Head cover structure and installation method of high-speed train head

A technology for high-speed trains and hoods, which is applied to railway car bodies, transportation and packaging, and railway car body parts, etc. It can solve the problems of narrow space at the head of the train and the inability to install automatic opening and closing hoods, etc., and achieve a good overall appearance effect , Simple structure, easy to install and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

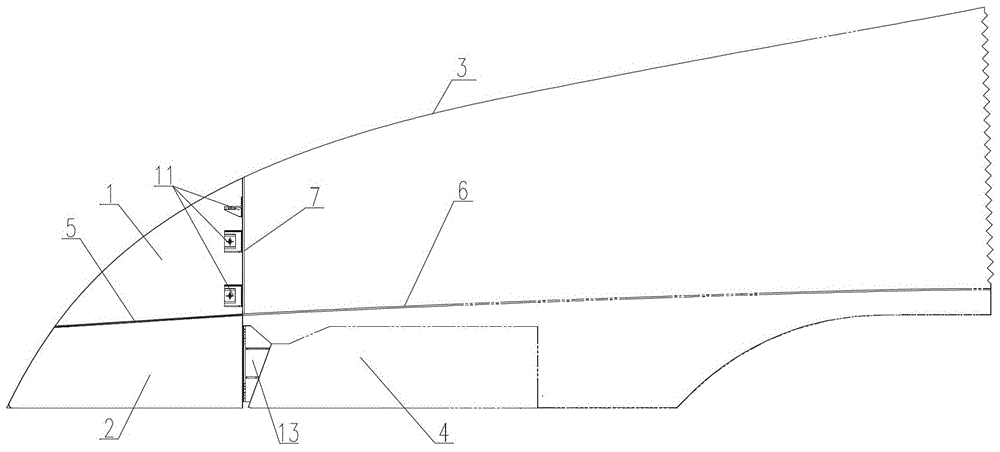

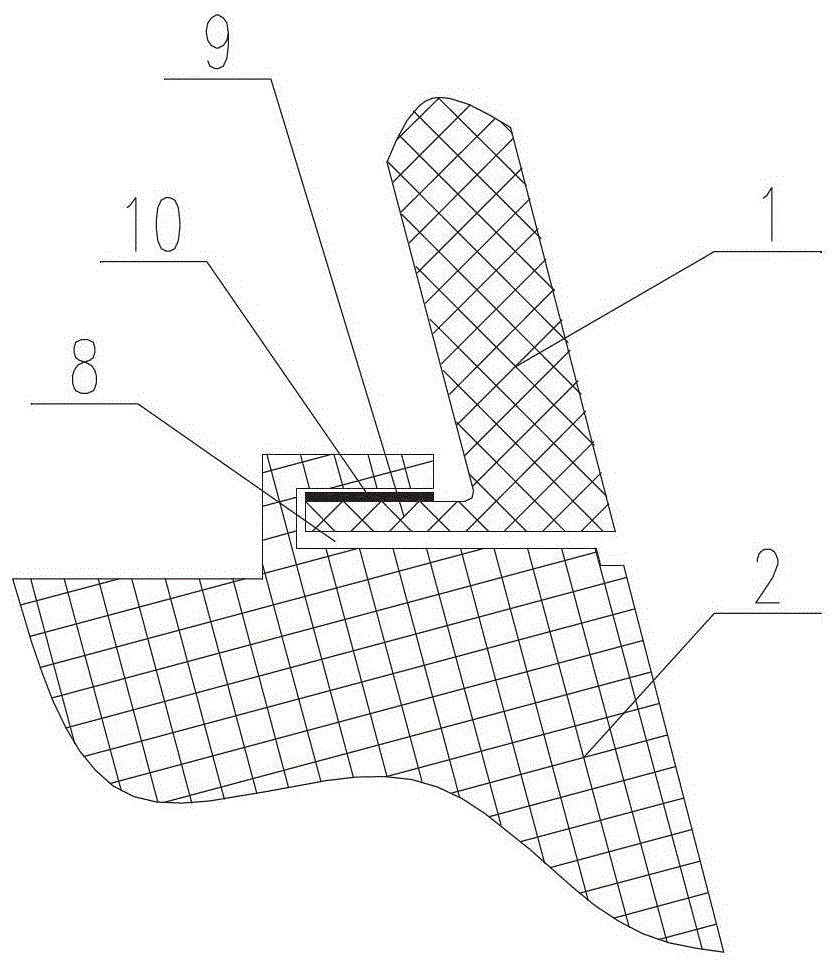

[0024] Such as figure 1 As shown, the head cover structure of the high-speed train head of the present invention is integrally cut into upper and lower parts, which are respectively an upper head cover 1 and a lower head cover 2 . Considering the overall shape of the train and the size of the doors, the dividing line 5 between the upper hood 1 and the lower hood 2 is set at the position of the dividing line between the car body 3 and the obstacle remover 4, and between the car body 3 and the obstacle remover 4. The dividing line 6 between them has a smooth transition.

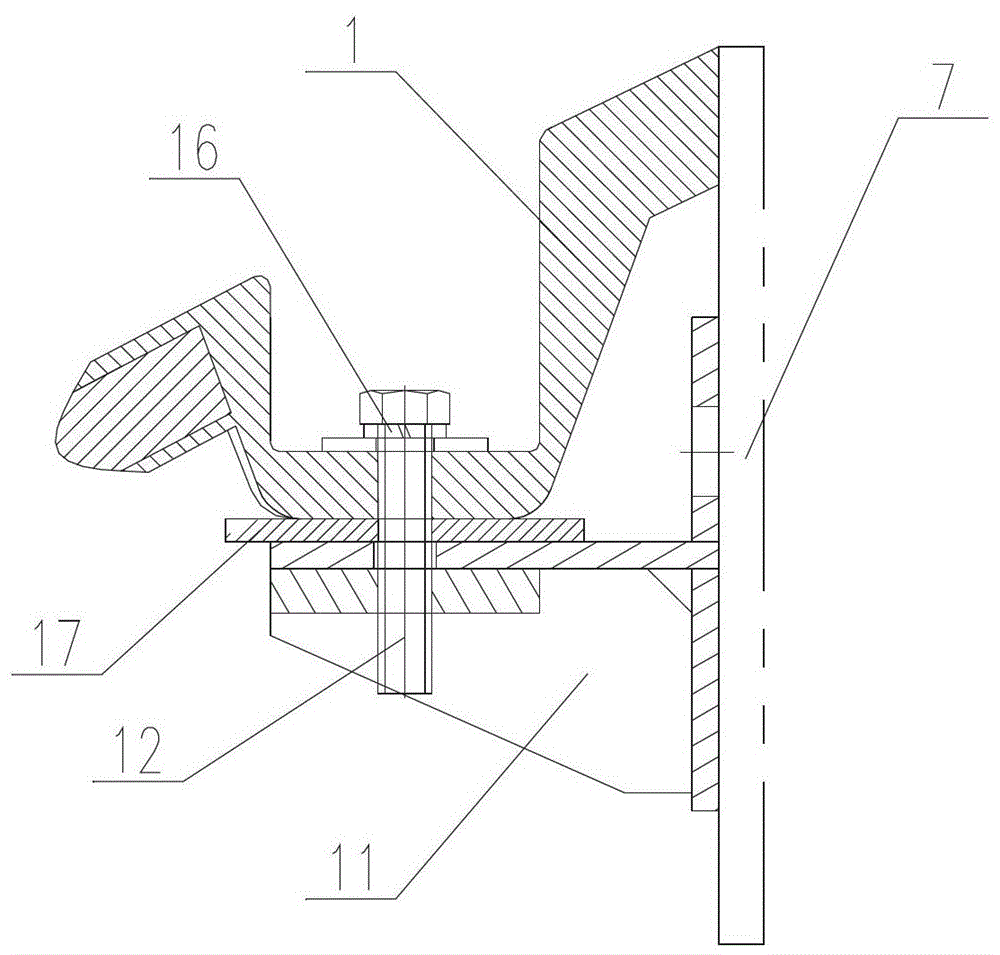

[0025] For the convenience of installation and disassembly, it is installed outside the car body. The upper hood 1 and the lower hood 2 are plugged and connected to each other through a plug-in structure. The upper hood 1 is fixedly connected to the car body plate beams 7 locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com