Automatic recovery speed-limiting sorting tube or wire winder

An automatic recovery and speed-limiting technology, applied in the field of online devices and winding pipes, can solve the problems that the recovery pipe or line speed cannot be automatically controlled and limited, and achieve the effect of simple structure and stable recovery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

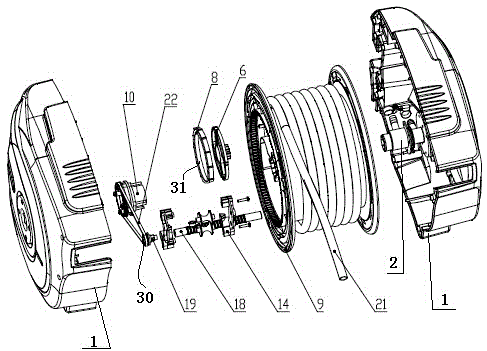

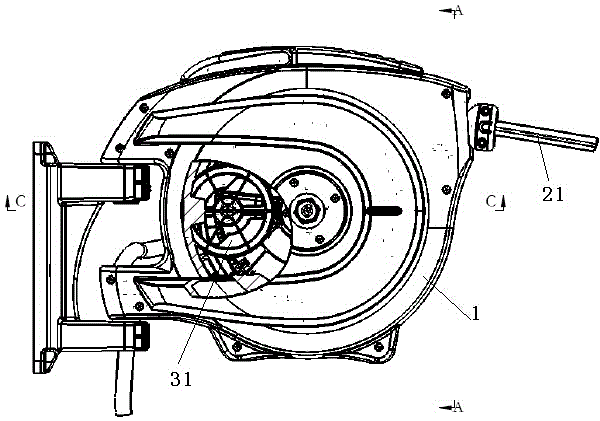

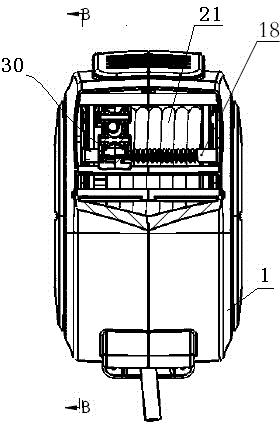

[0026] Such as Figure 1 to Figure 7 Shown, a kind of automatic recovery speed limiting sorting winder, wire device, comprises housing 1, disc body 9, scroll spring, axle 2, pipe or electric wire 21, sorting device 30, the speed limiting device 31 of slow recovery.

[0027] Such as Figure 1 to Figure 5 As shown, the middle of the housing 1 is connected to the disk body 9 through the rotation of the wheel shaft 2. The disk body 9 is equipped with a scroll spring. One end of the scroll spring is connected to the wheel shaft 2, and the other end is connected to the disk body 9. There are pipes or Wire 21. A sorting device 30 for pipes and wires is provided on the pipe and wire outlet at the front end of the housing 1, and a speed limiting device 31 for slow recovery of pipes and wires is provided between the side of the disc body 9 and the hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com