Lifting basket girder end fixing method

A fixing method and hanging basket technology, which are applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of consuming equipment rental costs, time-consuming and laborious installation and fixing, and low work efficiency, so as to reduce project costs , Improve work efficiency and speed up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

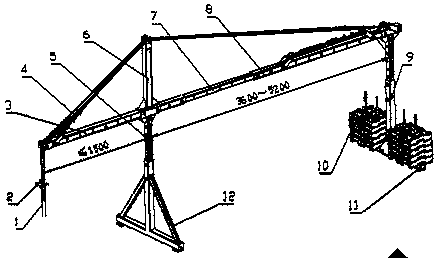

[0027] In the hanging basket girder end fixing method of the present invention, the hanging basket of the hanging mechanism is used for hoisting the insulation board of the outer wall, the flat roof of the attic is constructed on the top floor, and there is no platform for placing the front bracket and the rear bracket of the hanging basket on the top floor, so the hanging basket cannot be placed on the top floor of the building. Installation, including the following steps:

[0028] a. According to the actual situation of the site, install the hanging basket on the negative floor of the roof;

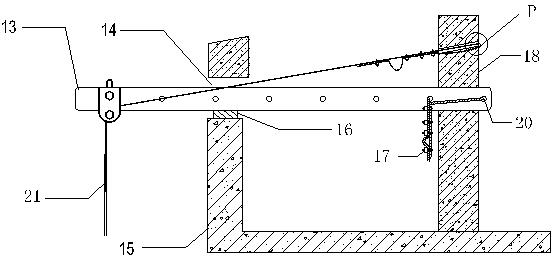

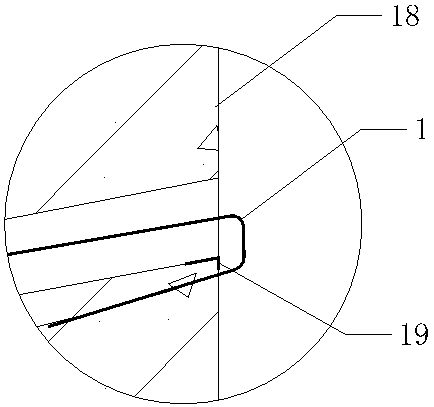

[0029] b, select the girder 13 to be arranged at the perforated hole of the concrete wall on the negative floor of the building, and the other side of the concrete shear wall at the perforated hole of the concrete wall is provided with a concrete shear wall At the orifice where body 15 is perforated. see now figure 2 and image 3 , figure 2 It is a structural schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com