Tower type truss installing structure and method without cooperation with altitude hoisting equipment

A technology of lifting equipment and installation structure, which is applied in the direction of cranes, load blocks, transportation and packaging, etc. It can solve the problems that the hoisting device has no slewing mechanism, cannot be used, and cannot realize the slewing action, so as to shorten the construction period and save installation costs , the effect of improving the degree of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Combine below Figure 1 to Figure 19 , the present invention is further described:

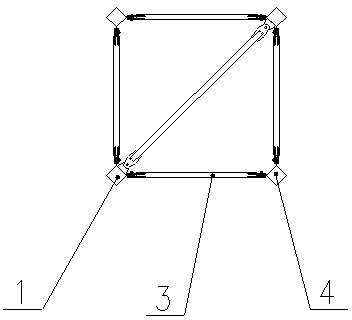

[0046] Such as figure 1 As shown, the truss is designed to be connected by several standard sections through pins or bolts. The standard section is designed so that the webs 2 and 3 and the chords 1 and 4 can be disassembled into a single member, and the members are connected by pins or bolts. The webs include horizontally arranged webs 3 and obliquely arranged webs 2 . The chords are fixedly connected by webs.

[0047] Such as figure 2 As shown, the four chords are fixed by horizontally arranged webs 3 and obliquely arranged webs 2 to form a stable fixed structure.

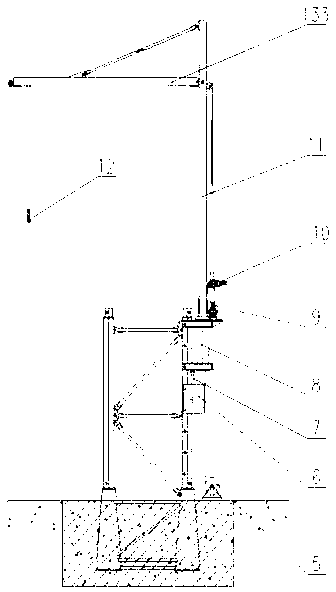

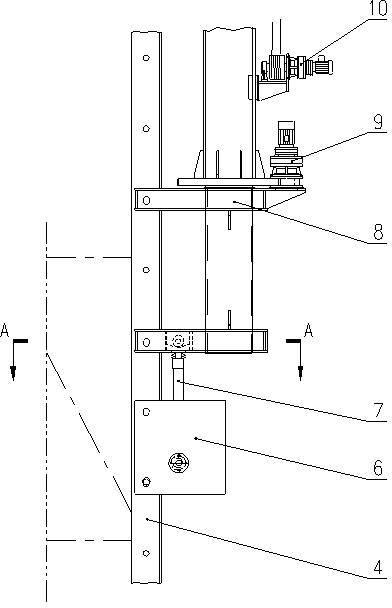

[0048] Such as image 3 As shown, the auxiliary crane in the tower truss installation structure without high-altitude lifting equipment in the present invention includes: hoisting hoist 5, jacking frame 6, electric push rod 7, support 8, slewing mechanism 9, trolley luffing mechanism 10 , frame 11, suspension hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com