A cob modular led dispensing structure

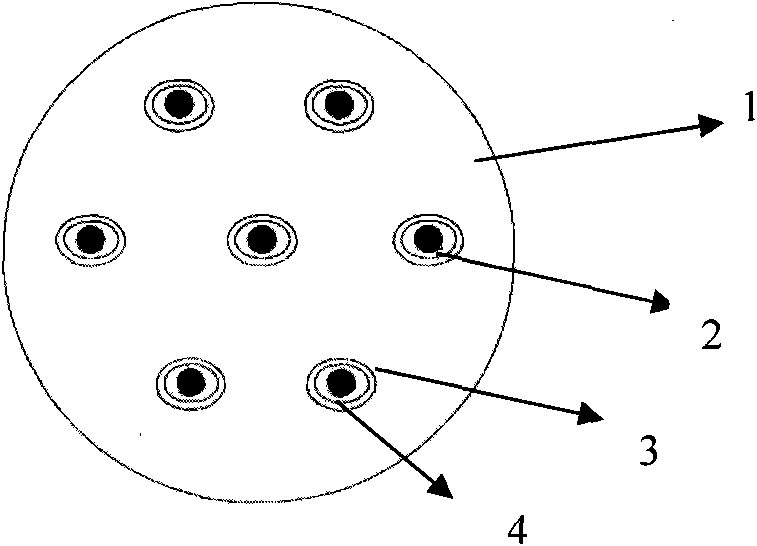

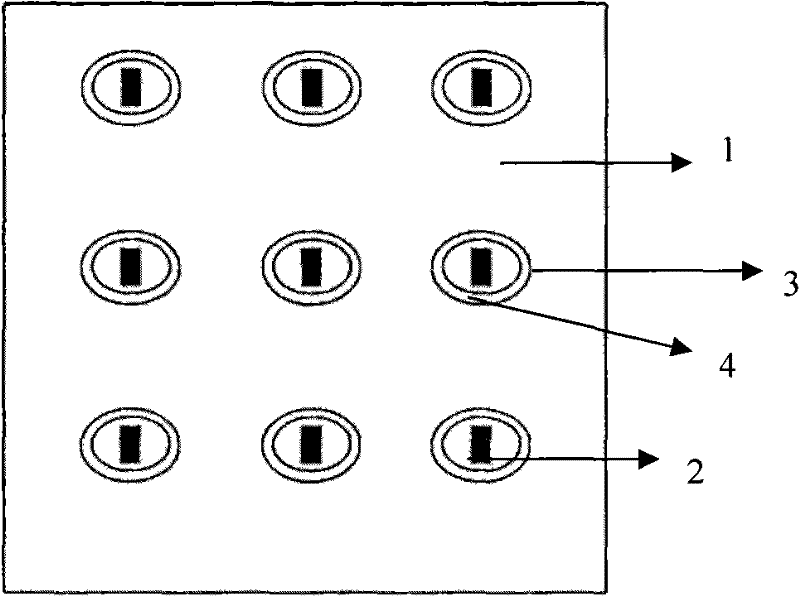

A modular, LED chip technology, applied to point light sources, lighting and heating equipment, electrical components, etc., can solve the problem of free flow of phosphor glue, improve light color consistency, reduce manufacturing costs, and simplify dispensing material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

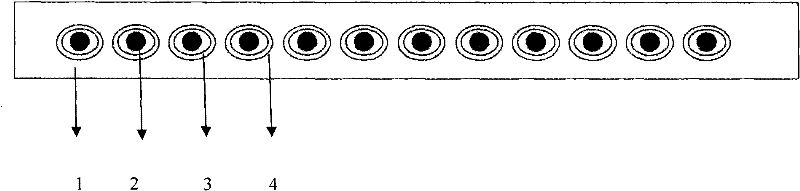

[0013] Embodiment 1: as Figure 4 As shown, on the strip-shaped aluminum substrate 1, 12 1-watt LED chips 2 are directly bonded, and each LED chip 2 is surrounded by a rubber ring 4. After the LED chips 2 are evenly coated with phosphor powder, they are packaged separately. An optical lens 3 whose light distribution meets road lighting requirements forms an LED package module specially used for road lighting. In the above-mentioned packaging process, since there is an apron around the environment where the chip is coated with rubber powder to limit the flow of the rubber powder, the orderly flow of the rubber powder is realized, and the uniformity of the phosphor powder coated on the chip is ensured; at the same time, the powder coating It is carried out in an environment of 15°C--20°C, and the process from coating to solidification is completed in the apron ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com