Novel light-emitting diode (LED) packaging structure and packaging method capable of forming white light

An LED packaging, white light technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of prolonged packaging process time, increased production cost, uneven light spot, etc., to achieve optimal excitation efficiency, improve production efficiency, high color The effect of district achievement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

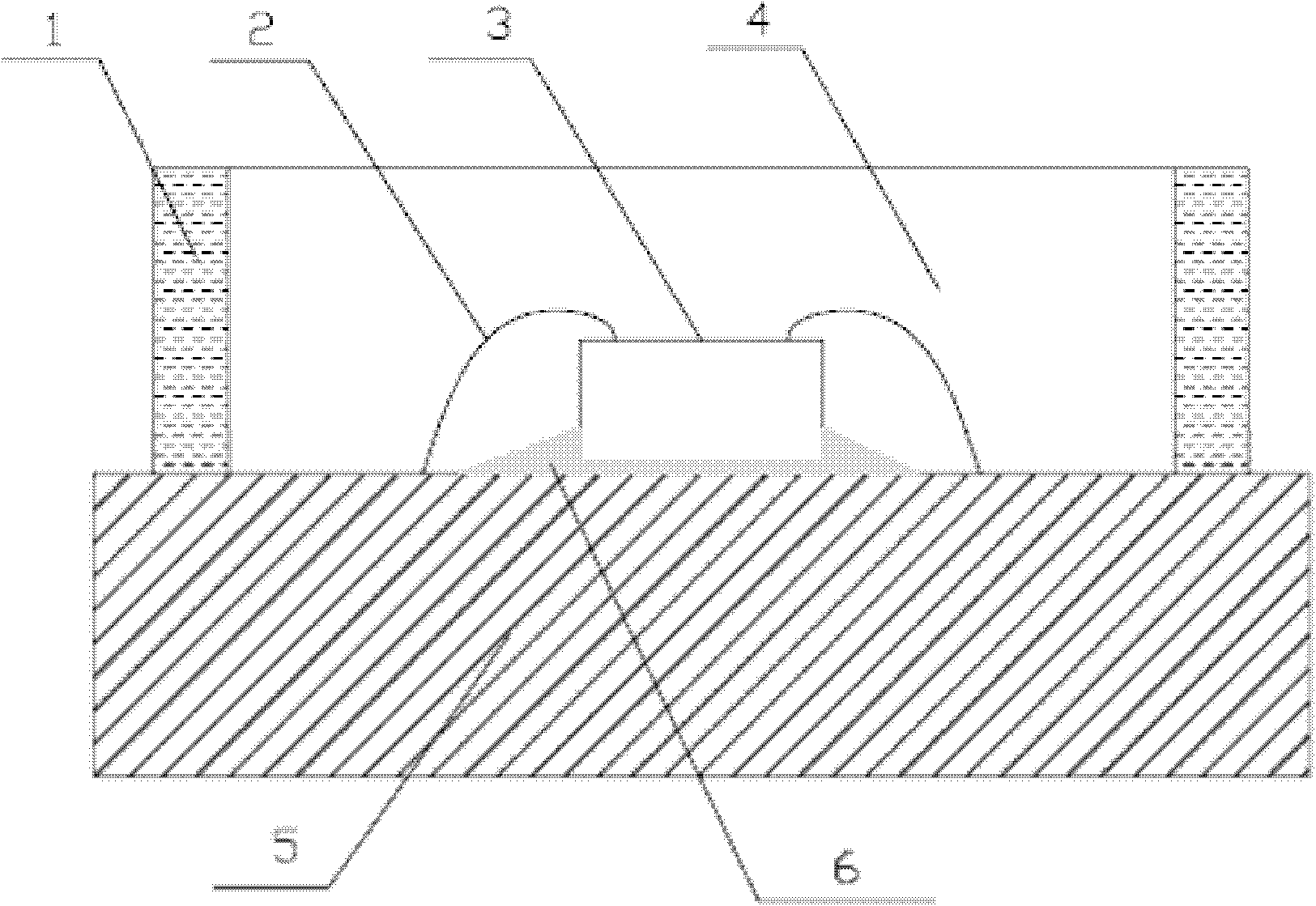

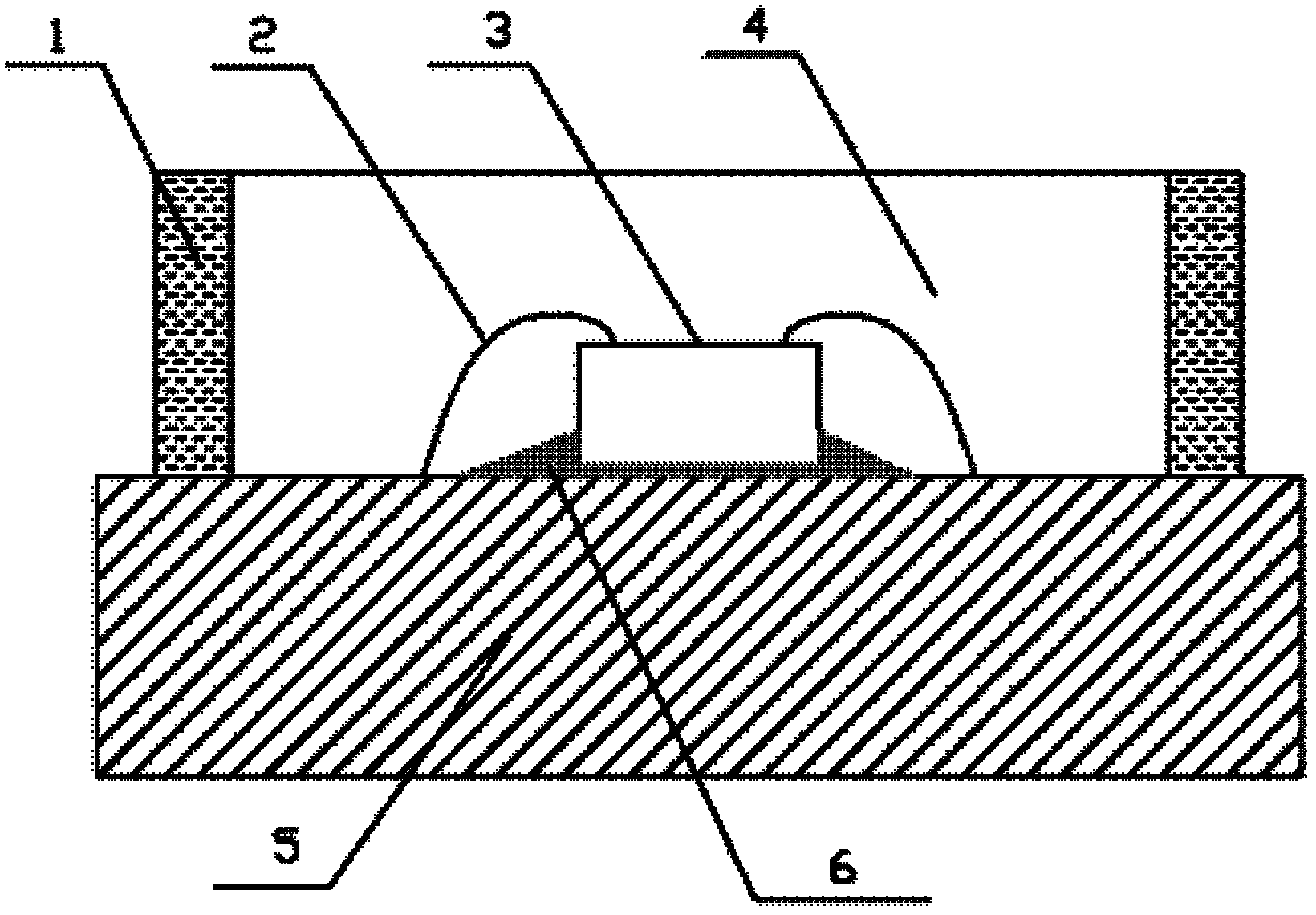

[0029] see figure 1 , the new LED packaging structure for achieving white light in this embodiment includes an LED packaging bracket, which includes a substrate 5 and a frame 1 surrounding the substrate 5, and an LED chip 3 is fixed on the substrate 5, that is, the bottom of the LED chip 3 It is fixed on the substrate 5 by a crystal-bonding glue mixed with phosphor powder. The LED chips are connected through gold wires 2 and connected to the positive and negative poles on the LED packaging support. The cavity formed between the substrate 5 and the frame 1 is filled with encapsulant 4 .

[0030] The novel LED encapsulation method for achieving white light of the present invention comprises the following steps:

[0031] 1) Add phosphor powder to the die-bonding glue;

[0032] 2) Fix the LED chip with the crystal-bonding glue added with phosphor powder in step 1) and the substrate of the LED packaging bracket; after fixing, dry the crystal-bonding glue at a drying temperature ...

Embodiment 2

[0039] The difference between the new LED packaging structure for achieving white light in this embodiment and the packaging structure in Embodiment 1 is that phosphor powder is also mixed into the packaging glue, and the rest are consistent with Embodiment 1, and will not be repeated here.

[0040] In this embodiment, the encapsulation method in which phosphor powder is mixed in both the encapsulation glue and the die-bonding glue, since the phosphor powder is mixed into the die-bonding glue at the bottom of the LED chip, the light emitted by the LED chip will produce diffuse reflection, and then After the phosphor powder is mixed into the upper encapsulant, it can enhance light scattering, obtain better excitation efficiency, better light color consistency, and obtain a higher color zone achievement rate. Therefore, the cooperation of these two aspects makes the light output uniform in all directions. The light extraction efficiency is improved, and the problem of yellow circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com