Method for efficiently packaging light-emitting diode (LED) chips by using substrate high diffuse reflection optical design

A technology for LED chips and LED packaging, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as reducing the reflectivity of the blue light band, reducing the luminous efficiency and color rendering index of the packaged LED, and affecting the efficiency of the LED light source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

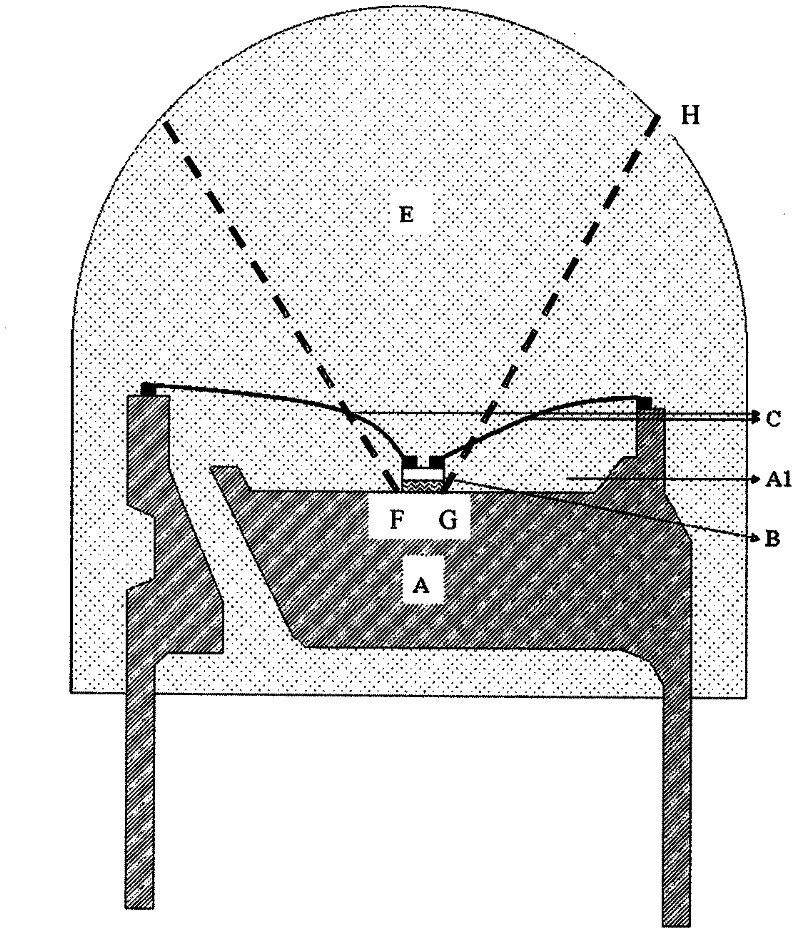

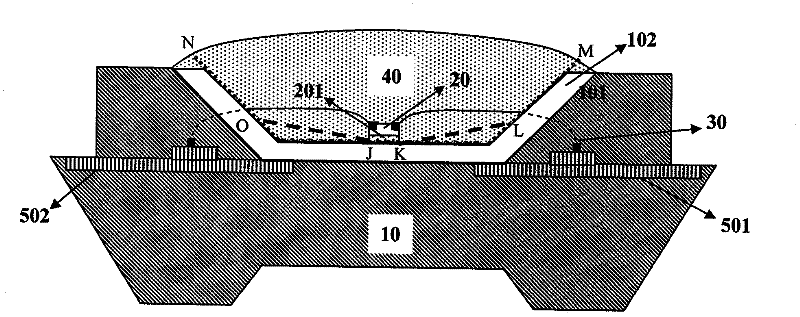

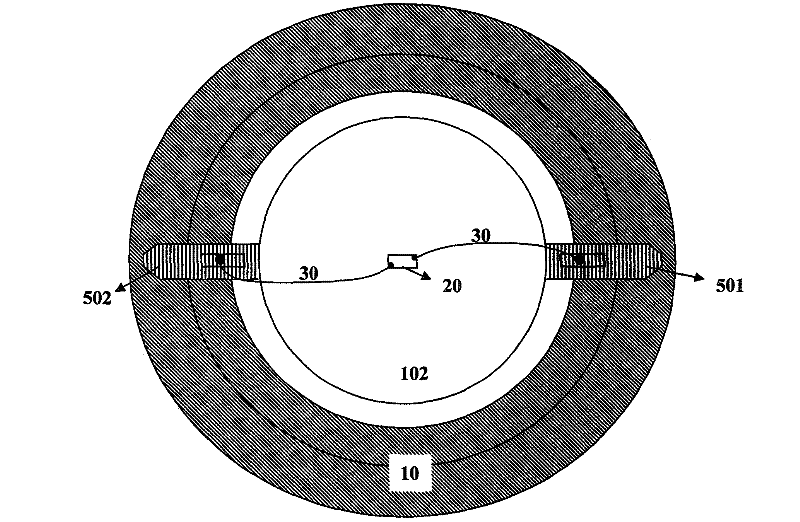

[0022] refer to figure 2 and image 3 , the present invention is implemented like this:

[0023] On the upper surface 101 of the LED packaging substrate 10 made of aluminum or copper or iron or ceramics or circuit boards, the surface diffuse reflection layer 102 is processed to make it have a diffuse reflectance greater than 80%, a specular reflection and a transmittance lower than 20% of the surface. The upper surface layer 102 with high diffuse reflection can be made of ceramic film with high diffuse reflection, ceramic glaze, inorganic or organic coating, Teflon film, etc., or even the surface of high white ceramic body. In Example 1, an ultra-white glaze with a diffuse reflection of 98% in the wavelength range of 200nm-760nm (that is, a whiteness of 98 at the same time) is used to coat the Cu substrate to form the high diffuse reflection layer 102 .

[0024] Install the pre-designed electrodes 501 and 502 on the corresponding positions of the substrate 10 and fix them ...

Embodiment 2

[0030] Embodiment 2 of the present invention is similar to the above embodiment column 1, but the high diffuse reflection glaze layer 102 of the above embodiment 1 is replaced by a barium sulfate coating or an aluminum oxide or magnesium oxide coating that utilizes thermal spraying, and the adjustment process makes the The diffuse reflection in the wavelength range of 300nm-600nm can reach 92% (that is, the whiteness can also reach 92 at the same time), and the rest of the steps are exactly the same as in Example 1. See Table 1 for specific data.

Embodiment 3

[0032] Embodiment 2 of the present invention is similar to above Embodiment 1, just change the high diffuse reflection glaze layer 102 of above Embodiment 1 and the Cu substrate together into a diffuse reflection that can reach 98% from the 400nm-620nm wavelength range (that is, at the same time Whiteness also can reach the pottery after the sintering of 98), all the other steps are identical with embodiment 1. See Table 1 for specific data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com