Real vehicle power load test system and method for power device of tracked vehicle

A vehicle power and load testing technology, applied in the field of vehicle engineering, can solve problems such as inability to simulate dynamic power load, inability to fully verify overall performance, and vehicle comprehensive performance lower than expected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

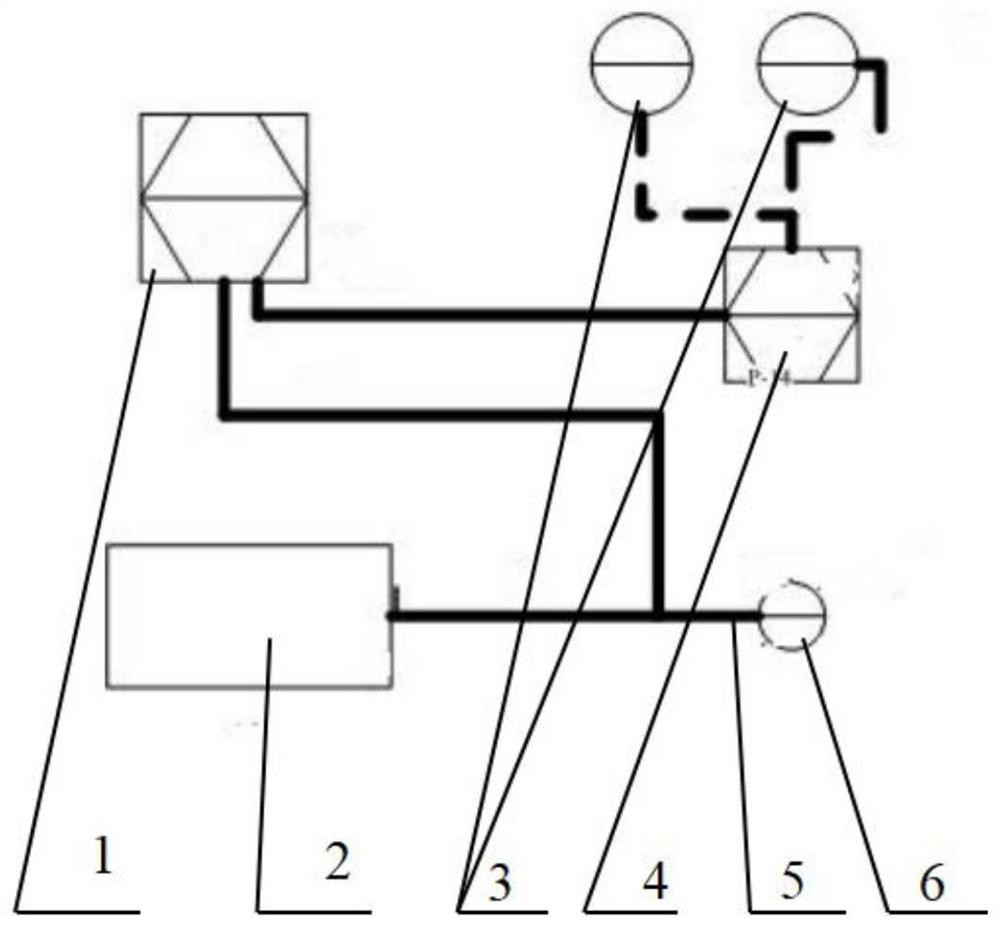

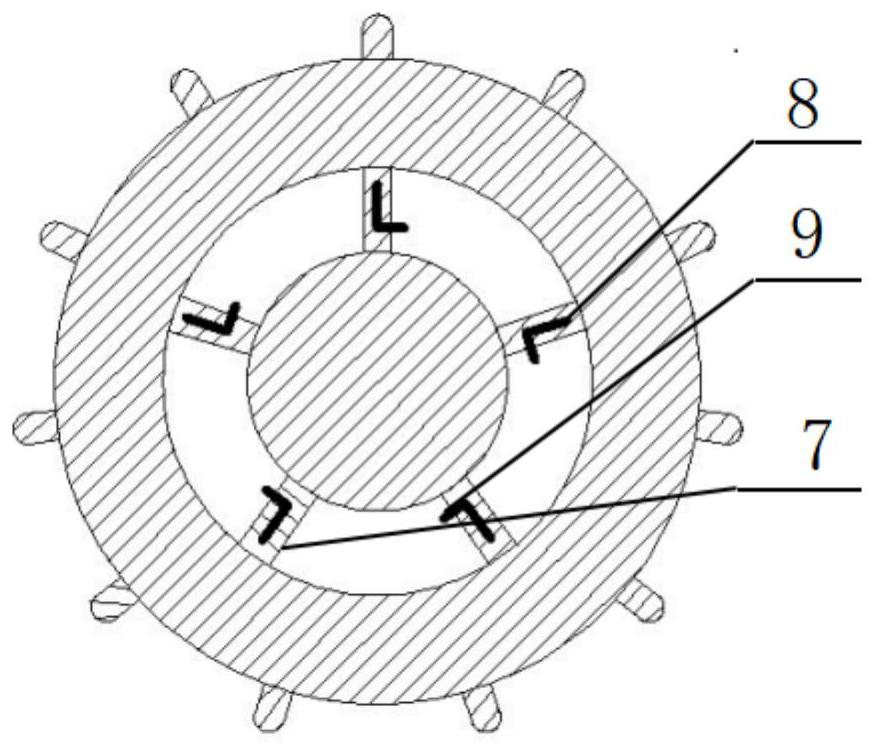

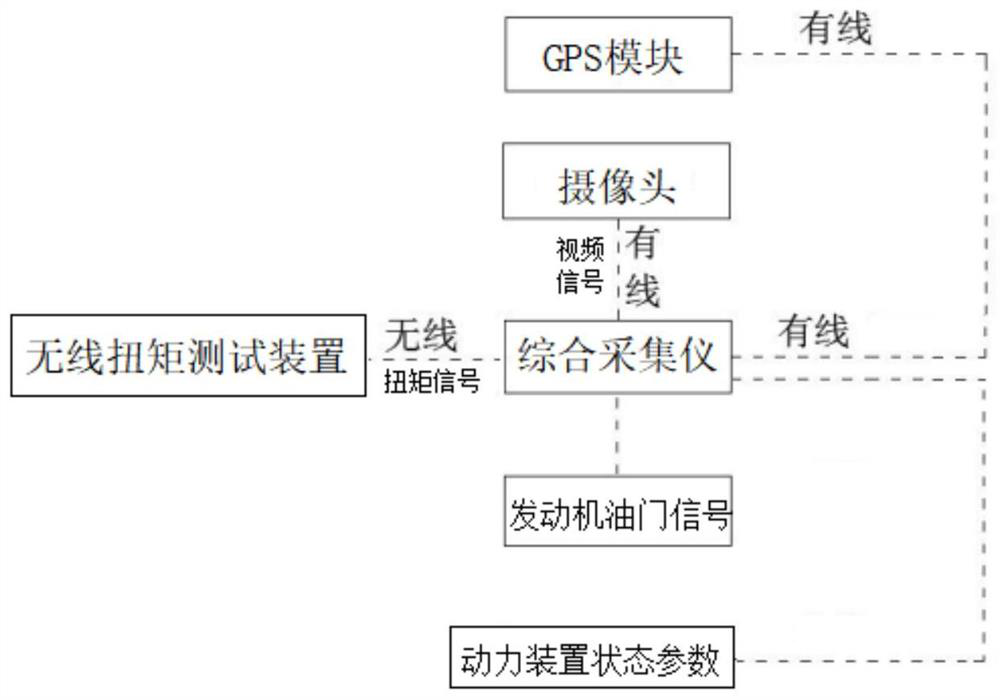

[0028] This embodiment provides a real vehicle power load test system and method for a tracked vehicle power device, aiming at that when a tracked vehicle is dynamically tested on a bench, it is impossible to simulate the rapidly changing dynamic power load of the real vehicle, which causes the bench test The exposed failure modes and faulty parts are inconsistent with the actual problems; and due to limited space, some performance parameters of the power plant cannot be obtained, and the overall performance of the integrated tracked vehicle power plant cannot be fully verified by relying solely on component tests. The actual dynamic power load of tracked vehicles can be obtained for a series of problems such as insufficient performance verification of tracked vehicle power units, lower than expected comprehensive vehicle performance, and high failure rate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com