Patents

Literature

36results about How to "Solve the problem of not being able to install" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

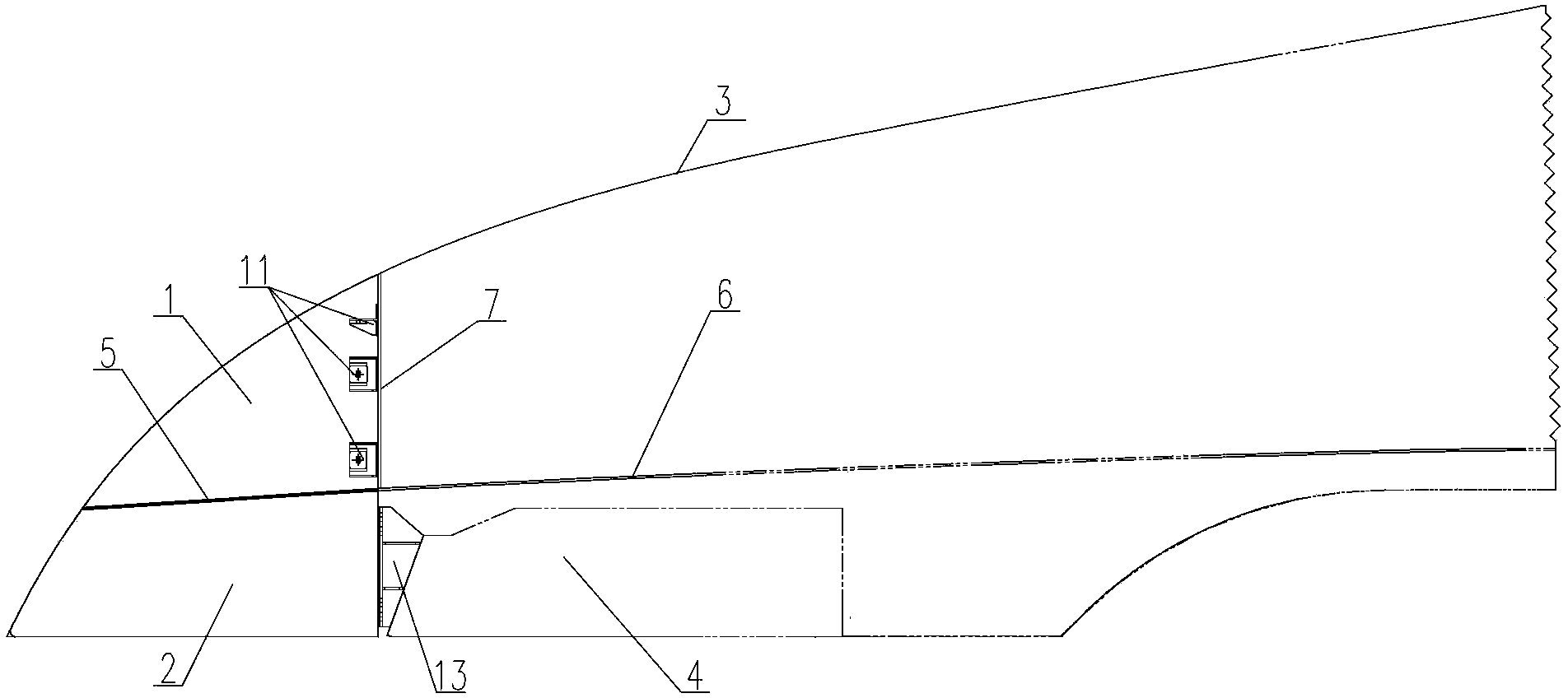

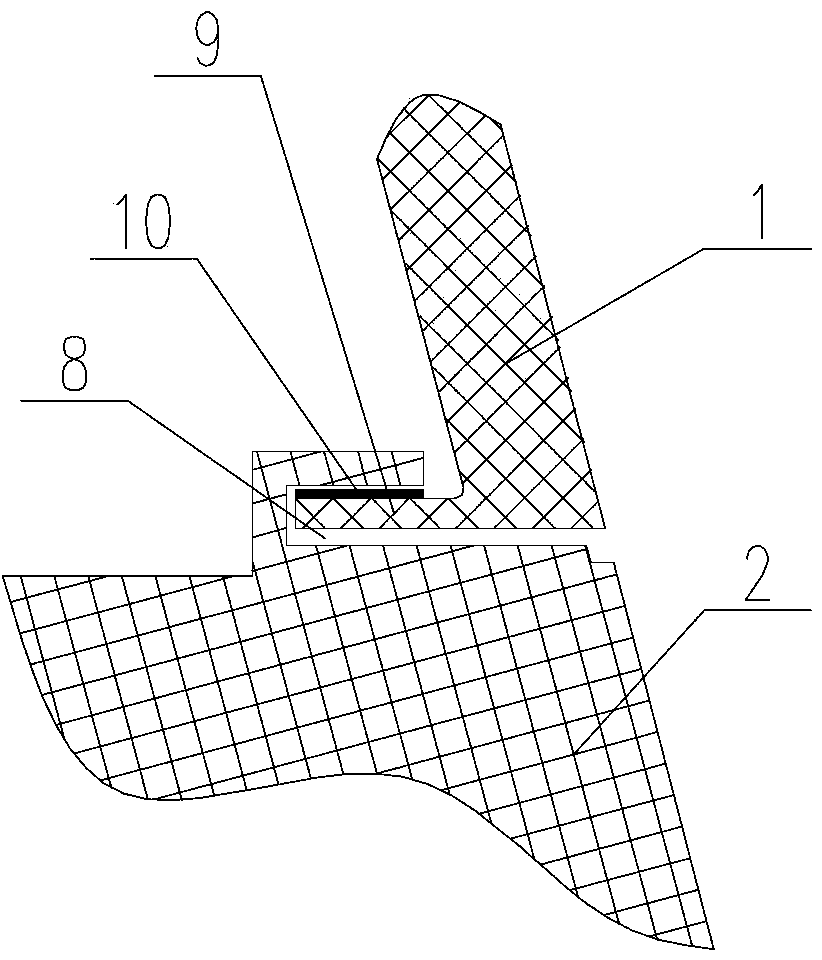

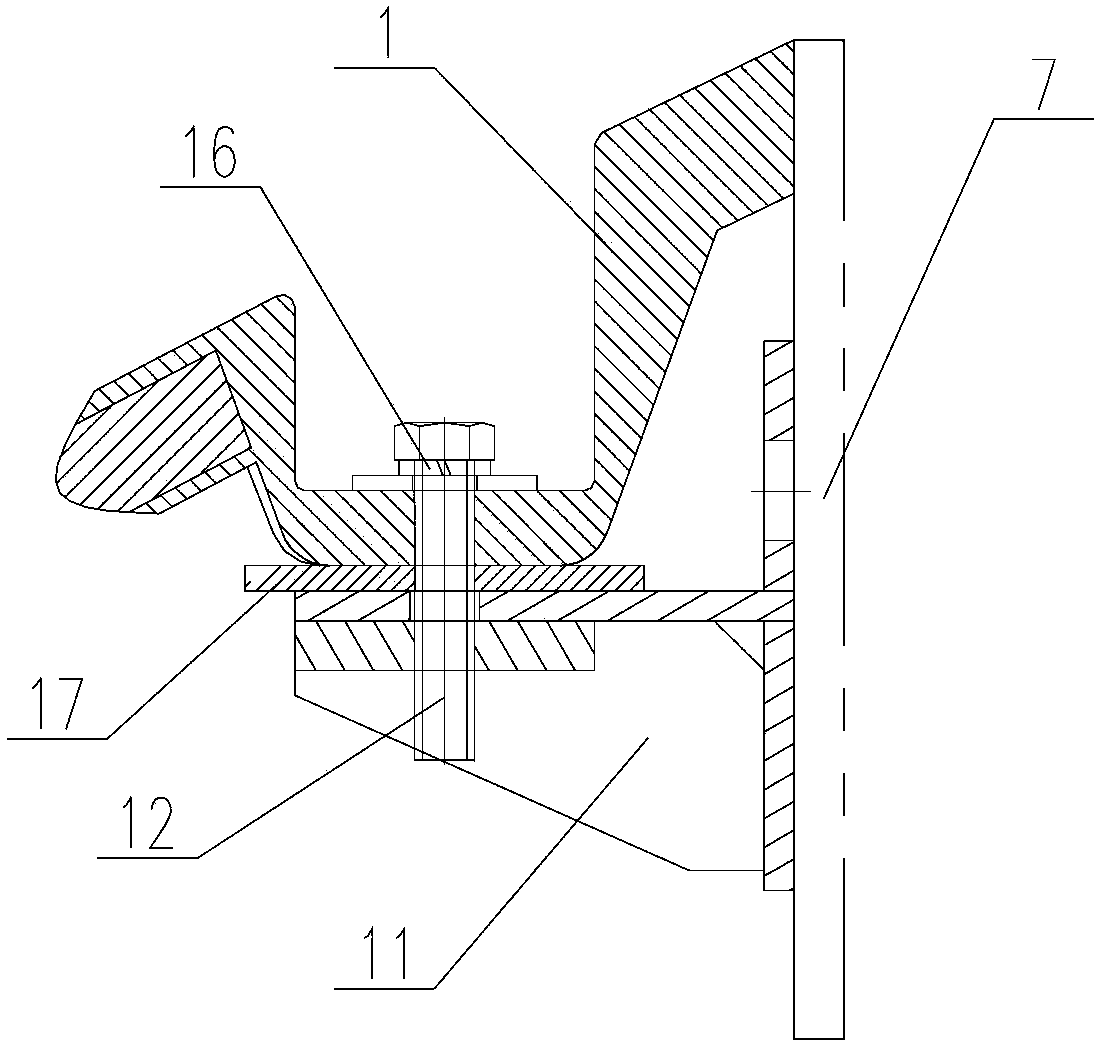

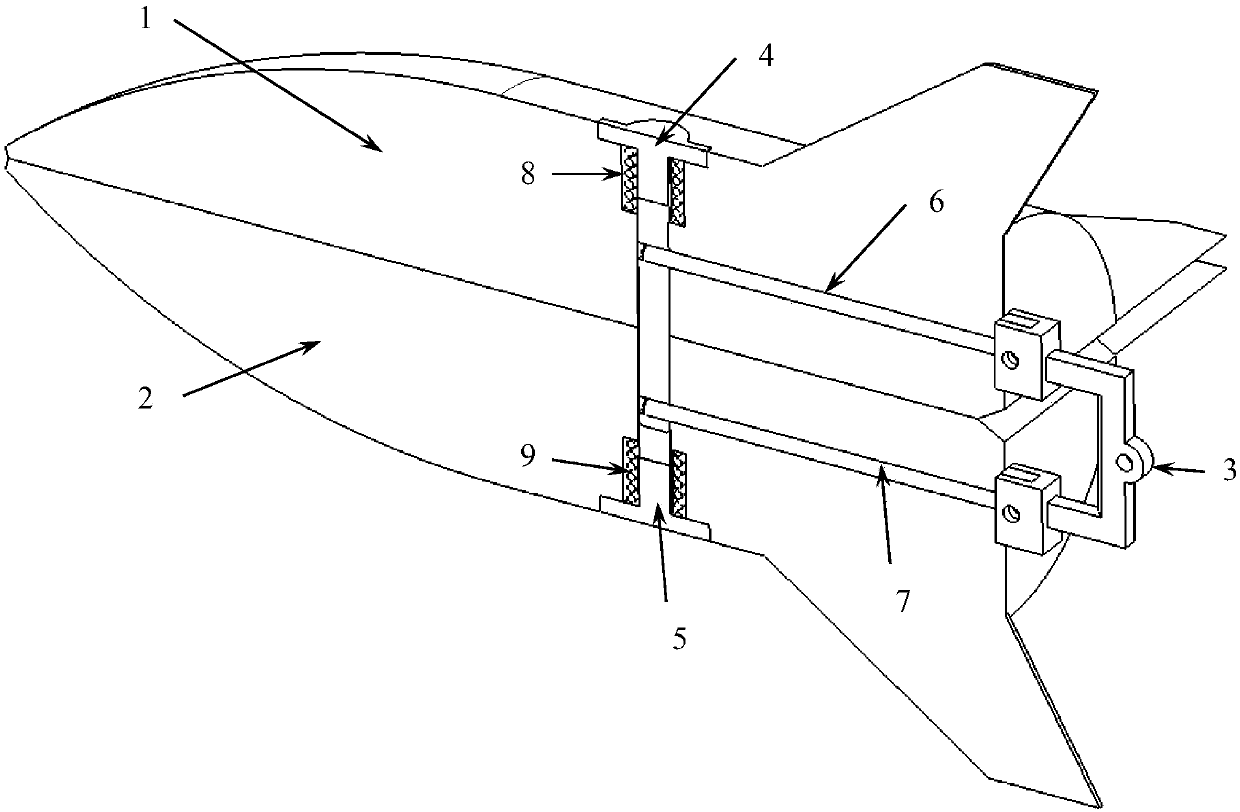

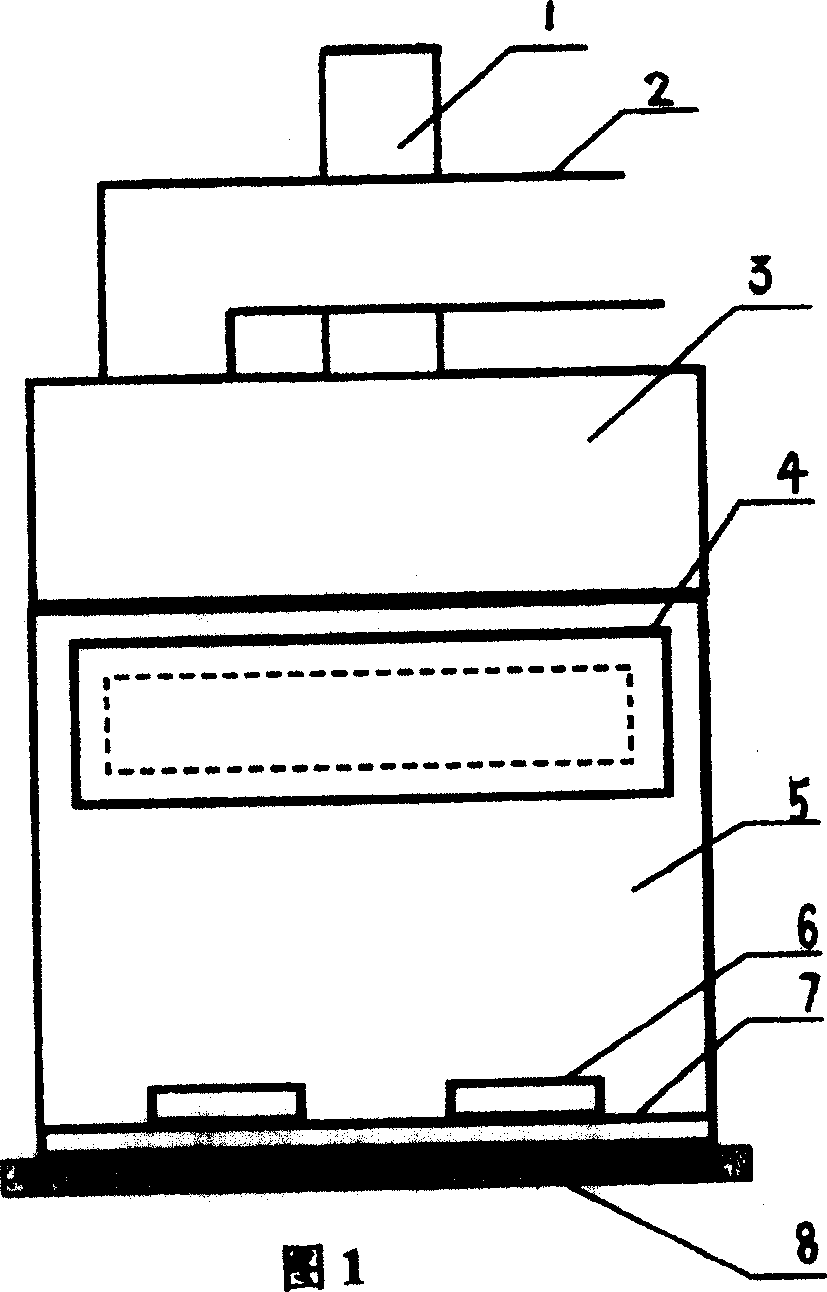

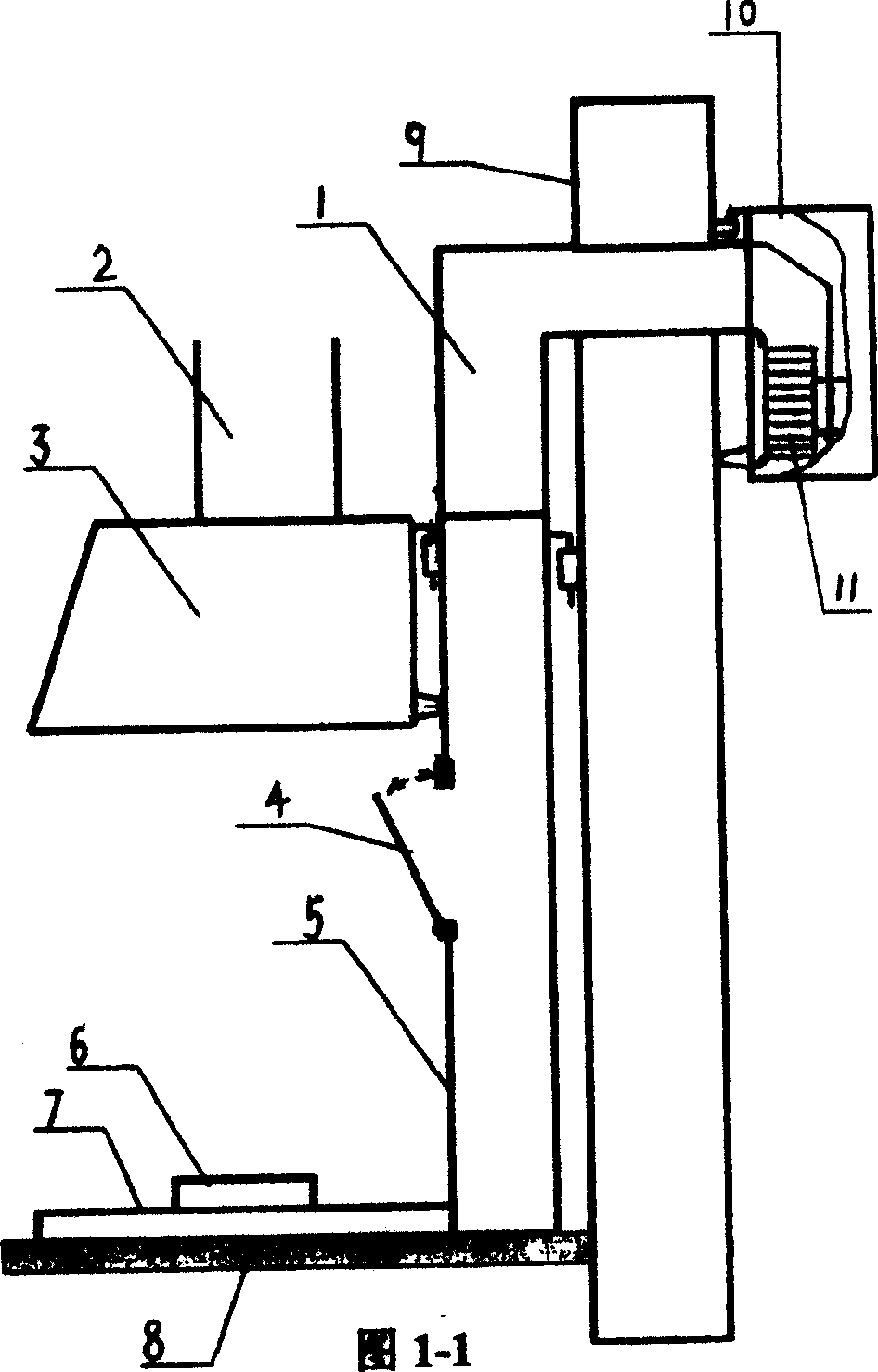

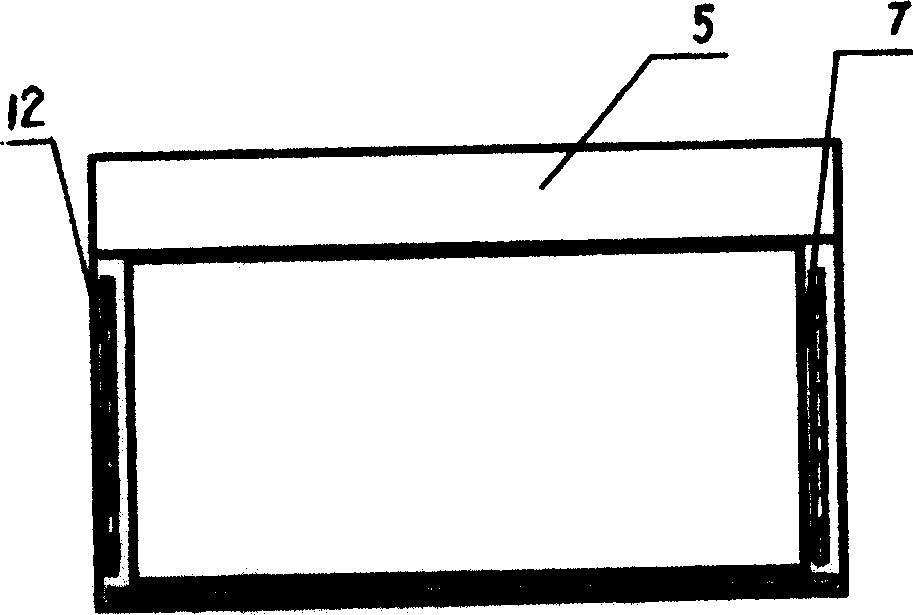

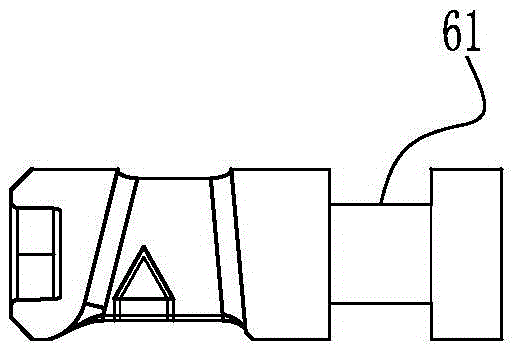

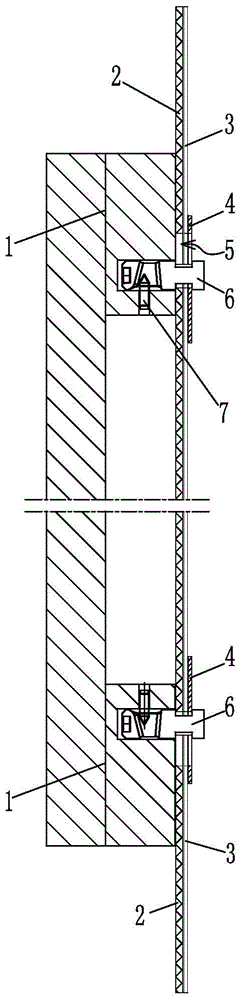

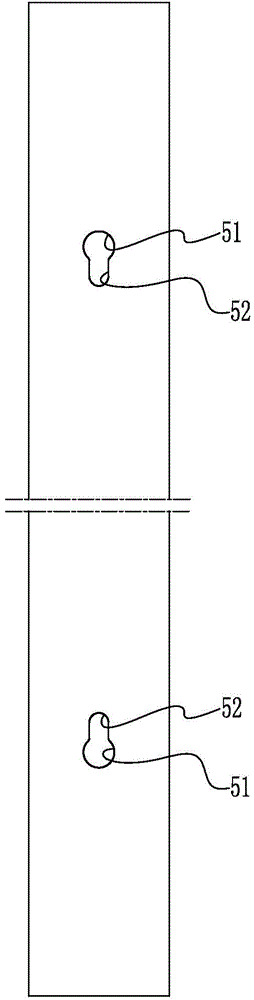

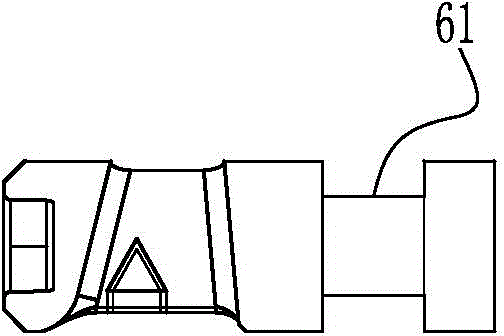

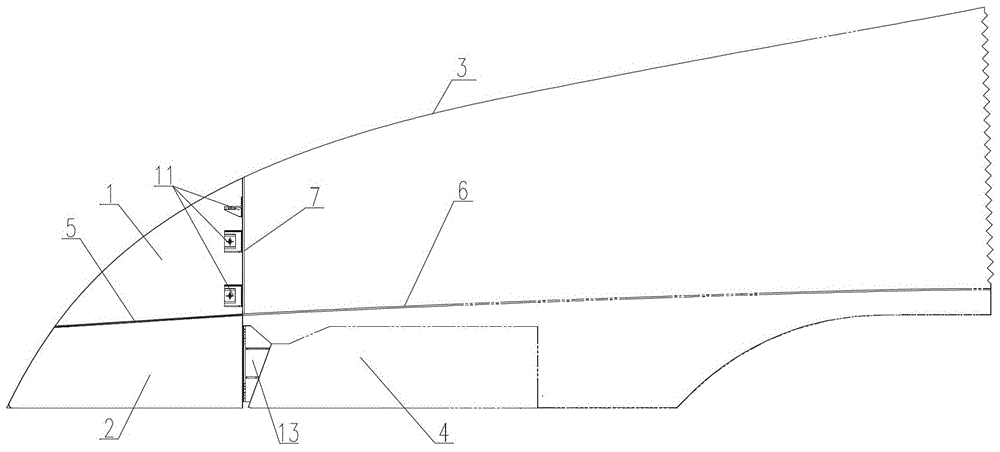

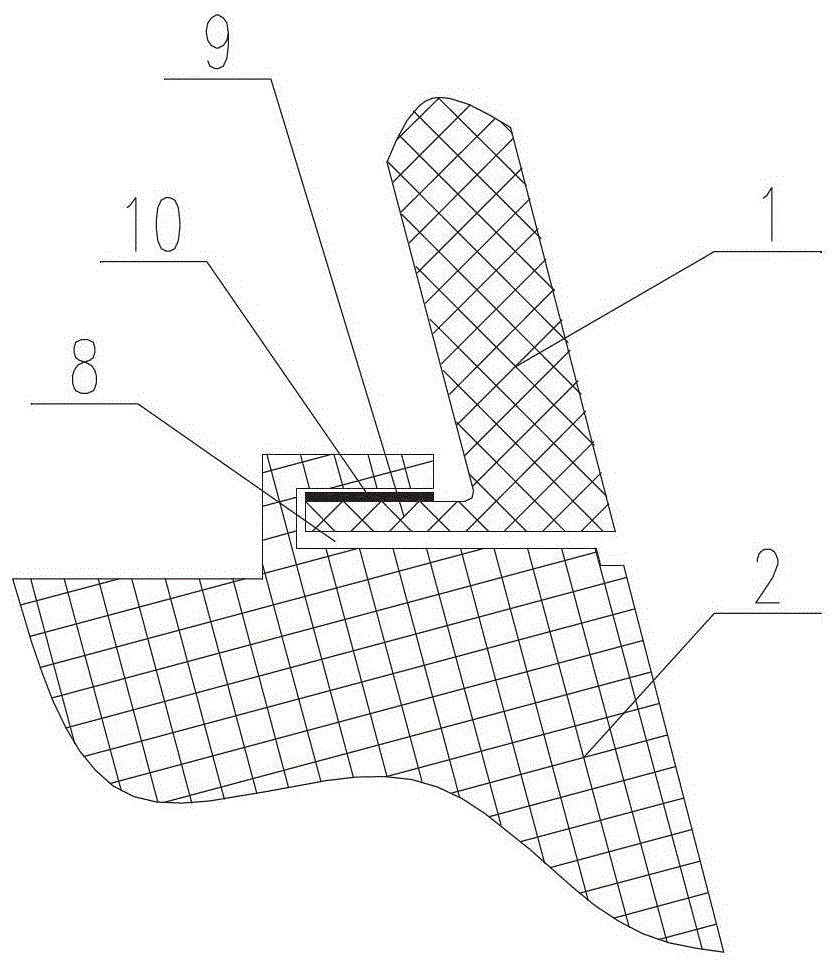

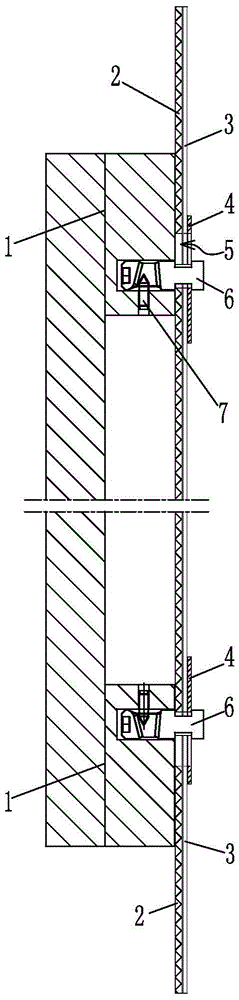

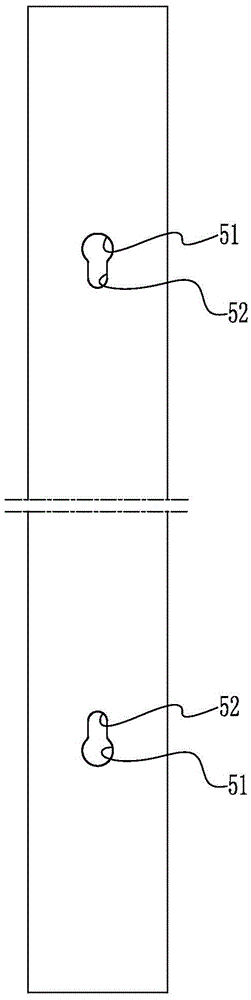

Hood structure of high speed train headstock and installation method

ActiveCN103802848ASolve the problem of not being able to installSimple structureRailway transportAxle-box lubricationEngineeringHeadstock

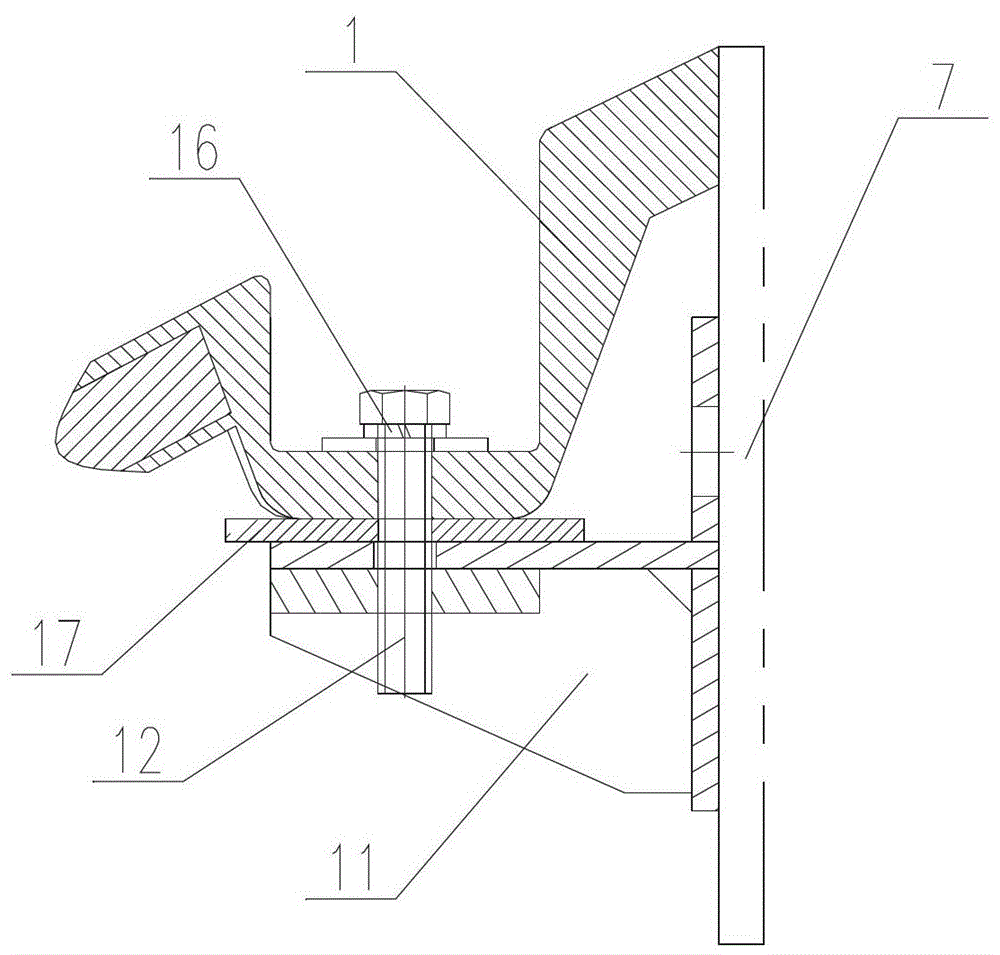

The invention relates to a hood structure of a high speed train headstock and an installation method. The hood structure consists of an upper hood and a lower hood, wherein the upper hood is connected with the lower hood through a plugging structure in a plugging manner, and the upper hood and the lower hood are respectively fixedly connected with a train body and / or train body accessory. The hood structure is simple in structure, the hood is divided into the upper hood and the lower hood, which are connected with each other in a plugging manner, the overall appearance effect is good, the entire structure is easy to install and disassemble, the upper hood and the lower hood can be placed into the train to run along the train after being disassembled, so that a link function and a rescuing function of the train can be realized. In addition, the hood can be installed externally, so that the problem that the hood cannot be installed due to the limited installation space inside the train body can be solved.

Owner:CRRC QINGDAO SIFANG CO LTD

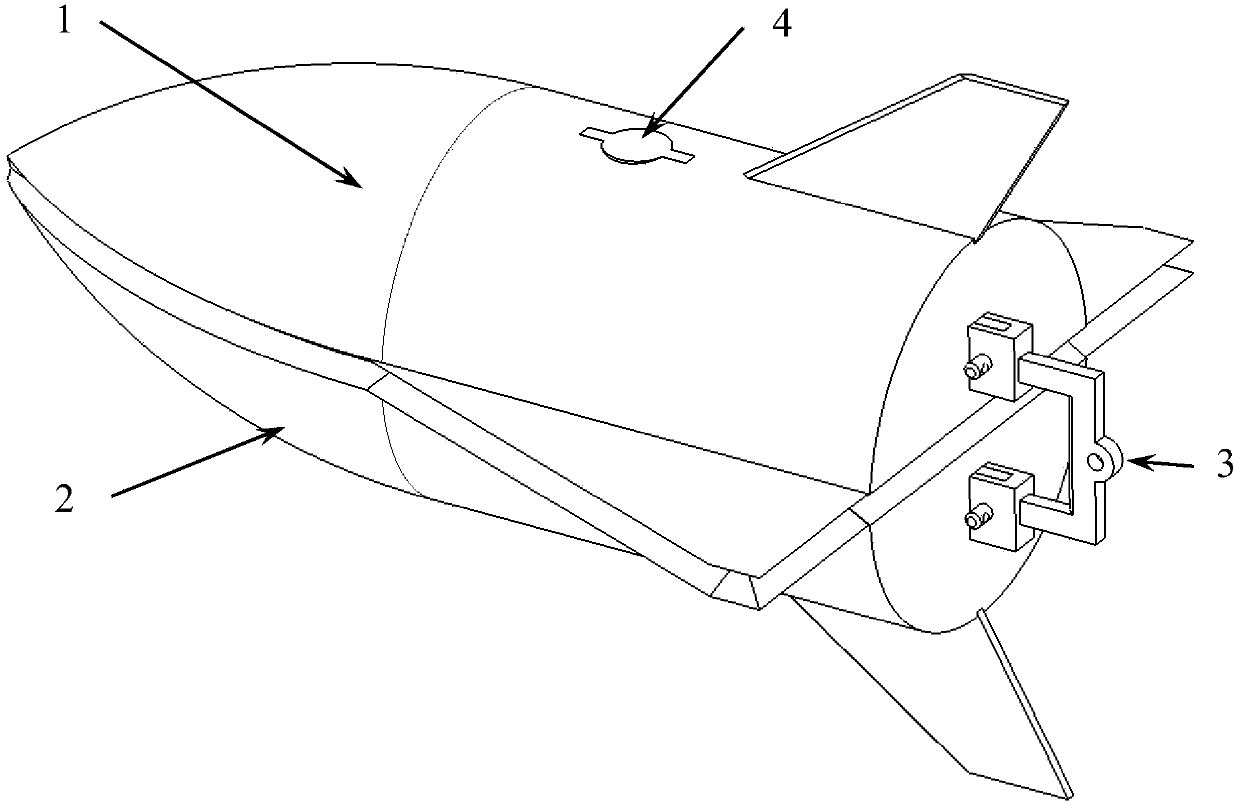

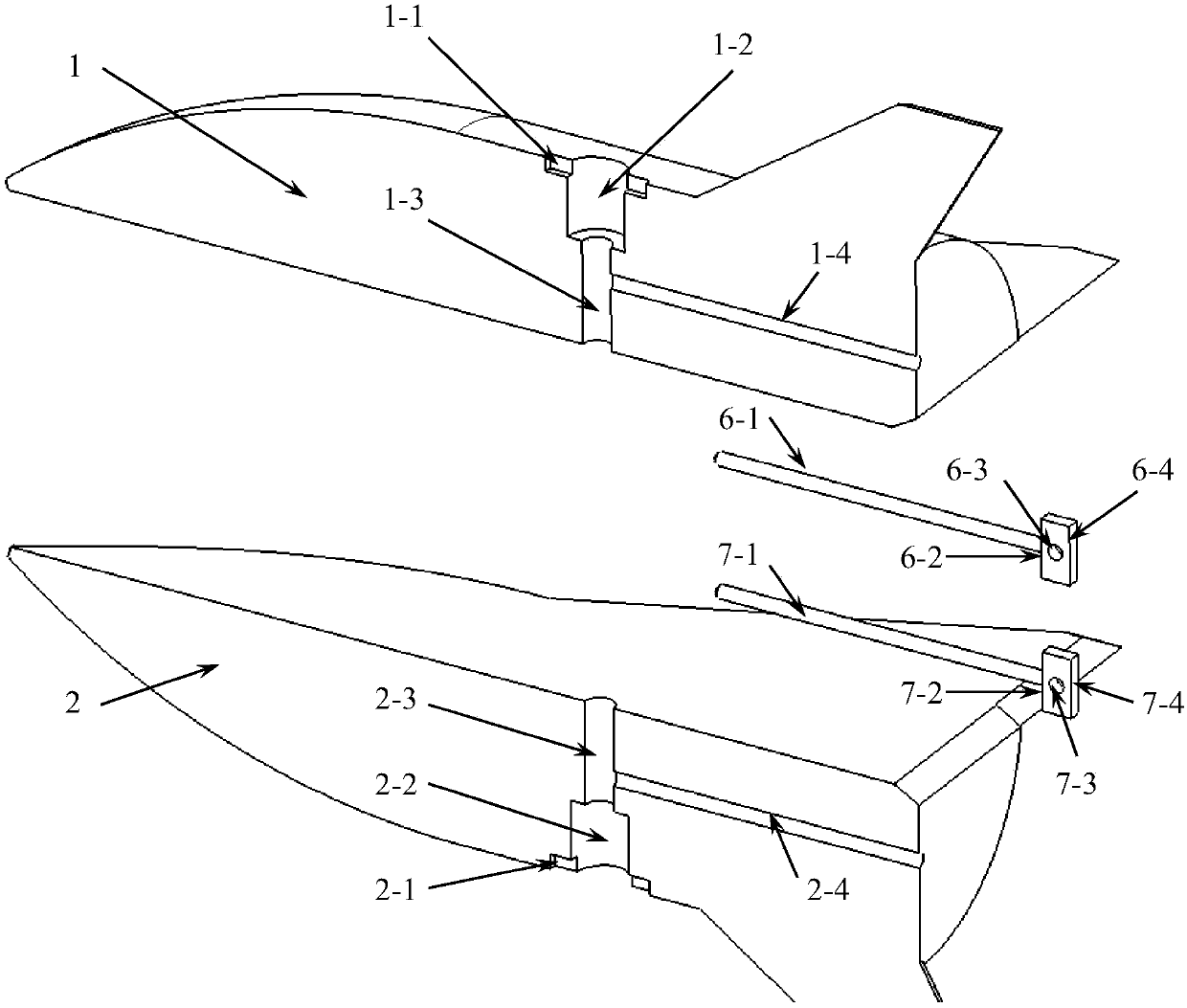

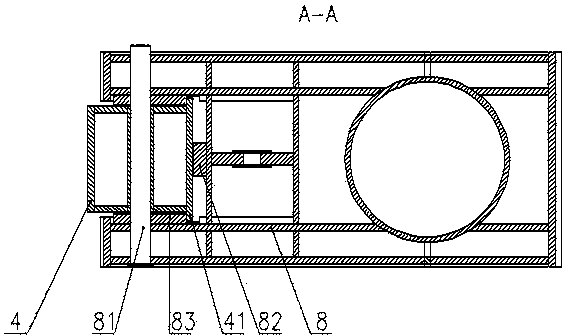

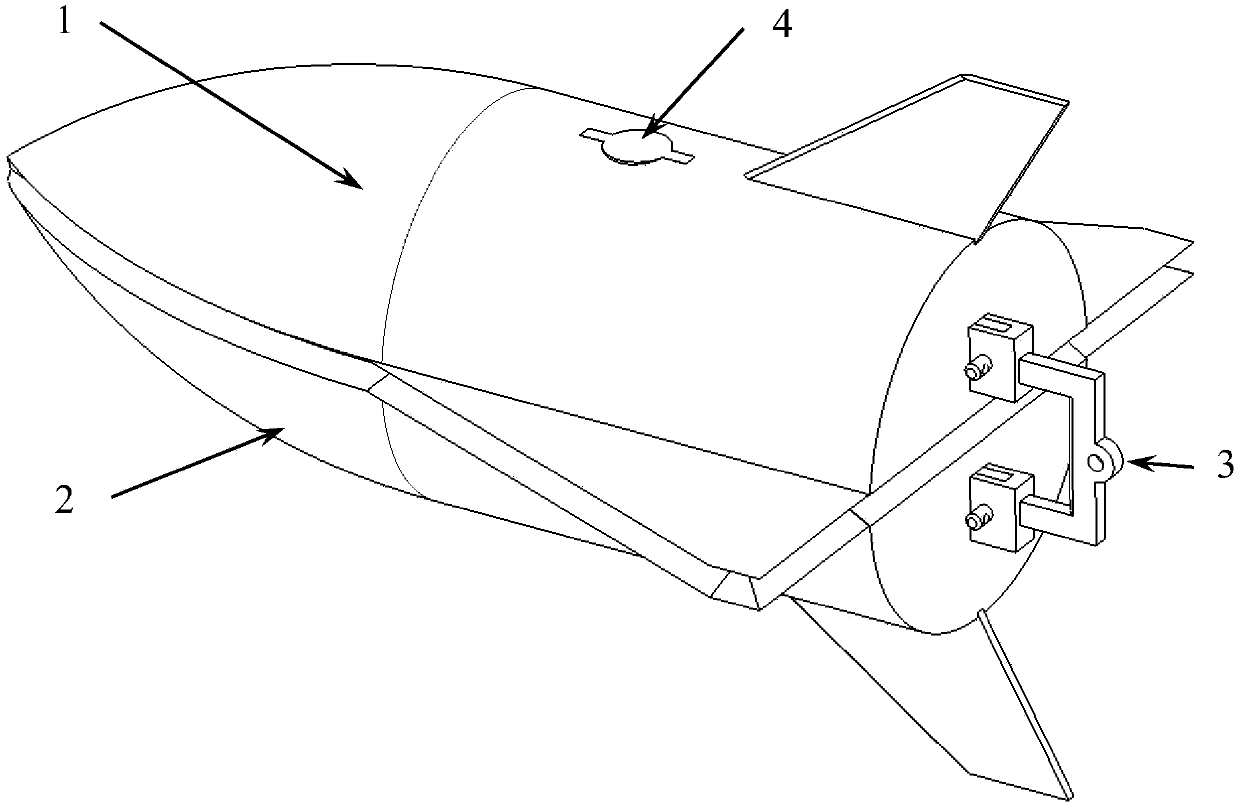

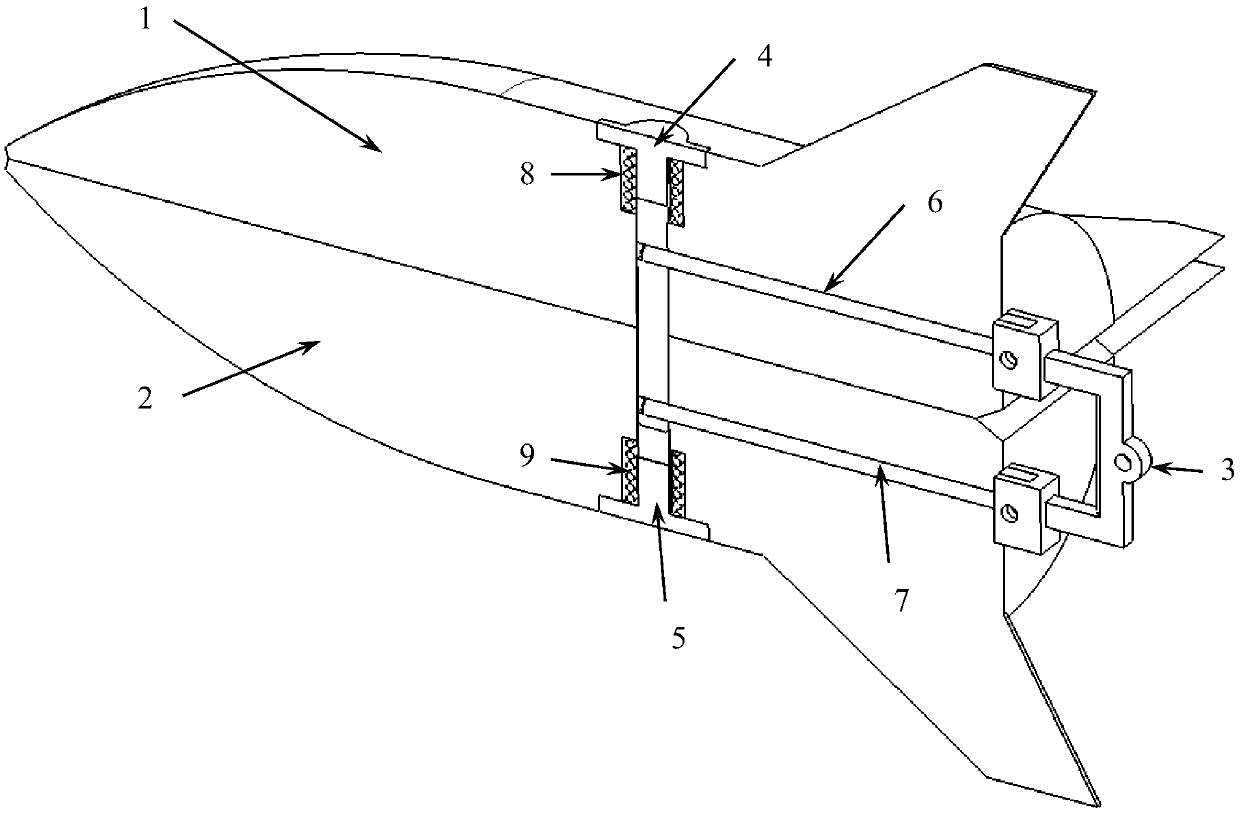

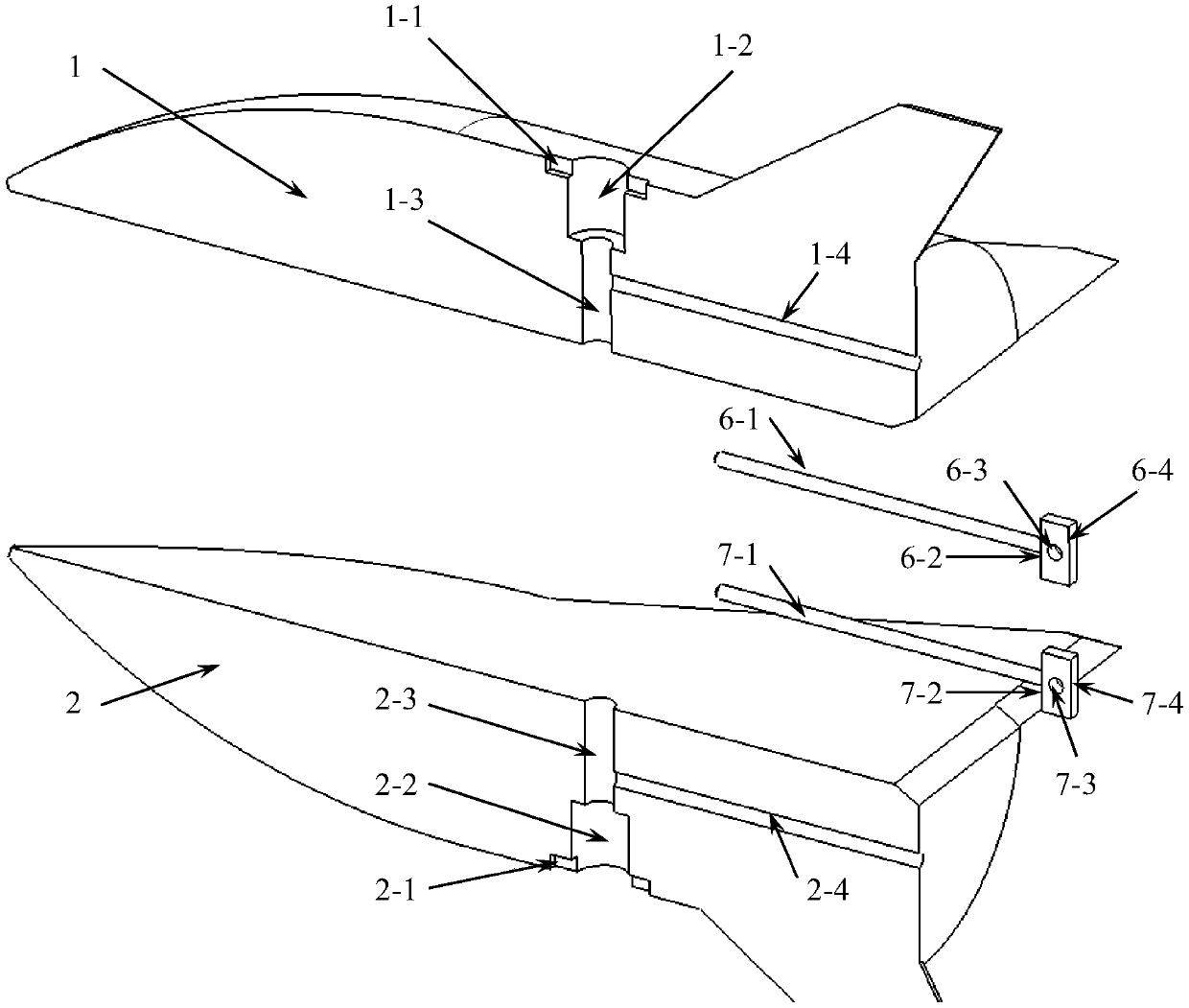

Parallel stage separation free flight wind tunnel testing device with mass center located on interface

ActiveCN107782526ASolve the problem of not being able to installUnplug the solutionAerodynamic testingEngineeringModel set

A parallel stage separation free flight wind tunnel testing device with the mass center located on the interface comprises a first model, a second model, a pull pin frame, pins, a first fixing nail, asecond fixing nail, a first spring, a second spring, a first pull pin and a second pull pin. The first pull pin, the second pull pin and the pull pin frame are installed together through the two pins, the first fixing nail and the second fixing nail penetrate through respective springs and are inserted into the first model and the second model, and the pull pins installed just are inserted into the models from the model tails and are just inserted into a round hole formed by a semi-circular groove of the first fixing nail and a round hole formed by a semi-circular groove of the second fixingnail to lock the whole model set. It is ensured that the first model and the second model can be fast and effectively separated without interference, the problem that a parallel stage separation freeflight wind tunnel test with the mass center located on the interface cannot be realized is solved mainly, and the defect that two stages cannot release the freedom degree at the same time due to theprevious model fixing mode is overcome.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

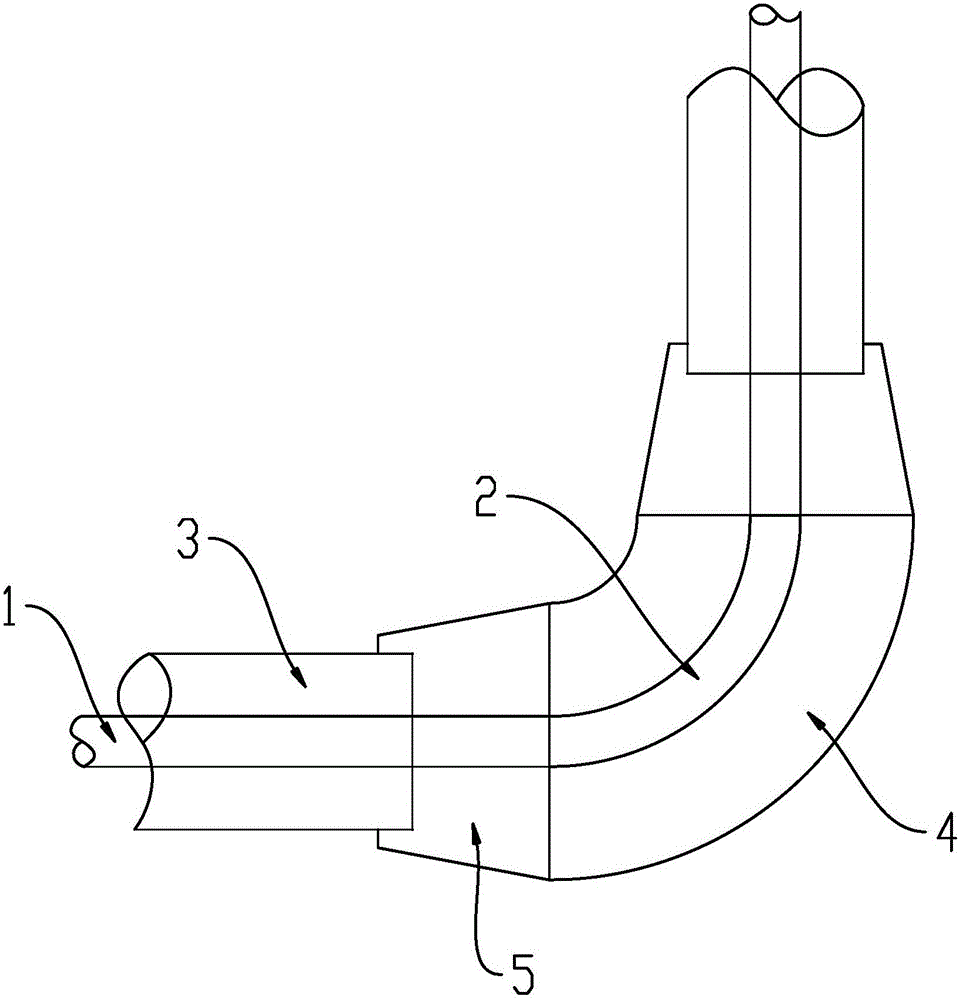

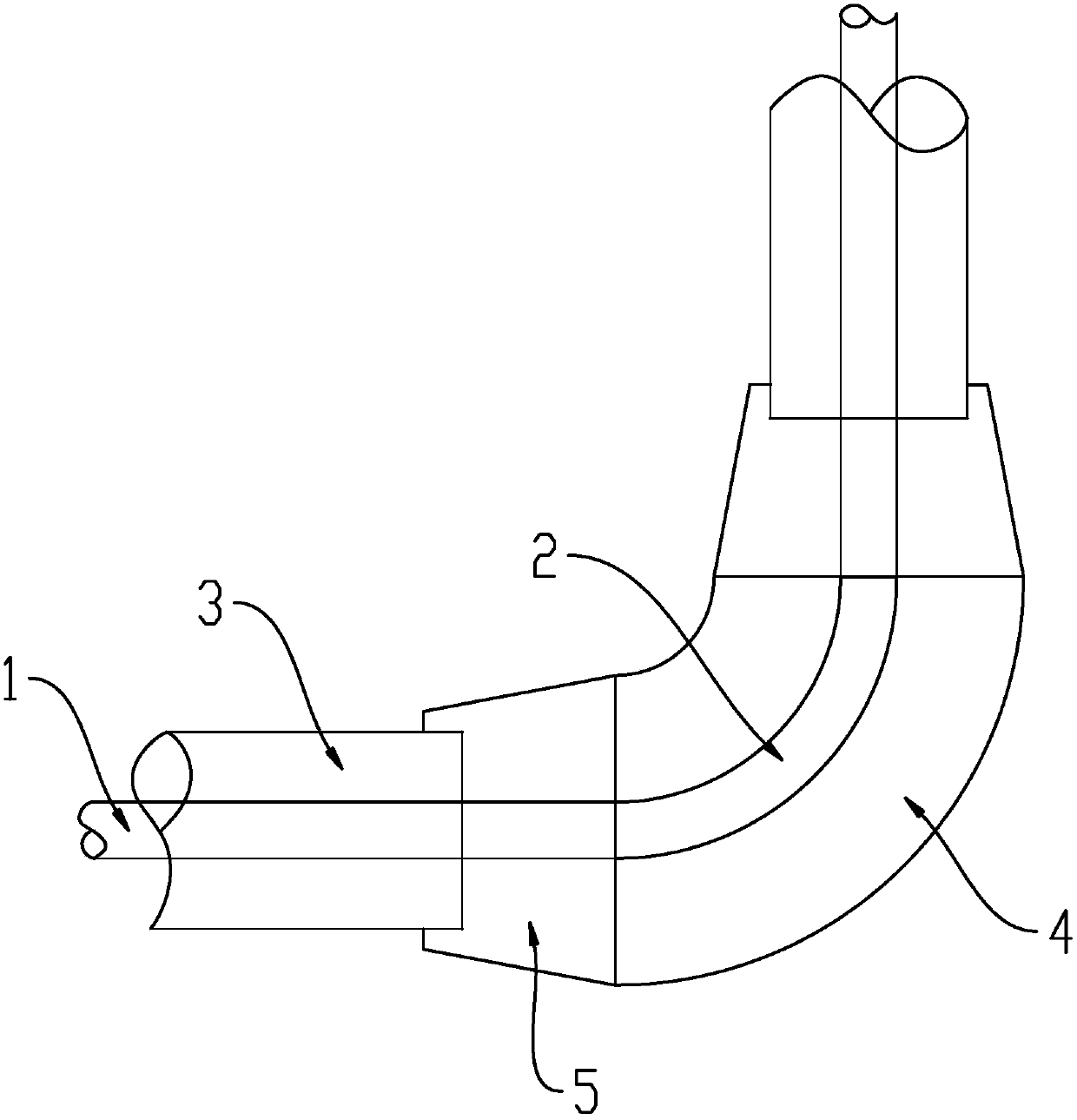

Welding method for two-layer pipe elbow

ActiveCN105834605ASolve the problem of not being able to installSolve the problem of not being able to weldWelding apparatusEngineering

The invention discloses a welding method for a two-layer pipe elbow. The two-layer pipe elbow comprises an inner straight pipe, an inner pipe elbow body, an outer straight pipe and an outer pipe elbow body. The inner diameter of the outer pipe elbow body is larger than the outer diameter of the outer straight pipe. The two sides of the outer pipe elbow body are provided with different-diameter connectors which are connected with the outer straight pipe. The problem that the two-layer pipe outer straight pipe cannot be installed is solved on the basis of the welding method for the two-layer pipe elbow. According to the welding method for the two-layer pipe elbow, the two-layer pipe elbow is reasonably divided into three parts, that is, the elbow body with an enlarged diameter and the two different-diameter connectors (welded to the outer straight pipe in an overlap mode), and thus the problem that the inner straight pipe cannot be welded is solved; and meanwhile, the outer pipe elbow body can be welded at last, and a space is easily transferred out by the outer pipe elbow body through moving of the different-diameter connectors on the outer straight pipe.

Owner:JIANGNAN SHIPYARD GRP CO LTD

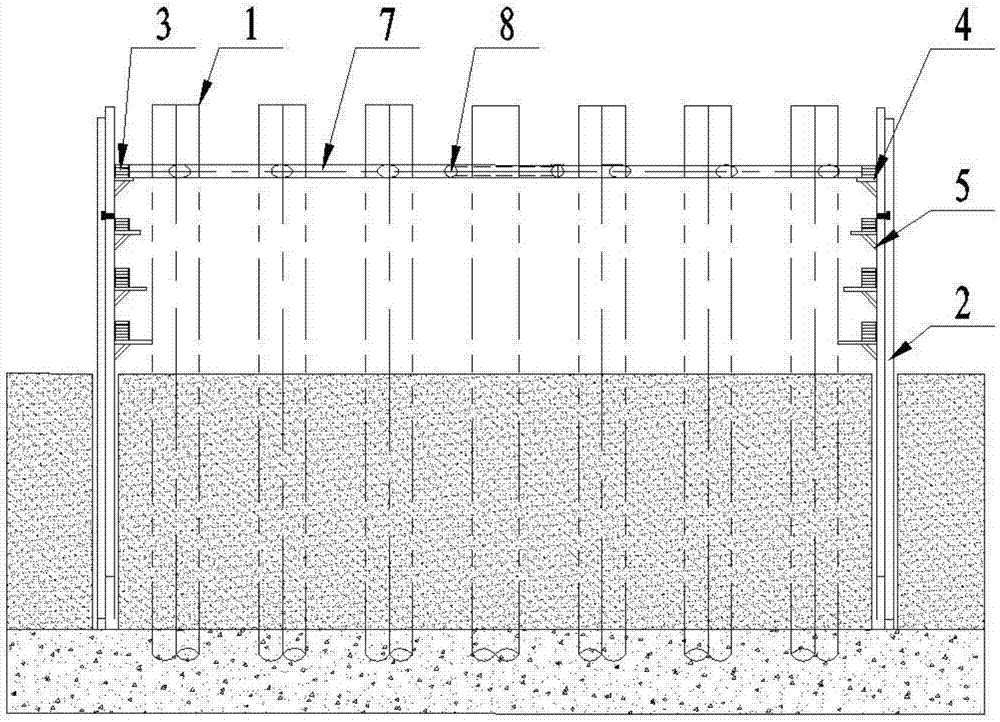

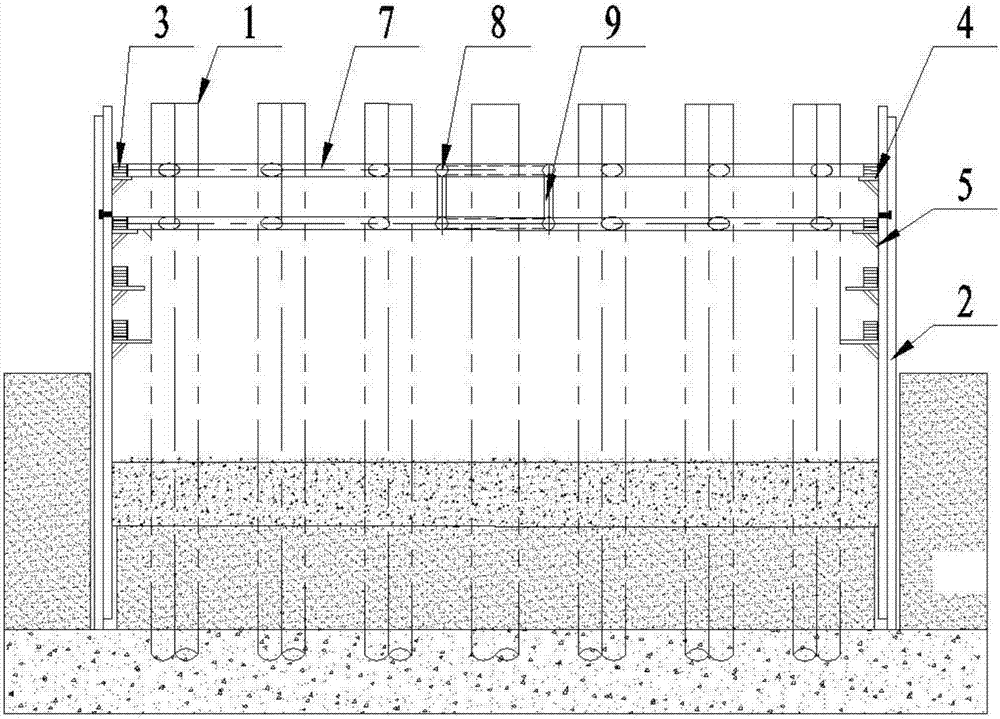

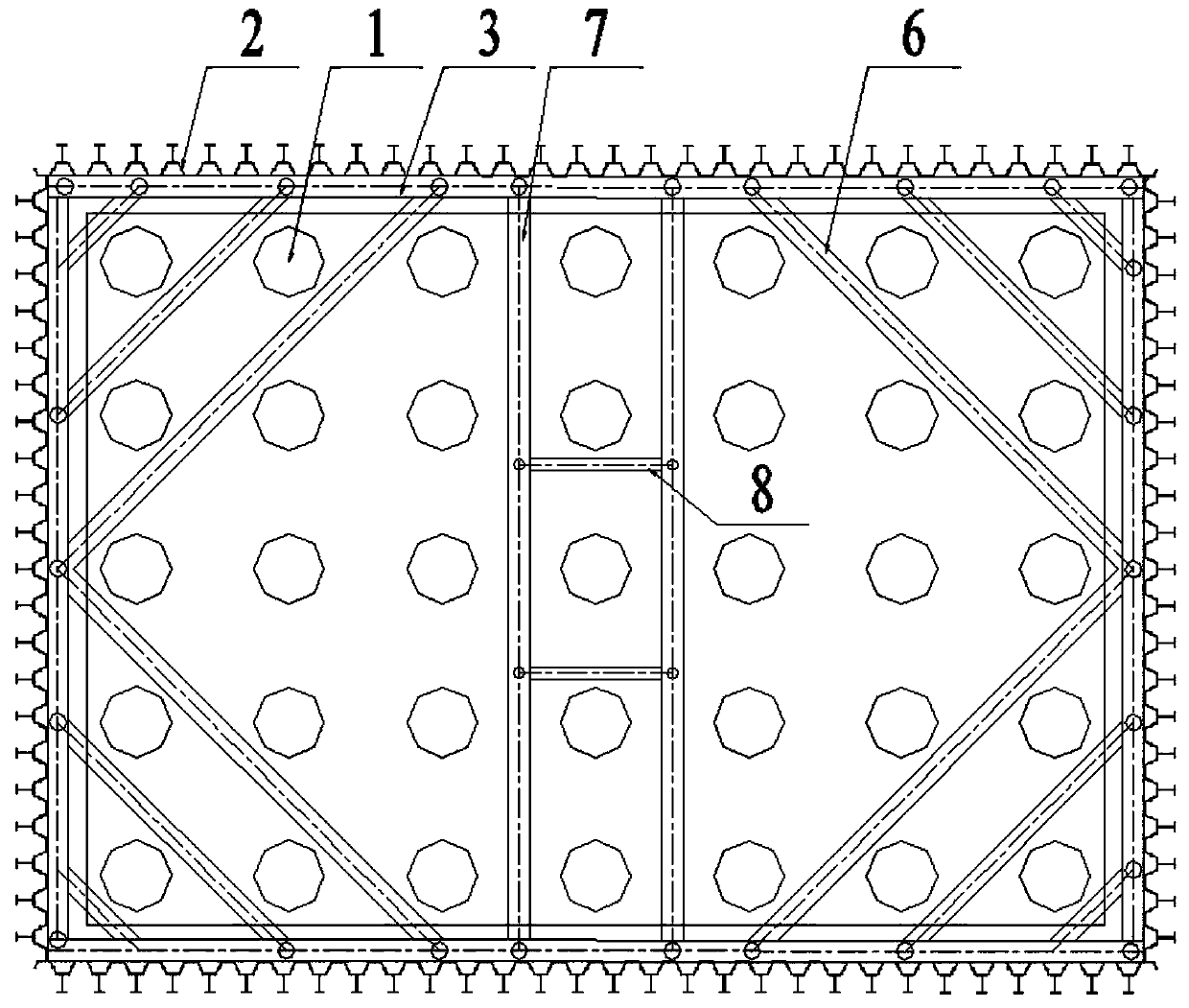

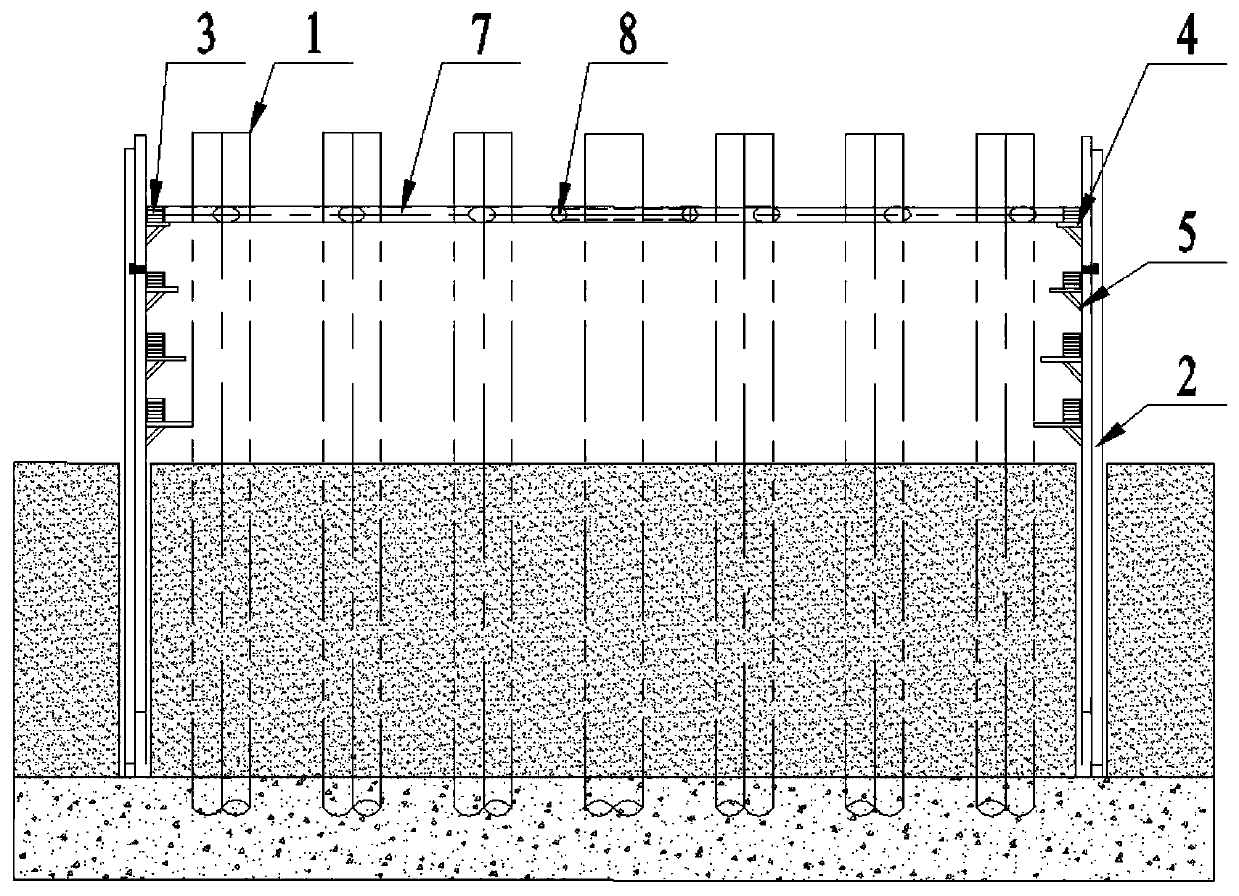

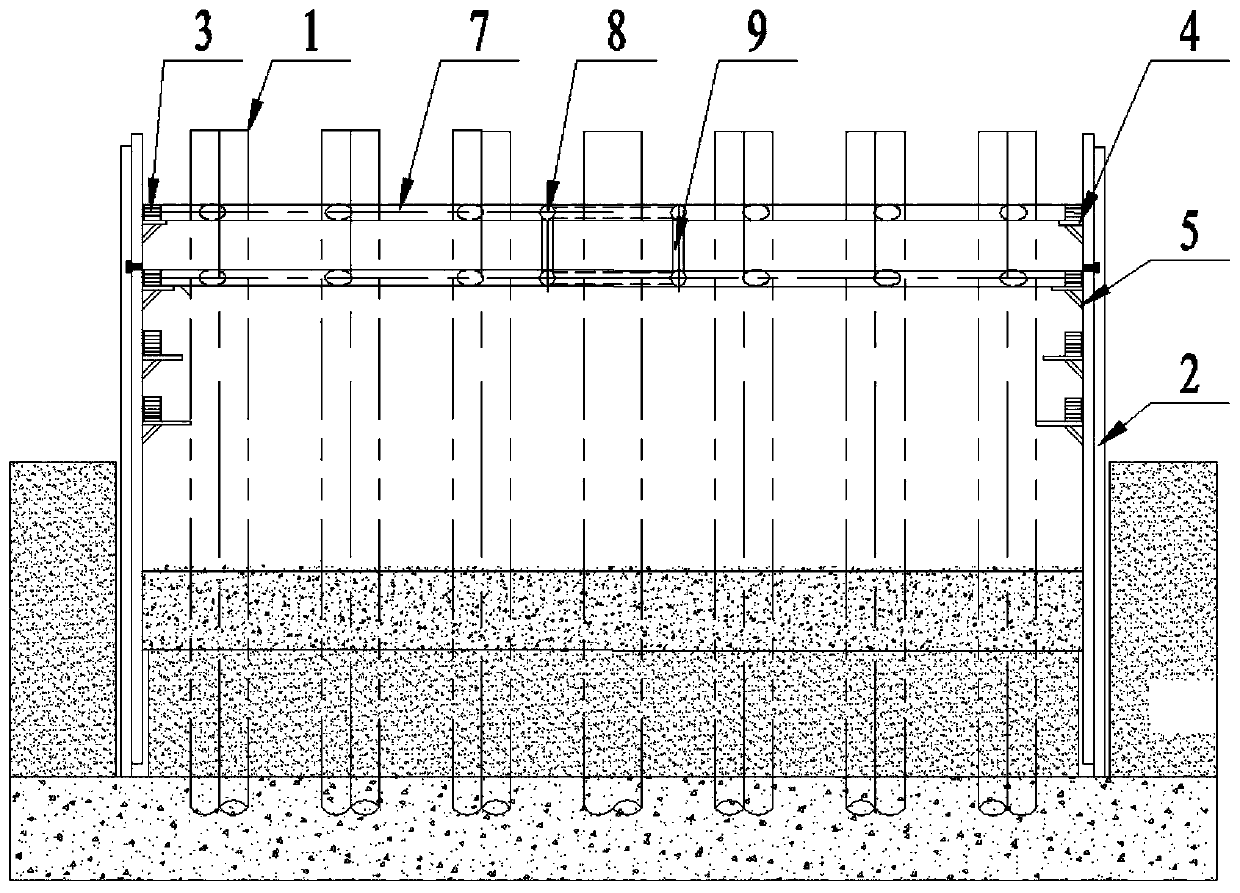

Deep water combined steel sheet pile cofferdam construction method

ActiveCN106948353ASolve the problem of not being able to installReduce installation difficultyFoundation engineeringPurlinSheet steel

The invention relates to the technical field of steel sheet pile cofferdam construction, in particular to a deep water combined steel sheet pile cofferdam construction method. The method comprises the steps that steel casings are inserted and driven into a cofferdam construction area; bearing structures are arranged in the positions, corresponding to enclosure purlin mounting positions, of steel sheet piles; the steel sheet piles are inserted and driven by relying on the steel casings to form a cofferdam structure in an encircling mode; enclosure purlins are sequentially hoisted onto the bearing structures on the inner sides of the steel sheet piles from bottom to top; water in the cofferdam is pumped layer by layer, and inner supports of the enclosure purlins are mounted layer by layer from top to bottom; and after all the inner supports are mounted, concrete is poured into the cofferdam to form a bearing platform structure. According to the method, corbels are arranged for the steel sheet piles in advance to realize in-place arrangement of the enclosure purlins in advance; through the construction method of conducting water pumping after bottom sealing, integral connecting of the enclosure purlins, and subsequent installation of the inner supports, adverse influences caused by existence of the steel casings, the upper-layer enclosure purlins and the inner supports on the operating space are avoided, the problem that large enclosure purlins cannot be installed is solved effectively, and the installation difficulty of the inner supports during the later period is lowered.

Owner:CCCC SECOND HARBOR ENG

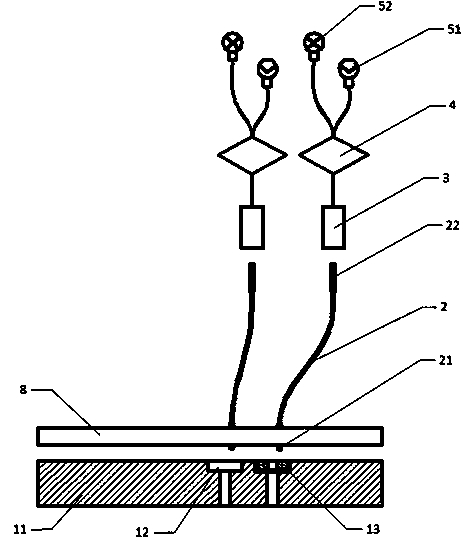

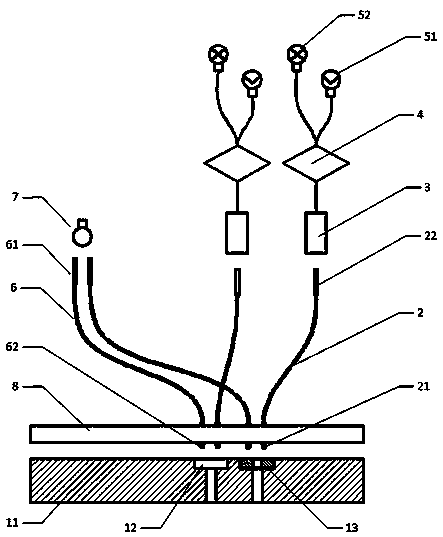

Operating method and device for replacing 10kV pole-mounted drop-out fuse

ActiveCN103532047AMeet the technical requirementsReduce the difficulty of homeworkApparatus for overhead lines/cablesEngineeringDistribution networks

The invention relates to the technical field of 10kV distribution network load operation, in particular to an operating method and device for replacing a 10kV pole-mounted drop-out fuse. A self-extinguishing bypass drop-out fuse is taken as temporary bypass equipment for shunting a drop-out fuse to be replaced in order to fulfill the aim of converting charge, so that the drop-out fuse to be replaced is replaced after exiting from operation. Compared with the prior art, the method has the beneficial effects that (1) the self-extinguishing drop-out fuse is taken as shunting equipment, so that the technical condition for charged replacement of the drop-out fuse is satisfied, and the operation difficulty is lowered; (2) stable connection of the shunting equipment and an electric pole is completed by adopting an insulating lifting bracket, so that enough safety distance can be provided for operating personnel, and the problems of small equipment interval and incapability of mounting the shunting equipment are solved; (3) the method is consistent with the technical characteristics of the national charged operation in China, charged replacement of the drop-out fuse is realized, and economic losses of downstream power utilization enterprises and residents caused by power cut are avoided.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

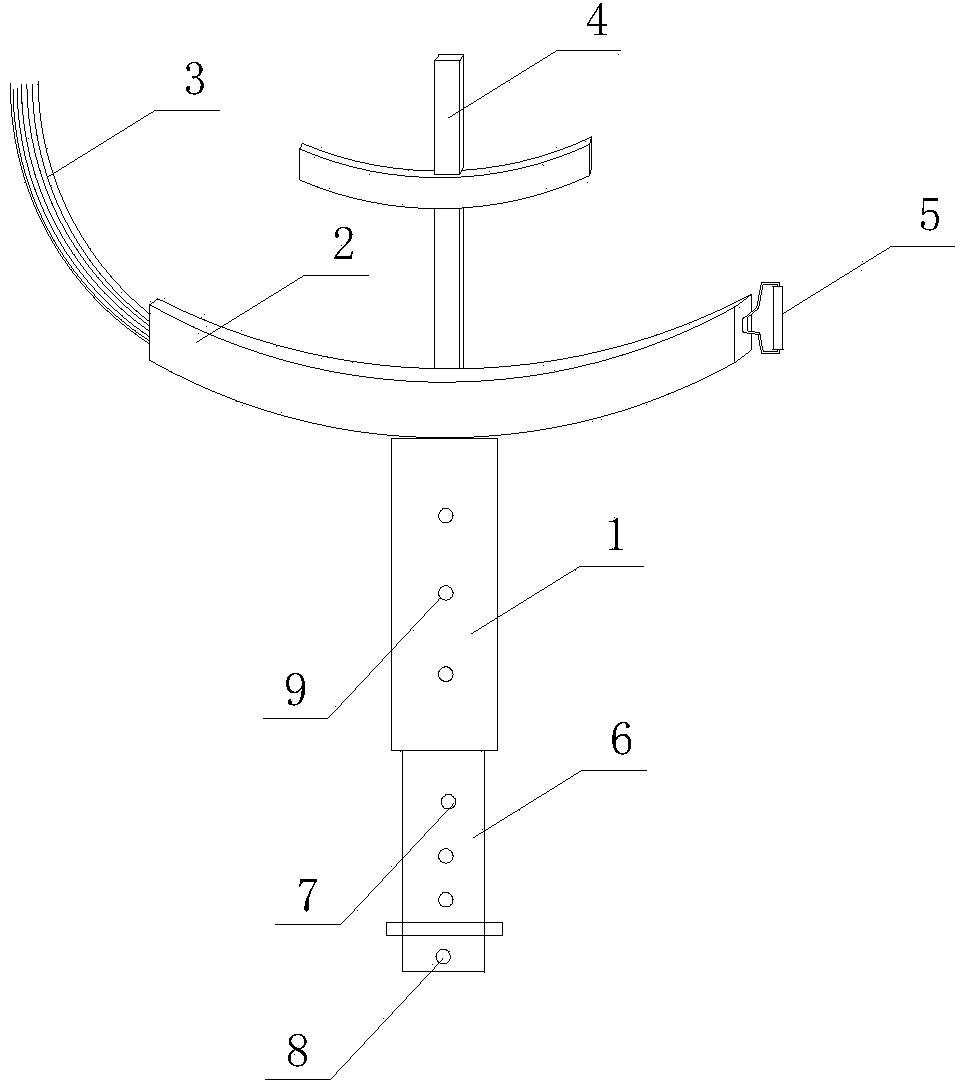

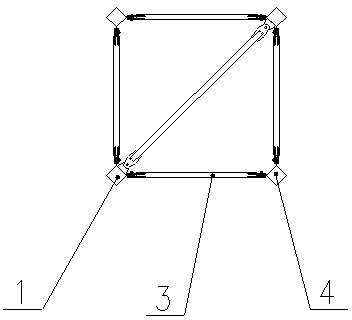

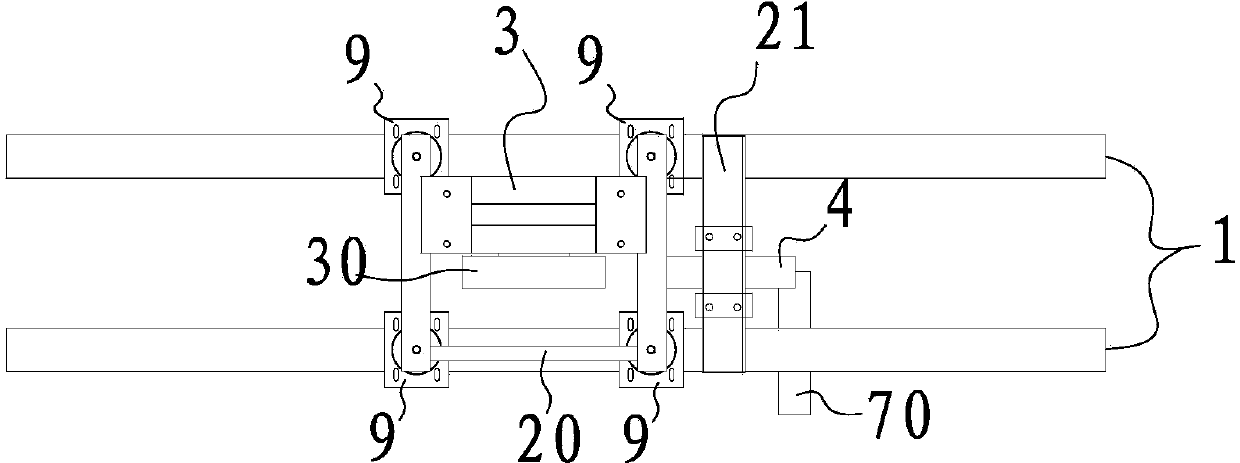

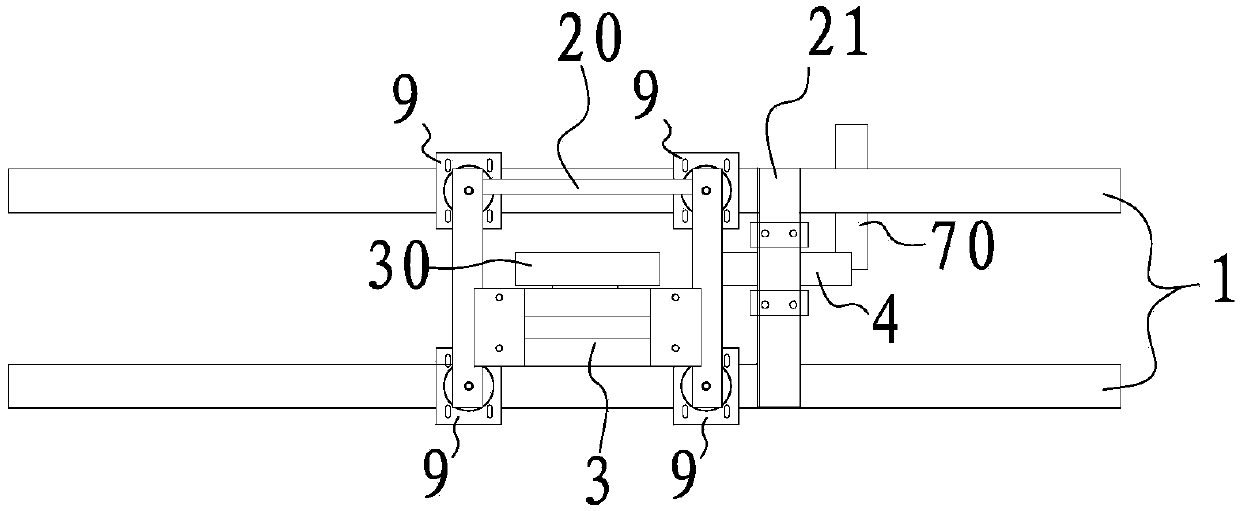

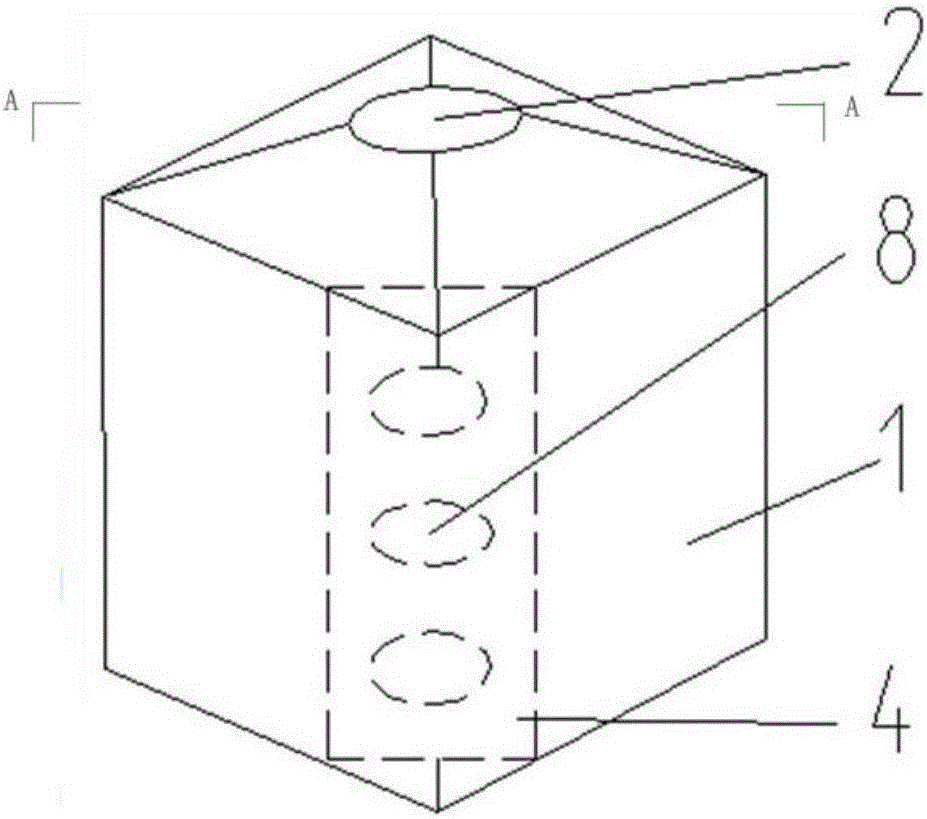

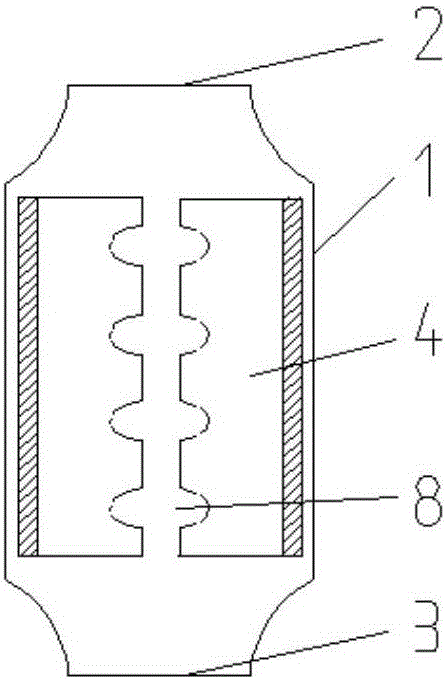

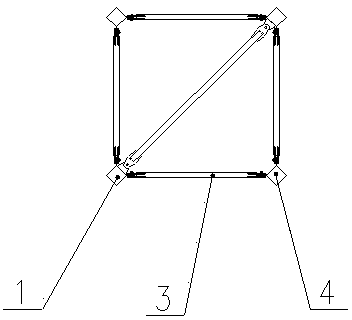

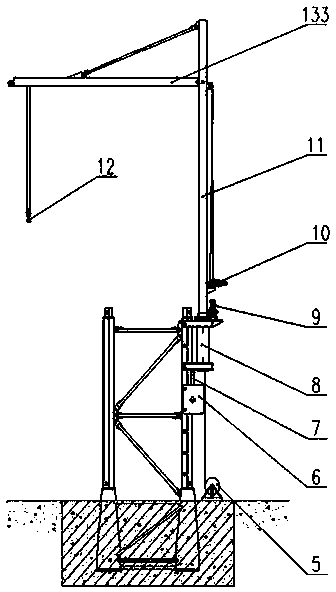

Tower type truss installing structure and method without cooperation with altitude hoisting equipment

ActiveCN103101847ASolve the problem of not being able to installImprove convenienceCranesTrolleysEngineeringTower

The invention relates to a tower type truss installing structure and a tower type truss installing method without cooperation with altitude hoisting equipment. The method comprises the step of overlapping a plurality of truss standard knots from bottom to top, wherein each truss standard knot consists of a plurality of vertical chord members (1 and 4), and the chord members (1 and 4) are fixedly connected with each other by web members (2 and 3). The structure and the method disclosed by invention are characterized in that one chord member (4) of the tower type truss is concurrently taken as a climbing rack and an attaching support for an assistant crane, and the chord members (1 and 4) and the web members (2 and 3) of the tower type truss are installed by the assistant crane attached on the chord member (4), so that the assistant crane can continuously climb along the chord members without the cooperation with the other hoisting equipment. According to the invention, the difficulty that a tower type truss can not be installed when the altitude hoisting equipment is unavailable can be solved, and a mass of installing cost can be saved, so that the tower type truss is applicable to the occasion without the altitude hoisting equipment, and the convenience degree for the distribution of engineering equipment can be greatly improved.

Owner:杭州国电大力机电工程有限公司

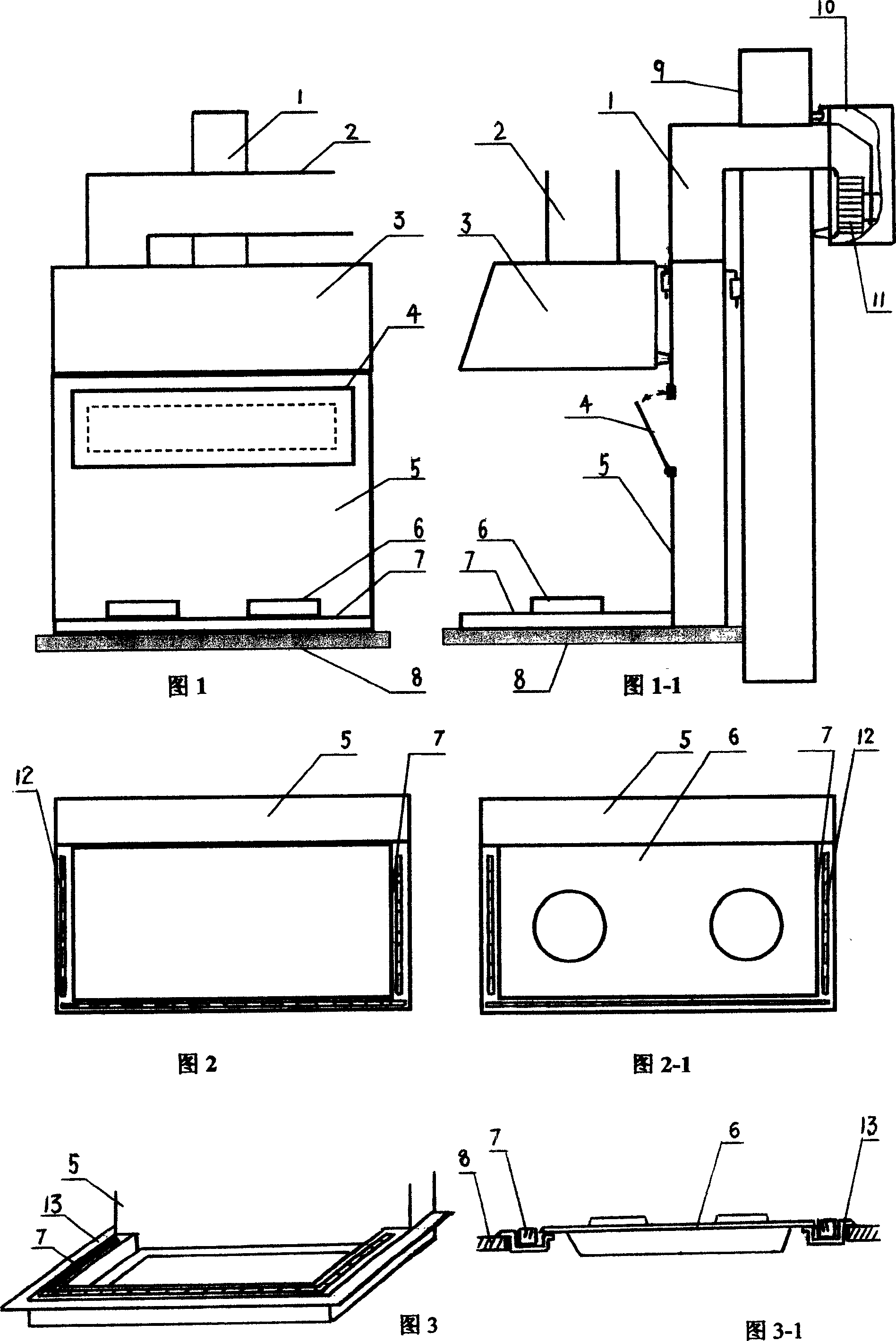

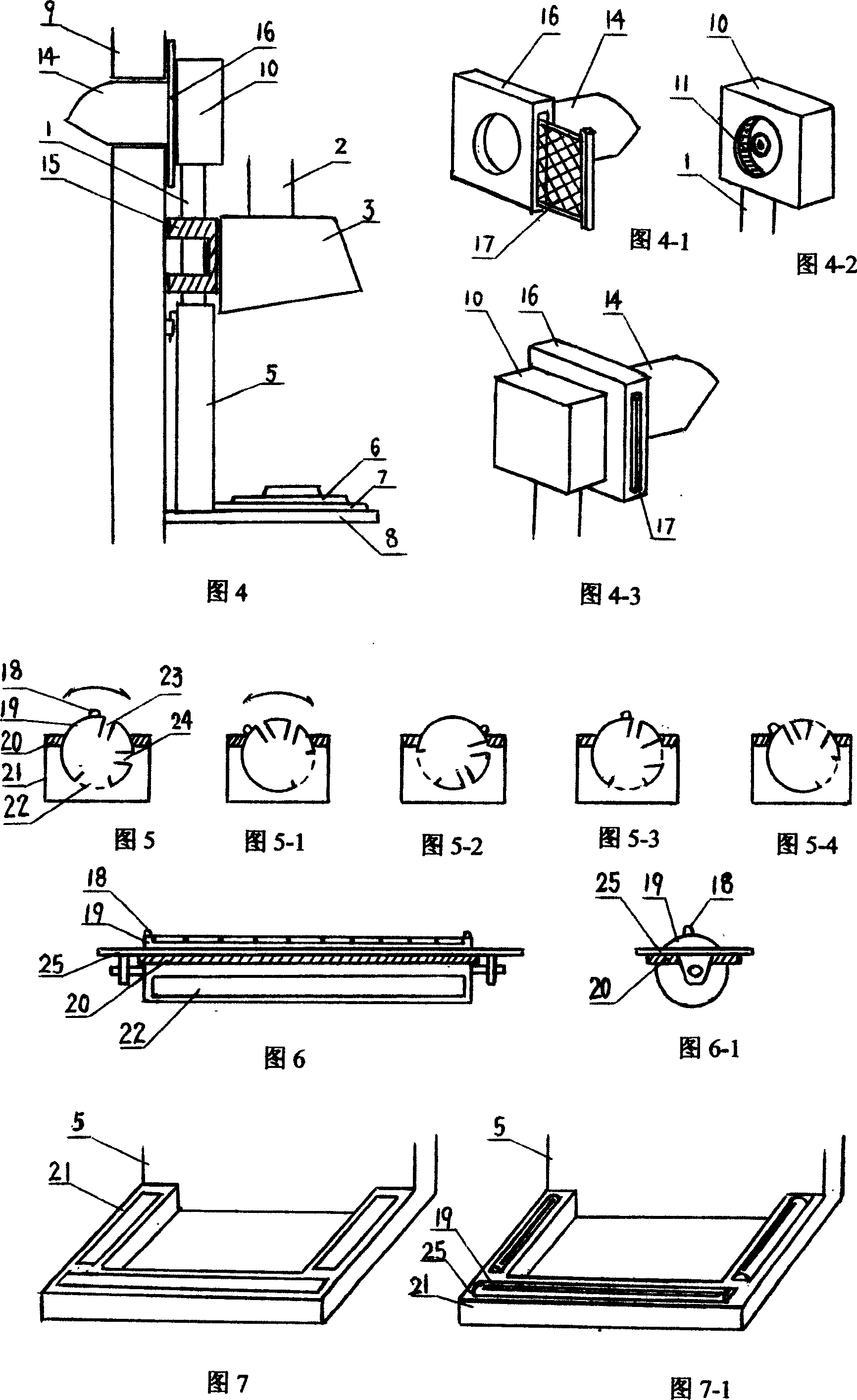

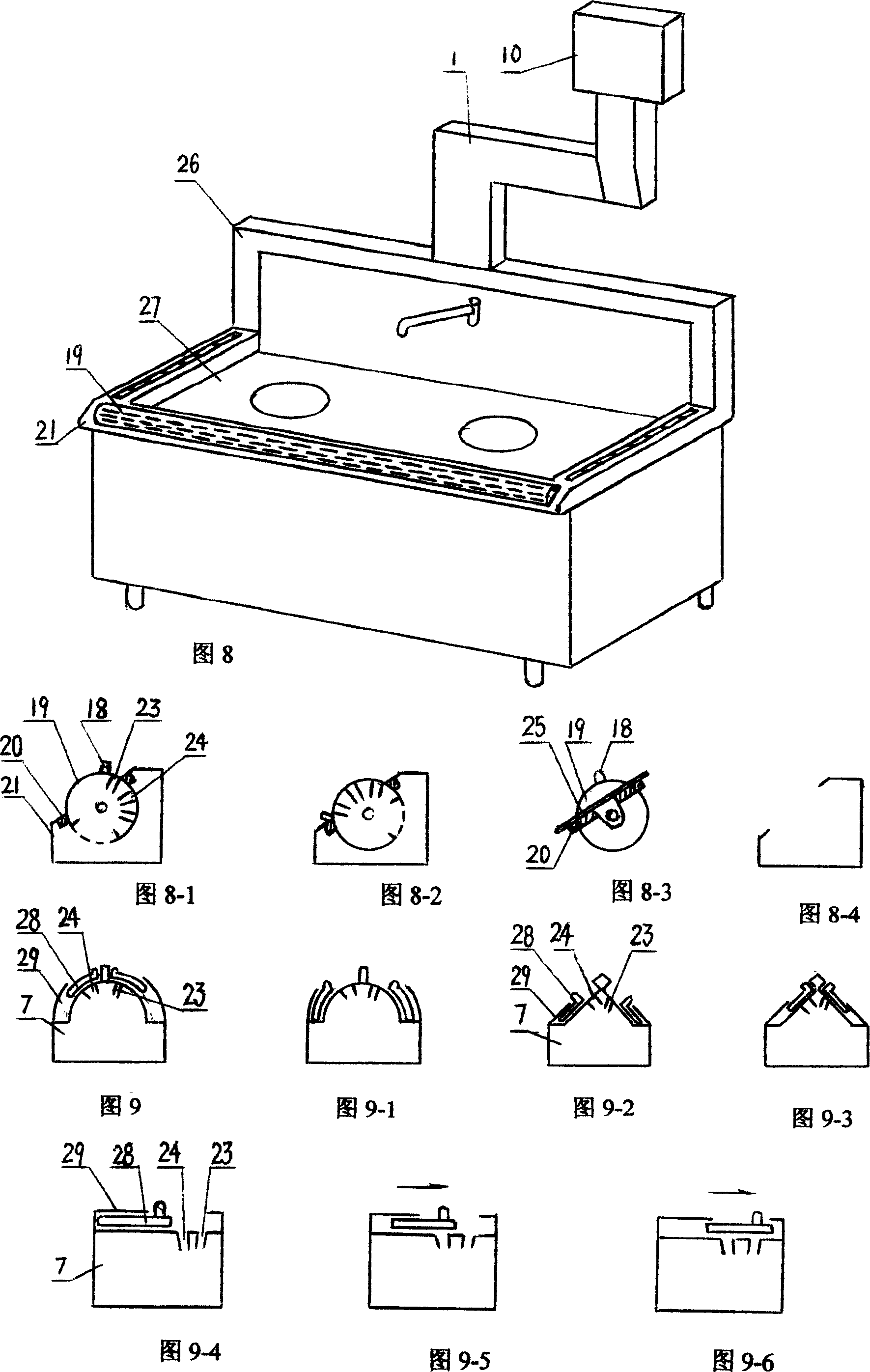

Air-intake and heat-proof device of health energy-saving environment protective kitchen range

InactiveCN101012946AImprove the operating environmentSolve air intake problemsDomestic stoves or rangesLighting and heating apparatusCold airEngineering

The invention provides an air inlet thermal-insulated device of kitchen tool, with simple installment and energy-saving property, for balancing the inner and outer pressures of room and eliminating the indoor smoke, and insulating the generated high temperature of kitchen tool and indoor room, to reduce the hot and cold air consumptions.

Owner:李孝龙

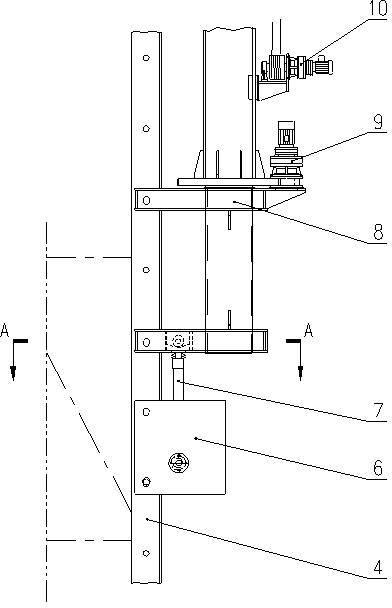

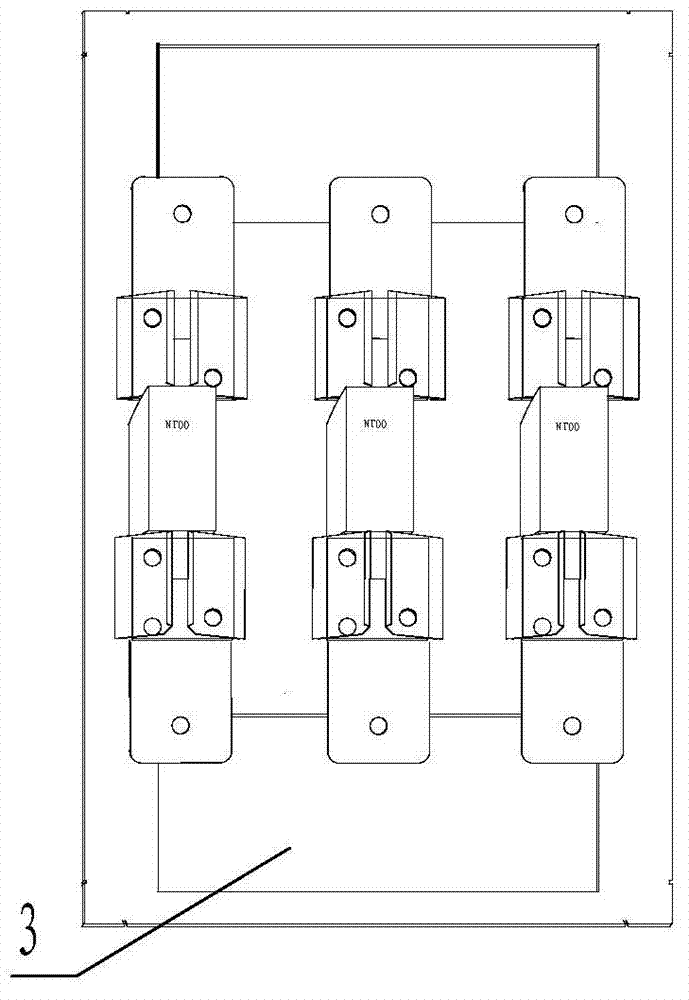

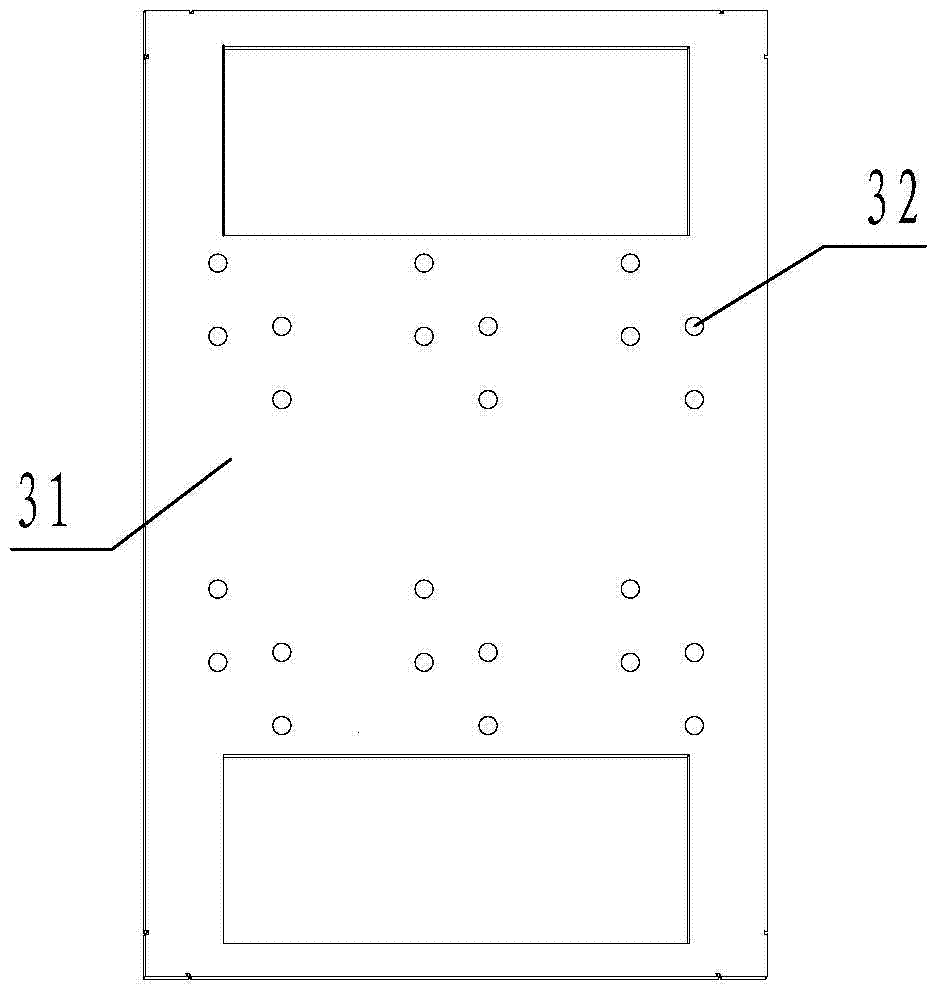

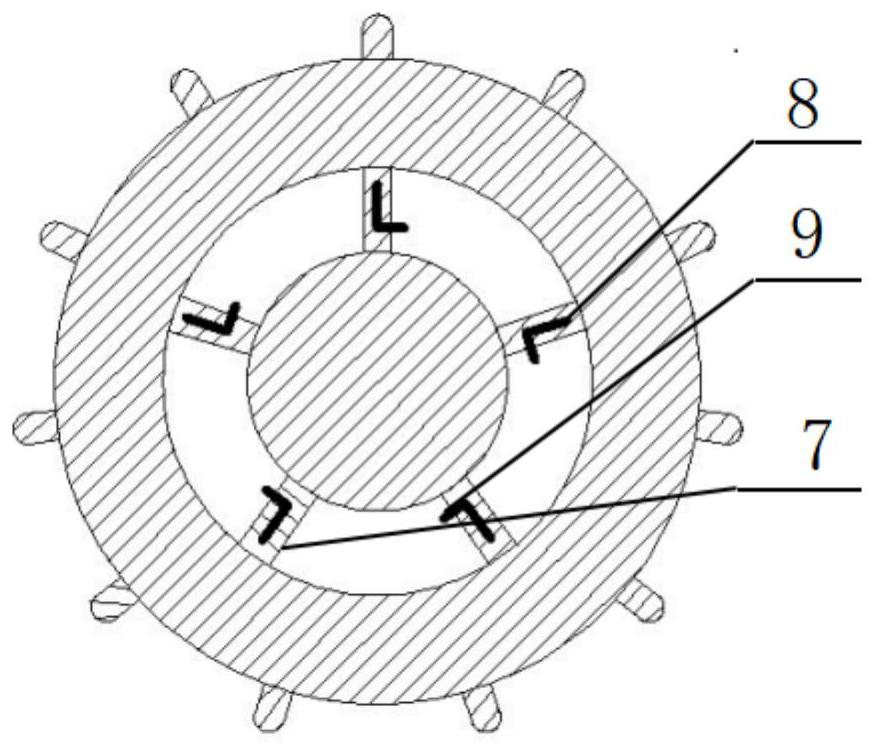

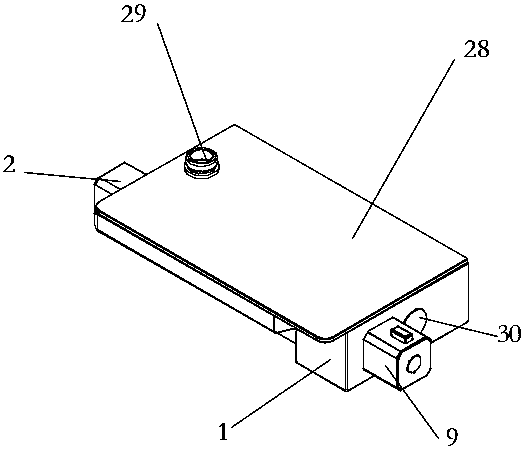

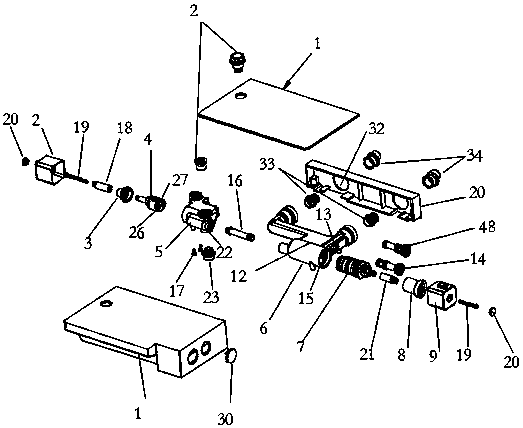

Motor speed measuring device

InactiveCN104251914ASolve the problem of not being able to installEasy to operateLinear/angular speed measurementSpeed/acceleration/shock instrument detailsMotor speedEncoder

The invention discloses a motor speed measuring device. The motor speed measuring device comprises a motor rotating shaft and a speed measuring rotating shaft, wherein the motor rotating shaft is hotly sleeved with a first gear; the speed measuring rotating shaft is hotly sleeved with a second gear; the first gear and the second gear are engaged by a gear; an encoder is mounted on the speed measuring rotating shaft; the speed measuring rotating shaft is mounted in a lug boss inner hole structure of an end cover by a bearing. The speed measuring device is simple and compact in structure, and reliable; the problem that the rotating speed of a motor cannot be accurately measured under the condition that double shaft extension motors have loads is solved, so that the structure guarantees for reliable speed measurement of the motors are provided.

Owner:SEC ELECTRIC MACHINERY

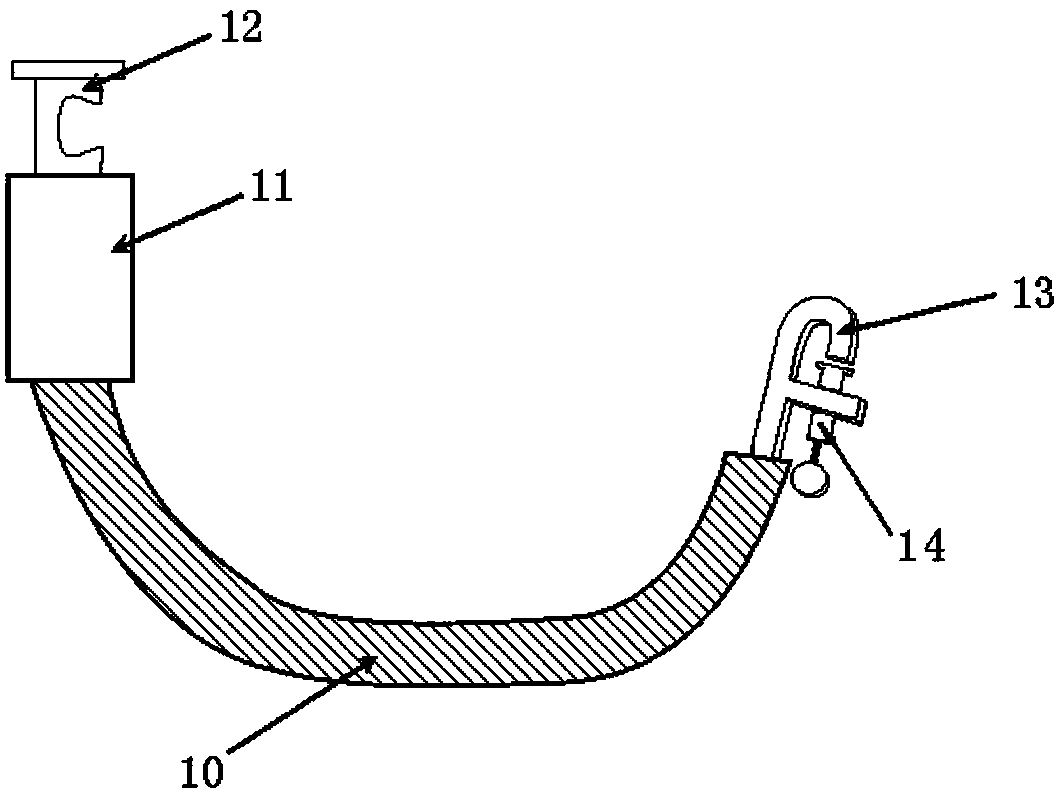

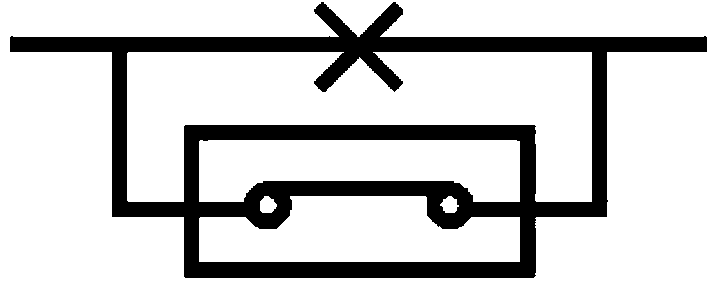

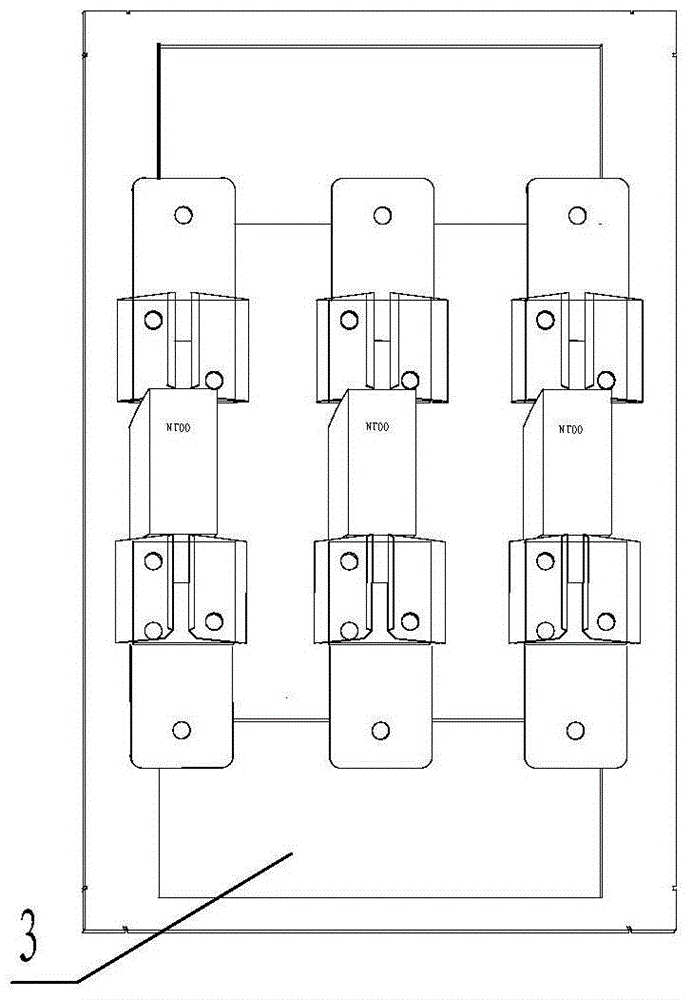

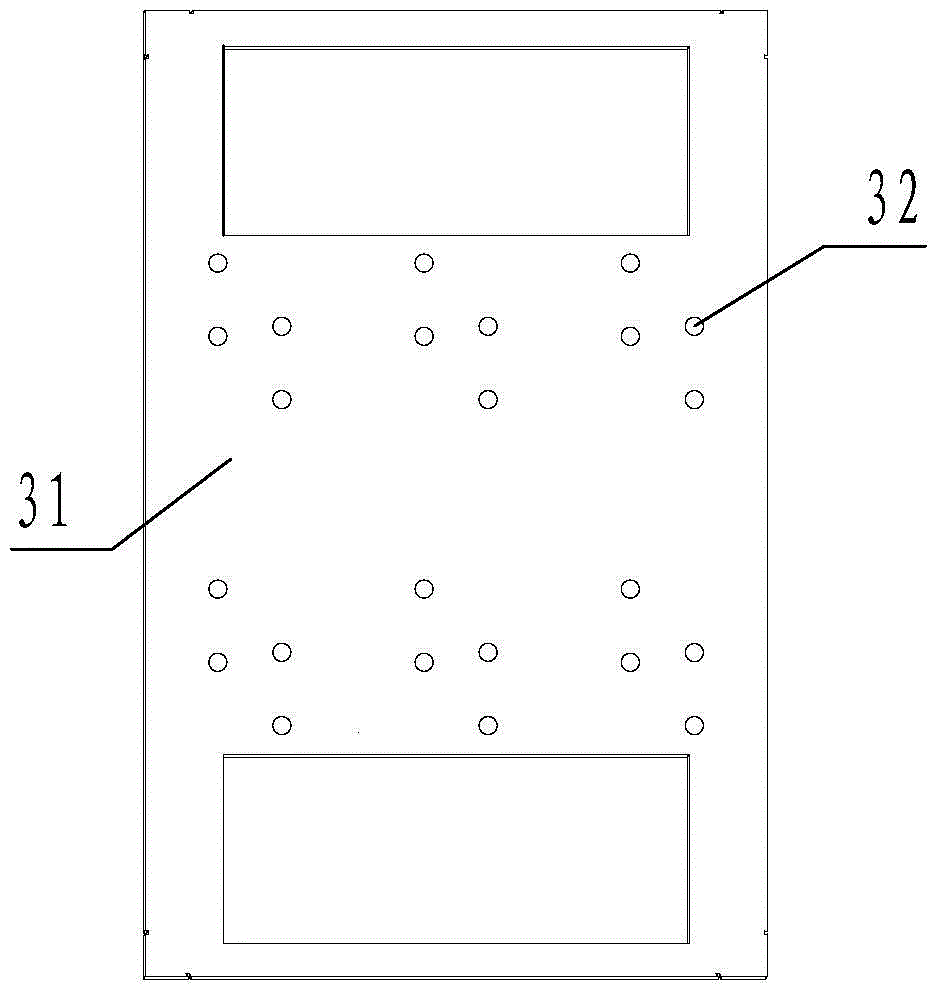

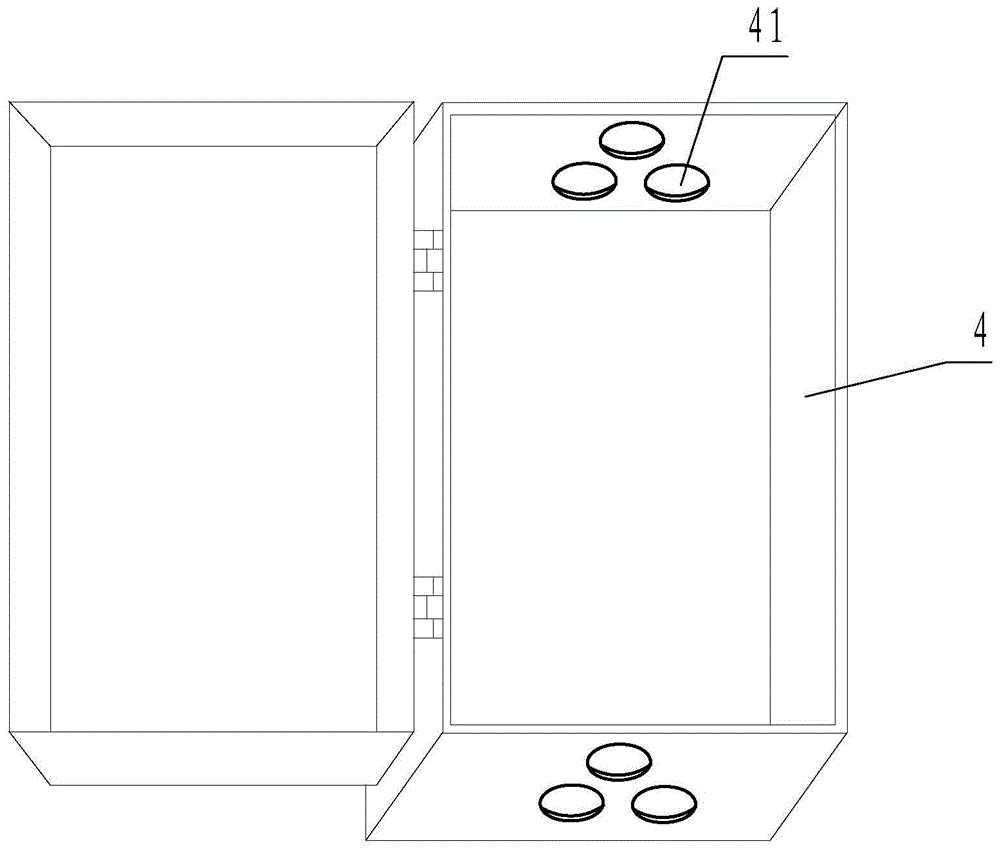

Low-voltage multipurpose short-circuit connector

ActiveCN104505714AVersatileImprove work efficiency and power supply reliabilityCoupling device connectionsSubstation/switching arrangement detailsBackplaneJumping

The invention discloses a low-voltage multipurpose short-circuit connector, comprising fixing clamps, flexible jumping wires and a short-circuit connecting member, wherein each fixing clamp comprises a conductive fixing member and a conductive adapting member; each of the flexible jumping wires is a conductive braided strap; each of two ends of each conductive braided strap is provided with a connecting hole; the short-circuit connecting member comprises a back plate which is made of a material with an insulating arc-isolating effect and is used for fixation; the back plate is provided with installation holes which are adapted to fuse wires with different pitches and the size of a base; the fuse wires are arranged on the base. In the field application, the low-voltage multipurpose short-circuit connector disclosed by the invention can be used as an effective measure for quickly repairing and recovering electric power after switches with different models and different specifications are in fault, and can also be fixedly used as the leading end of a short-circuit connection grounding wire. According to the low-voltage multipurpose short-circuit connector, not only are the problems that the rush repairing time is long due to the fact that a switch is not matched, and the power fault range is large solved, but also the problem that the leading end of the overhauling grounding wire of most switches cannot be installed is solved, and the operation efficiency and power supply reliability are improved.

Owner:STATE GRID CORP OF CHINA +2

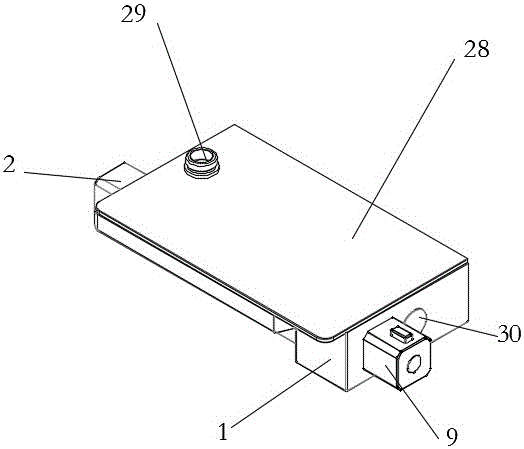

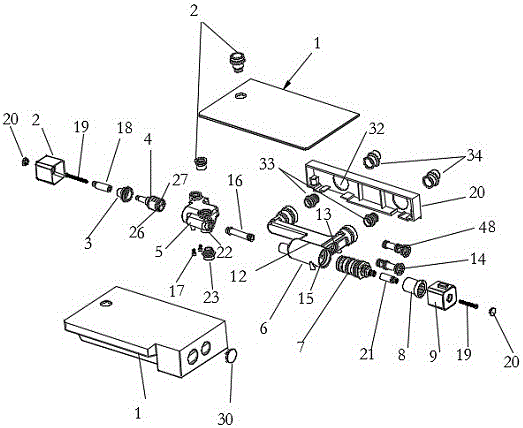

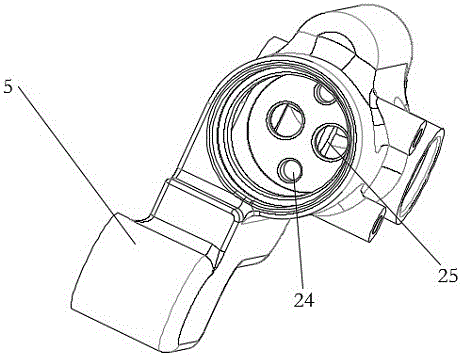

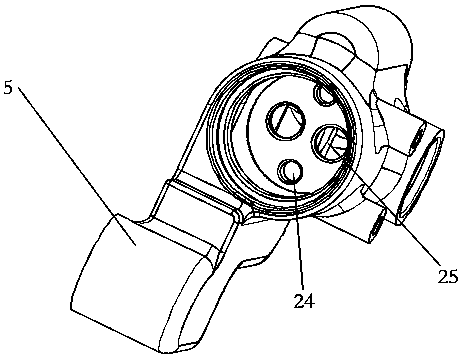

Constant temperature faucet with cooling pipe and heating pipe switchable

ActiveCN105805361ASatisfy usage preferenceMeet the needs of useMultiple way valvesWater flowEngineering

The embodiment of the invention discloses a constant temperature faucet with a cooling pipe and a heating pipe switchable. The constant temperature faucet comprises a constant temperature assembly, and the constant temperature assembly comprises a constant temperature body. The constant temperature body is provided with a cold water inlet part, a hot water inlet part and a connector part used for connecting the cold water inlet part with the hot water inlet part, and water flow runners are formed in the connector part. The connector part is internally provided with the cold water runner, the hot water runner, the adjustable runner, the cold water flow-out runner and the hot water flow-out runner, wherein the cold water runner communicates with the cold water inlet part; the hot water runner communicates with the hot water inlet part; the adjustable runner is arranged between the cold water runner and the hot water runner; the cold water flow-out runner and the hot water flow-out runner are separated from each other and communicate with a constant temperature valve element cavity. The design of the internal water flow runners of the constant temperature faucet is improved, switching between cold drained water and hot drained water is achieved through an adjustable component, the application range of the constant temperature faucet is extended, the constant temperature faucet can meet the different mounting conditions and use preferences, and accordingly the constant temperature faucet has broader market prospects.

Owner:江门市国人温控卫浴有限公司

Method and device for detecting nuts in trunk cover plate production

InactiveCN104375199ASolve the problem of mutual interference when the distance is too closeSolve the problem of not being able to installOptical detectionElectricityFiber

The invention relates to a method and device for detecting whether nuts mounted on a base plate are missed in trunk cover plate production. Light-guide fibers are used for transmitting reflected light on the nuts to photoelectric converting elements which convert the reflected light to electric signals, then the electric signals are sent to judging units, the strength of the reflected light is judged according to the strength of the electric signals, and therefore whether the nuts are missed can be known. The method and device solve the problem the detection is difficult due to the facts that the nuts are large in number and small in size, and the distances between the nuts are small, and the missing mounting detection problem is solved through the economical method.

Owner:YANTAI ZHENGHAI HIGH TECH

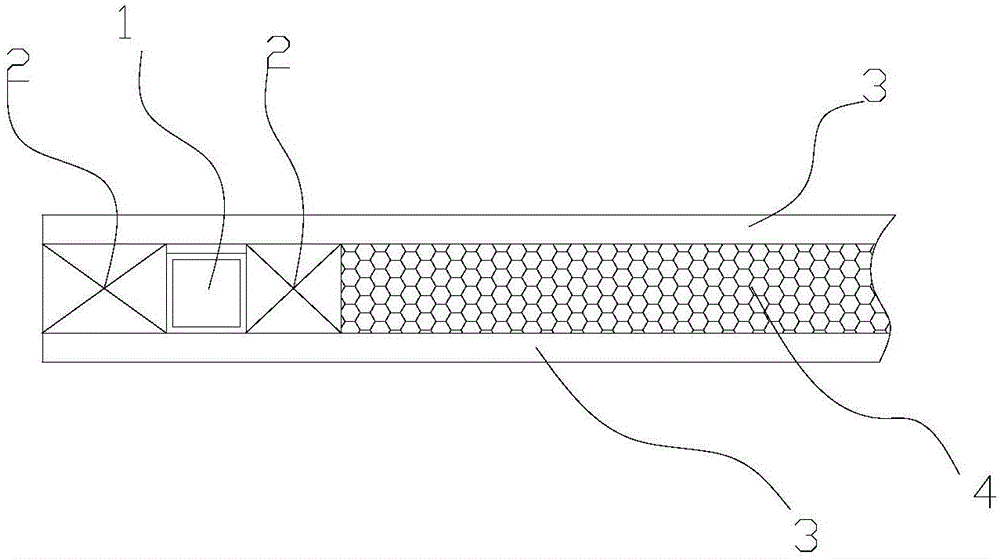

Large door leaf with square tube structure

InactiveCN106368572AEnhanced structural dimensional stabilityAchieve aestheticsDoor leavesHoneycombPaperboard

The invention belongs to the field of door leaf structures, and particularly provides a large door leaf with a square tube structure. The large door leaf with the square tube structure comprises a square tube, side frame materials, a honeycomb paperboard and panels. An outer frame around the door leaf is composed of the side frame materials; the square tube is arranged beside the side frame materials and is provided with the honeycomb paperboard; and the side frame materials, the square tube and the honeycomb paperboard are clamped between the two panels. According to the large door leaf with the square tube structure, the problem of door leaf bending due to the fact that the door leaf is too high or too large is solved, and the size stability of the door leaf is improved.

Owner:TIANJIN RESIDENTIAL GRP BUILDING MATERIAL TECH

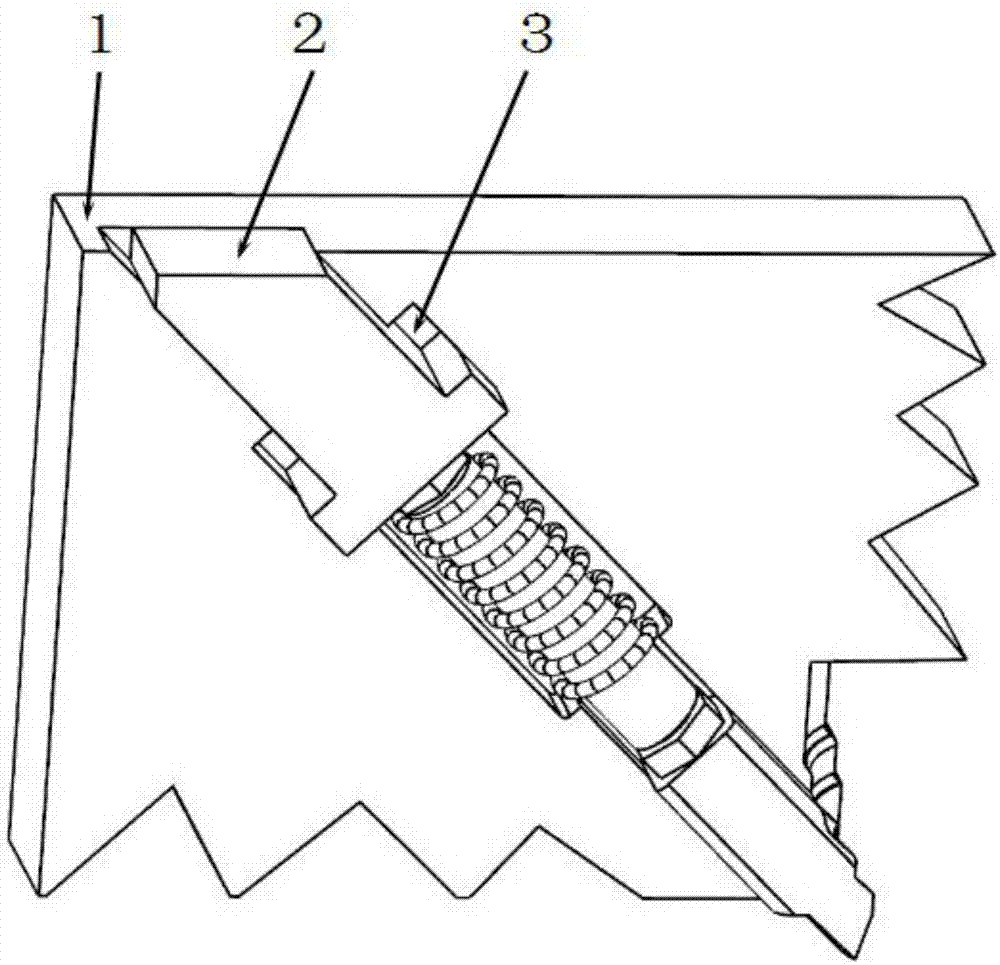

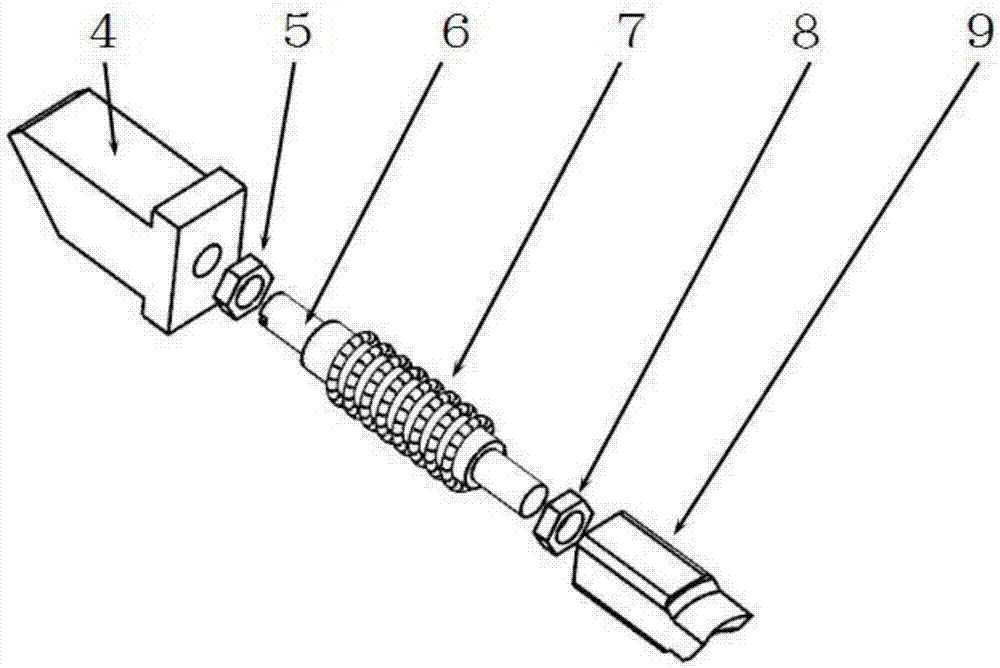

Automatic rebounding device for movable block

The invention provides an automatic rebounding device for a movable block, and the automatic rebounding device is used for movably arranging the movable block onto a body of a mould. The automatic rebounding device comprises a positioning block, a first locking nut, a second locking nut, a guide post, a positioning slot, a spring and a movable block, wherein when a core shooting mould is closed, the positioning block is pressed to move along the positioning slot, so that the movable block is driven to reach a predetermined position on the body of the mould; the spring is pressed, so that one end of the spring abuts against the positioning slot; and when the core shooting mould is opened, pressure borne on the tail end of the movable block is removed, so that the spring automatically rebounds to drive the positioning block to drive the movable block to return. The automatic rebounding device has the advantages of being simple in structure, convenient to operate, strong in applicability and the like, reduces dependency on labor power, improves manufacturing precision of a sand core, and effectively improves production efficiency.

Owner:NINGXIA KOCEL MOLD

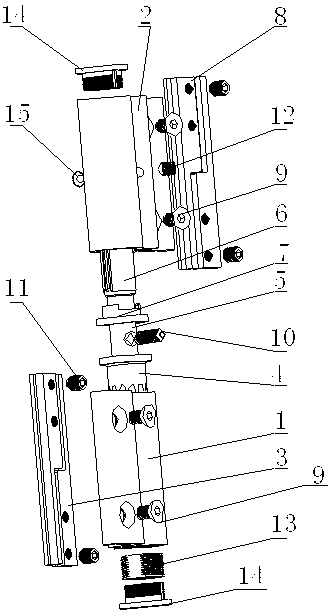

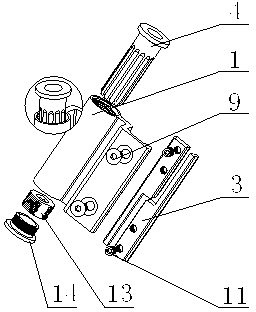

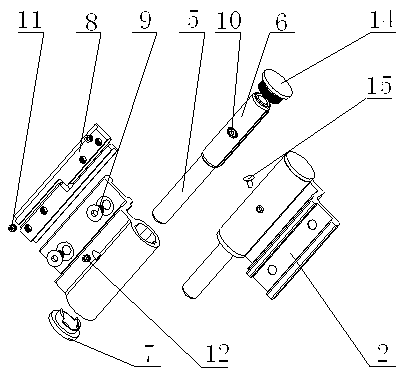

Three-dimensional hinge for aluminium-alloy flat-opening door

The invention belongs to the technical field of parts for doors and windows, and particularly relates to a three-dimensional hinge for an aluminium-alloy flat-opening door. The three-dimensional hinge comprises a base and a movable hinge, and is characterized in that the base is fixed on a frame bottom strip; the inner side of the base is provided with a frame shaft sleeve; one end of the connecting shaft is inserted in the frame shaft sleeve, and the other end of the connecting shaft is inserted into a sector shaft sleeve which is arranged at the inner side of the movable hinge; a positioning shaft sleeve is arranged between the connecting shaft and the sector shaft sleeve; and the movable hinge is fixed on a sector bottom strip. The three-dimensional hinge has the beneficial effects of reasonable structure, fast installation, convenience in use, strong adjustability, high bearing capability, strong corrosion resistance, long service life and wide application range.

Owner:ASSA ABLOY GUOQIANG SHANDONG HARDWARE TECH CO LTD

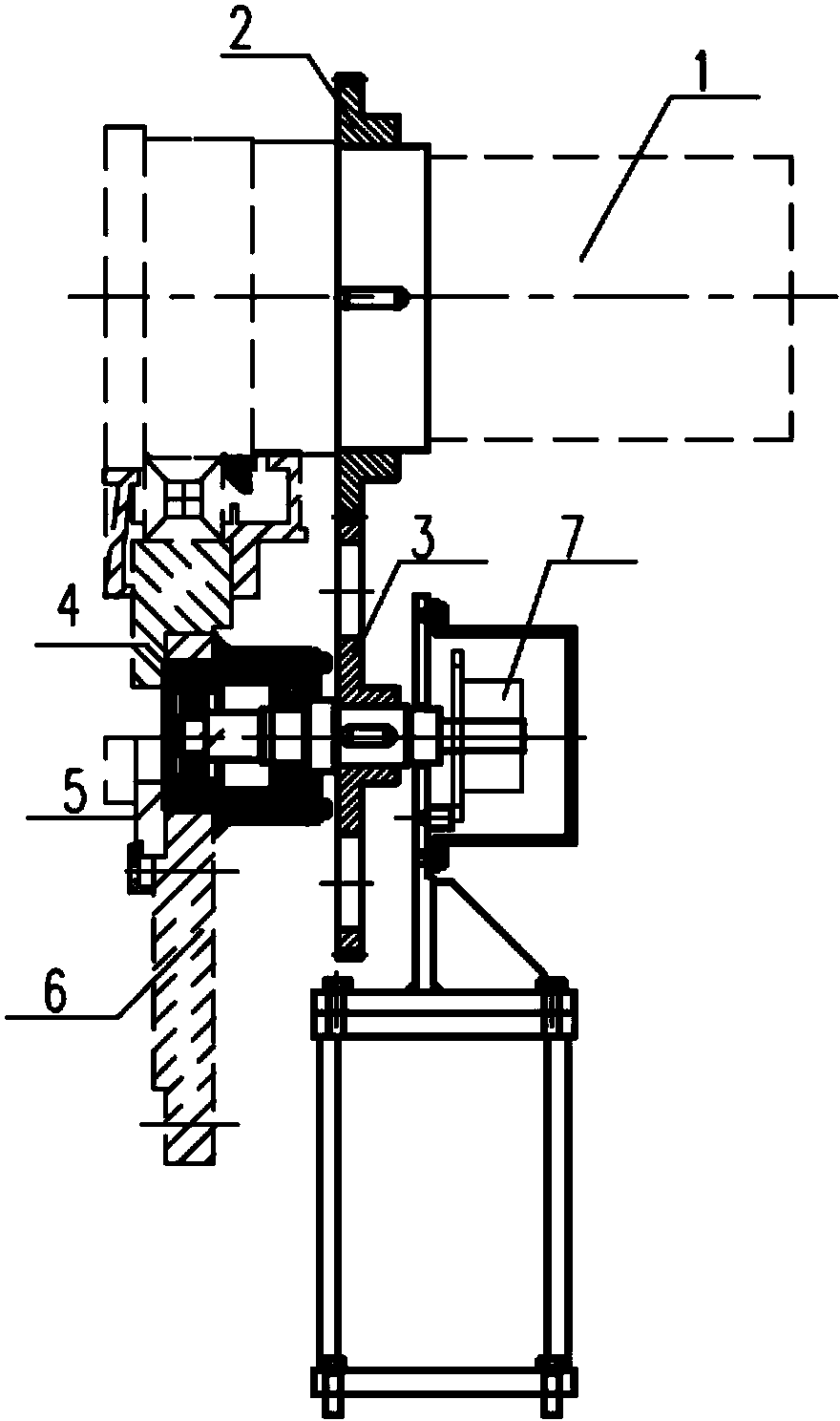

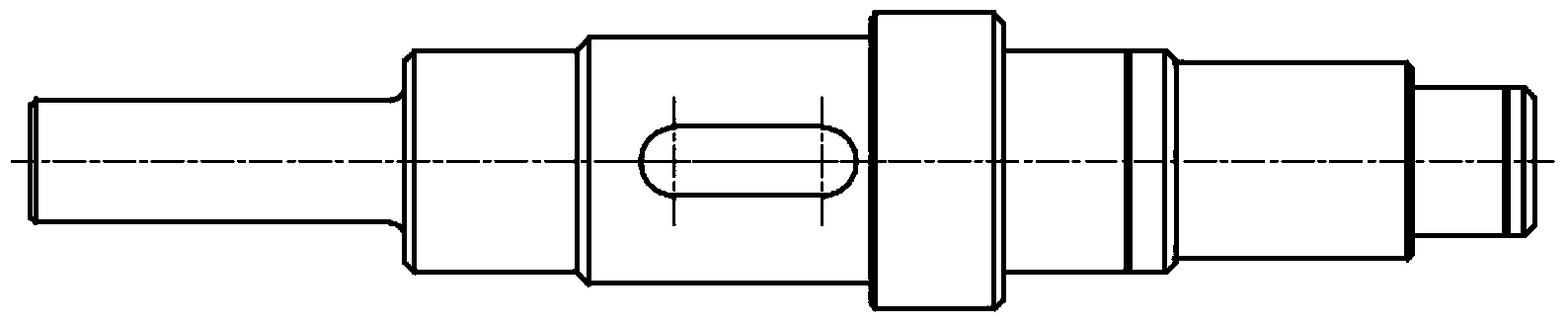

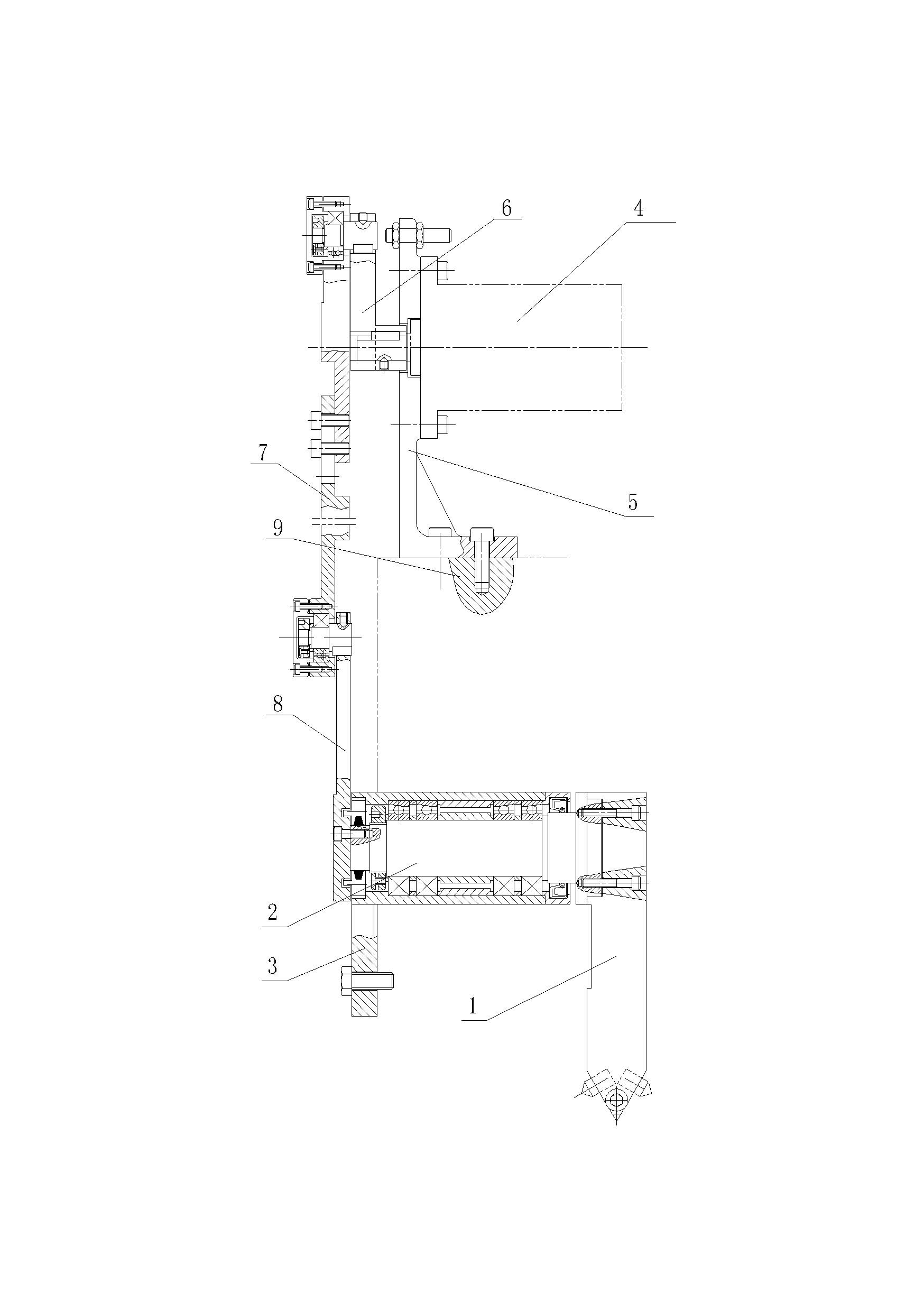

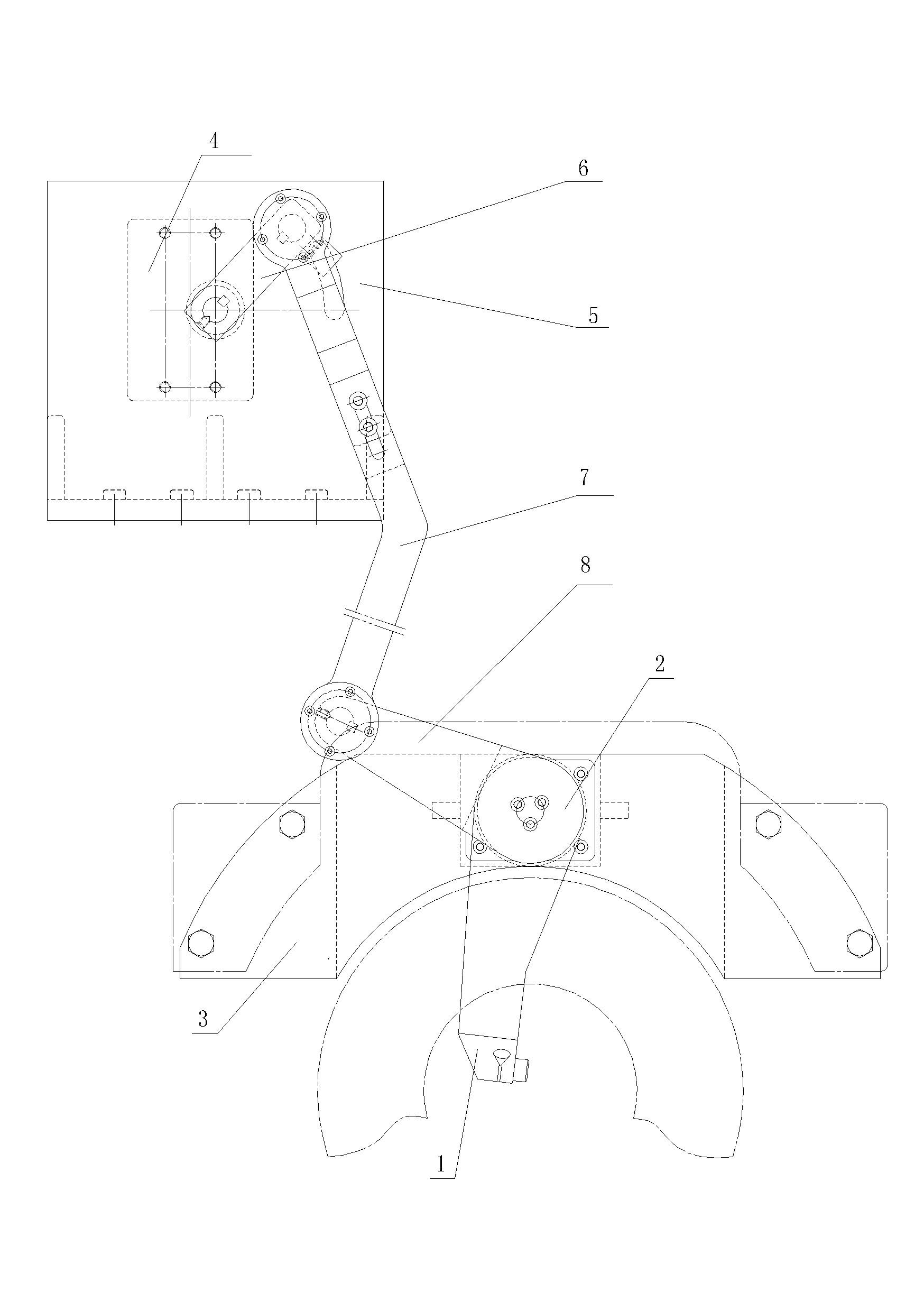

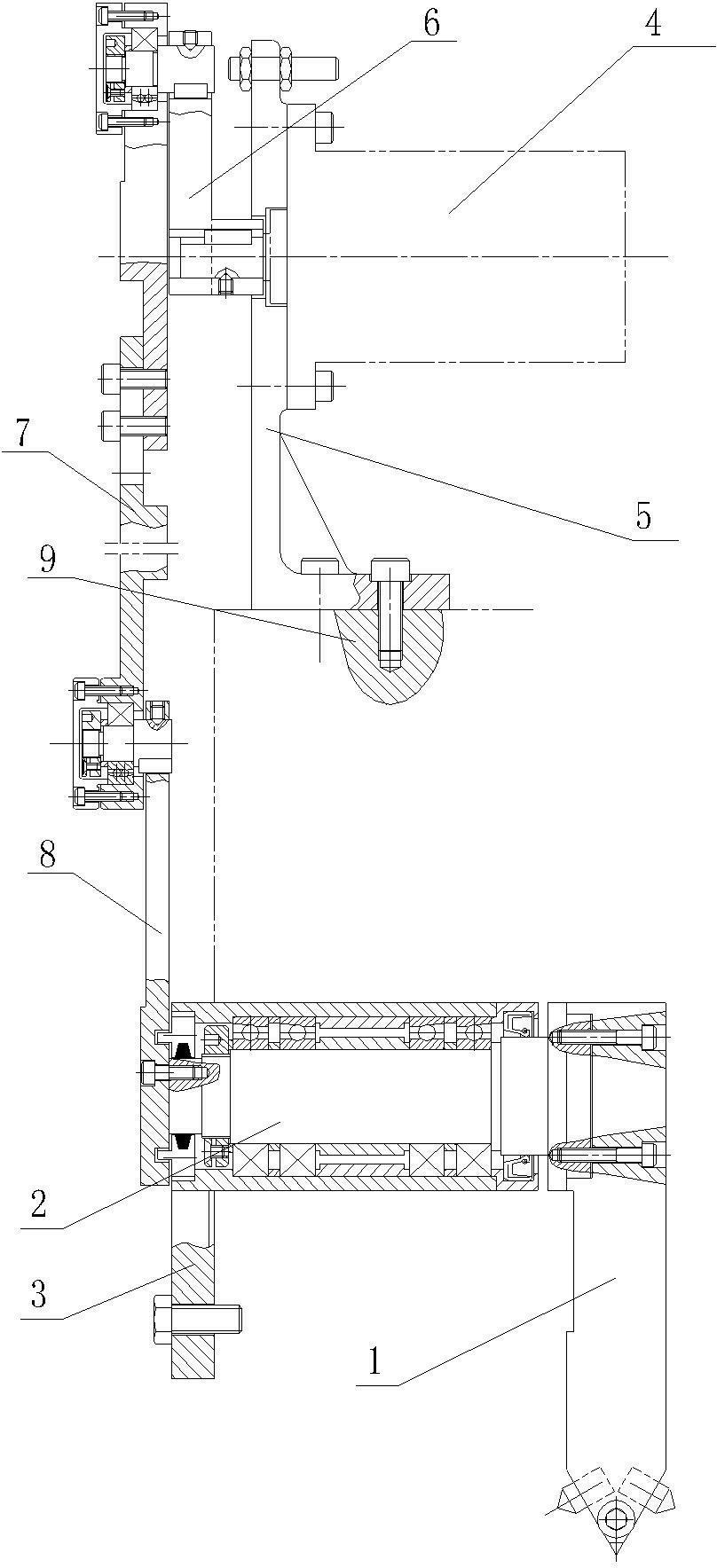

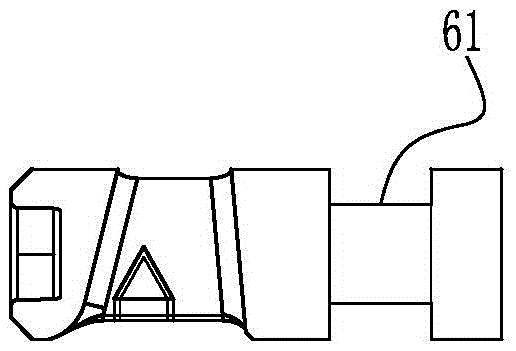

Power input connecting structure for special dresser of vertical shaft double-end surface grinding machine

InactiveCN102581767ASolve the problem of not being able to installReduce design costAbrasive surface conditioning devicesEngineeringSurface grinding

The invention provides a power input connecting structure for a special dresser of a vertical shaft double-end surface grinding machine, the invention solves the problem of spatial installation failure problem of the power input connecting structure and a grinding wheel dresser, needs no additional preserved space, and has low design cost and manufacturing cost. The power input connecting structure comprises a grinding wheel dresser rack, a dresser rotating shaft, a dresser pedestal and a motor, wherein the grinding wheel dresser rack is fastened on one end of the dresser rotating shaft, the other end of the dresser rotating shaft is inserted in the dresser pedestal, the power input connecting structure is characterized in that the motor is fastened on an external mounting plate, the external mounting plate is situated in the external space of the grinding wheel dresser rack, the output shaft of the motor is sleeved on one end of a driver plate, the other end of the driver plate is fixedly connected with one end of a transitional plate, the other end of the transitional plate is fixedly connected with one end of a rotating plate, the other end of the rotating plate is fixedly connected with the other end of the dresser rotating shaft, and the length of the rotating plate is larger than the length of the driver plate.

Owner:WUXI MACHINETOOL

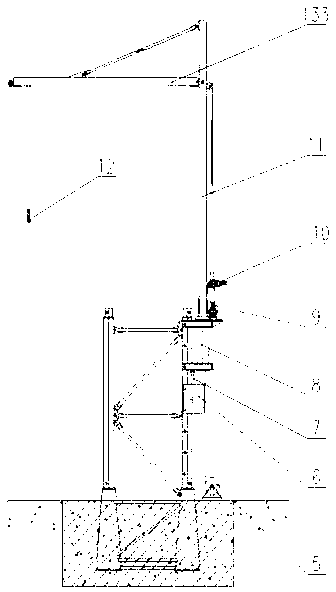

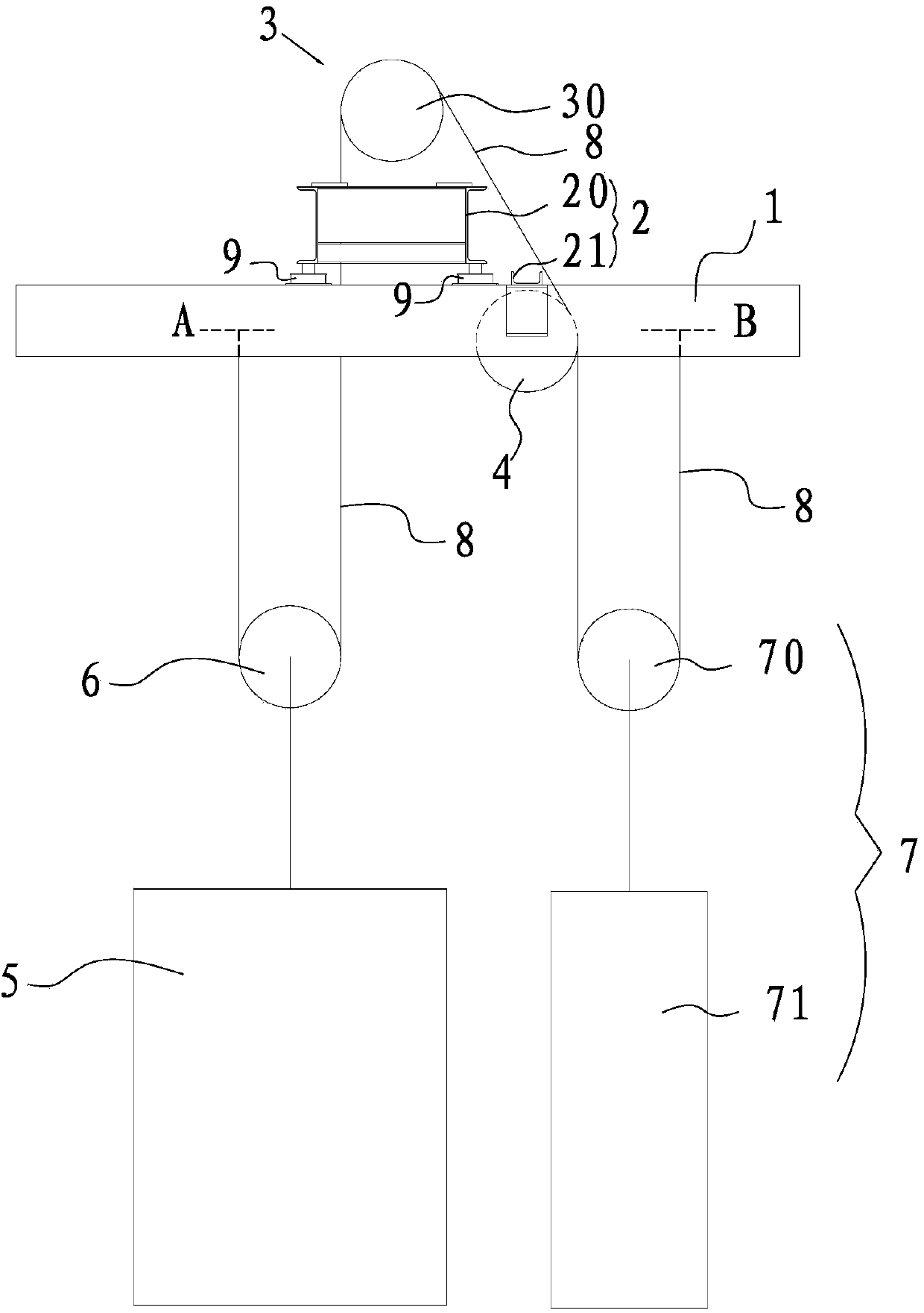

Traction system for traction type elevator

InactiveCN104176602ASolve the problem of not being able to installMeet installation needsElevatorsBuilding liftsTraction systemMachine

The invention discloses a traction system for a traction type elevator. The traction system comprises a rack, a traction machine and a guide pulley, a crosshead sheave arranged at the top of a lift car, a counterweight mechanism used for balancing the weight of the lift car, and a traction rope, wherein the rack comprises a traction rack used for mounting the traction machine, and a guide pulley support which can move horizontally and is arranged on a machine bearing beam; the traction rack is symmetric about the central line, in parallel to the extension direction of the machine bearing beam, of the traction rack; the guide pulley support can be erected on the machine bearing beam in a steering and adjusting manner according to the arrangement of a traction sheave in the horizontal direction, so that the guide pulley positioned on the guide pulley support is positioned on the same plane as the traction sheave. According to the invention, on one hand, the traction system can adjust the space between the crosshead sheave and a counterweight pulley so as to meet the mounting requirement; on the other hand, the traction system can solve the problem that elevator devices cannot be mounted as a preformed hole is formed in the wrong position during a mounting process, therefore, the traction system is good in universality, and facilitates mass production, modularization and standardized production.

Owner:BOSTON ELEVATOR SUZHOU

Aluminum foil flexible intermediate bulk container with inner tie bar

InactiveCN105857964AGuaranteed molding effectImprove airtightnessLarge containersEngineeringAluminum foil

The invention discloses an aluminum foil flexible intermediate bulk container with an inner tie bar. The aluminum foil flexible intermediate bulk container comprises a bag body, wherein a feeing inlet is formed in the upper end of the bag body; a discharging outlet is formed in the lower end of the bag body; the bag body comprises an inner bag and an outer bag; the outer bag is a plastic woven bag; the inner bag is made of an aluminum film; and the inner tie bar is vertically arranged in the inner bag, propped against the four opposite angles inside the inner bag, and fixed in the inner bag in a cold ironing manner. The bag body composed of the plastic woven bag and the aluminum film is high in impermeability, good in barrier property and excellent in anti-swelling property, and the bag type meets transportation requirements; through the inner tie bar arranged in the aluminum foil flexible intermediate bulk container, the molding effect of the aluminum foil flexible intermediate bulk container is guaranteed and a plenty of space is saved, so that the aluminum foil flexible intermediate bulk container can be utilized for transportation of small-particle and fine powder cargos as well as cargos with high sanitary requirements, and the application range of the aluminum foil flexible intermediate bulk container is expanded; and the inner tie bar is fixed in the bag body by adopting the cold ironing technology, so as to solve the problem that the inner tie bar cannot be additionally mounted in the bag body.

Owner:SHIJIAZHUANG NEW GOLD ALUMINUM PACKAGING CO LTD

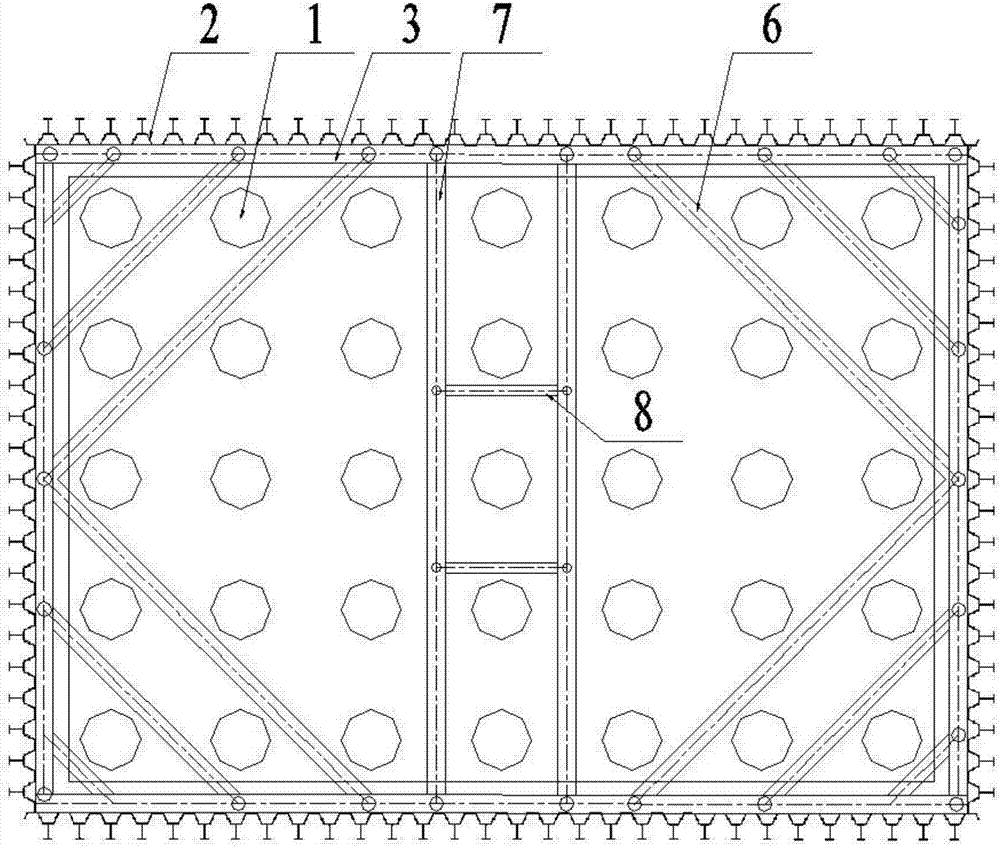

Prefabricated hollow column and superposed beam connecting structure and construction method

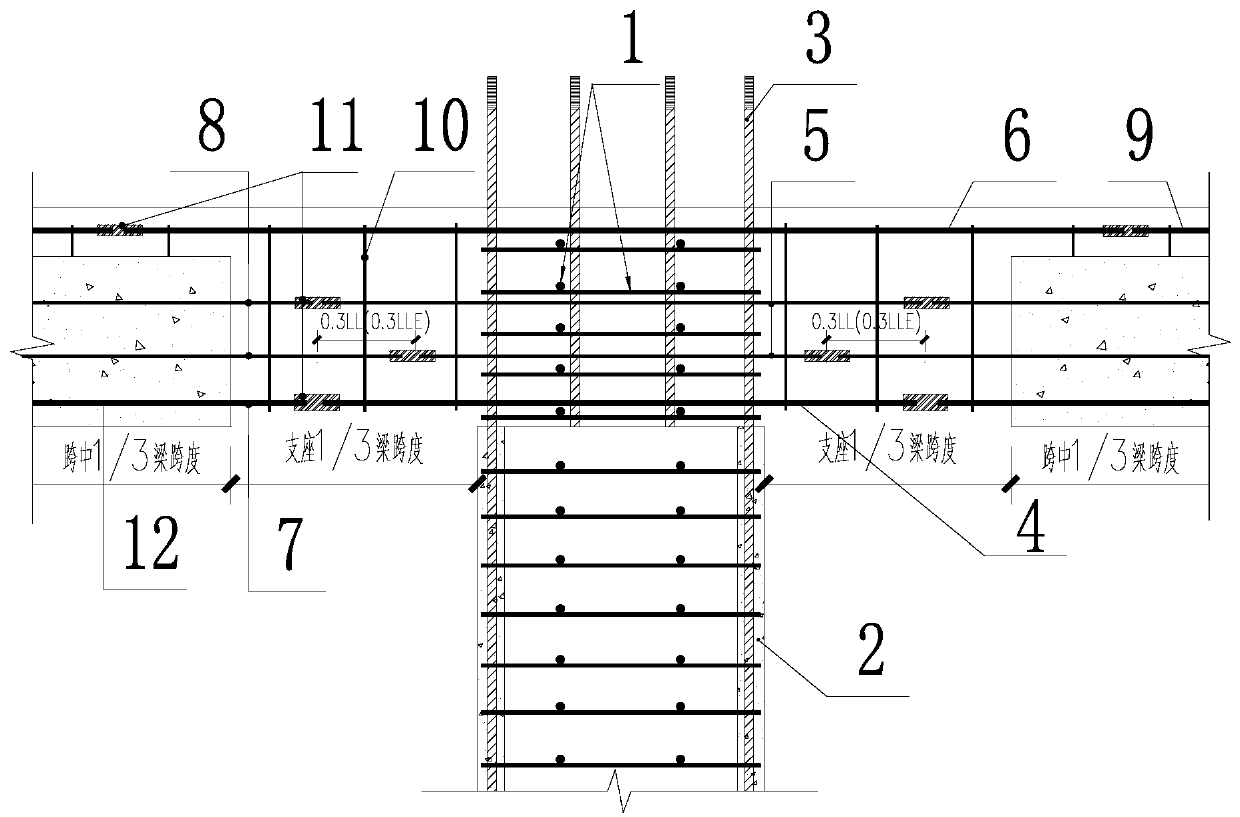

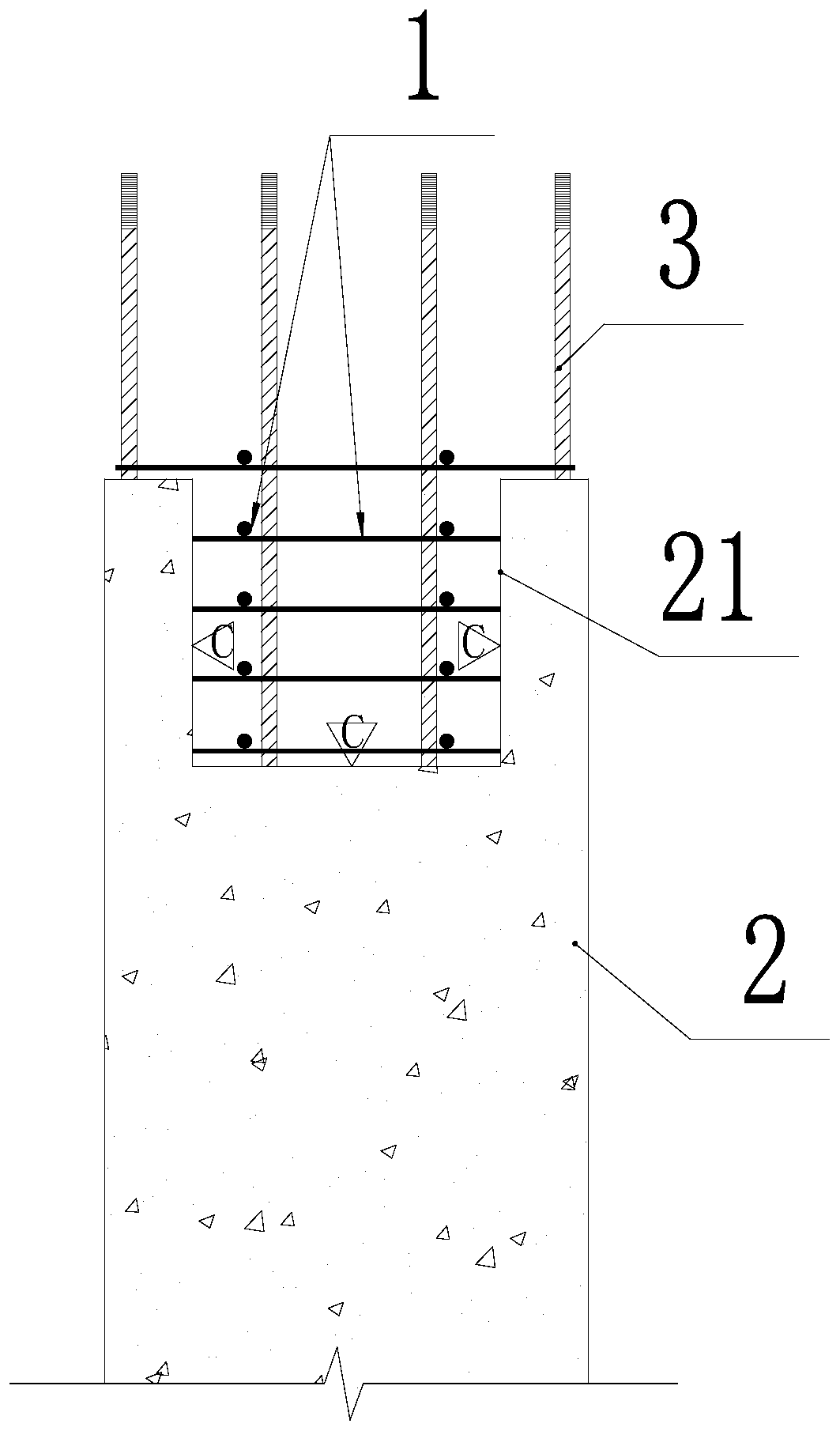

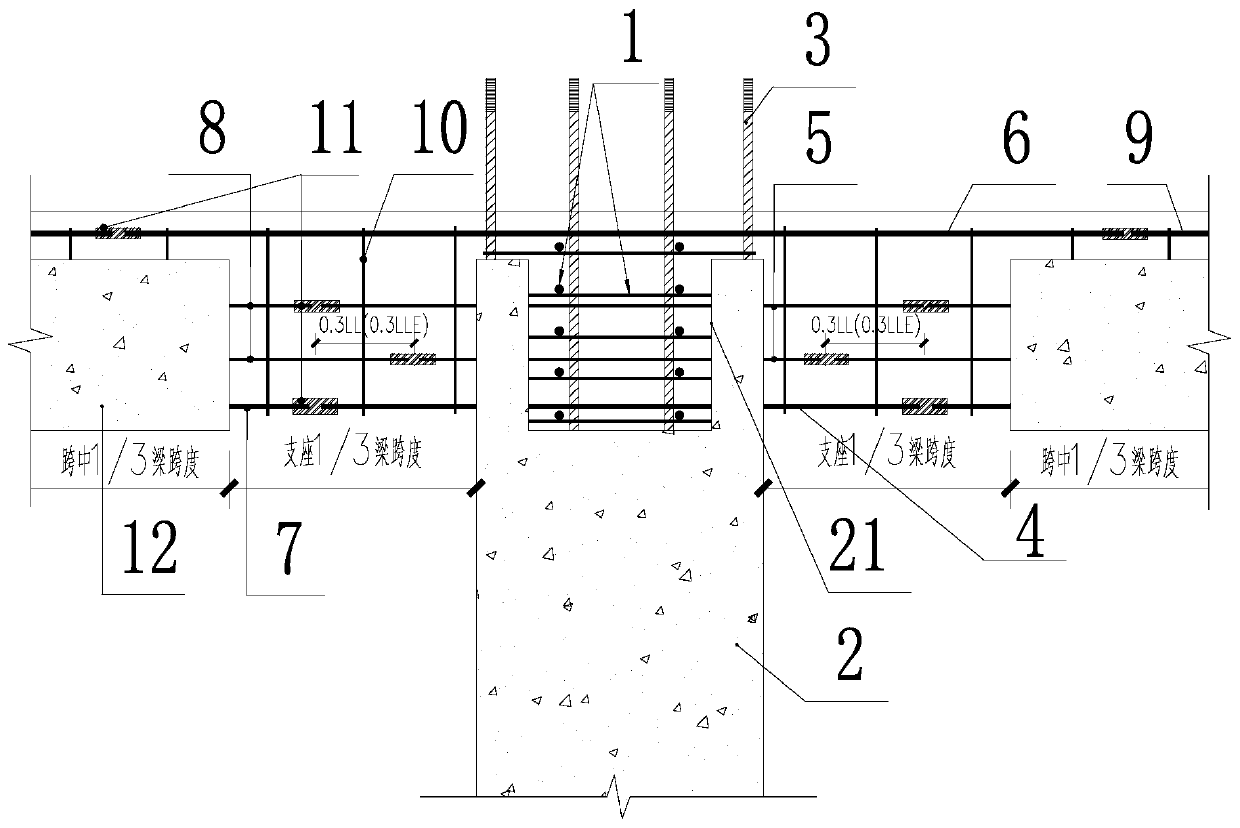

PendingCN110565796AFast constructionSolve the problem of not being able to installBuilding constructionsRebarHollow core

The invention relates to a prefabricated hollow column and superposed beam connecting structure and a construction method. The prefabricated hollow column and superposed beam connecting structure comprises a hollow column and a superposed beam, wherein the hollow column and the superposed beam are connected with each other; a beam hole is reserved in the beam and column junction area of the hollowcolumn according to the size of the superposed beam, and hoop ribs of the hollow column in the beam hole are normally arranged; bottom longitudinal stressed rebars and beam side constructed ribs or twisted ribs of the superposed beam are mechanically connected or connected in a binding mode within a 1 / 3 superposed beam support seat span range outside the hollow column; and upper longitudinal stressed rebars of the superposed beam are mechanically connected or connected in the binding mode within a 1 / 3 superposed beam midspan range outside the hollow column. The construction method of the rebars in the beam and column core area of the prefabricated hollow column of prefabricated concrete has the advantages of high construction speed and high installation efficiency and conforms to the development trend of assembled and standardized building industrialization.

Owner:SANY CONSTR TECH CO LTD

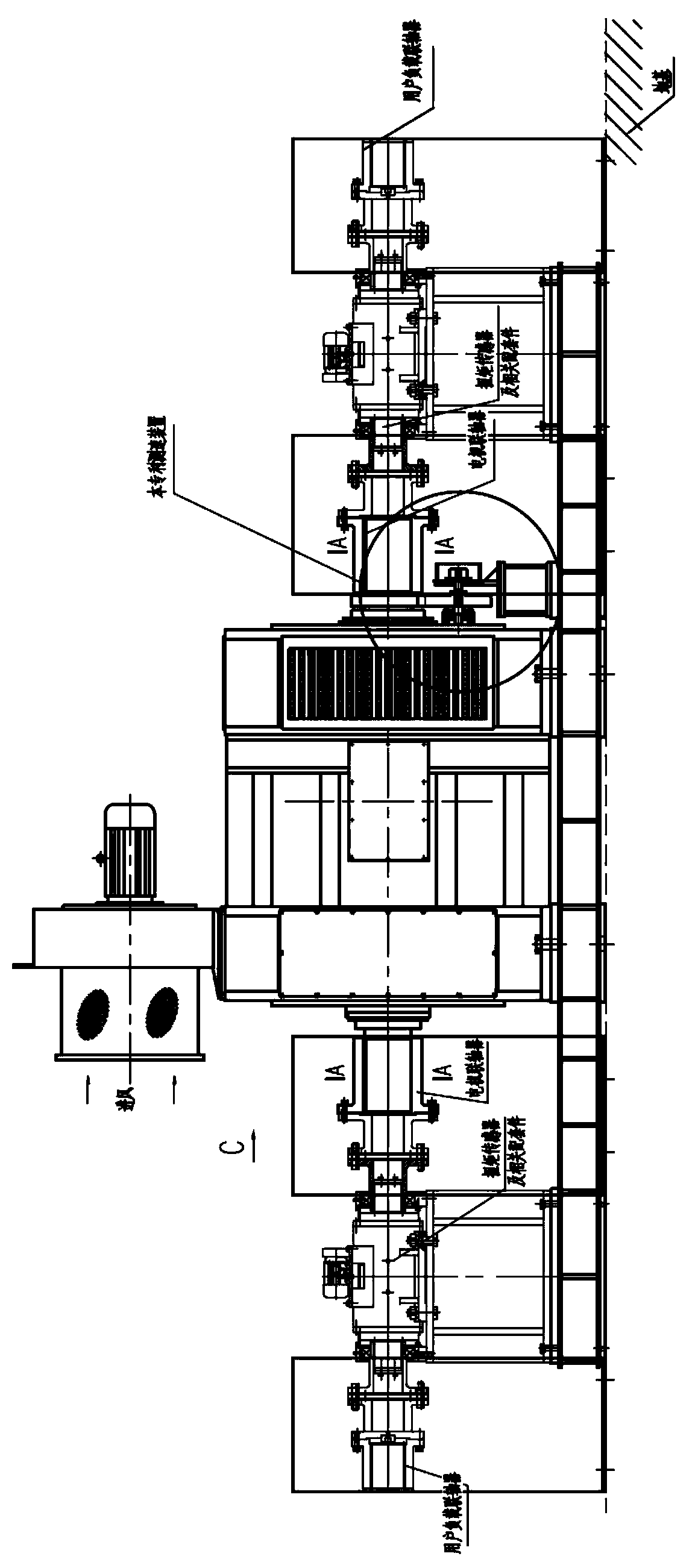

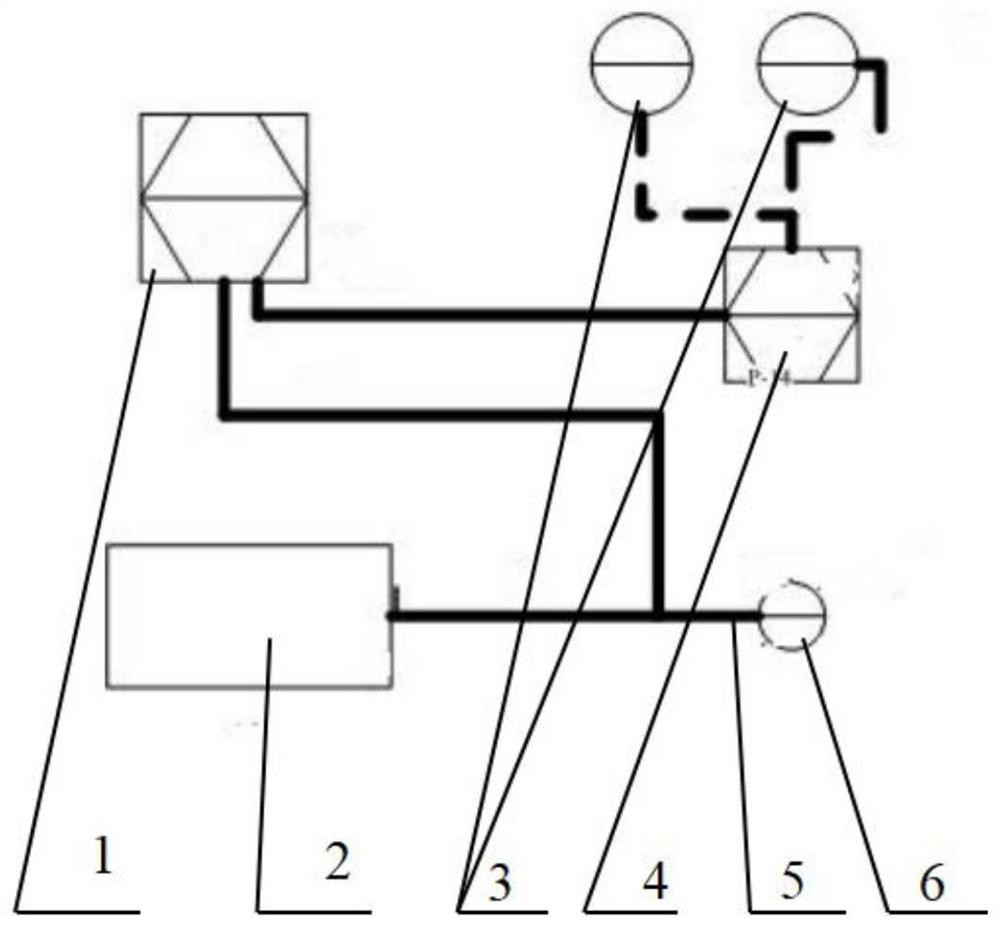

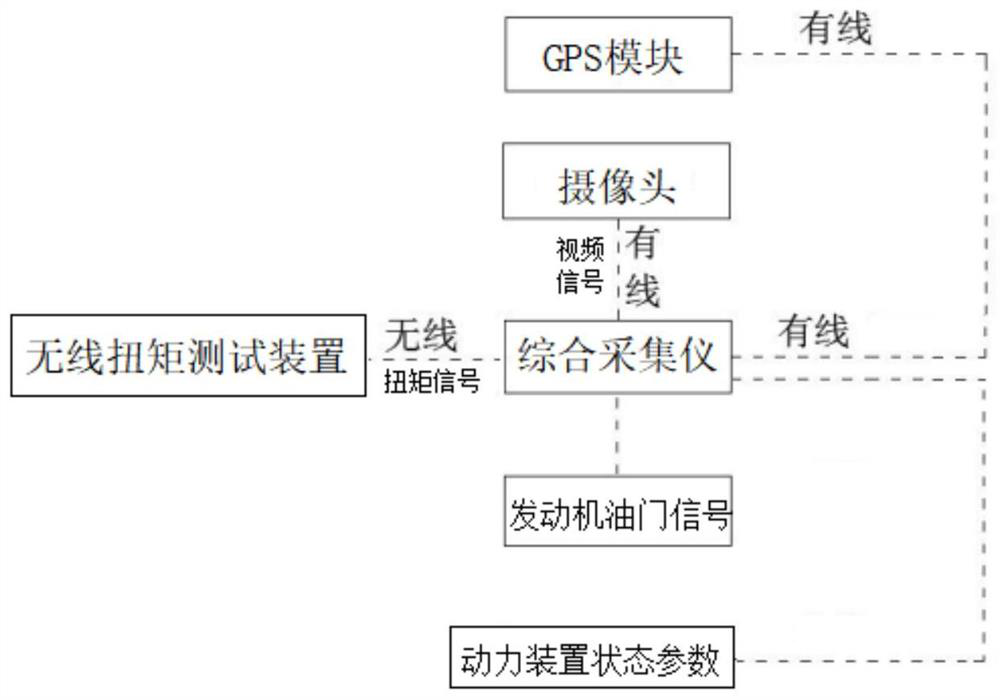

Real vehicle power load test system and method for power device of tracked vehicle

ActiveCN113324762AImprove reliabilitySolve the problem of high difficulty in output torque measurementVehicle testingTransmission systemsData signalData acquisition

The invention discloses a real vehicle power load test system and method for a crawler-type vehicle power device. The real vehicle power load test system comprises a signal adapter, a data acquisition module, a wireless torque test device, a comprehensive acquisition instrument and a camera, wherein the data acquisition module is installed in a cockpit and receives the video information of the camera and switching data of the signal adapter; the signal adapter is connected with the comprehensive acquisition instrument; the camera is mounted at a set position of a vehicle head, and the signal adapter is arranged in a power cabin, receives the information acquired by the comprehensive acquisition instrument and transmits the information to the data acquisition module; the system solves a problem that the dynamic load cannot be obtained due to limited space of the special vehicle and inconvenient installation of equipment.

Owner:CHINA NORTH VEHICLE RES INST

Welding method of double-layer pipe elbow

ActiveCN105834605BSolve the problem of not being able to installSolve the problem of not being able to weldWelding apparatusDouble tubeStraight tube

The invention discloses a welding method for a two-layer pipe elbow. The two-layer pipe elbow comprises an inner straight pipe, an inner pipe elbow body, an outer straight pipe and an outer pipe elbow body. The inner diameter of the outer pipe elbow body is larger than the outer diameter of the outer straight pipe. The two sides of the outer pipe elbow body are provided with different-diameter connectors which are connected with the outer straight pipe. The problem that the two-layer pipe outer straight pipe cannot be installed is solved on the basis of the welding method for the two-layer pipe elbow. According to the welding method for the two-layer pipe elbow, the two-layer pipe elbow is reasonably divided into three parts, that is, the elbow body with an enlarged diameter and the two different-diameter connectors (welded to the outer straight pipe in an overlap mode), and thus the problem that the inner straight pipe cannot be welded is solved; and meanwhile, the outer pipe elbow body can be welded at last, and a space is easily transferred out by the outer pipe elbow body through moving of the different-diameter connectors on the outer straight pipe.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Air-intake and heat-proof device of health energy-saving environment protective kitchen range

InactiveCN100487324CImprove the operating environmentSolve air intake problemsDomestic stoves or rangesLighting and heating apparatusCold airEngineering

Owner:李孝龙

Tower type truss installing structure and method without cooperation with altitude hoisting equipment

ActiveCN103101847BSolve the problem of not being able to installImprove convenienceCranesTrolleysEngineeringTower

The invention relates to a tower type truss installing structure and a tower type truss installing method without cooperation with altitude hoisting equipment. The method comprises the step of overlapping a plurality of truss standard knots from bottom to top, wherein each truss standard knot consists of a plurality of vertical chord members (1 and 4), and the chord members (1 and 4) are fixedly connected with each other by web members (2 and 3). The structure and the method disclosed by invention are characterized in that one chord member (4) of the tower type truss is concurrently taken as a climbing rack and an attaching support for an assistant crane, and the chord members (1 and 4) and the web members (2 and 3) of the tower type truss are installed by the assistant crane attached on the chord member (4), so that the assistant crane can continuously climb along the chord members without the cooperation with the other hoisting equipment. According to the invention, the difficulty that a tower type truss can not be installed when the altitude hoisting equipment is unavailable can be solved, and a mass of installing cost can be saved, so that the tower type truss is applicable to the occasion without the altitude hoisting equipment, and the convenience degree for the distribution of engineering equipment can be greatly improved.

Owner:杭州国电大力机电工程有限公司

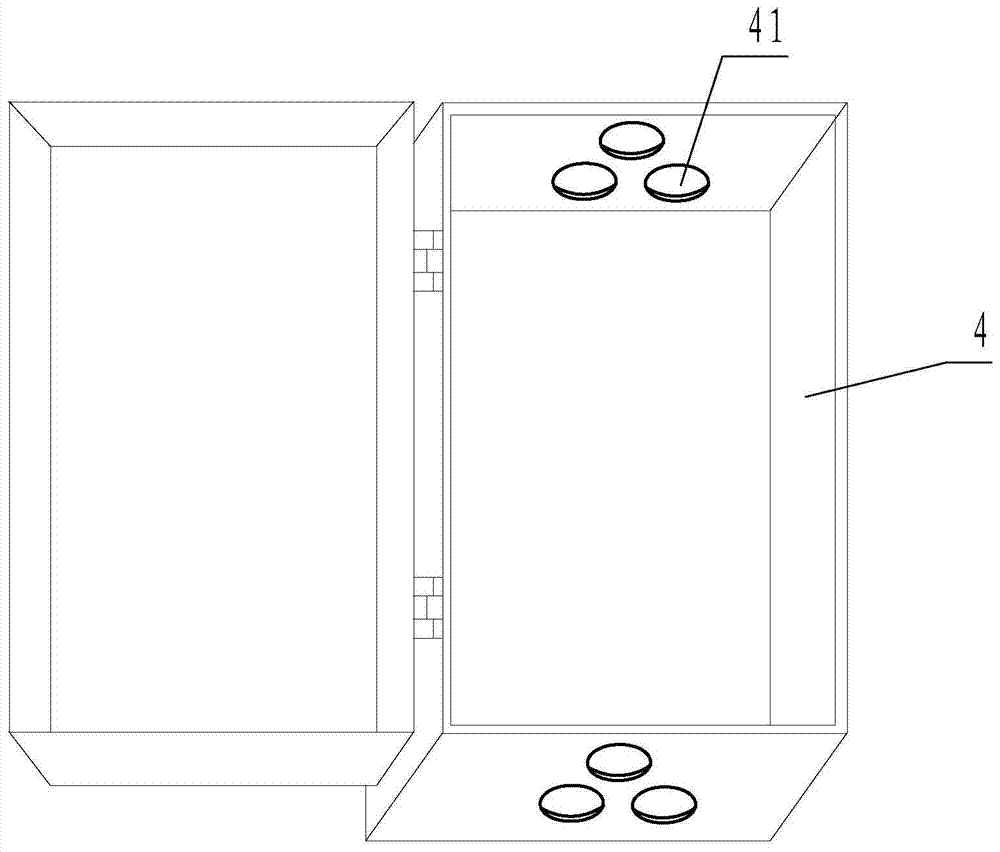

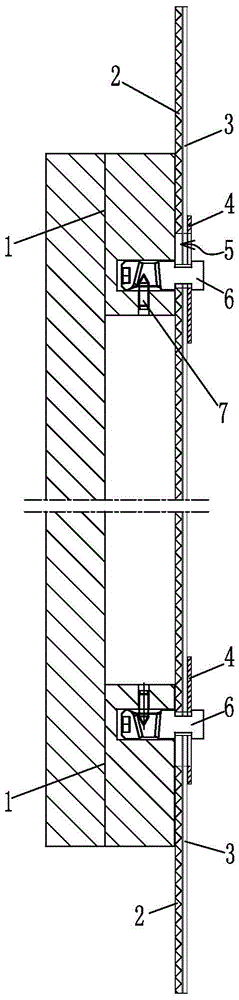

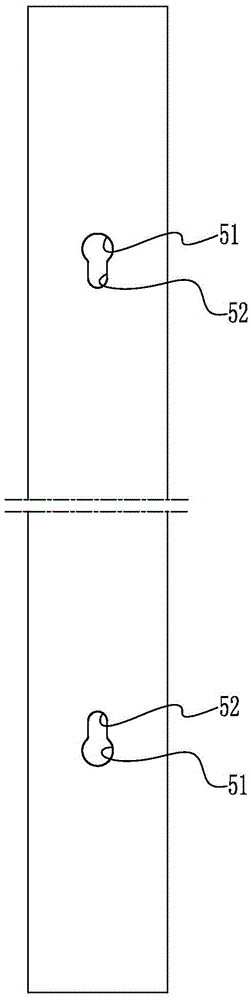

a door body

ActiveCN104110162BSolve the problem of not being able to installSolve the problem that cannot be installedWing handlesWing knobsEngineeringSmall hole

The invention discloses a door body. The door body comprises a handle assembly and a door body frame; the handle assembly is connected to two special-shaped through holes formed in the door body frame by use of two connecting columns; annular grooves are formed in one end, inserted into the special-shaped through holes, of the connecting columns; the outer diameter of the annular groove part of each connecting column is matched with the outer diameter of the small-diameter end of the corresponding special-shaped through hole, while the outer diameter of the parts, at the two sides of the annular groove, of the connecting column is greater than the outer diameter of the small-diameter end of the corresponding special-shaped through hole and small than the outer diameter of the large-diameter end of the special-shaped through hole; the other ends, inserted in the handle assembly, of the connecting columns are fixedly connected with the handle assembly; the two special-shaped through holes in the door body frame are arranged in a mirror symmetry way, the space between the centers of the two large-diameter ends is greater than that between the centers of the two small-diameter ends, and the space between the centers of the two small-diameter ends is matched with the mounting space between the two connecting columns on the handle assembly. The door body is used for solving the problem that the mounting fails due to de-concentricity of the handle holes, and the handle is adjustable in position and convenient to detach and replace.

Owner:ZHEJIANG SANXING NEW MATERIALS

A thermostatic faucet with convertible hot and cold pipes

ActiveCN105805361BOne piece casting process is simpleSimple casting processMultiple way valvesWater flowEngineering

The embodiment of the invention discloses a constant temperature faucet with a cooling pipe and a heating pipe switchable. The constant temperature faucet comprises a constant temperature assembly, and the constant temperature assembly comprises a constant temperature body. The constant temperature body is provided with a cold water inlet part, a hot water inlet part and a connector part used for connecting the cold water inlet part with the hot water inlet part, and water flow runners are formed in the connector part. The connector part is internally provided with the cold water runner, the hot water runner, the adjustable runner, the cold water flow-out runner and the hot water flow-out runner, wherein the cold water runner communicates with the cold water inlet part; the hot water runner communicates with the hot water inlet part; the adjustable runner is arranged between the cold water runner and the hot water runner; the cold water flow-out runner and the hot water flow-out runner are separated from each other and communicate with a constant temperature valve element cavity. The design of the internal water flow runners of the constant temperature faucet is improved, switching between cold drained water and hot drained water is achieved through an adjustable component, the application range of the constant temperature faucet is extended, the constant temperature faucet can meet the different mounting conditions and use preferences, and accordingly the constant temperature faucet has broader market prospects.

Owner:江门市国人温控卫浴有限公司

Handle fixing structure

ActiveCN104088511ASolve the problems of non-adjustable and difficult to replaceSolve the problem of not being able to installWing handlesWing knobsEngineeringMechanical engineering

The invention discloses a handle fixing structure which comprises a handle assembly and a door shell assembly. The handle assembly is connected with two special-shaped through holes in the door shell assembly through two connecting columns. The end, inserted into the corresponding special-shaped through hole, of each connecting column is provided with an annular groove. The outer diameters, at the portion of the annular grooves, of the connecting columns are matched with the outer diameters of the small-bore ends of the special-shaped through holes. The outer diameters, at the two side portions of the annular grooves, of the connecting columns are larger than the outer diameters of the small-bore ends of the special-shaped through holes and smaller than the outer diameters of the large-bore ends of the special-shaped through holes. The end, inserted into the handle assembly, of each connecting column is fixedly connected with the handle assembly. The two special-shaped through holes in the door shell assembly are arranged in a mirror-symmetry mode. The distance between the centers of the two large-bore ends is larger than the distance between the centers of the two small-bore ends. The distance between the centers of the two small-bore ends is matched with the installation distance of the two connecting columns on the handle assembly. According to the scheme, the problem that installation cannot be achieved due to the fact that handle holes are not concentric is solved, the position of a handle can be adjusted, and disassembly and replacement are convenient.

Owner:ZHEJIANG SANXING NEW MATERIALS

Parallel inter-stage separation free-flying wind tunnel test device with the center of mass at the interface

ActiveCN107782526BSolve the problem of not being able to installUnplug the solutionAerodynamic testingEngineeringModel set

A parallel stage separation free flight wind tunnel testing device with the mass center located on the interface comprises a first model, a second model, a pull pin frame, pins, a first fixing nail, asecond fixing nail, a first spring, a second spring, a first pull pin and a second pull pin. The first pull pin, the second pull pin and the pull pin frame are installed together through the two pins, the first fixing nail and the second fixing nail penetrate through respective springs and are inserted into the first model and the second model, and the pull pins installed just are inserted into the models from the model tails and are just inserted into a round hole formed by a semi-circular groove of the first fixing nail and a round hole formed by a semi-circular groove of the second fixingnail to lock the whole model set. It is ensured that the first model and the second model can be fast and effectively separated without interference, the problem that a parallel stage separation freeflight wind tunnel test with the mass center located on the interface cannot be realized is solved mainly, and the defect that two stages cannot release the freedom degree at the same time due to theprevious model fixing mode is overcome.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Head cover structure and installation method of high-speed train head

ActiveCN103802848BSolve the problem of not being able to installSimple structureRailway transportAxle-box lubricationEngineeringMechanical engineering

Owner:CRRC QINGDAO SIFANG CO LTD

A construction method of combined steel sheet pile cofferdam in deep water

ActiveCN106948353BReduce installation difficultyAffect the installationFoundation engineeringPurlinSheet steel

The invention relates to the technical field of steel sheet pile cofferdam construction, in particular to a deep water combined steel sheet pile cofferdam construction method. The method comprises the steps that steel casings are inserted and driven into a cofferdam construction area; bearing structures are arranged in the positions, corresponding to enclosure purlin mounting positions, of steel sheet piles; the steel sheet piles are inserted and driven by relying on the steel casings to form a cofferdam structure in an encircling mode; enclosure purlins are sequentially hoisted onto the bearing structures on the inner sides of the steel sheet piles from bottom to top; water in the cofferdam is pumped layer by layer, and inner supports of the enclosure purlins are mounted layer by layer from top to bottom; and after all the inner supports are mounted, concrete is poured into the cofferdam to form a bearing platform structure. According to the method, corbels are arranged for the steel sheet piles in advance to realize in-place arrangement of the enclosure purlins in advance; through the construction method of conducting water pumping after bottom sealing, integral connecting of the enclosure purlins, and subsequent installation of the inner supports, adverse influences caused by existence of the steel casings, the upper-layer enclosure purlins and the inner supports on the operating space are avoided, the problem that large enclosure purlins cannot be installed is solved effectively, and the installation difficulty of the inner supports during the later period is lowered.

Owner:CCCC SECOND HARBOR ENG

Low Voltage Multipurpose Short Connector

ActiveCN104505714BSolve the problem of not being able to installImprove work efficiencyCoupling device connectionsSubstation/switching arrangement detailsLow voltageEngineering

The invention discloses a low-voltage multipurpose short-circuit connector, comprising fixing clamps, flexible jumping wires and a short-circuit connecting member, wherein each fixing clamp comprises a conductive fixing member and a conductive adapting member; each of the flexible jumping wires is a conductive braided strap; each of two ends of each conductive braided strap is provided with a connecting hole; the short-circuit connecting member comprises a back plate which is made of a material with an insulating arc-isolating effect and is used for fixation; the back plate is provided with installation holes which are adapted to fuse wires with different pitches and the size of a base; the fuse wires are arranged on the base. In the field application, the low-voltage multipurpose short-circuit connector disclosed by the invention can be used as an effective measure for quickly repairing and recovering electric power after switches with different models and different specifications are in fault, and can also be fixedly used as the leading end of a short-circuit connection grounding wire. According to the low-voltage multipurpose short-circuit connector, not only are the problems that the rush repairing time is long due to the fact that a switch is not matched, and the power fault range is large solved, but also the problem that the leading end of the overhauling grounding wire of most switches cannot be installed is solved, and the operation efficiency and power supply reliability are improved.

Owner:STATE GRID CORP OF CHINA +2

A handle fixing structure

ActiveCN104088511BSolve the problem of not being able to installSolve the problem that cannot be installedWing handlesWing knobsEngineeringMechanical engineering

The invention discloses a handle fixing structure which comprises a handle assembly and a door shell assembly. The handle assembly is connected with two special-shaped through holes in the door shell assembly through two connecting columns. The end, inserted into the corresponding special-shaped through hole, of each connecting column is provided with an annular groove. The outer diameters, at the portion of the annular grooves, of the connecting columns are matched with the outer diameters of the small-bore ends of the special-shaped through holes. The outer diameters, at the two side portions of the annular grooves, of the connecting columns are larger than the outer diameters of the small-bore ends of the special-shaped through holes and smaller than the outer diameters of the large-bore ends of the special-shaped through holes. The end, inserted into the handle assembly, of each connecting column is fixedly connected with the handle assembly. The two special-shaped through holes in the door shell assembly are arranged in a mirror-symmetry mode. The distance between the centers of the two large-bore ends is larger than the distance between the centers of the two small-bore ends. The distance between the centers of the two small-bore ends is matched with the installation distance of the two connecting columns on the handle assembly. According to the scheme, the problem that installation cannot be achieved due to the fact that handle holes are not concentric is solved, the position of a handle can be adjusted, and disassembly and replacement are convenient.

Owner:ZHEJIANG SANXING NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com