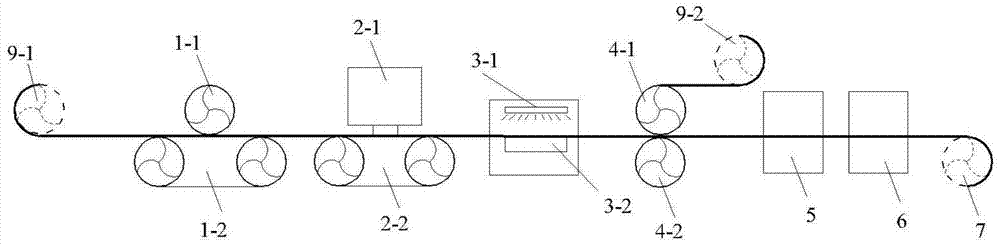

[0096] Embodiment 2: The refining equipment system adopted in the process method of a refined light conversion body packaged LED proposed by the present invention, which includes a special-shaped microporous carrier film roll for shaping the special-shaped microporous carrier film Compression molding device, semi-cured light conversion film precision molding device for forming a pre-cured light conversion film on the shaped special-shaped microporous carrier film, and a rolling press for rolling and laminating molding of LED package components Laminating device; the special-shaped microporous carrier film rolling forming device, semi-cured light conversion film fine forming device and rolling laminating device are arranged in sequence to form a coordinated linkage process equipment; wherein:

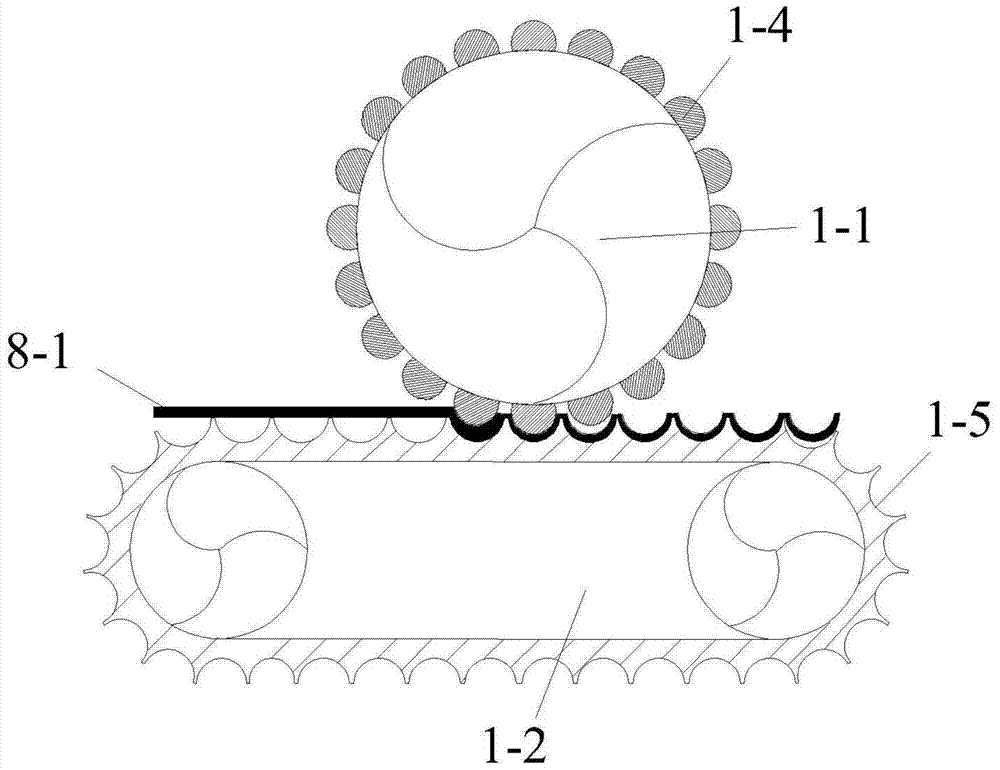

[0097] The special-shaped microporous carrier membrane rolling molding device includes a first rolling device with a bump array and a second rolling device with a groove array arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com