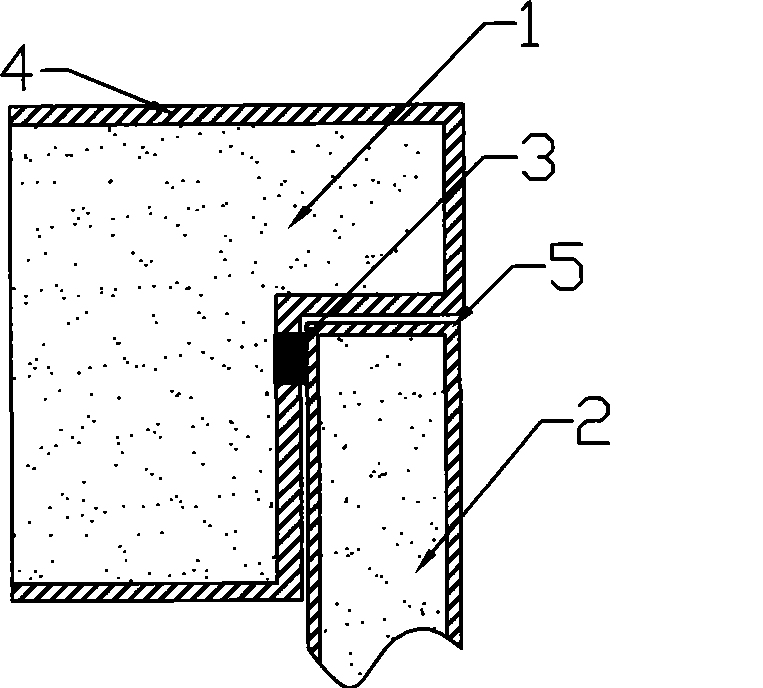

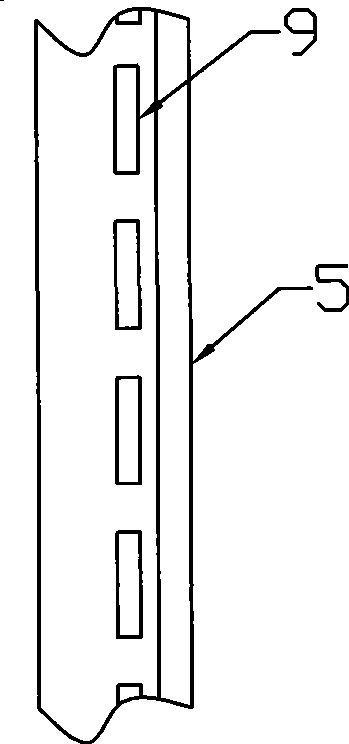

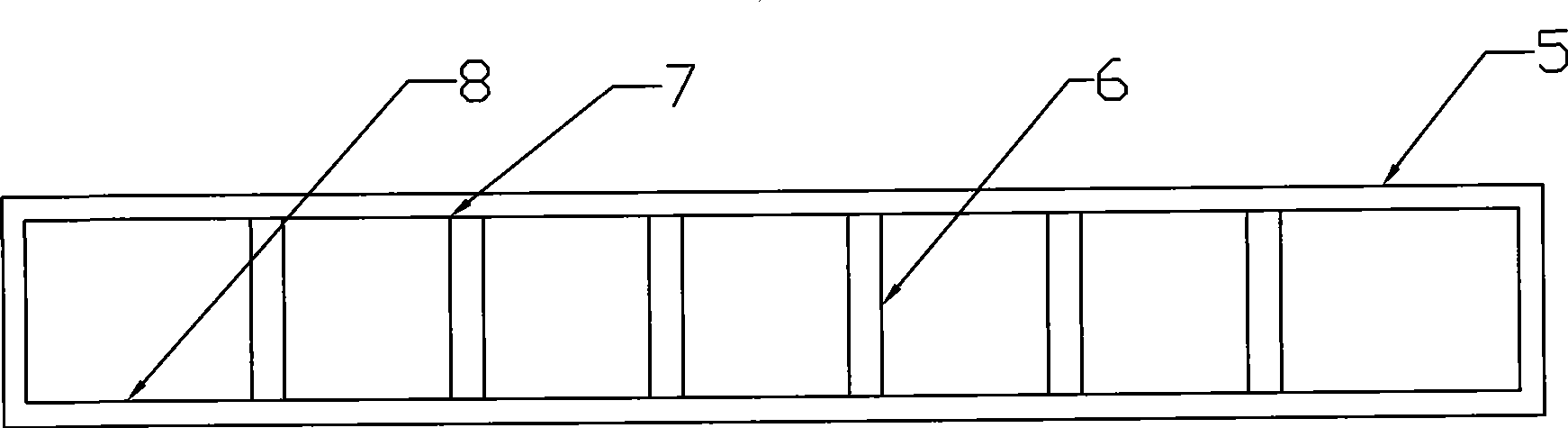

Combination fire-proof door and method for making same

A fire door, combined technology, applied in the direction of fire doors, chemical instruments and methods, layered products, etc., can solve the problems of large changes in standards, potential safety hazards, human body dangers, etc., to save production processes and improve installation time , the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] BDF expansion materials, including Portland cement, sulphoaluminate cement, fly ash, early strength agent, water reducing agent, suspending agent, diffusing agent, foaming liquid, foam stabilizer and brightener, its weight percentage 12%, 58%, 22%, 1.2%, 0.6%, 1.1%, 1.2%, 0.9%, 1.1%, 1.9%, respectively, the early strength agent is triethanolamine compound early strength agent, and the water reducing agent is naphthalenesulfonic acid The sodium salt of formaldehyde condensate, the suspending agent adopts alkylphenyl sulfonate, the diffusing agent adopts sodium hexametaphosphate, the foaming agent adopts petroleum ether, the foam stabilizer adopts dodecyl dimethyl amine oxide, and the brightener adopts It is a substance formed by copolymerization of methyl methacrylate and butyl acrylate. The weight percentage of foaming agent and water in the foaming liquid is 3.1%. Abrasion-resistant, waterproof and seepage-proof performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com