Hybrid power unmanned aerial vehicle

A hybrid power and unmanned aerial vehicle technology, applied in the field of aircraft, can solve the problems of difficult real-time speed regulation, short endurance time, small load, etc., and achieve the effect of improving load and endurance time, high load and endurance time, and stable rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

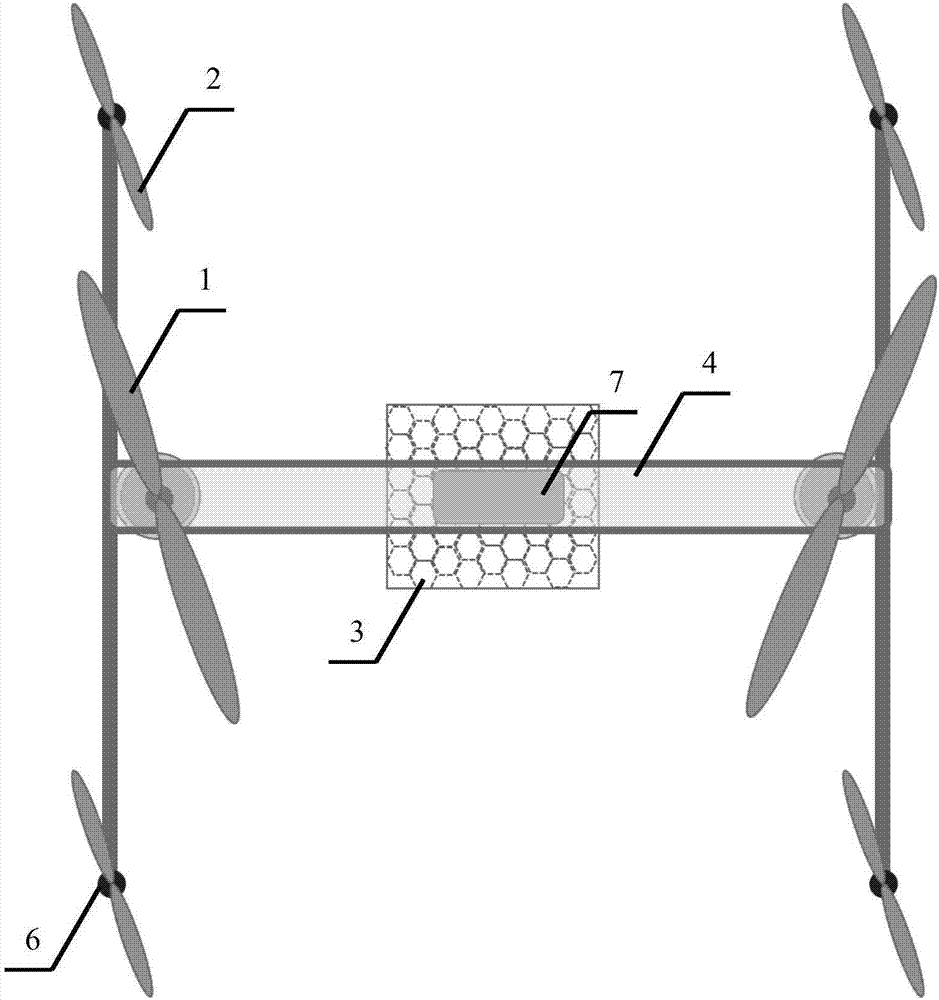

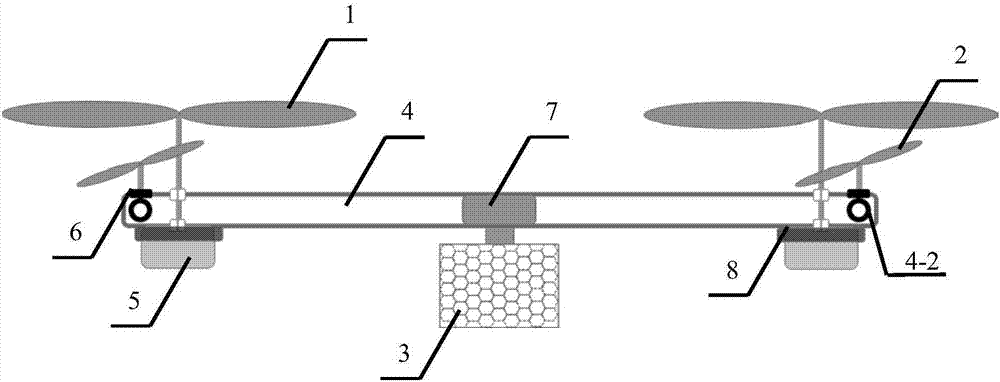

[0053] Embodiment 1: A hybrid six-rotor UAV with dual-fuel motors and direct-drive dual-blade rotors

[0054] Such as figure 1 , 2 , 3, shown in 4, a kind of hybrid power, hybrid six-rotor unmanned aerial vehicle, comprise two lift rotors 1, four control rotors 2, load frame 3 and frame 4 of symmetrical arrangement, described lift rotor 1, control Rotor 2 and load frame 3 are all installed on the frame 4. The lift rotor 1 is arranged on both sides of the central axis of the drone, and the rotor surface of the lift rotor 1 is perpendicular to the central axis of the drone; the lift rotor 1 is driven by a fuel motor 5; the lift rotor 1 directly Installed on the fuel motor 5. The control rotor 2 is driven by four electric motors 6 with identical parameters. The electric motor 6 is powered by a battery pack 7 . The fuel tank of the fuel motor 5 is equipped with a honeycomb thin-walled porous structure, which is used to eliminate the drone control problem caused by the sloshin...

Embodiment 2

[0066] Embodiment 2: A hybrid six-rotor UAV with dual-fuel motors driving dual-blade rotors through pulleys

[0067] The only difference between this embodiment and Embodiment 1 is that the fuel motor drives the two-blade rotor through the pulley, such as Figure 5 , 6 , shown in 7, a kind of hybrid power, hybrid six-rotor UAV, comprise two lift rotors 1, four control rotors 2, load frame 3 and frame 4, described lift rotor 1, control rotor 2 and load frame 3 are installed on the frame 4. The lift rotor 1 is arranged on both sides of the central axis of the drone, and the rotor surface of the lift rotor 1 is perpendicular to the central axis of the drone; the lift rotor 1 is driven by a fuel motor 5; the control rotor 2, It is installed on four electric motors 6 with identical parameters, and is driven by the electric motors 6 described above. The electric motor 6 is powered by a battery pack 7 . The fuel tank of the fuel motor 5 is equipped with a honeycomb thin-walled po...

Embodiment 3

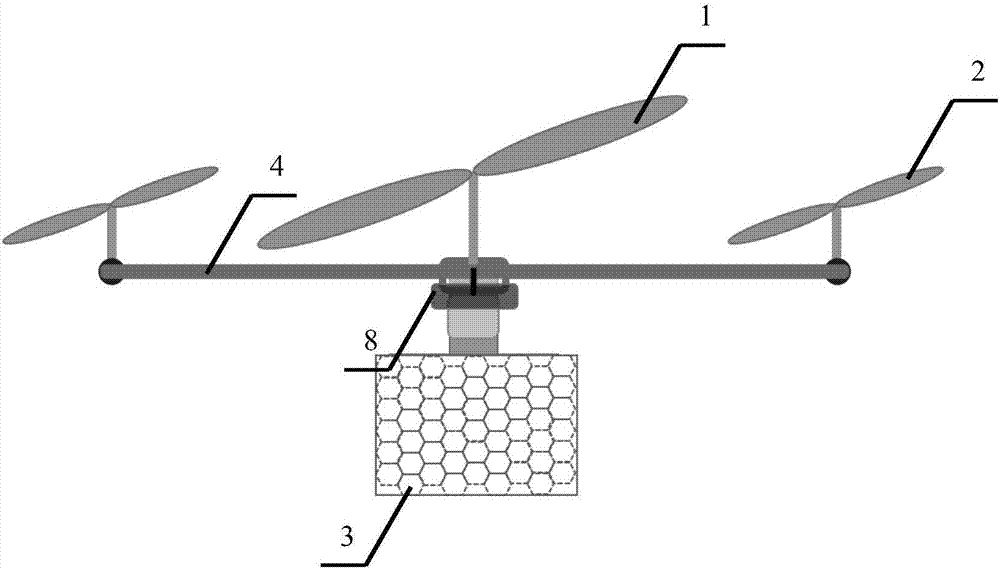

[0070] Embodiment 3: A hybrid power hybrid six-rotor UAV with a single fuel motor driving a dual-blade rotor through a pulley

[0071] The difference between this embodiment and Embodiment 2 is that the drive is changed from a dual fuel motor to a single fuel motor. Such as Figure 8 , 9 , shown in 10 and 11, a kind of hybrid power, hybrid six-rotor UAV, comprise two lift rotors 1, four control rotors 2, load frame 3 and frame 4, described lift rotor 1, control rotor 2 and The load frames 3 are all installed on the frame 4 . The lift rotor 1 is arranged on both sides of the central axis of the drone, and the rotor surface of the lift rotor 1 is perpendicular to the central axis of the drone; the lift rotor 1 is driven by a fuel motor 5; the control rotor 2, It is installed on four electric motors 6 with identical parameters, and is driven by the electric motors 6 described above. The electric motor 6 is powered by a battery pack 7 . The fuel tank of the fuel motor 5 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com