Vertical axis wind turbine

A wind turbine, vertical axis technology, which is applied to wind turbines, wind turbine combinations, wind turbines at right angles to the wind direction, etc. , Guarantee stability, prolong life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

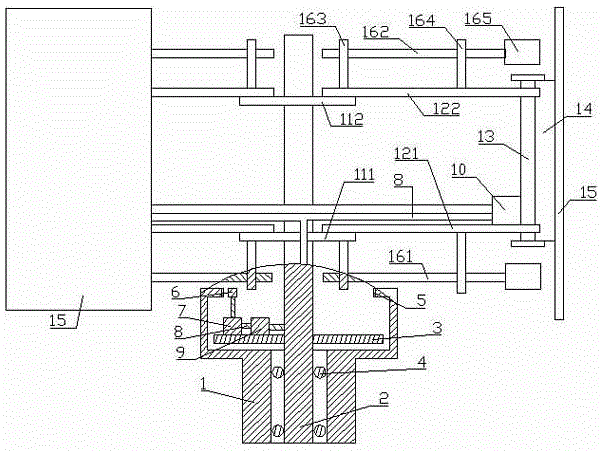

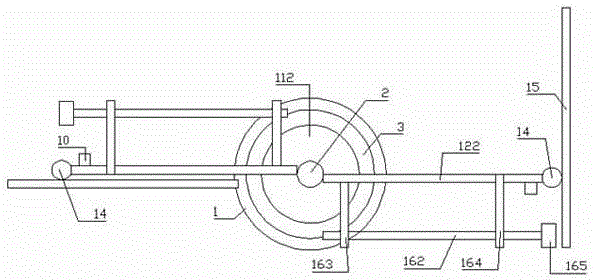

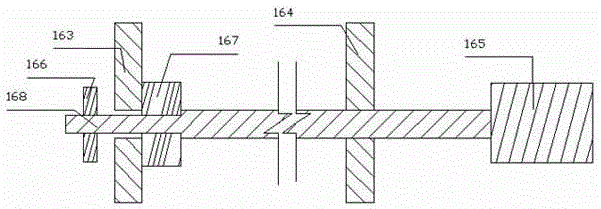

[0020] A vertical axis wind turbine, such as figure 1 with figure 2 As shown, it includes a base 1, a generator and a rotating shaft 2. The base 1 is provided with two rotating bearings 4, the rotating shaft 2 is connected to the generator, and the rotating shaft 2 is rotatably arranged in the base 1 through the rotating bearing 4. The rotating shaft 2 is provided with a fixed disk 3 and a number of evenly distributed blade groups; the blade group includes blades 15 and laterally arranged support rods, the support rods are hinged with the blades 15, and the position of the hinge points of the blades 15 and the support rods is biased The outer end of the blade 15. The provided rotating bearing 4 reduces the frictional force when the rotating shaft 2 rotates relative to the base 1, thereby reducing energy consumption.

[0021] Generators are not shown in the figure, and are commonly used equipment in the field of power generation.

[0022] The blade 15 drives the rotating shaft 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com