Europium-activated silicate green fluorescent powder and application thereof in white light-emitting diode

A technology of green fluorescent powder and silicate, which is applied in the direction of luminescent materials, the use of gas discharge lamps, sustainable buildings, etc., can solve the problems of temperature quenching characteristics, particle size and distribution improvement, etc., and achieve the improvement of temperature quenching characteristics , improve lattice stability, enhance the effect of emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

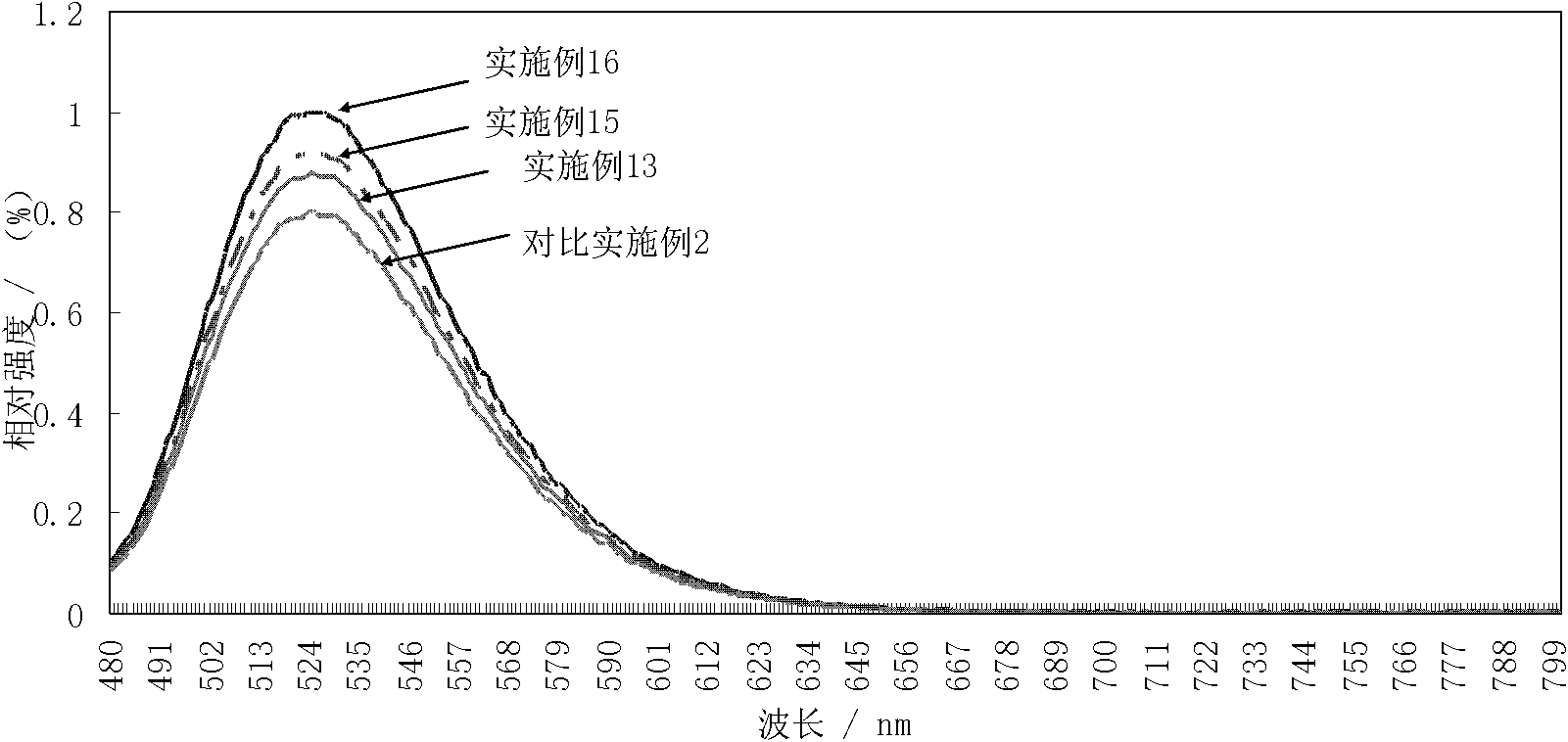

Examples

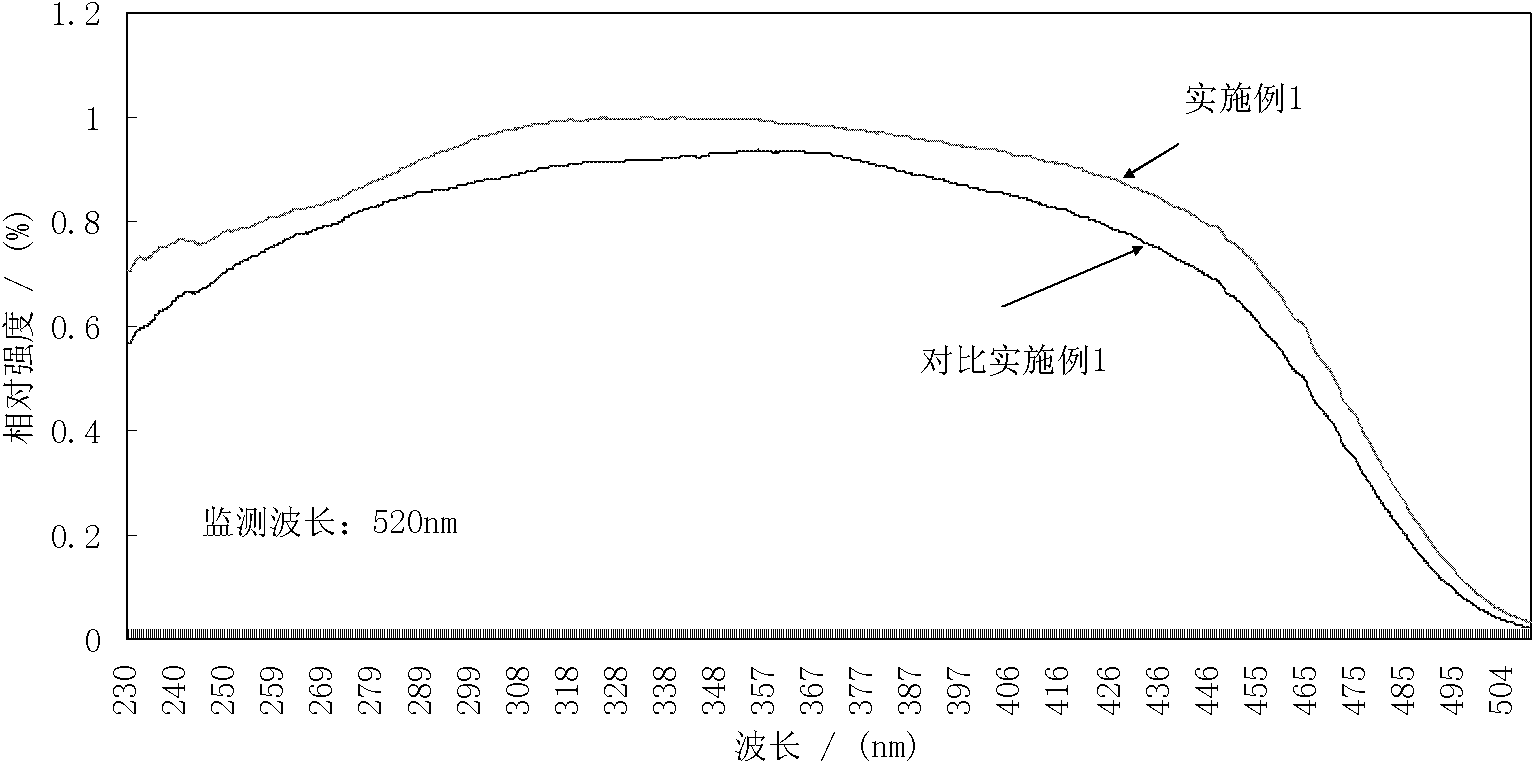

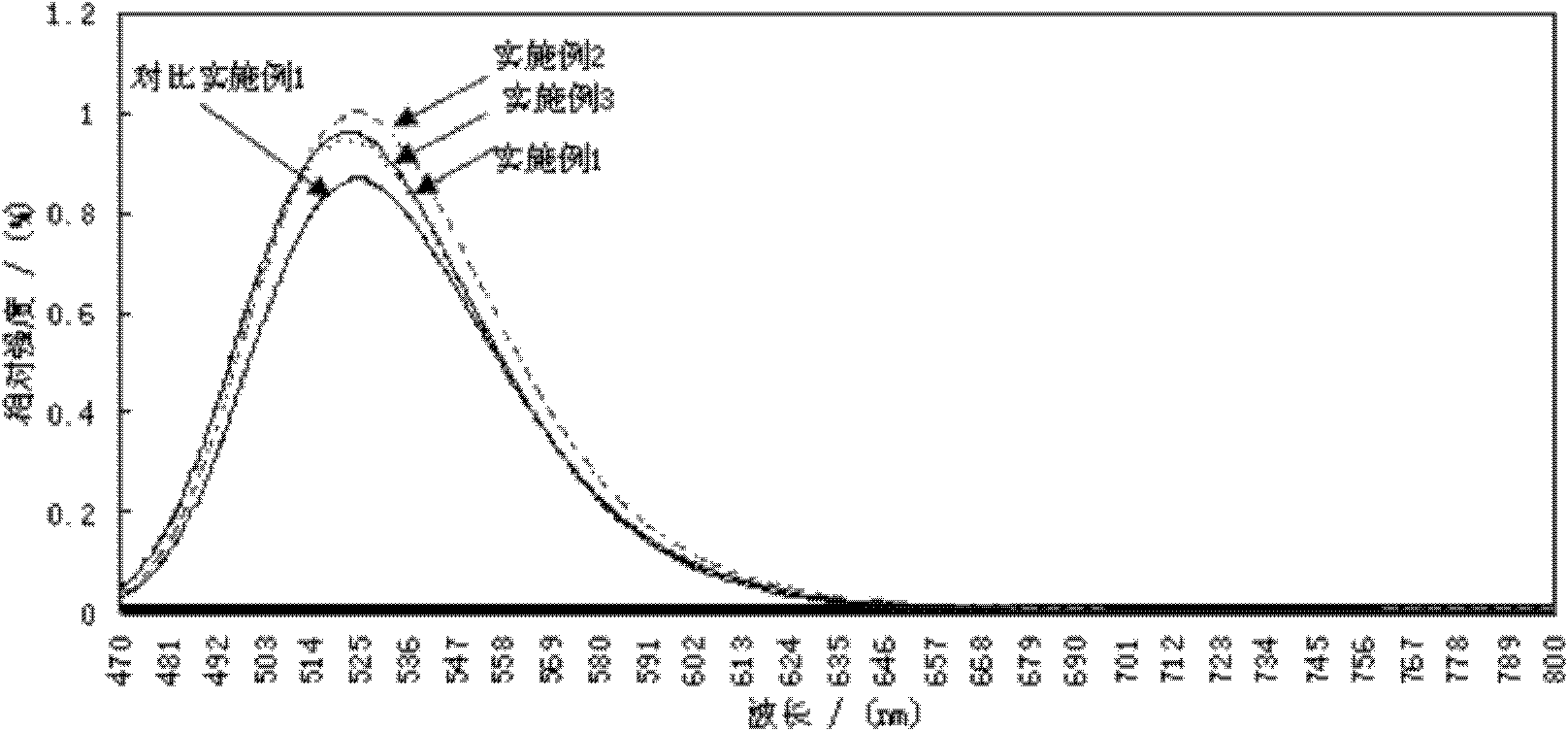

Embodiment 1

[0044] Weigh SrCO 3 4.92g, BaCO 3 252.6g, Sc 2 o 3 0.23g, SiO 2 30.4g, Eu 2 o 3 2.35g, LiF0.35g, AlN0.15g, mix well and put into a corundum crucible, burn at 1000°C for 10h, crush the burnt product, pass through a 350 sieve, add to a citric acid solution with a mass percentage of 0.12% , prepared into a suspension with a mass percentage of 10%, heated to 80°C, stirred for 60 minutes while keeping warm, washed with deionized water until neutral, separated from water and powder, and dried to obtain the composition of Ba 1.925 Sr 0.05 sc 0.005 Si 0.76 o 3.52 :Eu 0.02 green phosphor.

Embodiment 2

[0046] Weigh SrCO 3 5.91g, BaCO 3 250.2g, Y 2 o 3 0.6g, SiO 2 32g, Eu 2 o 3 3.52g, LiF0.35g, AlN0.15g, mix well and put into corundum crucible, burn at 1100°C for 6h, then crush the burnt product, sieve and add to citric acid solution with a mass percentage of 1.05% , prepared into a suspension with a mass percentage of 15%, heated to 75°C, stirred for 90 minutes while keeping warm, washed with deionized water until neutral, separated from water and powder, and dried to obtain the chemical composition of Ba 1.90 2Sr 0.06 Y 0.008 Si 0.8 o 3.6 :Eu 0.03 Green phosphor.

Embodiment 3

[0048] Weigh SrCO 3 5.91g, BaCO 3 244.7g, La 2 o 3 3.26g, SiO 2 36g, Eu 2 o 3 3.52g, LiF0.44g, AlN0.15g, mix them evenly, put them into a corundum crucible, burn them at 920°C for 10h, crush the burnt products, sieve them and add them to a citric acid solution with a mass percentage of 1.23% , prepared into a suspension with a mass percentage of 18%, heated to 100°C, stirred for 110 minutes while keeping warm, washed with deionized water until neutral, separated from water and powder, and dried to obtain the chemical composition of Ba 1.86 Sr 0.06 La 0.03 Si 0.9 o 3.8 : Eu0.05 green phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com