Parallel inter-stage separation free-flying wind tunnel test device with the center of mass at the interface

A technology of inter-stage separation and wind tunnel testing, which is applied to measuring devices, aerodynamic testing, and testing of machine/structural components, etc. It can solve problems such as destroying the shape of the model, obtaining inconsistent degrees of freedom, and reducing the reliability of test results, etc. , to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

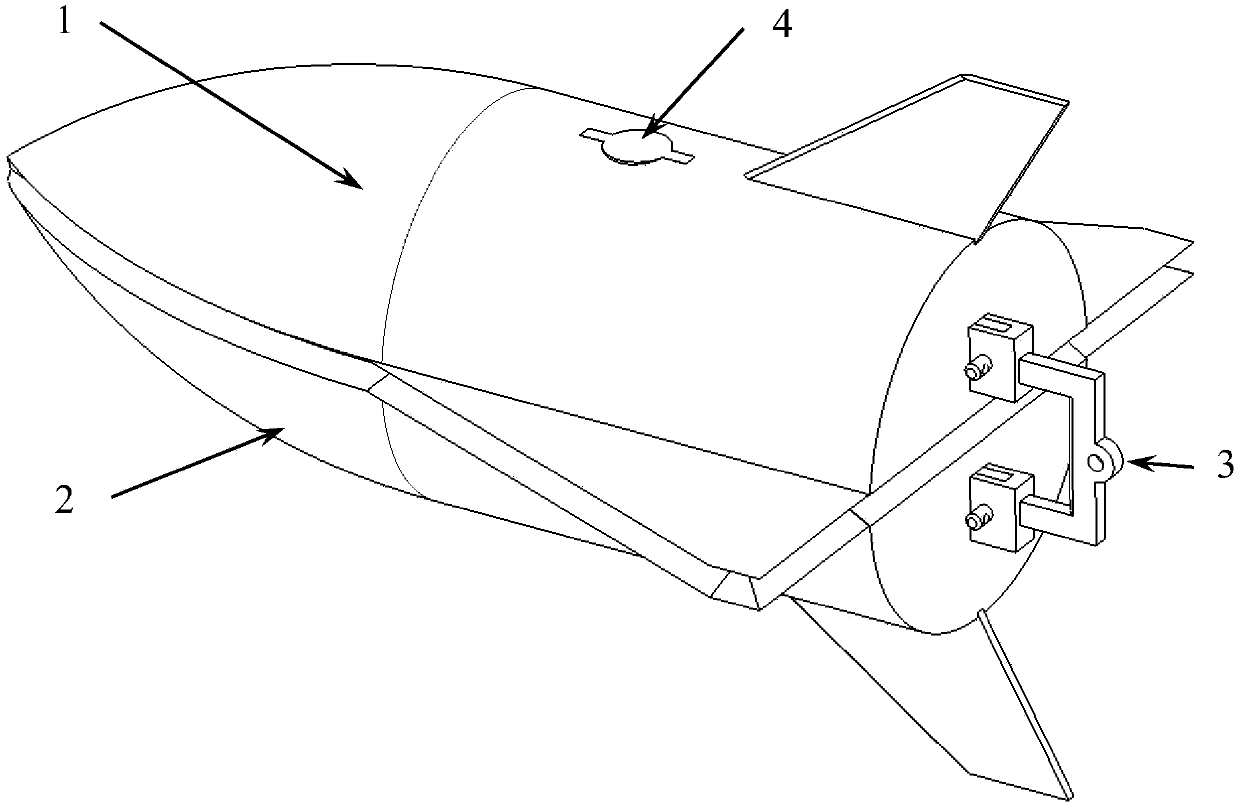

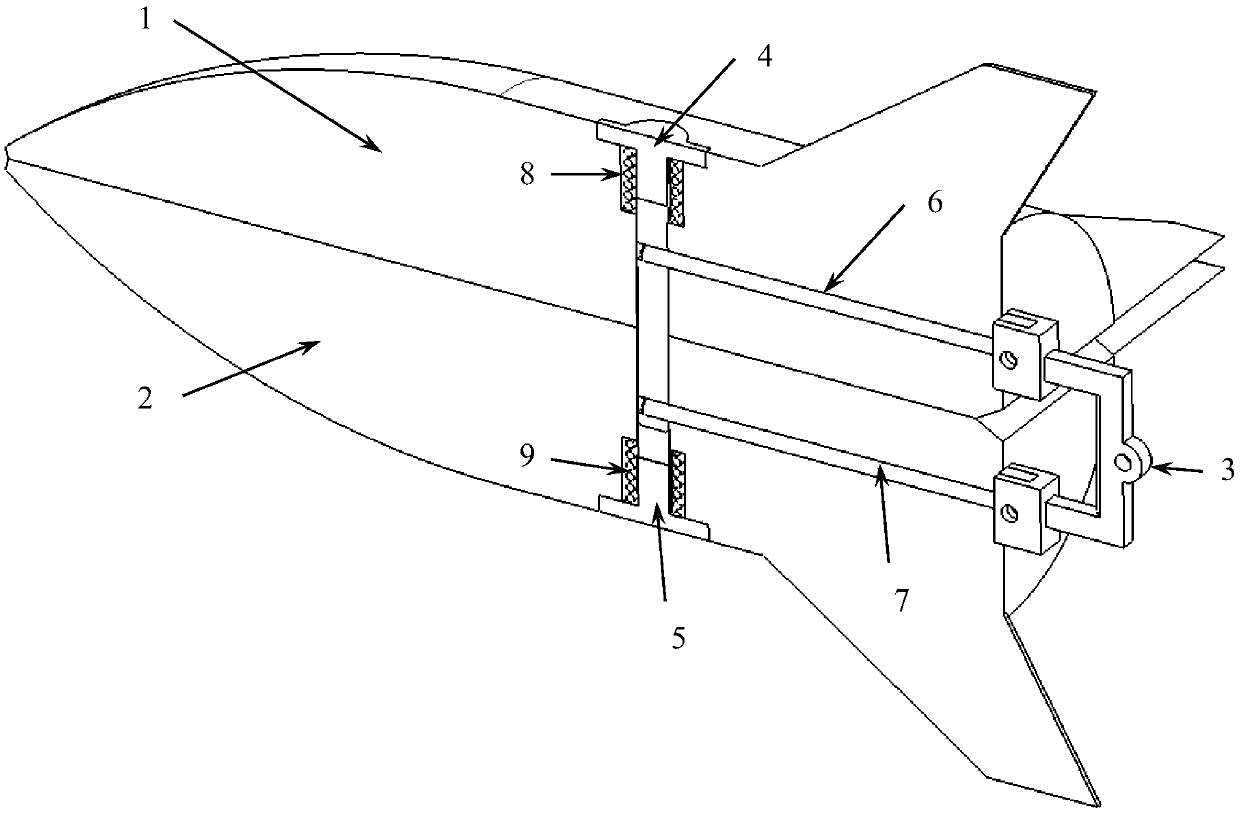

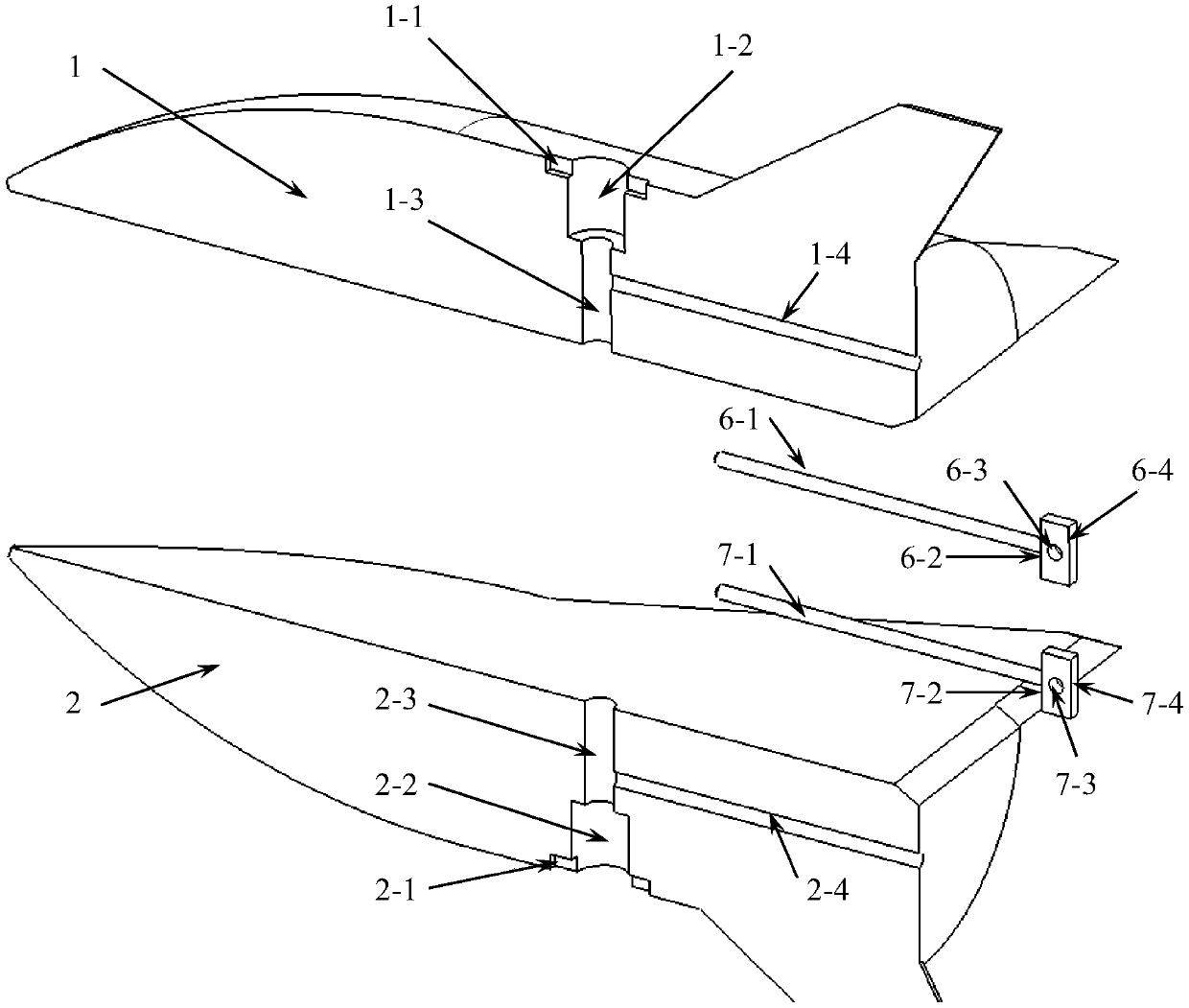

[0027] Such as figure 1 , figure 2 As shown, a parallel inter-stage separation free-flying wind tunnel test device with the center of mass located at the interface includes a first model 1, a second model 2, a pin holder 3, a first fixing nail 4, a second fixing nail 5, The first pull pin 6, the second pull pin 7, the first spring 8, the second spring 9, the pin 10; the pin pull frame 3 is connected with the first pull pin 6 and the second pull pin 7 respectively, and the primary fixing nail 4, Insert the first model 1 through the first spring 8, and insert the secondary fixing nail 5 into the second model 2 through the second spring 9; 2 Insert the end face of the tail into the first model 1 and the second model 2, so that the first model 1 and the second model 2 are dock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com