Flexible red fluorescent film

A red fluorescent, thin film technology, applied in the field of materials science, can solve the problems of affecting the uniformity of light emission, easy formation of light spots, uneven light output, etc., to achieve the effect of improving the consistency of light color, improving consistency and heat dissipation, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

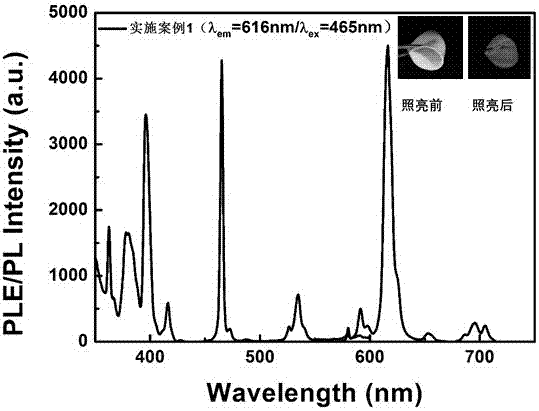

Embodiment 1

[0017] 1) According to Na 2 O: La 2 o 3 :MgO:WO 3 : Eu 2 o 3 = 6.58: 20.74: 8.55: 49.2: 14.93 (based on oxide content) component ratio, accurately weigh 10g of NaCO 3 , La 2 o 3 , 4MgCO 3 ·Mg(OH) 2 ·5H 2 O, WO 3 , Eu 2 o 3 Put it in an agate mortar and grind it evenly, then place it in a muffle furnace and heat it at 1050°C for 18 hours, then cool it down to room temperature to finally get red phosphor.

[0018] 2) Accurately weigh 0.3148g of red fluorescent powder and 2.99g of organic matter according to the mass ratio of powder to organic matter of 0.18:1; among them, accurately weigh 2.7182 g of polydimethylsiloxane (A ) and 0.2718 g curing agent (B);

[0019] 3) Put the above mixture into a 10mL sample bottle, and sonicate in an ultrasonic generator for 40min;

[0020] 4) Transfer the sonicated sample to a watch glass;

[0021] 5) Dry at 100°C for 45 minutes to obtain a flexible red fluorescent film.

[0022] 5) Use the fluorescence spectrometer of model F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com