Handle fixing structure

A technology for fixing the structure and handle, which is applied in the direction of the handle of the wing fan, the spherical handle of the wing fan, the building structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

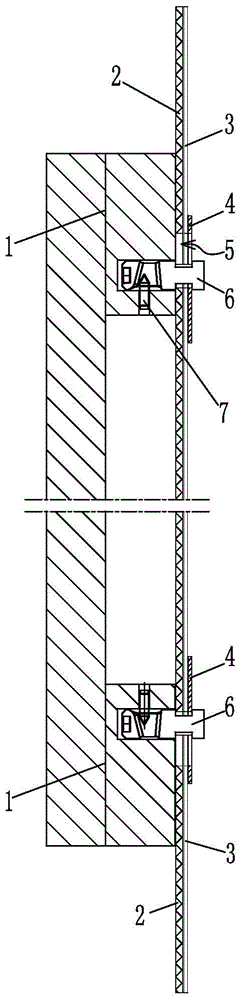

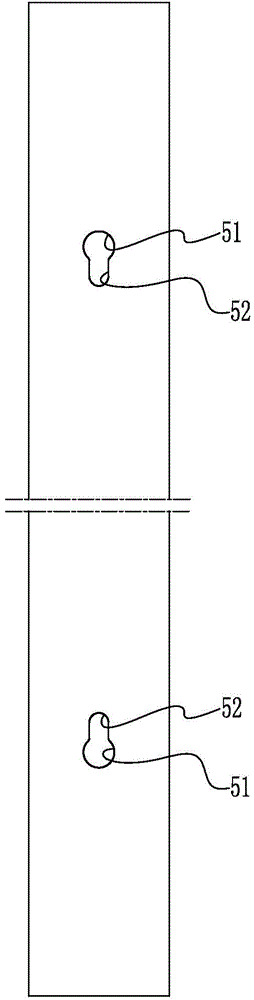

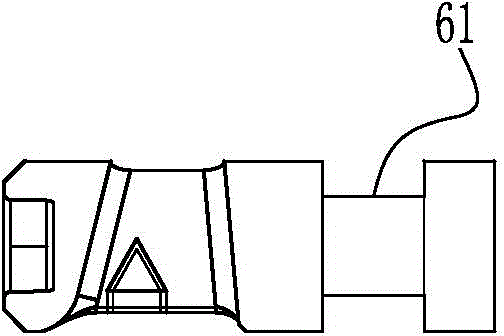

[0013] Such as figure 1 The shown handle fixing structure includes a handle assembly 1 and a door shell assembly. The door shell assembly includes an outer glass 2, an aluminum alloy frame 3, and an inner reinforcing iron 4. The door shell assembly is provided with two special-shaped through holes 5 , The special-shaped through hole 5 penetrates the corresponding positions on the outer glass 2, the aluminum alloy frame 3 and the inner reinforcing iron 4, such as figure 2 As shown, the special-shaped through hole 5 includes a large-aperture end 51 and a small-aperture end 52; the handle assembly 1 is connected to two special-shaped through holes 5 on the door shell assembly through two connecting posts 6, such as image 3 As shown, one end of the connecting column 6 inserted into the special-shaped through hole 5 has an annular groove 61. The outer diameter of the connecting column 6 in the annular groove 61 matches the outer diameter of the special-shaped through hole 5 at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com